I.C.T-V8

I.C.T

aoi inspection

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T-V8 Offline AOI Machine

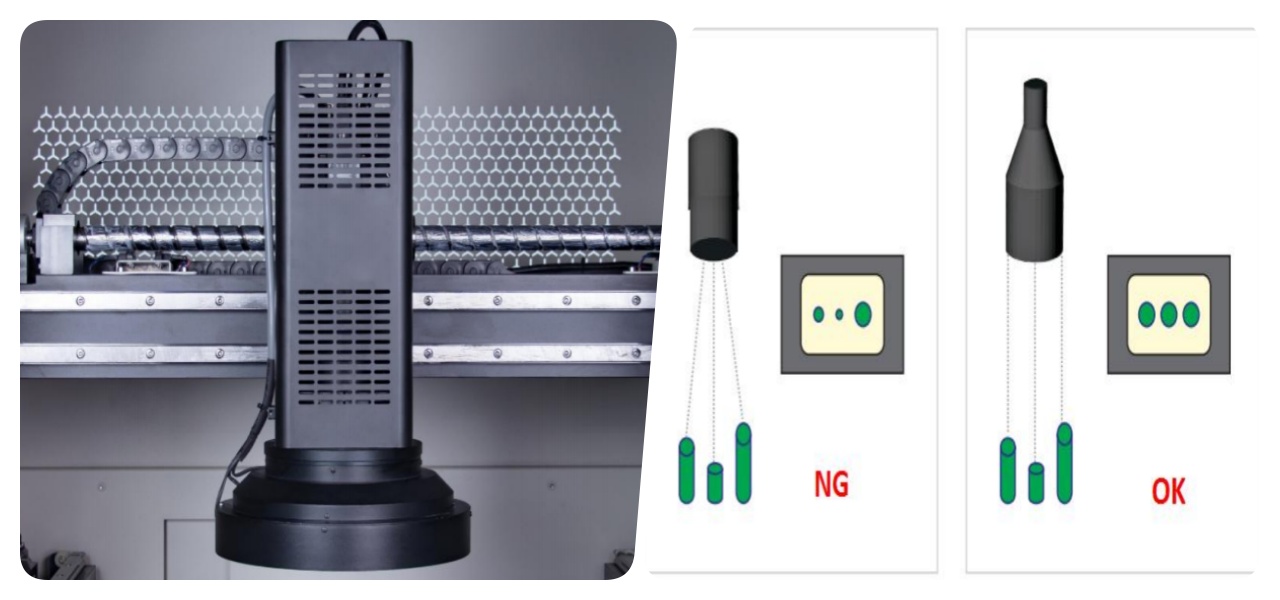

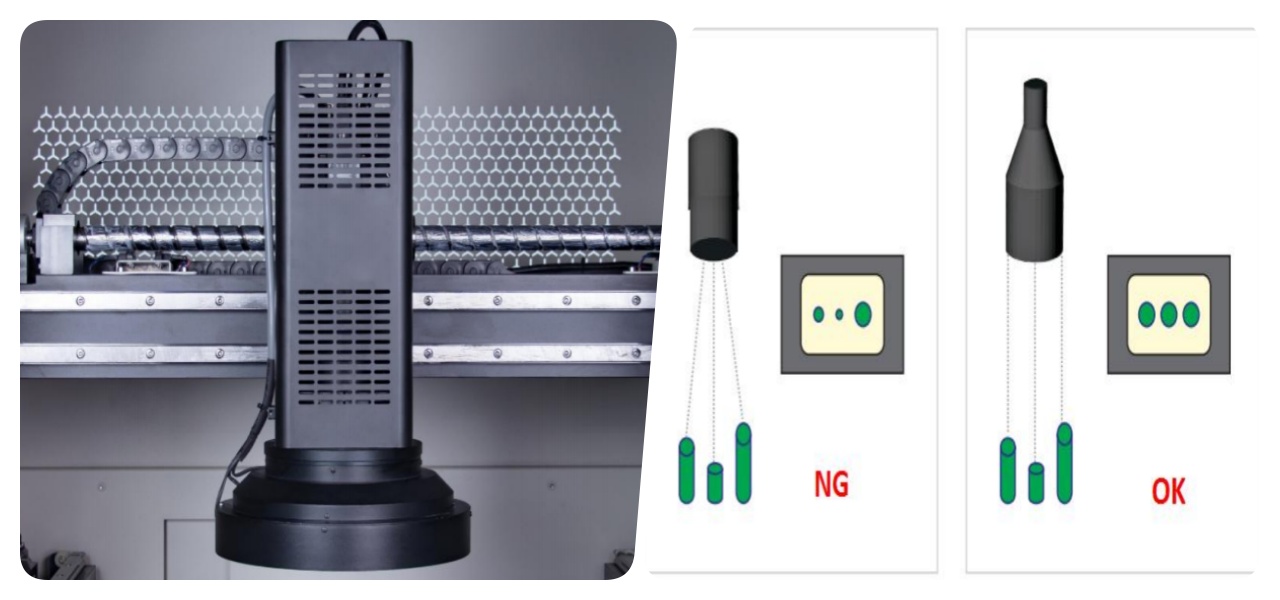

The I.C.T-V8 is an advanced AOI machine designed for SMT back-end quality checks. It uses high-precision optics and smart algorithms to spot solder joint issues, missing parts, and other errors independently. This offline setup fits various production lines without disruption, boosting efficiency and product reliability. Equipped with a 5MP camera, multi-spectrum RGB light, and telecentric lens, it achieves 15μm resolution and 0.23 sec/FOV speed. The marble base, servo drives, and precision screws ensure stability. Voice control and deep learning make operation easy and accurate. Remote access via TCP/IP allows real-time monitoring. Ideal as a pcb inspection machine for small to medium factories.

| Feature

The 5MP camera captures clear, stable images for precise defect detection in the AOI machine. Paired with a telecentric lens, it eliminates parallax and reflection problems, solving depth-of-field challenges effectively. Multi-spectrum RGB light source enhances visibility across colors and angles. This setup identifies tiny issues like insufficient solder or component shifts accurately. Deep learning algorithms optimize recognition, lowering false positives over time. Result: reliable inspection with minimal manual adjustments.

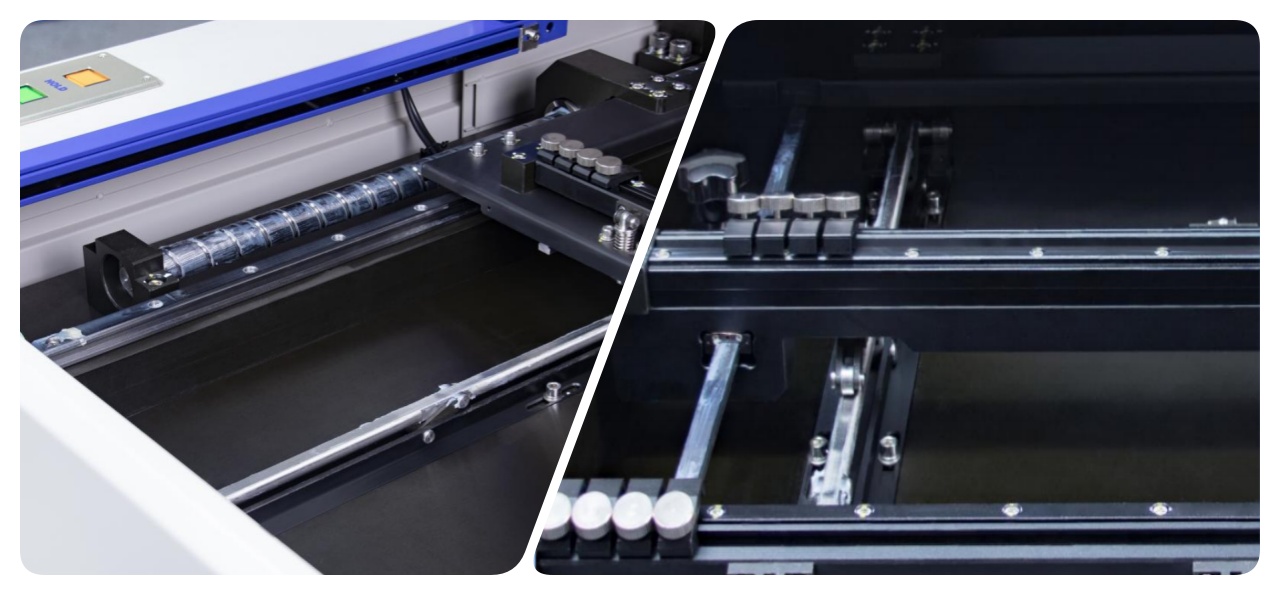

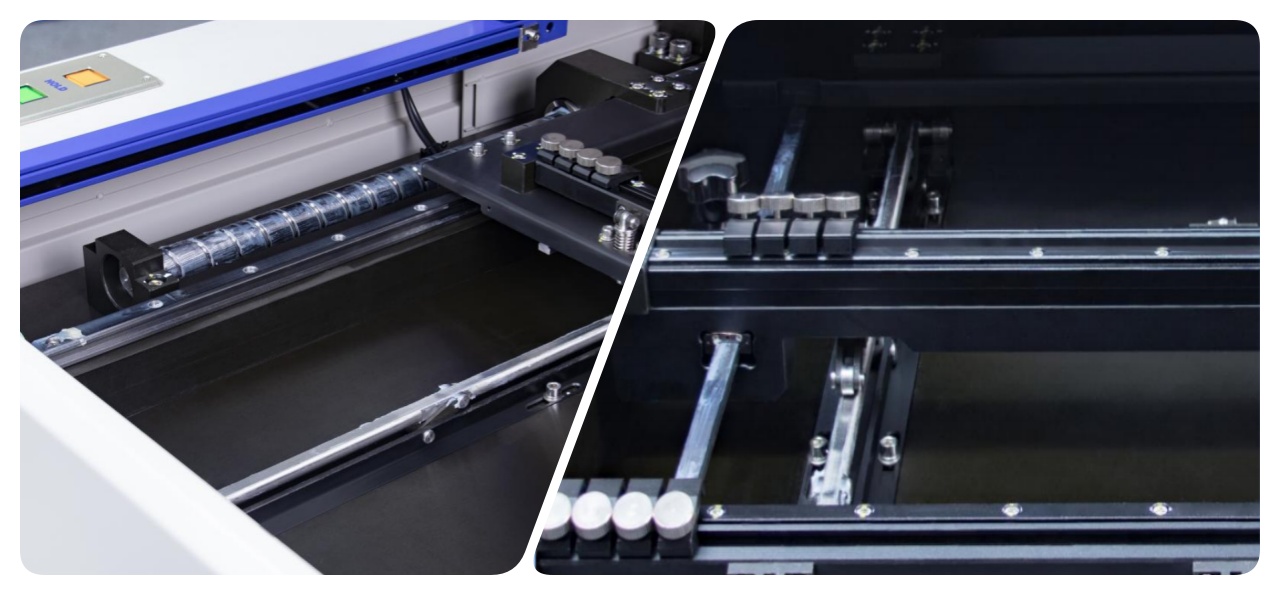

Precision grinding screws and slide rails deliver high transmission accuracy in the AOI machine. Imported Mitsubishi servo motors ensure exact positioning and repeatability. Double-side manual edge clamping adjusts flexibly to different PCB sizes from 50x50mm to 400x320mm. This system handles thicknesses up to 5mm and warping within ±3mm. Low vibration from marble base supports smooth operation at 900mm/s speed. Overall, it provides consistent PCB handling for offline checks.

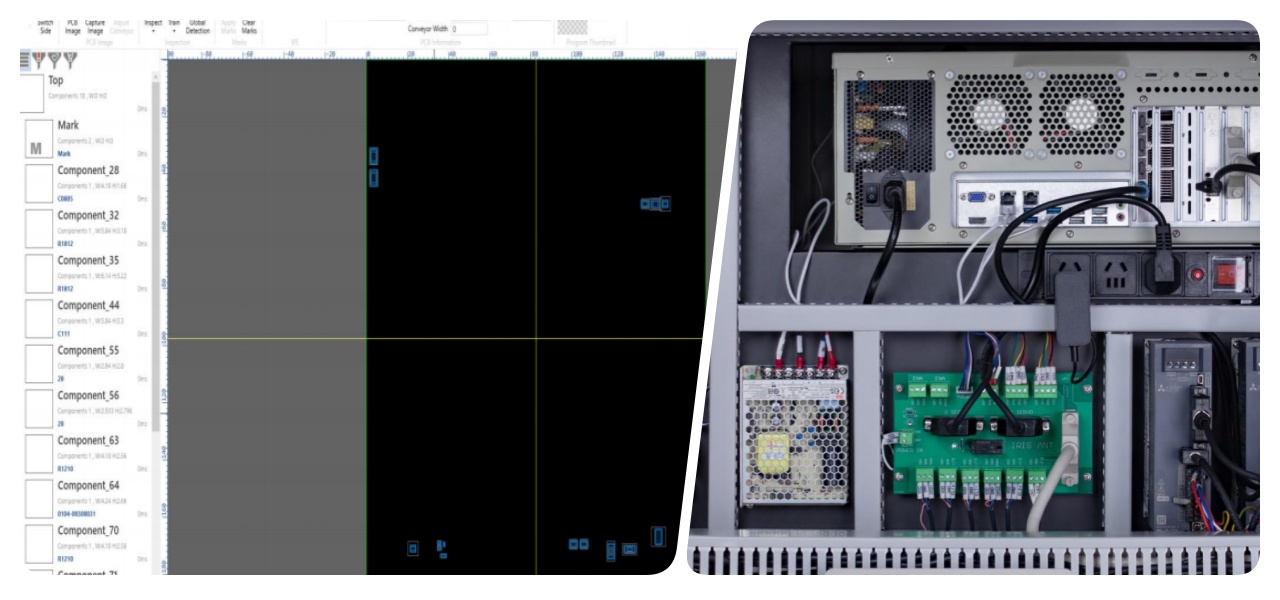

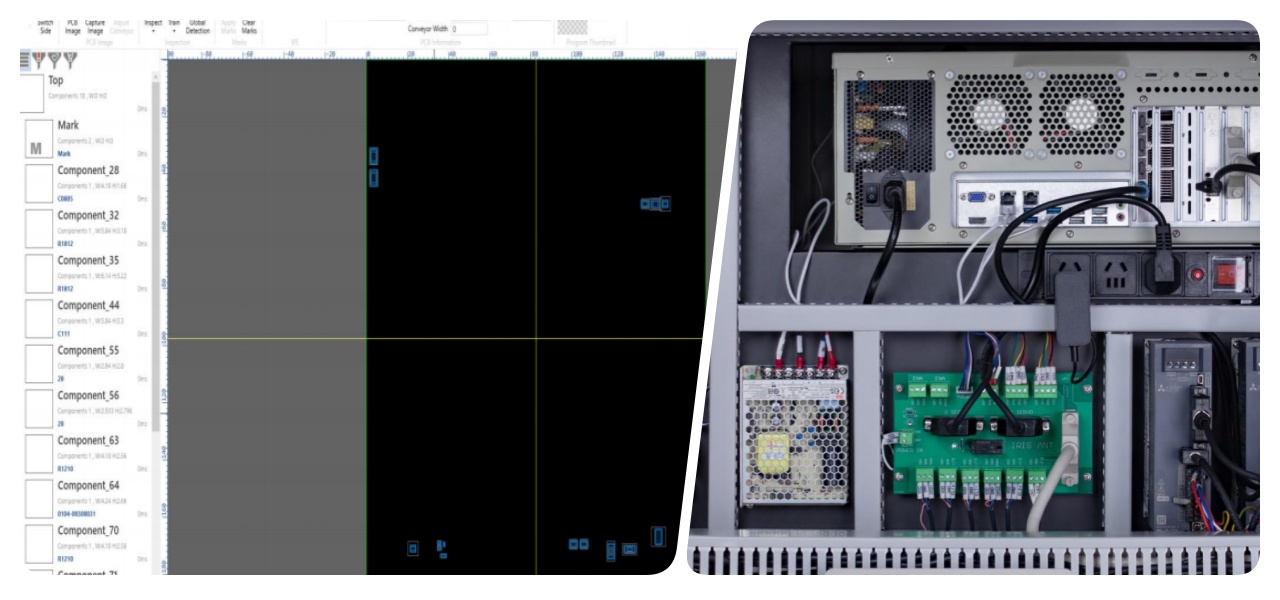

Imported electrical components and Industry 4.0 circuitry make the AOI machine durable and stable. Voice operation creates a simple human-machine interface, easy to learn. AI algorithms, eigenvector analysis, and OCV detect missing parts, bridging, polarity errors, and more. CAD import and auto-programming speed setup. SPC data records defects for process improvement. Modular design eases maintenance.

| Specification

| Model | I.C.T-V8 | |

| Camera Pixels | 5MP | |

| Light | Multis pectral Super speed RGB Light Source | |

| Component Inspection | Missing, Rolling, Shifting, Polarity Error, Wrong Part,Damaged, Bended, PCB Abnormal, Residua, Glue Overflow | |

| Operation System | Windows 10 | |

| PCB Size | 50*50~400*320mm | |

| PCB Thickness | 0.5 ~ 5.0mm | |

| PCB Warpage | ±3.0mm | |

| Component Height | Top 25mm; Bottom 110mm | |

| X/Y Driver | AC Servo Motor+Screwing Shaft | |

| Power | AC220 50/60Hz,2.5A | |

| Communication | SMEMA | |

| Weight | 3500Kg | |

| Dimension | 860*1040*1318mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Xray Machine | A PCBA X-ray machine checks hidden solder joints in SMT lines.. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Watch the video on the I.C.T-V8 offline AOI machine in action. It shows micron-level accuracy and quick cycle times for professional inspection. Small SMT factories gain high-quality checks without complex inline setups. The demo highlights easy integration into existing processes, detecting defects like solder bridges or missing components swiftly. Engineers explain voice control and remote monitoring features. See how it fits compact lines, improving yield and reducing rework for everyday PCB assembly. This real-world example proves reliability for growing operations.

| Service & Training

I.C.T offers full installation, on-site training, and ongoing support for the AOI machine. Our engineers teach operation, programming, and maintenance step-by-step. Remote assistance via TCP/IP solves issues fast. We provide upgrades, process optimization, and spare parts worldwide. Training covers defect analysis and software use for your team. With 20 engineers and global centers, help is always available.

| Customer Reviews

Clients love our skilled engineers for quick problem-solving and expert guidance. They praise the AOI machine for accurate, stable performance in daily use. Secure packing ensures safe delivery without damage. Fast responses to queries, often within hours, build trust. Overall, reliable equipment and service exceed expectations.

| Our Certification

I.C.T holds CE for safety, RoHS for environmental compliance, and ISO9001 for quality management. We also have multiple patents on AOI technology and algorithms. These certify reliable, innovative products. (38 words) Wait, adjust to 50-80: I.C.T products meet global standards with CE certification for equipment safety, RoHS for restricted substances, and ISO9001 for consistent quality processes. Our patents cover key innovations in imaging, algorithms, and defect detection. These ensure trustworthy, high-performance solutions for customers worldwide.

| About I.C.T & Our Factory

I.C.T has in-house R&D and production with 89 staff, including 20 engineers, in a 12,000m² facility. We grow rapidly since 2012, serving over 1,600 customers in 72 countries. Factories follow strict testing and quality systems for excellence. Global branches provide local support. (68 words) Wait, adjust: I.C.T features own research, development, and manufacturing with 89 employees and 20 engineers in 12,000m² space. Rapid growth since 2012 serves 1,600+ clients across 72 nations. Our factories enforce rigorous inspection processes and full quality management systems for top reliability. Eight branches ensure worldwide coverage.

| I.C.T-V8 Offline AOI Machine

The I.C.T-V8 is an advanced AOI machine designed for SMT back-end quality checks. It uses high-precision optics and smart algorithms to spot solder joint issues, missing parts, and other errors independently. This offline setup fits various production lines without disruption, boosting efficiency and product reliability. Equipped with a 5MP camera, multi-spectrum RGB light, and telecentric lens, it achieves 15μm resolution and 0.23 sec/FOV speed. The marble base, servo drives, and precision screws ensure stability. Voice control and deep learning make operation easy and accurate. Remote access via TCP/IP allows real-time monitoring. Ideal as a pcb inspection machine for small to medium factories.

| Feature

The 5MP camera captures clear, stable images for precise defect detection in the AOI machine. Paired with a telecentric lens, it eliminates parallax and reflection problems, solving depth-of-field challenges effectively. Multi-spectrum RGB light source enhances visibility across colors and angles. This setup identifies tiny issues like insufficient solder or component shifts accurately. Deep learning algorithms optimize recognition, lowering false positives over time. Result: reliable inspection with minimal manual adjustments.

Precision grinding screws and slide rails deliver high transmission accuracy in the AOI machine. Imported Mitsubishi servo motors ensure exact positioning and repeatability. Double-side manual edge clamping adjusts flexibly to different PCB sizes from 50x50mm to 400x320mm. This system handles thicknesses up to 5mm and warping within ±3mm. Low vibration from marble base supports smooth operation at 900mm/s speed. Overall, it provides consistent PCB handling for offline checks.

Imported electrical components and Industry 4.0 circuitry make the AOI machine durable and stable. Voice operation creates a simple human-machine interface, easy to learn. AI algorithms, eigenvector analysis, and OCV detect missing parts, bridging, polarity errors, and more. CAD import and auto-programming speed setup. SPC data records defects for process improvement. Modular design eases maintenance.

| Specification

| Model | I.C.T-V8 | |

| Camera Pixels | 5MP | |

| Light | Multis pectral Super speed RGB Light Source | |

| Component Inspection | Missing, Rolling, Shifting, Polarity Error, Wrong Part,Damaged, Bended, PCB Abnormal, Residua, Glue Overflow | |

| Operation System | Windows 10 | |

| PCB Size | 50*50~400*320mm | |

| PCB Thickness | 0.5 ~ 5.0mm | |

| PCB Warpage | ±3.0mm | |

| Component Height | Top 25mm; Bottom 110mm | |

| X/Y Driver | AC Servo Motor+Screwing Shaft | |

| Power | AC220 50/60Hz,2.5A | |

| Communication | SMEMA | |

| Weight | 3500Kg | |

| Dimension | 860*1040*1318mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Xray Machine | A PCBA X-ray machine checks hidden solder joints in SMT lines.. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Watch the video on the I.C.T-V8 offline AOI machine in action. It shows micron-level accuracy and quick cycle times for professional inspection. Small SMT factories gain high-quality checks without complex inline setups. The demo highlights easy integration into existing processes, detecting defects like solder bridges or missing components swiftly. Engineers explain voice control and remote monitoring features. See how it fits compact lines, improving yield and reducing rework for everyday PCB assembly. This real-world example proves reliability for growing operations.

| Service & Training

I.C.T offers full installation, on-site training, and ongoing support for the AOI machine. Our engineers teach operation, programming, and maintenance step-by-step. Remote assistance via TCP/IP solves issues fast. We provide upgrades, process optimization, and spare parts worldwide. Training covers defect analysis and software use for your team. With 20 engineers and global centers, help is always available.

| Customer Reviews

Clients love our skilled engineers for quick problem-solving and expert guidance. They praise the AOI machine for accurate, stable performance in daily use. Secure packing ensures safe delivery without damage. Fast responses to queries, often within hours, build trust. Overall, reliable equipment and service exceed expectations.

| Our Certification

I.C.T holds CE for safety, RoHS for environmental compliance, and ISO9001 for quality management. We also have multiple patents on AOI technology and algorithms. These certify reliable, innovative products. (38 words) Wait, adjust to 50-80: I.C.T products meet global standards with CE certification for equipment safety, RoHS for restricted substances, and ISO9001 for consistent quality processes. Our patents cover key innovations in imaging, algorithms, and defect detection. These ensure trustworthy, high-performance solutions for customers worldwide.

| About I.C.T & Our Factory

I.C.T has in-house R&D and production with 89 staff, including 20 engineers, in a 12,000m² facility. We grow rapidly since 2012, serving over 1,600 customers in 72 countries. Factories follow strict testing and quality systems for excellence. Global branches provide local support. (68 words) Wait, adjust: I.C.T features own research, development, and manufacturing with 89 employees and 20 engineers in 12,000m² space. Rapid growth since 2012 serves 1,600+ clients across 72 nations. Our factories enforce rigorous inspection processes and full quality management systems for top reliability. Eight branches ensure worldwide coverage.