X-7100

I.C.T

X-ray inspection machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T X-7100 PCB X-ray Inspection Machine

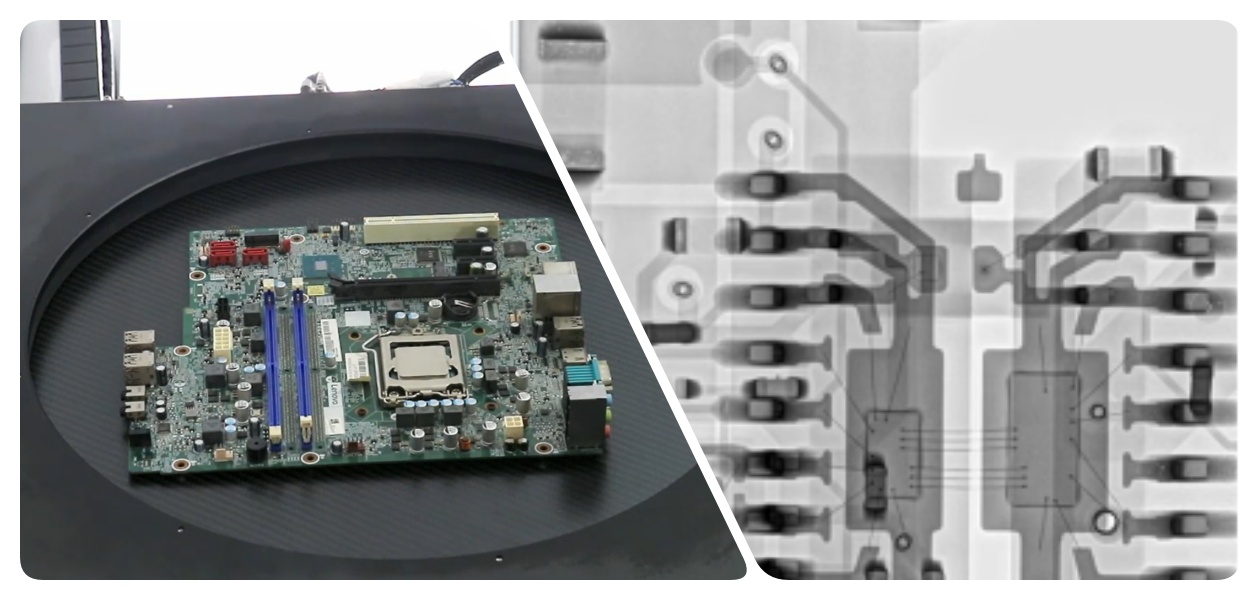

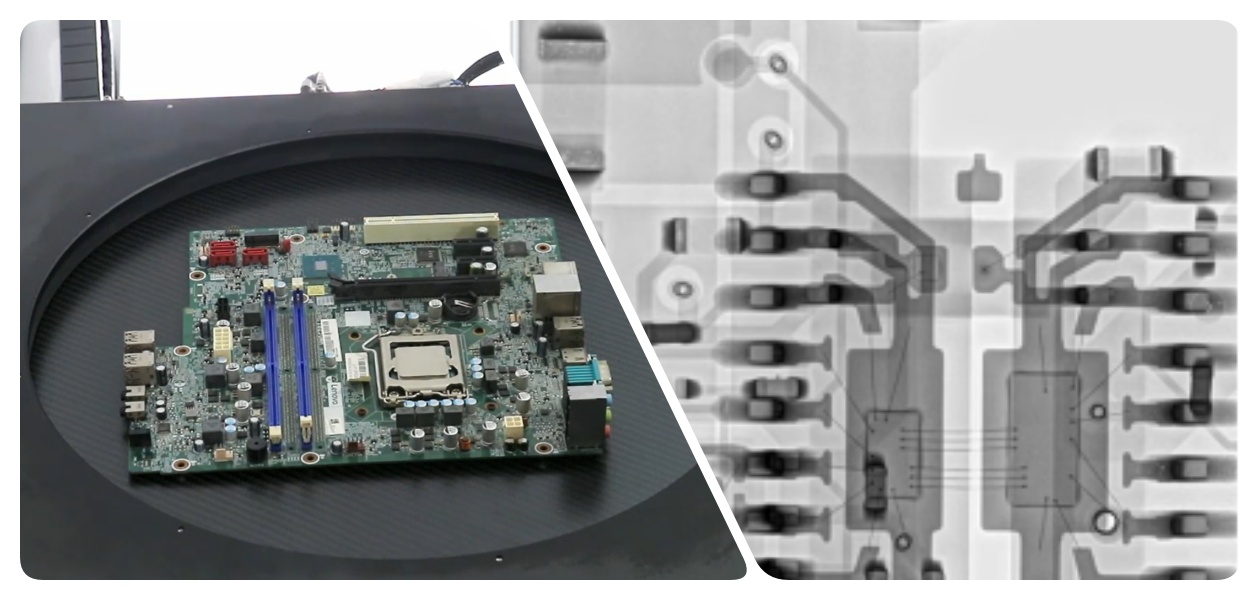

The I.C.T X-7100 is an advanced offline SMT PCB X-ray Inspection Machine designed for detailed internal checks in electronics manufacturing. It excels in spotting issues like air bubbles, voids, short circuits, open circuits, missing solder, and cracks in components. With features like CNC programming for automatic detection and a visual navigation interface, it simplifies the process for operators. This PCB X-ray Inspection Machine supports various applications, from SMT and BGA to lithium batteries and automotive parts. Its high-resolution digital flat panel and stable X-ray tube ensure clear images, while safety certifications like EU CE and ISO make it reliable. Ideal for quality control, it helps manufacturers reduce defects and improve product reliability in a user-friendly way.

| Feature

The I.C.T X-7100 PCB X-ray Inspection Machine uses a high-resolution digital flat panel detector with 1536x1536 pixels, providing sharp images for precise defect detection. This feature captures real-time corrections and offers multiple gain modes for better visibility. It helps identify tiny issues like solder ball defects or wire bonding problems in semiconductors. With passive cooling and temperature sensors, it maintains consistent performance during long sessions. This makes the X-ray inspection machine essential for industries needing accurate internal views, ensuring fewer errors in production.

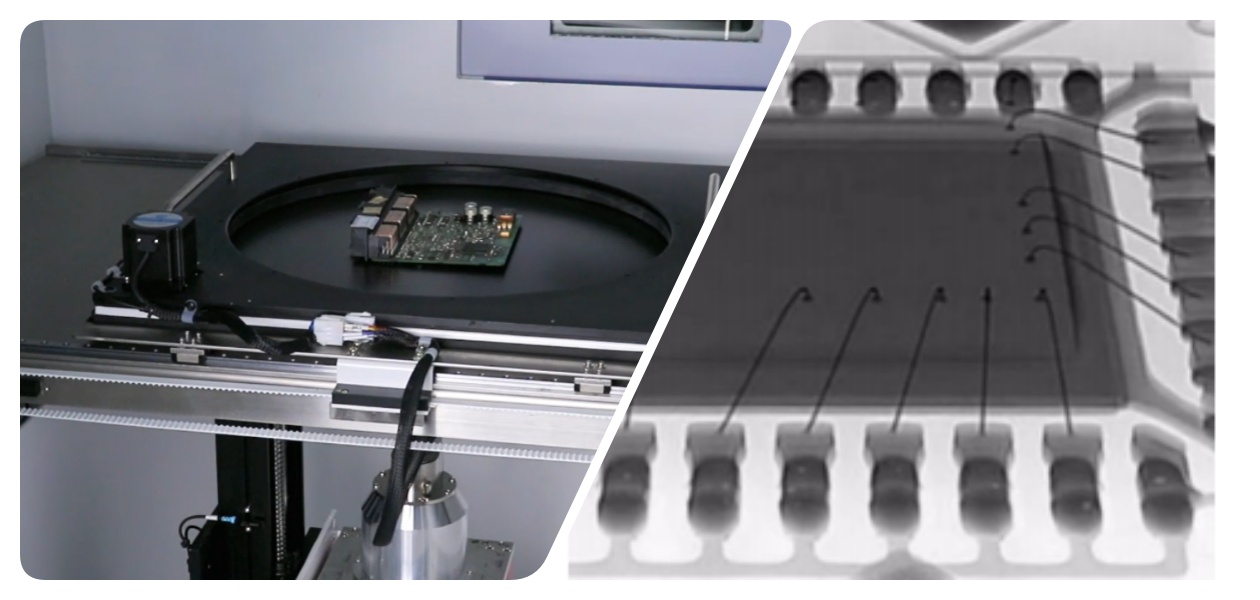

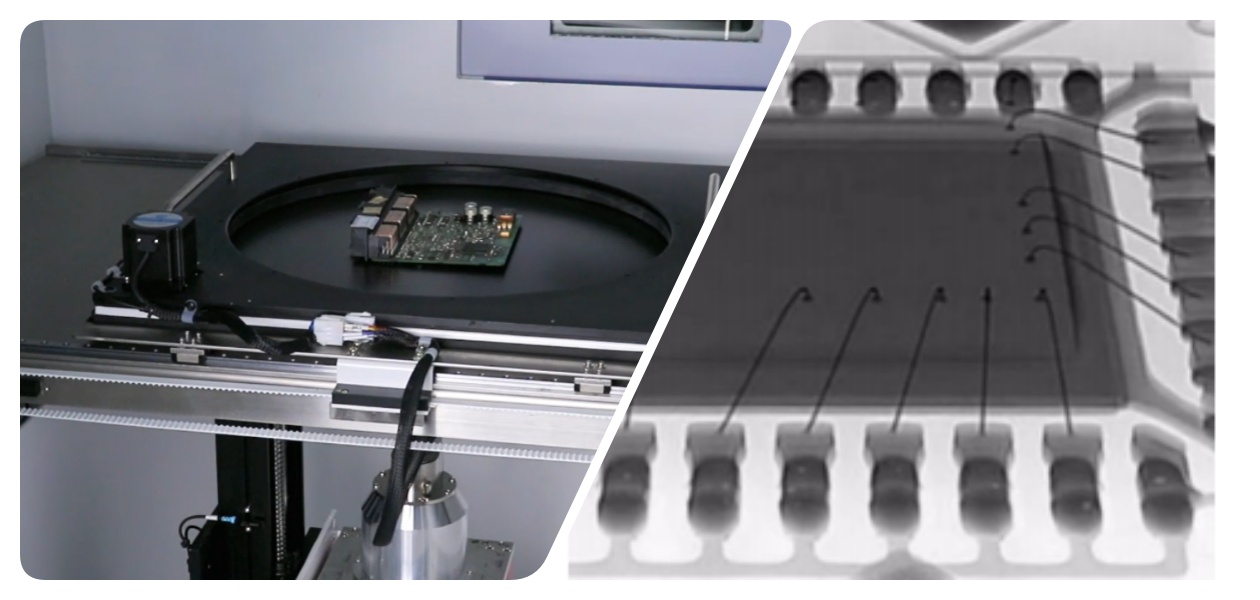

CNC programming in this PCB X-ray Inspection Machine allows automatic scanning of multiple sample positions without manual input. It supports array functions for fixed-spacing samples, speeding up inspections in high-volume settings. Operators can set programs easily via mouse clicks, reducing time and errors. The anti-collision system protects the device during movement. This offline SMT PCB X-ray Inspection Machine is perfect for batch testing in SMT lines, boosting efficiency and repeatability.

One-key measurement tools in the X-7100 quickly calculate bubble size, void rate, and solder height. This helps in quality checks for soldering joints in PCBA assemblies. The simulate color feature enhances image observation for better analysis. Equipped with joystick control for precise adjustments, it ensures accurate results. As a versatile PCB X-ray Inspection Machine, it applies to various materials like ceramics and plastics, aiding in defect prevention.

| Specification

| Item | Model | I.C.T X-7100 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T SMT AI total solution line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT PCB Loader Unloader | Automatically loads bare PCBs to the line. |

| SMT paste printer | Prints solder paste on PCB pads accurately. |

| Modular Chip Shooter | Mounts components onto PCBs precisely. |

| Dual-rails Reflow Oven | Melts solder to form solid joints. |

| AOI Automatic Testing Machine | Inspects solder joints and placement defects. |

| SPI SMT machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| Stencil cleaning machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB depanel machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: Laser Engraving Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

In our video, we showcase the I.C.T X-7100 PCB X-ray Inspection Machine in action at a client's electronics factory. The video starts with an overview of its sleek exterior and key functions like joystick control and programming interface. Inside, it reveals the high-precision X-ray tube from Hamamatsu and the digital flat panel detector. During operation, the machine scans PCBA samples, detecting BGA bubbles and solder balls in real time. Engineers demonstrate automatic batch mode on lithium batteries and wire harnesses, highlighting quick measurements of voids and tilts up to 60 degrees. This setup helped the client improve defect detection by 30%, ensuring higher quality in their SMT production line. The video emphasizes how this offline SMT PCB X-ray Inspection Machine integrates seamlessly into workflows for reliable results.

| Service and Training Support

I.C.T offers comprehensive services and training for the PCB X-ray Inspection Machine. Our team provides on-site installation, regular maintenance, and quick technical support to keep your equipment running smoothly. Training programs cover basic operation, programming, and safety protocols, tailored for operators with simple instructions. We also include process optimization advice to enhance your production efficiency. With global service centers, we ensure fast response times and spare parts availability. This support helps clients maximize the machine's potential without downtime.

| What Customers Say

Our customers praise I.C.T engineers for their expert setup and troubleshooting skills. They love the PCB X-ray Inspection Machine for its accurate detections and easy use. Many highlight our secure packaging and fast shipping that prevent damage. Quick responses to queries resolve issues promptly, building trust. Overall, clients rate us highly for reliable equipment and service.

| Certifications and Standards

I.C.T holds key certifications like CE, RoHS, ISO9001, and various patents. These ensure our PCB X-ray Inspection Machine meets international safety and quality standards. CE confirms compliance with EU regulations for health and environment. RoHS guarantees no harmful substances. ISO9001 reflects our strong quality management system. Patents protect innovative features like bubble measurement tools. This makes our products dependable worldwide.

| About I.C.T Company and Our Factory

I.C.T is a leading provider with in-house R&D and production, employing over 89 staff in a 12,000m² facility. We've grown rapidly since 2012, serving more than 1,600 customers in 72 countries. Our factories follow strict testing processes and quality management systems to ensure high standards. We offer full SMT solutions, from planning to optimization, helping clients build efficient manufacturing lines globally.

| I.C.T X-7100 PCB X-ray Inspection Machine

The I.C.T X-7100 is an advanced offline SMT PCB X-ray Inspection Machine designed for detailed internal checks in electronics manufacturing. It excels in spotting issues like air bubbles, voids, short circuits, open circuits, missing solder, and cracks in components. With features like CNC programming for automatic detection and a visual navigation interface, it simplifies the process for operators. This PCB X-ray Inspection Machine supports various applications, from SMT and BGA to lithium batteries and automotive parts. Its high-resolution digital flat panel and stable X-ray tube ensure clear images, while safety certifications like EU CE and ISO make it reliable. Ideal for quality control, it helps manufacturers reduce defects and improve product reliability in a user-friendly way.

| Feature

The I.C.T X-7100 PCB X-ray Inspection Machine uses a high-resolution digital flat panel detector with 1536x1536 pixels, providing sharp images for precise defect detection. This feature captures real-time corrections and offers multiple gain modes for better visibility. It helps identify tiny issues like solder ball defects or wire bonding problems in semiconductors. With passive cooling and temperature sensors, it maintains consistent performance during long sessions. This makes the X-ray inspection machine essential for industries needing accurate internal views, ensuring fewer errors in production.

CNC programming in this PCB X-ray Inspection Machine allows automatic scanning of multiple sample positions without manual input. It supports array functions for fixed-spacing samples, speeding up inspections in high-volume settings. Operators can set programs easily via mouse clicks, reducing time and errors. The anti-collision system protects the device during movement. This offline SMT PCB X-ray Inspection Machine is perfect for batch testing in SMT lines, boosting efficiency and repeatability.

One-key measurement tools in the X-7100 quickly calculate bubble size, void rate, and solder height. This helps in quality checks for soldering joints in PCBA assemblies. The simulate color feature enhances image observation for better analysis. Equipped with joystick control for precise adjustments, it ensures accurate results. As a versatile PCB X-ray Inspection Machine, it applies to various materials like ceramics and plastics, aiding in defect prevention.

| Specification

| Item | Model | I.C.T X-7100 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T SMT AI total solution line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT PCB Loader Unloader | Automatically loads bare PCBs to the line. |

| SMT paste printer | Prints solder paste on PCB pads accurately. |

| Modular Chip Shooter | Mounts components onto PCBs precisely. |

| Dual-rails Reflow Oven | Melts solder to form solid joints. |

| AOI Automatic Testing Machine | Inspects solder joints and placement defects. |

| SPI SMT machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| Stencil cleaning machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB depanel machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: Laser Engraving Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

In our video, we showcase the I.C.T X-7100 PCB X-ray Inspection Machine in action at a client's electronics factory. The video starts with an overview of its sleek exterior and key functions like joystick control and programming interface. Inside, it reveals the high-precision X-ray tube from Hamamatsu and the digital flat panel detector. During operation, the machine scans PCBA samples, detecting BGA bubbles and solder balls in real time. Engineers demonstrate automatic batch mode on lithium batteries and wire harnesses, highlighting quick measurements of voids and tilts up to 60 degrees. This setup helped the client improve defect detection by 30%, ensuring higher quality in their SMT production line. The video emphasizes how this offline SMT PCB X-ray Inspection Machine integrates seamlessly into workflows for reliable results.

| Service and Training Support

I.C.T offers comprehensive services and training for the PCB X-ray Inspection Machine. Our team provides on-site installation, regular maintenance, and quick technical support to keep your equipment running smoothly. Training programs cover basic operation, programming, and safety protocols, tailored for operators with simple instructions. We also include process optimization advice to enhance your production efficiency. With global service centers, we ensure fast response times and spare parts availability. This support helps clients maximize the machine's potential without downtime.

| What Customers Say

Our customers praise I.C.T engineers for their expert setup and troubleshooting skills. They love the PCB X-ray Inspection Machine for its accurate detections and easy use. Many highlight our secure packaging and fast shipping that prevent damage. Quick responses to queries resolve issues promptly, building trust. Overall, clients rate us highly for reliable equipment and service.

| Certifications and Standards

I.C.T holds key certifications like CE, RoHS, ISO9001, and various patents. These ensure our PCB X-ray Inspection Machine meets international safety and quality standards. CE confirms compliance with EU regulations for health and environment. RoHS guarantees no harmful substances. ISO9001 reflects our strong quality management system. Patents protect innovative features like bubble measurement tools. This makes our products dependable worldwide.

| About I.C.T Company and Our Factory

I.C.T is a leading provider with in-house R&D and production, employing over 89 staff in a 12,000m² facility. We've grown rapidly since 2012, serving more than 1,600 customers in 72 countries. Our factories follow strict testing processes and quality management systems to ensure high standards. We offer full SMT solutions, from planning to optimization, helping clients build efficient manufacturing lines globally.