I.C.T-W2

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| DIP Soldering Machine – Special DIP Soldering Machine for Heat Exchanger

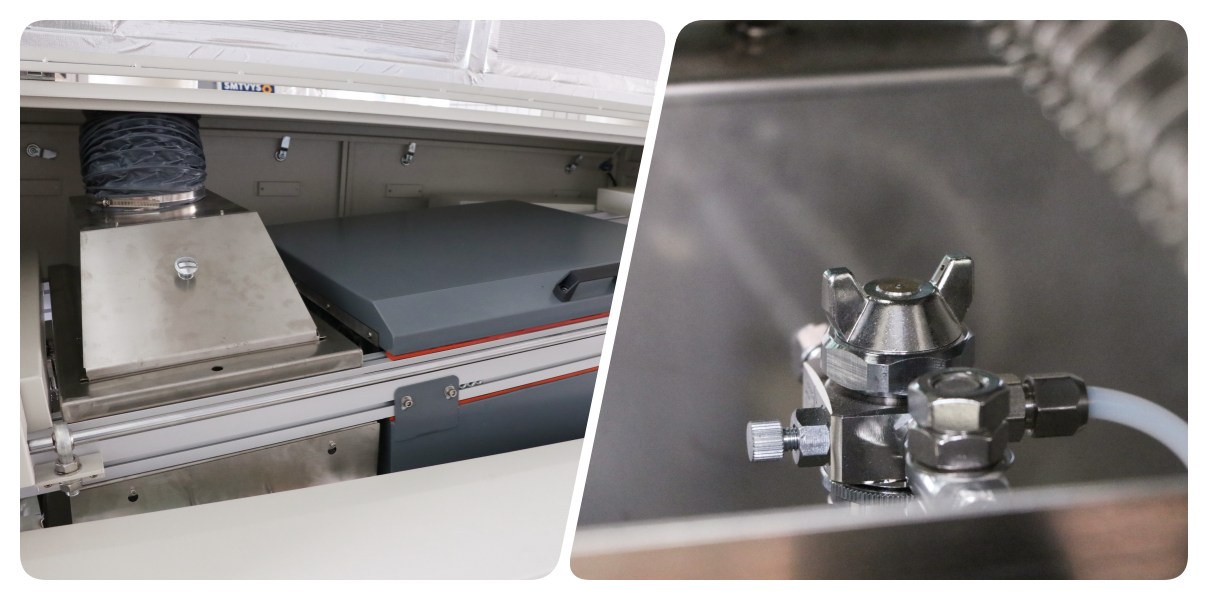

I.C.T W-series DIP Soldering Machine is the professional hot dip solder coating machine for THT production lines, especially designed for thick boards and large copper areas like heat exchangers. This DIP Soldering Machine uses Japanese Kuroda precision nozzle for uniform flux, fully independent horizontal heating zones for accurate temperature curves, and energy-saving design to keep running power at only 7kW. Optional nitrogen protection gives perfect lead-free joints on heavy components. After long-term use in heat exchanger factories worldwide, this DIP Soldering Machine has become the first choice for customers who need strong and stable dip soldering machine.

| Feature

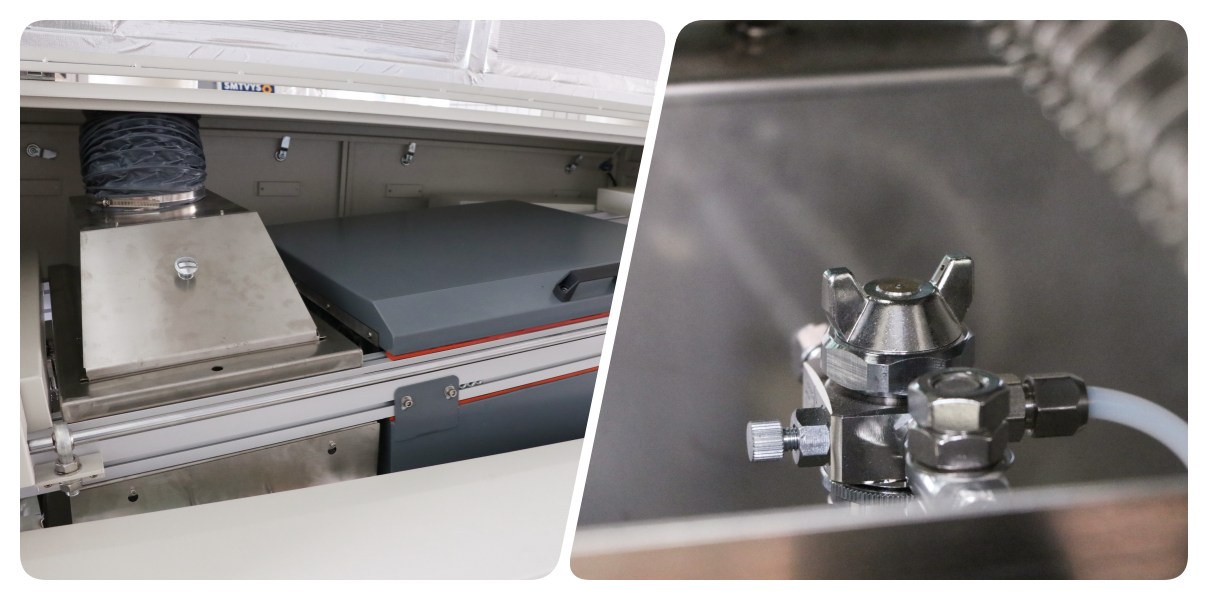

Japanese Kuroda nozzle with adjustable atomizing area and pyramid filter deliver stable, low-waste flux coating even on large heat exchanger boards. Digital flow control and pressure tank keep flux supply constant – ideal for Special DIP Soldering Machine for Heat Exchanger in continuous THT lines.

Third-party independent over-temperature protection plus PLC+PID closed-loop control provide complete safety backup. Real-time monitoring and instant emergency stop protect operators and the whole hot dip solder coating machine during 24-hour production.

Fully independent horizontal heating zones with closed hot-air path and rectifier plates create perfectly even temperature on thick copper boards. Warm-up takes only about 15 minutes and normal power stays at 7kW – the most powerful heating among similar DIP Soldering Machine.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

Our team flew to Uruguay to help a major smart meter producer install the W-series DIP Soldering Machine on their busy THT line. The factory needed strong lead-free soldering for complex boards with big components. After three days of careful setup and local operator training, the DIP Soldering Machine ran at full capacity with only 7kW power and zero defects. The customer filmed the entire line in operation and praised the clean joints, low running cost and our professional support – this project is now a popular reference for heat exchanger and smart meter factories in Latin America.

| Expert Services and Training

We offer end-to-end partnership for every DIP Soldering Machine: detailed line layout planning, on-site commissioning by experienced engineers, customized operator training programs and 7×24 remote monitoring. Whether you need spare parts for hot dip solder coating machine or process optimization, our global warehouse network guarantees delivery within 48 hours.

| Customer Praise

Heat exchanger manufacturers especially love our DIP Soldering Machine for handling thick copper boards without bridges or icicles. They highlight the extremely low electricity bill, rock-solid mechanical structure, quick spare parts supply and the best price-performance ratio among similar Special DIP Soldering Machine for Heat Exchanger.

| Quality Certifications

All I.C.T DIP Soldering Machine models hold full CE, CCC, UL, RoHS and ISO9001 certifications, plus over ten invention patents on flux saving and heating technology, meeting the highest global standards for safety and environmental protection.

| About I.C.T Company and Factory

Headquartered in Dongguan with a 12,000㎡ modern factory and 89 dedicated staff (including 20 senior engineers), I.C.T has been the trusted full-line partner for SMT and DIP equipment since 2012. We serve more than 1600 active customers in 72 countries through 8 branch offices and multiple overseas warehouses. From initial consultation to lifetime upgrades, we focus on delivering real value and zero-risk solutions for every dip soldering machine user worldwide.

| DIP Soldering Machine – Special DIP Soldering Machine for Heat Exchanger

I.C.T W-series DIP Soldering Machine is the professional hot dip solder coating machine for THT production lines, especially designed for thick boards and large copper areas like heat exchangers. This DIP Soldering Machine uses Japanese Kuroda precision nozzle for uniform flux, fully independent horizontal heating zones for accurate temperature curves, and energy-saving design to keep running power at only 7kW. Optional nitrogen protection gives perfect lead-free joints on heavy components. After long-term use in heat exchanger factories worldwide, this DIP Soldering Machine has become the first choice for customers who need strong and stable dip soldering machine.

| Feature

Japanese Kuroda nozzle with adjustable atomizing area and pyramid filter deliver stable, low-waste flux coating even on large heat exchanger boards. Digital flow control and pressure tank keep flux supply constant – ideal for Special DIP Soldering Machine for Heat Exchanger in continuous THT lines.

Third-party independent over-temperature protection plus PLC+PID closed-loop control provide complete safety backup. Real-time monitoring and instant emergency stop protect operators and the whole hot dip solder coating machine during 24-hour production.

Fully independent horizontal heating zones with closed hot-air path and rectifier plates create perfectly even temperature on thick copper boards. Warm-up takes only about 15 minutes and normal power stays at 7kW – the most powerful heating among similar DIP Soldering Machine.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

Our team flew to Uruguay to help a major smart meter producer install the W-series DIP Soldering Machine on their busy THT line. The factory needed strong lead-free soldering for complex boards with big components. After three days of careful setup and local operator training, the DIP Soldering Machine ran at full capacity with only 7kW power and zero defects. The customer filmed the entire line in operation and praised the clean joints, low running cost and our professional support – this project is now a popular reference for heat exchanger and smart meter factories in Latin America.

| Expert Services and Training

We offer end-to-end partnership for every DIP Soldering Machine: detailed line layout planning, on-site commissioning by experienced engineers, customized operator training programs and 7×24 remote monitoring. Whether you need spare parts for hot dip solder coating machine or process optimization, our global warehouse network guarantees delivery within 48 hours.

| Customer Praise

Heat exchanger manufacturers especially love our DIP Soldering Machine for handling thick copper boards without bridges or icicles. They highlight the extremely low electricity bill, rock-solid mechanical structure, quick spare parts supply and the best price-performance ratio among similar Special DIP Soldering Machine for Heat Exchanger.

| Quality Certifications

All I.C.T DIP Soldering Machine models hold full CE, CCC, UL, RoHS and ISO9001 certifications, plus over ten invention patents on flux saving and heating technology, meeting the highest global standards for safety and environmental protection.

| About I.C.T Company and Factory

Headquartered in Dongguan with a 12,000㎡ modern factory and 89 dedicated staff (including 20 senior engineers), I.C.T has been the trusted full-line partner for SMT and DIP equipment since 2012. We serve more than 1600 active customers in 72 countries through 8 branch offices and multiple overseas warehouses. From initial consultation to lifetime upgrades, we focus on delivering real value and zero-risk solutions for every dip soldering machine user worldwide.