I.C.T-750

I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| High-Performance SMT Stencil Cleaner

The I.C.T-800 is a reliable SMT Stencil Cleaner designed for electronics manufacturers who need consistent, thorough cleaning of solder paste stencils, red glue stencils, copper masks, misprinted PCBs, and large PCBAs. It completes the full process—aqueous detergent cleaning, water rinsing, and hot air drying—inside a single wash chamber. With its unique design of four fixed spray rods and four air knives plus stencil movement, it ensures stable and efficient removal of residues while keeping stencil tension safe. The machine includes heating for detergent, stirring to keep liquid uniform, precise filtering, and resistivity monitoring. This SMT Stencil Cleaner helps improve print quality, reduce defects, and lower cleaning costs in high-volume SMT production lines.

| Feature

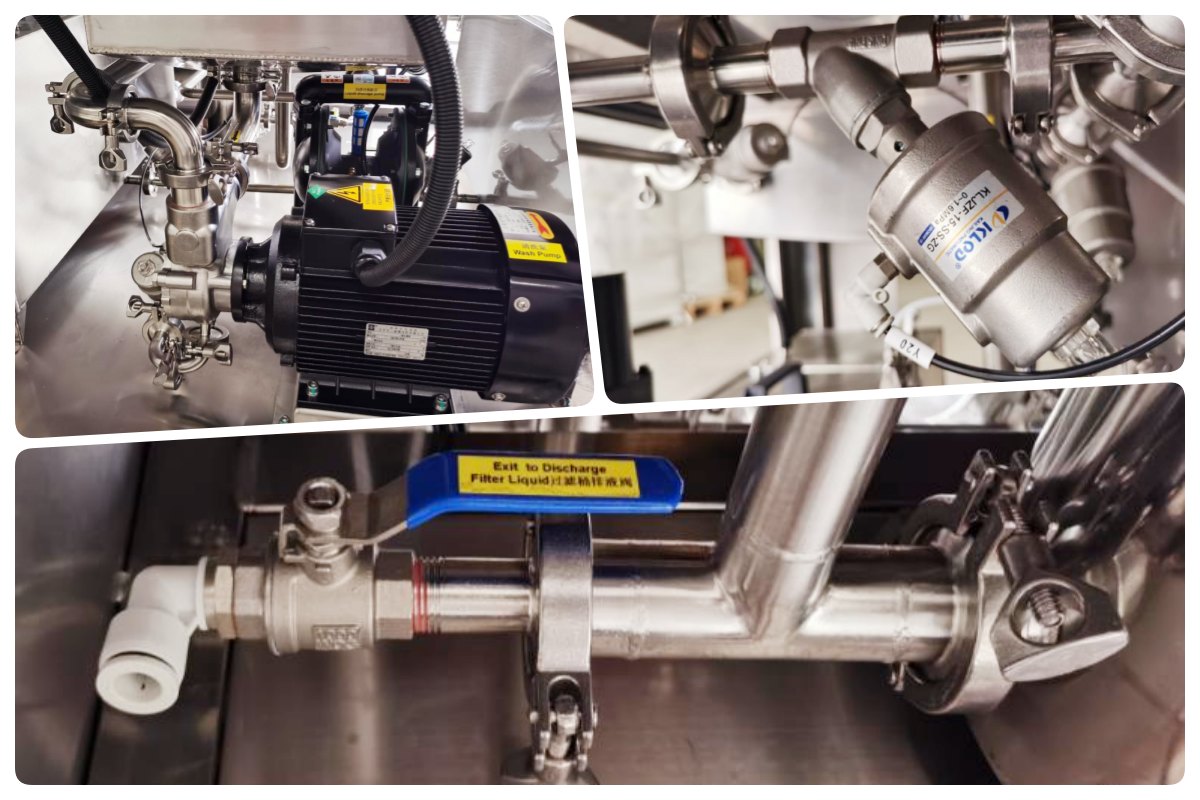

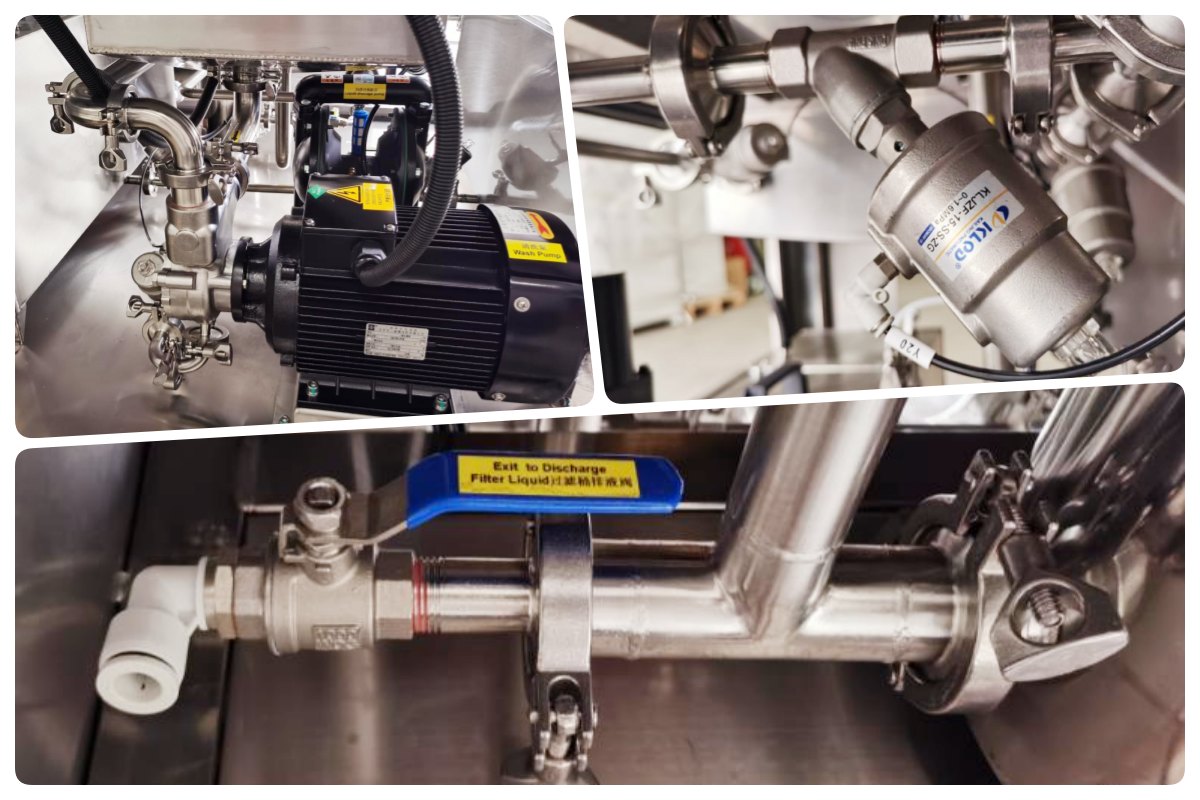

The supply system in the I.C.T-800 SMT Stencil Cleaner uses a high-power motor combined with a strong diaphragm pump to deliver powerful spraying and fast liquid recovery. All pneumatic parts feature quick-connect interfaces for simple and fast maintenance. Pipeline interfaces are quick-release, allowing easy replacement when needed. Angle seat valves at key points let the same loop handle both filling and recovery of cleaning fluid. Clear marking on pipelines shows flow direction, reducing mistakes during operation. This setup ensures reliable performance and quick service, keeping your production running smoothly.

The cleaning system stands out with its unique four fixed spray rods and four air knives, while the stencil moves back and forth for even coverage. This design makes cleaning more stable, fast, and efficient than traditional methods. An adjustable clamping device fits various stencil sizes and allows quick changes. Guide channels with bottom pulleys prevent water buildup and make loading/unloading easy. Double-sealed doors with a recovery tank stop residual liquid from leaking near the door. A stepper motor drives precise reciprocating motion, ensuring thorough cleaning of solder paste, red glue, flux on stencils, copper plates, resin masks, misprinted PCB, and PCBA.

The I.C.T-800 features extra-large 60L cleaning fluid and rinse tanks to reduce the need for frequent refills. Built-in heating tubes warm the aqueous detergent to the ideal temperature (up to 60°C) for better cleaning power. Temperature probes allow custom settings, and four arc-shaped stirring blades keep the liquid well mixed. A customized liquid level sensor gives sound and light alerts when fluid is low. Multiple precision filters (before spraying and during recycling) protect both the parts and the cleaning liquid from contamination. This tank system supports long, uninterrupted operation with consistent results.

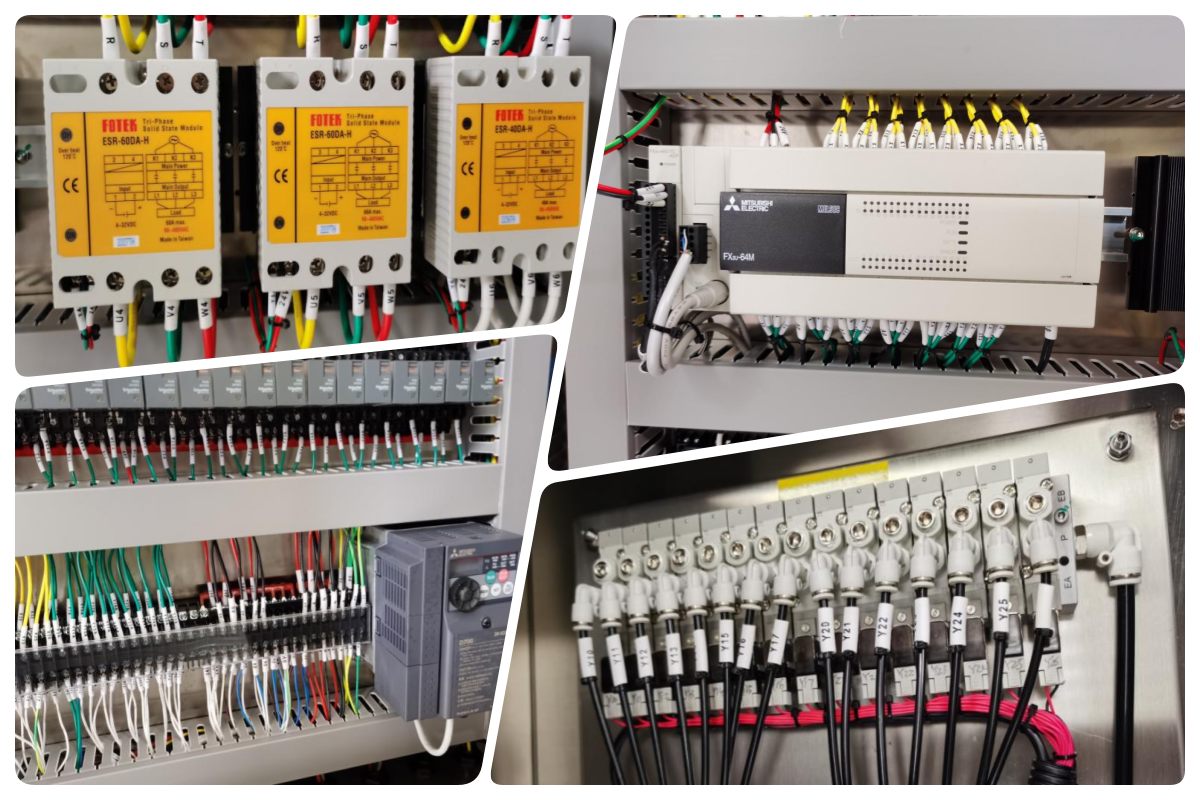

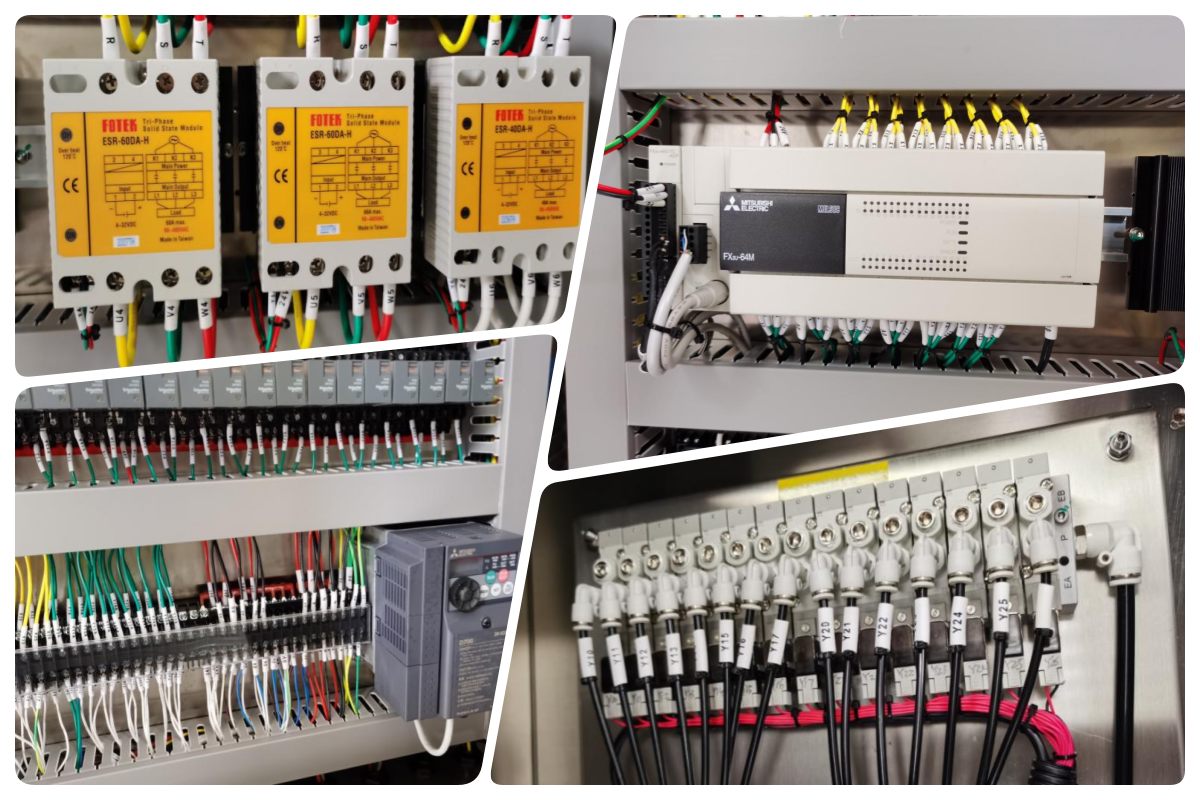

The control system uses a user-friendly English color touch screen and PLC program for easy operation. Operators can set and monitor cleaning temperature, cleaning time, rinse time and cycles, rinse temperature, hot air dry time and temperature, and water resistivity. All main components come from trusted imported brands for high reliability. The electrical and pneumatic control boxes are separated to avoid interference. The layout meets CE and UL standards, making maintenance simple and safe. This advanced control gives precise process management and helps achieve repeatable, high-quality cleaning every time.

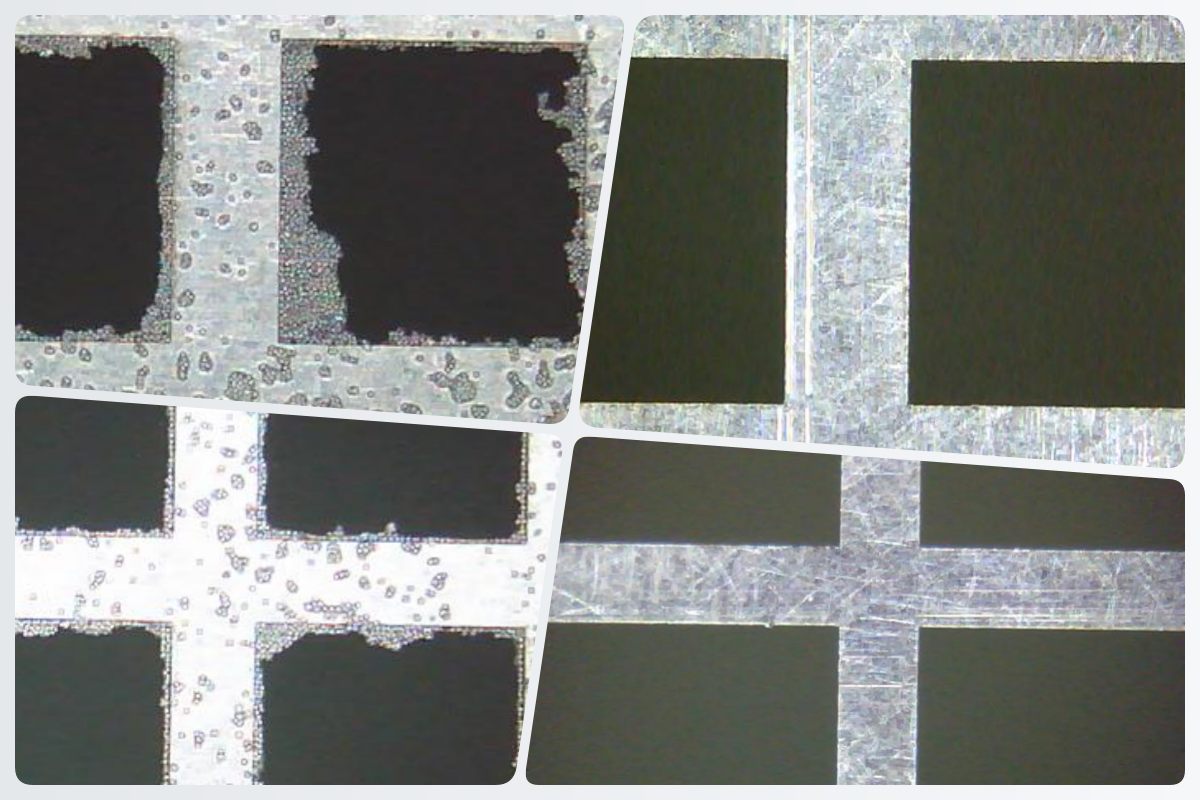

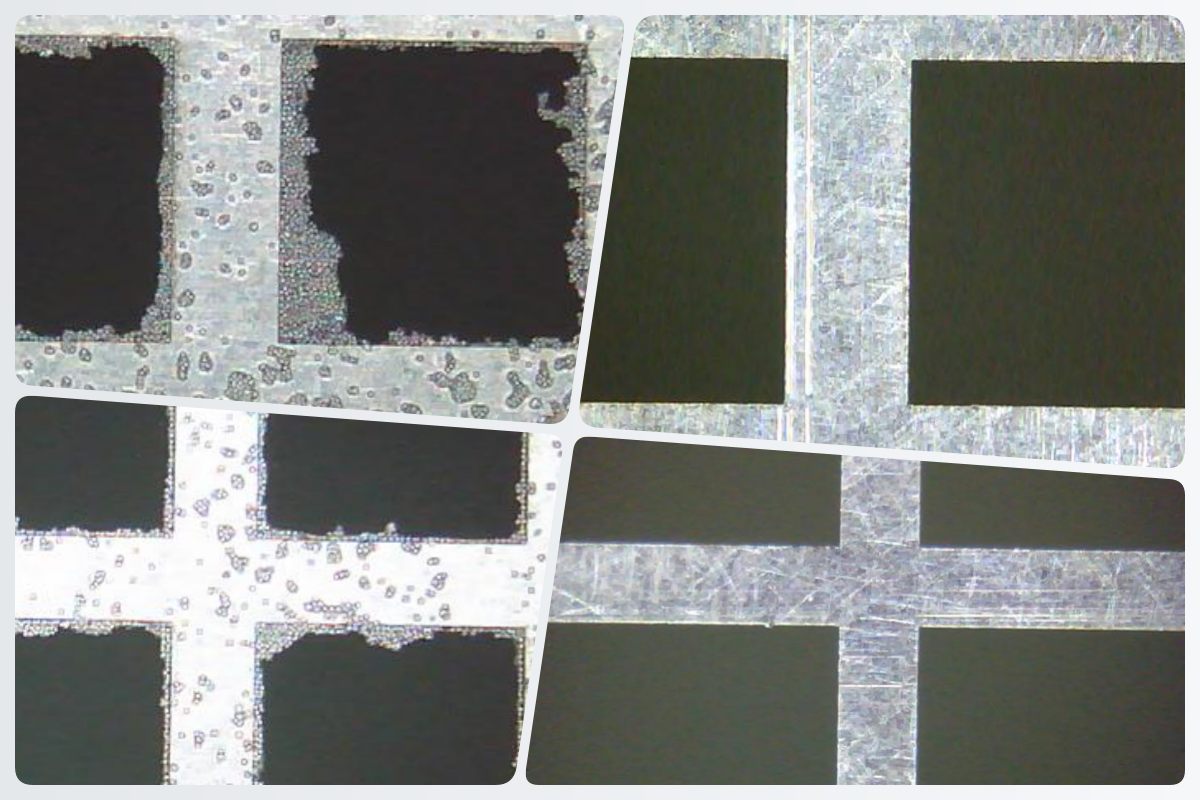

| Comparison Before and After

| Specification

| Parameter | I.C.T-750 (Pneumatic) | I.C.T-800 (Auto Aqueous) |

|---|---|---|

| Power Source | Compressed air only (no electricity) | Electric (AC380V, 3-phase, 33KW total) |

| Max Stencil Size | L750 × W750 × H40 mm | L750 × W750 × H40 mm |

| Cleaning Method | 360° rotation spray + air blow dry | 4 fixed spray rods + 4 air knives, stencil moves back & forth |

| Cleaning Liquid | Solvent or aqueous (both supported) | Aqueous detergent only |

| Liquid Tank Capacity | 40 L | 60 L × 2 (cleaning + rinse) |

| Cleaning Time | 2–4 minutes | 2–5 minutes |

| Drying Time | 2–5 minutes | 3–5 minutes (hot air) |

| Heating Function | No heating (room temperature) | Yes (detergent up to 60°C, hot air up to 90°C) |

| SMT Line Equipment List

For a complete PCB Assembly Line, I.C.T offers key machines like SMT stencil printers, SPI systems, high-speed pick & Place machine, reflow ovens, AOI inspection equipment, PCB conveyors, and PCBA cleaners. These work together to create efficient, high-quality SMT assembly. For DIP lines, we provide selective soldering machines and wave soldering equipment to handle through-hole components with precision and reliability. Whether building SMT, DIP, or mixed lines, I.C.T supplies matched equipment and full support for smooth production.

| Customer Success Video

I.C.T successfully supported a North American beauty instrument manufacturer by completing overseas installation and Factory Acceptance Test (FAT) for two full SMT production lines. The project passed production acceptance smoothly and on time. The lines included key equipment such as laser marking machine, SMT printer with SPI, Panasonic placement machine, Heller reflow oven, AOI inspection system, PCB conveyors, PCBA cleaner, and fully automatic solder paste storage and thawing box. Our experienced engineers provided on-site setup, training, and debugging to ensure everything ran perfectly. This successful delivery strengthened the customer's confidence in building efficient, high-quality SMT lines with I.C.T as their trusted partner.

| Service and Training

I.C.T offers full support to help customers get the best performance from their SMT Stencil Cleaner and entire production lines. Our skilled engineers provide on-site installation, commissioning, and operator training worldwide. We teach proper machine operation, daily maintenance, parameter adjustment, and troubleshooting to keep equipment running smoothly. Remote technical support is available for fast answers to questions. We also offer process optimization advice to improve yield and reduce costs. With over 25 years of experience, our team ensures quick response and long-term reliability, so customers can focus on production while we handle the rest.

| Customer Reviews

Customers praise our engineers for their professional skills, patience, and fast response to questions during installation and support. Many highlight the SMT Stencil Cleaner for its stable performance, thorough cleaning results, and low detergent usage. Several mention excellent packaging and safe transportation, with machines arriving in perfect condition even after long overseas shipping. Quick problem-solving and clear communication also receive high marks. Overall, clients value I.C.T as a reliable partner that delivers quality equipment and caring service.

| Our Certification

The I.C.T-800 SMT Stencil Cleaner meets international standards with CE certification for safety, RoHS compliance for environmental protection, and ISO9001 for quality management. We also hold multiple patents for innovative designs like the fixed spray rod and moving stencil mechanism. These certifications and patents prove our commitment to high safety, eco-friendly operation, and advanced technology. Customers can trust that every machine follows strict global requirements for performance, reliability, and environmental care.

| About Us and Factory

I.C.T is a leading provider of full SMT factory solutions with our own research, development, and production facilities. Established in 2012, we now have 89 staff, 20 experienced engineers, and an 12,000 m² industrial park in Dongguan, China. Our registered capital is $30 million, and we have 8 branch offices worldwide. Over the years, we have grown rapidly and served more than 1600 customers in 72 countries. Our factory follows strict testing processes and a complete quality management system to ensure every machine meets high standards. We deliver reliable equipment and one-stop support to help customers build and optimize their production lines.

| High-Performance SMT Stencil Cleaner

The I.C.T-800 is a reliable SMT Stencil Cleaner designed for electronics manufacturers who need consistent, thorough cleaning of solder paste stencils, red glue stencils, copper masks, misprinted PCBs, and large PCBAs. It completes the full process—aqueous detergent cleaning, water rinsing, and hot air drying—inside a single wash chamber. With its unique design of four fixed spray rods and four air knives plus stencil movement, it ensures stable and efficient removal of residues while keeping stencil tension safe. The machine includes heating for detergent, stirring to keep liquid uniform, precise filtering, and resistivity monitoring. This SMT Stencil Cleaner helps improve print quality, reduce defects, and lower cleaning costs in high-volume SMT production lines.

| Feature

The supply system in the I.C.T-800 SMT Stencil Cleaner uses a high-power motor combined with a strong diaphragm pump to deliver powerful spraying and fast liquid recovery. All pneumatic parts feature quick-connect interfaces for simple and fast maintenance. Pipeline interfaces are quick-release, allowing easy replacement when needed. Angle seat valves at key points let the same loop handle both filling and recovery of cleaning fluid. Clear marking on pipelines shows flow direction, reducing mistakes during operation. This setup ensures reliable performance and quick service, keeping your production running smoothly.

The cleaning system stands out with its unique four fixed spray rods and four air knives, while the stencil moves back and forth for even coverage. This design makes cleaning more stable, fast, and efficient than traditional methods. An adjustable clamping device fits various stencil sizes and allows quick changes. Guide channels with bottom pulleys prevent water buildup and make loading/unloading easy. Double-sealed doors with a recovery tank stop residual liquid from leaking near the door. A stepper motor drives precise reciprocating motion, ensuring thorough cleaning of solder paste, red glue, flux on stencils, copper plates, resin masks, misprinted PCB, and PCBA.

The I.C.T-800 features extra-large 60L cleaning fluid and rinse tanks to reduce the need for frequent refills. Built-in heating tubes warm the aqueous detergent to the ideal temperature (up to 60°C) for better cleaning power. Temperature probes allow custom settings, and four arc-shaped stirring blades keep the liquid well mixed. A customized liquid level sensor gives sound and light alerts when fluid is low. Multiple precision filters (before spraying and during recycling) protect both the parts and the cleaning liquid from contamination. This tank system supports long, uninterrupted operation with consistent results.

The control system uses a user-friendly English color touch screen and PLC program for easy operation. Operators can set and monitor cleaning temperature, cleaning time, rinse time and cycles, rinse temperature, hot air dry time and temperature, and water resistivity. All main components come from trusted imported brands for high reliability. The electrical and pneumatic control boxes are separated to avoid interference. The layout meets CE and UL standards, making maintenance simple and safe. This advanced control gives precise process management and helps achieve repeatable, high-quality cleaning every time.

| Comparison Before and After

| Specification

| Parameter | I.C.T-750 (Pneumatic) | I.C.T-800 (Auto Aqueous) |

|---|---|---|

| Power Source | Compressed air only (no electricity) | Electric (AC380V, 3-phase, 33KW total) |

| Max Stencil Size | L750 × W750 × H40 mm | L750 × W750 × H40 mm |

| Cleaning Method | 360° rotation spray + air blow dry | 4 fixed spray rods + 4 air knives, stencil moves back & forth |

| Cleaning Liquid | Solvent or aqueous (both supported) | Aqueous detergent only |

| Liquid Tank Capacity | 40 L | 60 L × 2 (cleaning + rinse) |

| Cleaning Time | 2–4 minutes | 2–5 minutes |

| Drying Time | 2–5 minutes | 3–5 minutes (hot air) |

| Heating Function | No heating (room temperature) | Yes (detergent up to 60°C, hot air up to 90°C) |

| SMT Line Equipment List

For a complete PCB Assembly Line, I.C.T offers key machines like SMT stencil printers, SPI systems, high-speed pick & Place machine, reflow ovens, AOI inspection equipment, PCB conveyors, and PCBA cleaners. These work together to create efficient, high-quality SMT assembly. For DIP lines, we provide selective soldering machines and wave soldering equipment to handle through-hole components with precision and reliability. Whether building SMT, DIP, or mixed lines, I.C.T supplies matched equipment and full support for smooth production.

| Customer Success Video

I.C.T successfully supported a North American beauty instrument manufacturer by completing overseas installation and Factory Acceptance Test (FAT) for two full SMT production lines. The project passed production acceptance smoothly and on time. The lines included key equipment such as laser marking machine, SMT printer with SPI, Panasonic placement machine, Heller reflow oven, AOI inspection system, PCB conveyors, PCBA cleaner, and fully automatic solder paste storage and thawing box. Our experienced engineers provided on-site setup, training, and debugging to ensure everything ran perfectly. This successful delivery strengthened the customer's confidence in building efficient, high-quality SMT lines with I.C.T as their trusted partner.

| Service and Training

I.C.T offers full support to help customers get the best performance from their SMT Stencil Cleaner and entire production lines. Our skilled engineers provide on-site installation, commissioning, and operator training worldwide. We teach proper machine operation, daily maintenance, parameter adjustment, and troubleshooting to keep equipment running smoothly. Remote technical support is available for fast answers to questions. We also offer process optimization advice to improve yield and reduce costs. With over 25 years of experience, our team ensures quick response and long-term reliability, so customers can focus on production while we handle the rest.

| Customer Reviews

Customers praise our engineers for their professional skills, patience, and fast response to questions during installation and support. Many highlight the SMT Stencil Cleaner for its stable performance, thorough cleaning results, and low detergent usage. Several mention excellent packaging and safe transportation, with machines arriving in perfect condition even after long overseas shipping. Quick problem-solving and clear communication also receive high marks. Overall, clients value I.C.T as a reliable partner that delivers quality equipment and caring service.

| Our Certification

The I.C.T-800 SMT Stencil Cleaner meets international standards with CE certification for safety, RoHS compliance for environmental protection, and ISO9001 for quality management. We also hold multiple patents for innovative designs like the fixed spray rod and moving stencil mechanism. These certifications and patents prove our commitment to high safety, eco-friendly operation, and advanced technology. Customers can trust that every machine follows strict global requirements for performance, reliability, and environmental care.

| About Us and Factory

I.C.T is a leading provider of full SMT factory solutions with our own research, development, and production facilities. Established in 2012, we now have 89 staff, 20 experienced engineers, and an 12,000 m² industrial park in Dongguan, China. Our registered capital is $30 million, and we have 8 branch offices worldwide. Over the years, we have grown rapidly and served more than 1600 customers in 72 countries. Our factory follows strict testing processes and a complete quality management system to ensure every machine meets high standards. We deliver reliable equipment and one-stop support to help customers build and optimize their production lines.