This wave soldering machine efficiently welds PCBs, reduces costs, and enhances productivity.

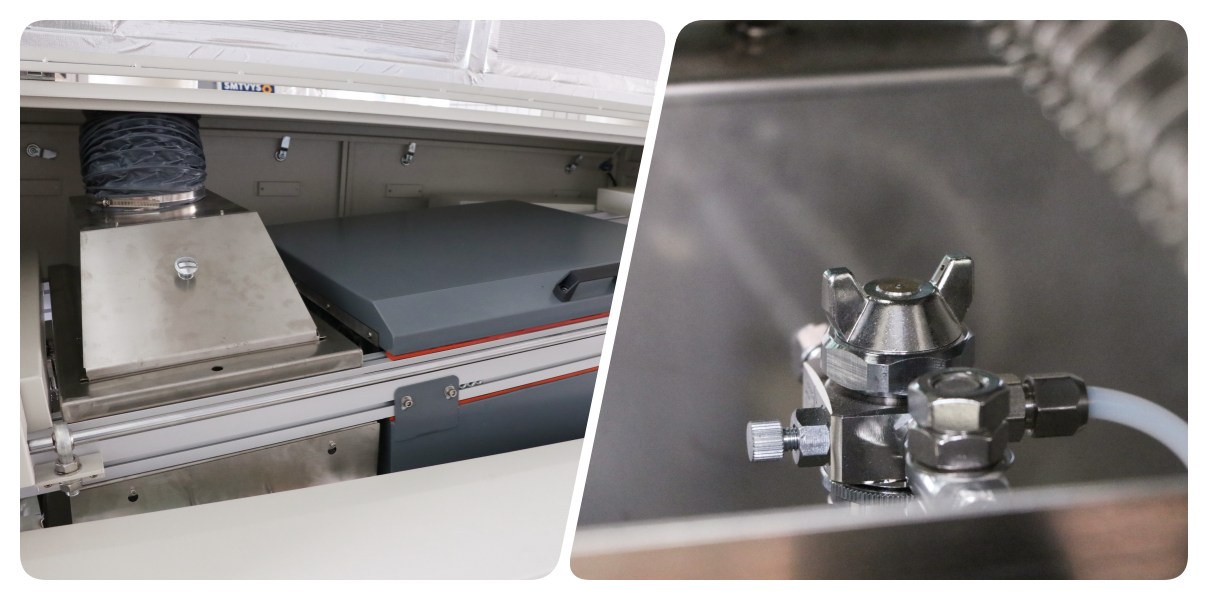

a. Features Japan Kuroda nozzles for consistent and reliable spray.

b. PLC controls ensure precise spray time and speed, promoting efficiency.

c. Offers third-party over-temperature protection for safe operations.

d. Meets CE, CCC, UL standards for high-quality performance.

e. Horizontal heating design delivers accurate temperature control.

f. Uses imported components to minimize maintenance costs.

g. Provides global service and training for complete customer support.

I.C.T-W2

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| W-Series Lead-Free Wave Soldering Machines

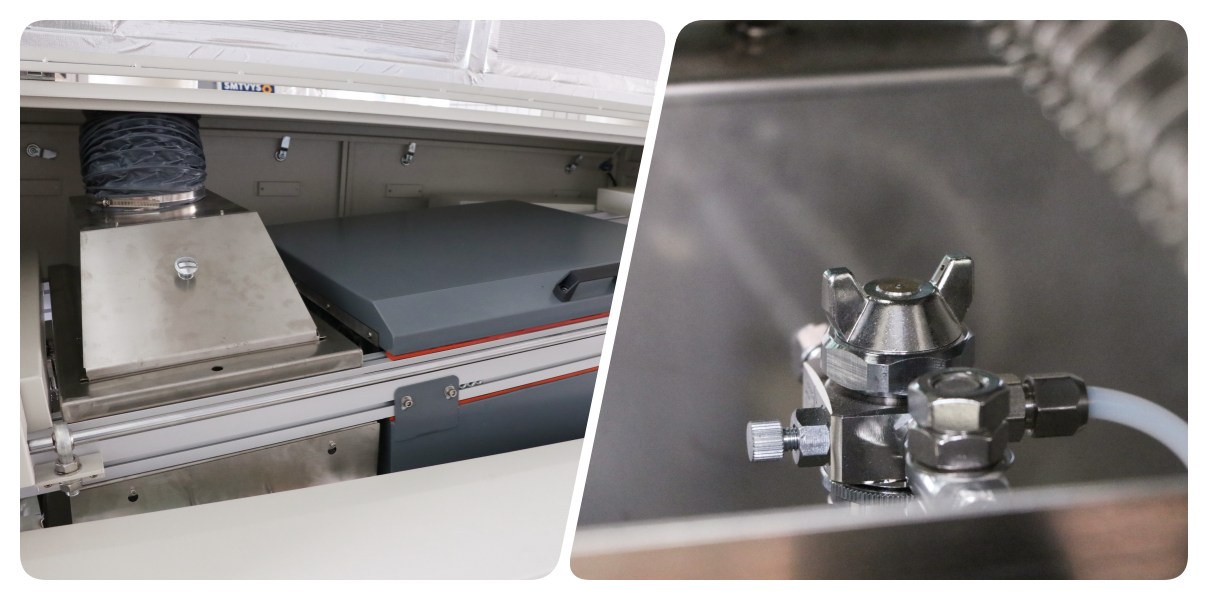

The W-Series Lead-Free Wave Soldering Machines from I.C.T are proven products, refined through years of market testing and earning positive feedback. Known for unparalleled heating performance and precise temperature control, these wave soldering machines cater to diverse welding processes, with an energy-saving design that lowers costs.

Supporting PCBs up to 400mm, with a 180kg solder pot capacity and 750±20mm transmission height, they are ideal for THT PCB Wave Soldering Machine applications in automotive, communication, and consumer electronics. Equipped with Japan Kuroda nozzles and PLC systems, they ensure safety and efficiency. I.C.T offers global installation, maintenance, and training, optimizing production worldwide.

| Feature

The W-Series features an adjustable spray system with Japan Kuroda nozzles, ensuring long-term uniformity and reliability. PLC control allows precise adjustment of spray time, speed, and FLUX flow, with digital settings for flow, angle, and width that can be recorded. The pyramid-shaped mask and filter screen reduce FLUX waste, making this Wave Soldering Equipment both economical and eco-friendly, perfect for high-volume PCB production.

Safety is enhanced with third-party over-temperature protection and multiple safety layers, ensuring secure operation of wave soldering machines. The horizontal heating design prevents zone interference, providing an accurate temperature curve for sensitive electronics. This robust system extends equipment life and is ideal for THT PCB Wave Soldering Machine tasks in demanding industries.

The horizontal heating module ensures independent zone operation, offering high production capacity and heat exchange efficiency. With PLC and PID control for real-time monitoring, it preheats to 150°C in 15 minutes, adapting to various welding needs. This efficiency makes the W-Series a top choice for fast-paced manufacturing environments using Wave Soldering Equipment.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2024, two I.C.T engineers visited Uruguay to support a smart meter manufacturer, as shown in a video with glowing customer reviews. The footage features equipment like board loaders, placement machines 471 and 481, Lyra622, AOI, corner conveyors, W2 wave soldering machines, junction stations, material frame belt lines, roller lines, and bullseye workbenches.

Clients praised the engineers’ expertise and the W2’s stable performance, noting improved production efficiency and expressing interest in future partnerships.

| Expert Services and Training

I.C.T provides extensive services and training for wave soldering machines, including installation, maintenance, and operational guidance. Our global engineer network, covering 72 countries, offers on-site support and customized training to enhance production efficiency.

With 25 years of experience and 20 engineers, we deliver timely technical upgrades and process optimizations. Clients benefit from our $30 million registered fund and eight branch offices, ensuring reliable, long-term support for PCB Wave Soldering Machine operations worldwide.

| Customer Testimonials

Customers highly commend I.C.T engineers for their professional skills and swift problem-solving, especially during overseas missions like in Uruguay. The wave soldering machines are celebrated for their reliable welding quality and efficiency, crucial for THT PCB Wave Soldering Machine applications.

Our robust packaging ensures damage-free delivery, while our rapid response to technical issues—often resolved within hours—earns consistent praise. Clients value our innovative solutions and see I.C.T as a trusted partner in global manufacturing.

| Quality Certifications

I.C.T’s wave soldering machines are certified with CE, RoHS, ISO9001, and multiple patents, reflecting adherence to global safety and quality standards. These credentials, validated in our 12,000m² Dongguan factory, ensure the reliability of Wave Soldering Equipment. Our patented technologies enhance durability and performance, giving customers confidence in choosing I.C.T for their PCB production needs, backed by a strong quality management system.

| About I.C.T Company and Factory

I.C.T is a leader in electronics manufacturing with in-house R&D and production, employing a large team that has grown rapidly over 25 years. Serving over 1,600 clients across 72 countries, our 12,000m² industrial park in Dongguan features strict quality control and a robust management system, producing top-tier wave soldering machines.

With eight branch offices and a $30 million registered fund, we deliver innovative solutions globally. Our commitment to excellence supports clients from initial setup to ongoing optimization, making I.C.T a trusted name in the industry.

| W-Series Lead-Free Wave Soldering Machines

The W-Series Lead-Free Wave Soldering Machines from I.C.T are proven products, refined through years of market testing and earning positive feedback. Known for unparalleled heating performance and precise temperature control, these wave soldering machines cater to diverse welding processes, with an energy-saving design that lowers costs.

Supporting PCBs up to 400mm, with a 180kg solder pot capacity and 750±20mm transmission height, they are ideal for THT PCB Wave Soldering Machine applications in automotive, communication, and consumer electronics. Equipped with Japan Kuroda nozzles and PLC systems, they ensure safety and efficiency. I.C.T offers global installation, maintenance, and training, optimizing production worldwide.

| Feature

The W-Series features an adjustable spray system with Japan Kuroda nozzles, ensuring long-term uniformity and reliability. PLC control allows precise adjustment of spray time, speed, and FLUX flow, with digital settings for flow, angle, and width that can be recorded. The pyramid-shaped mask and filter screen reduce FLUX waste, making this Wave Soldering Equipment both economical and eco-friendly, perfect for high-volume PCB production.

Safety is enhanced with third-party over-temperature protection and multiple safety layers, ensuring secure operation of wave soldering machines. The horizontal heating design prevents zone interference, providing an accurate temperature curve for sensitive electronics. This robust system extends equipment life and is ideal for THT PCB Wave Soldering Machine tasks in demanding industries.

The horizontal heating module ensures independent zone operation, offering high production capacity and heat exchange efficiency. With PLC and PID control for real-time monitoring, it preheats to 150°C in 15 minutes, adapting to various welding needs. This efficiency makes the W-Series a top choice for fast-paced manufacturing environments using Wave Soldering Equipment.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2024, two I.C.T engineers visited Uruguay to support a smart meter manufacturer, as shown in a video with glowing customer reviews. The footage features equipment like board loaders, placement machines 471 and 481, Lyra622, AOI, corner conveyors, W2 wave soldering machines, junction stations, material frame belt lines, roller lines, and bullseye workbenches.

Clients praised the engineers’ expertise and the W2’s stable performance, noting improved production efficiency and expressing interest in future partnerships.

| Expert Services and Training

I.C.T provides extensive services and training for wave soldering machines, including installation, maintenance, and operational guidance. Our global engineer network, covering 72 countries, offers on-site support and customized training to enhance production efficiency.

With 25 years of experience and 20 engineers, we deliver timely technical upgrades and process optimizations. Clients benefit from our $30 million registered fund and eight branch offices, ensuring reliable, long-term support for PCB Wave Soldering Machine operations worldwide.

| Customer Testimonials

Customers highly commend I.C.T engineers for their professional skills and swift problem-solving, especially during overseas missions like in Uruguay. The wave soldering machines are celebrated for their reliable welding quality and efficiency, crucial for THT PCB Wave Soldering Machine applications.

Our robust packaging ensures damage-free delivery, while our rapid response to technical issues—often resolved within hours—earns consistent praise. Clients value our innovative solutions and see I.C.T as a trusted partner in global manufacturing.

| Quality Certifications

I.C.T’s wave soldering machines are certified with CE, RoHS, ISO9001, and multiple patents, reflecting adherence to global safety and quality standards. These credentials, validated in our 12,000m² Dongguan factory, ensure the reliability of Wave Soldering Equipment. Our patented technologies enhance durability and performance, giving customers confidence in choosing I.C.T for their PCB production needs, backed by a strong quality management system.

| About I.C.T Company and Factory

I.C.T is a leader in electronics manufacturing with in-house R&D and production, employing a large team that has grown rapidly over 25 years. Serving over 1,600 clients across 72 countries, our 12,000m² industrial park in Dongguan features strict quality control and a robust management system, producing top-tier wave soldering machines.

With eight branch offices and a $30 million registered fund, we deliver innovative solutions globally. Our commitment to excellence supports clients from initial setup to ongoing optimization, making I.C.T a trusted name in the industry.

FAQ:

Q: Is wave soldering suitable for high-volume production?

A: Wave soldering machines are designed to excel in high-volume production settings, maintaining the highest quality standards throughout.

Q: Can wave soldering machines be integrated into automated production lines?

A: Wave soldering machines can seamlessly integrate into automated production lines, streamlining processes and enhancing overall efficiency.

Q: What industries benefit from wave soldering technology?

A: Industries such as electronics manufacturing, automotive, aerospace, and more benefit significantly from the application of wave soldering technology in their production processes.

FAQ:

Q: Is wave soldering suitable for high-volume production?

A: Wave soldering machines are designed to excel in high-volume production settings, maintaining the highest quality standards throughout.

Q: Can wave soldering machines be integrated into automated production lines?

A: Wave soldering machines can seamlessly integrate into automated production lines, streamlining processes and enhancing overall efficiency.

Q: What industries benefit from wave soldering technology?

A: Industries such as electronics manufacturing, automotive, aerospace, and more benefit significantly from the application of wave soldering technology in their production processes.