I.C.T-S510D

I.C.T

spi machine

| Availability: | |

|---|---|

| Quantity: | |

| High-Throughput Dual-Lane SPI SMT Machine

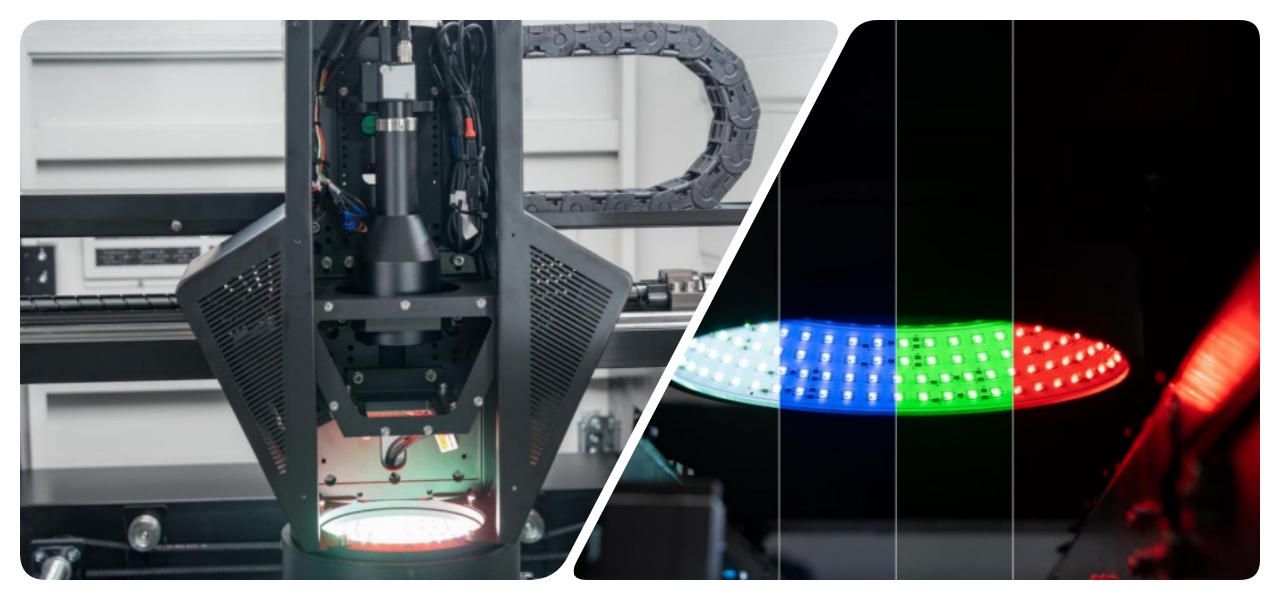

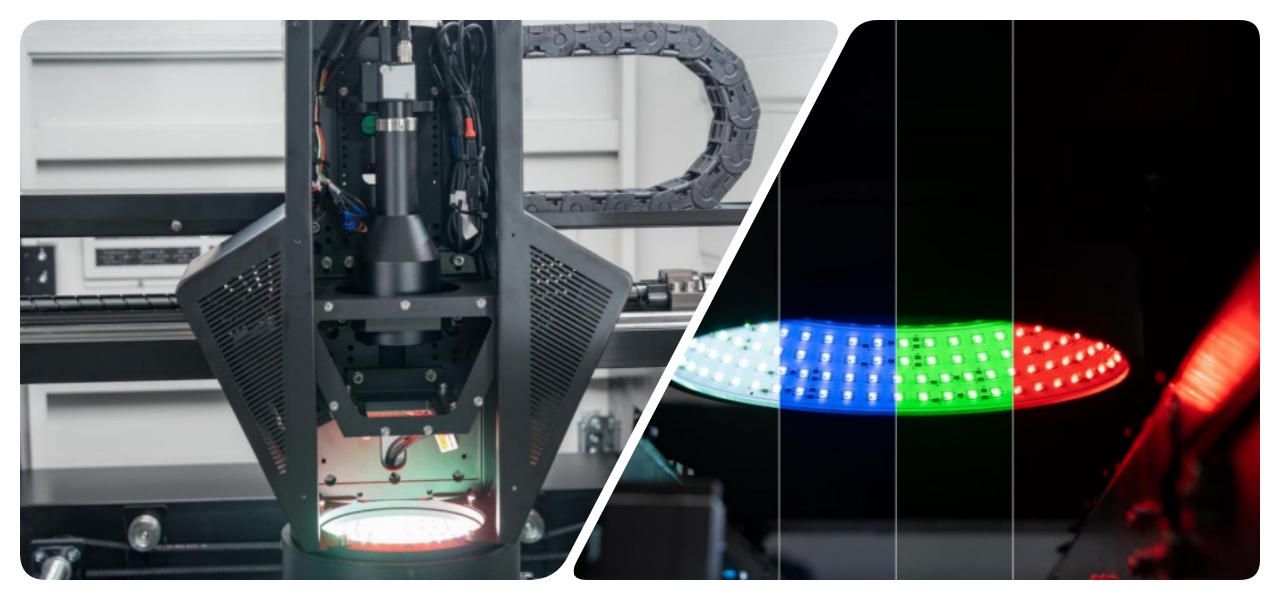

The I.C.T-S510D is a powerful dual-lane online SPI SMT machine built for high-volume electronics manufacturing. Using genuine 3D blue-light PSLM PMP technology and a 5M-pixel high-speed camera (12M optional), this advanced solder paste inspection machine measures height, volume, area, and shape with micron-level precision while running two boards in parallel. It completely removes shadow problems and random reflections that plague traditional systems, supports PCB sizes from 50×60mm up to 510×310mm per lane, and programs new products in under 10 minutes via Gerber import or graphical editing. Perfect for customers who need maximum output with zero compromise on quality, the S510D is the ultimate 3D solder paste inspection solution for modern SMT factories.

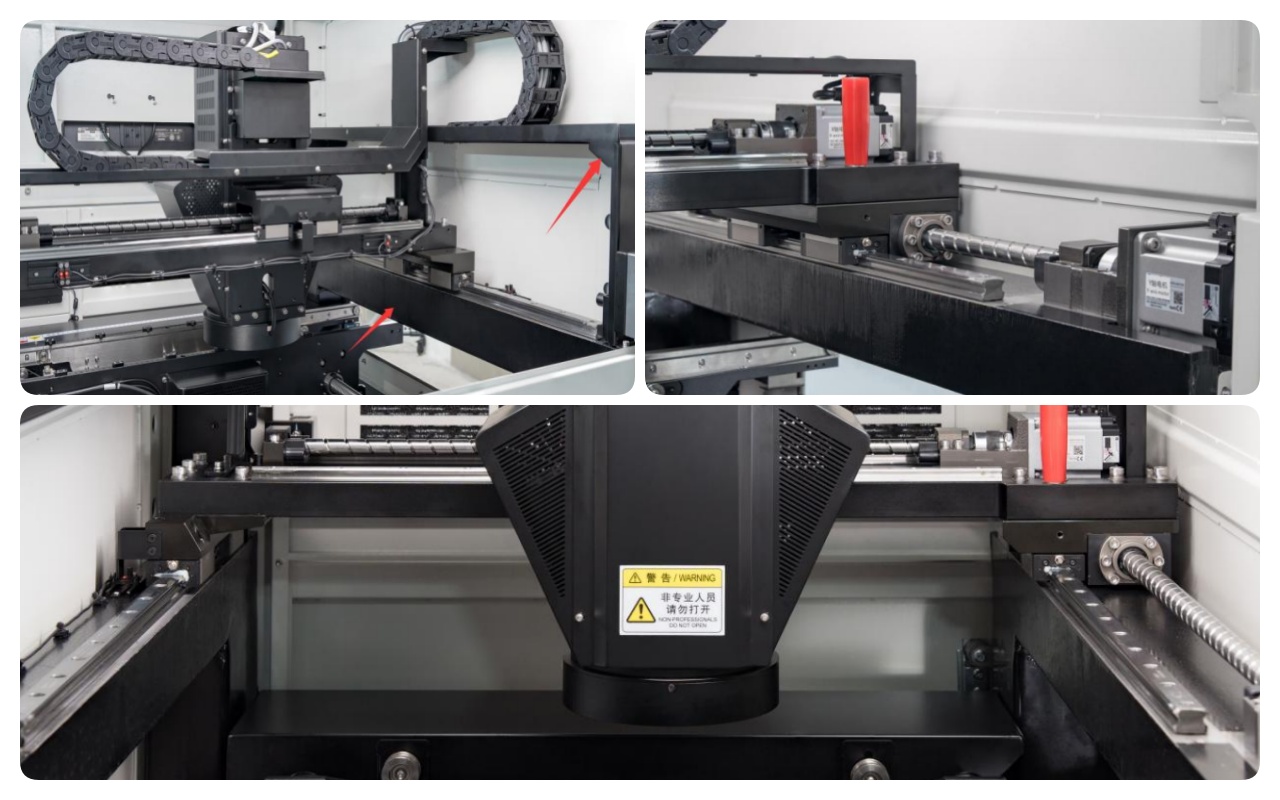

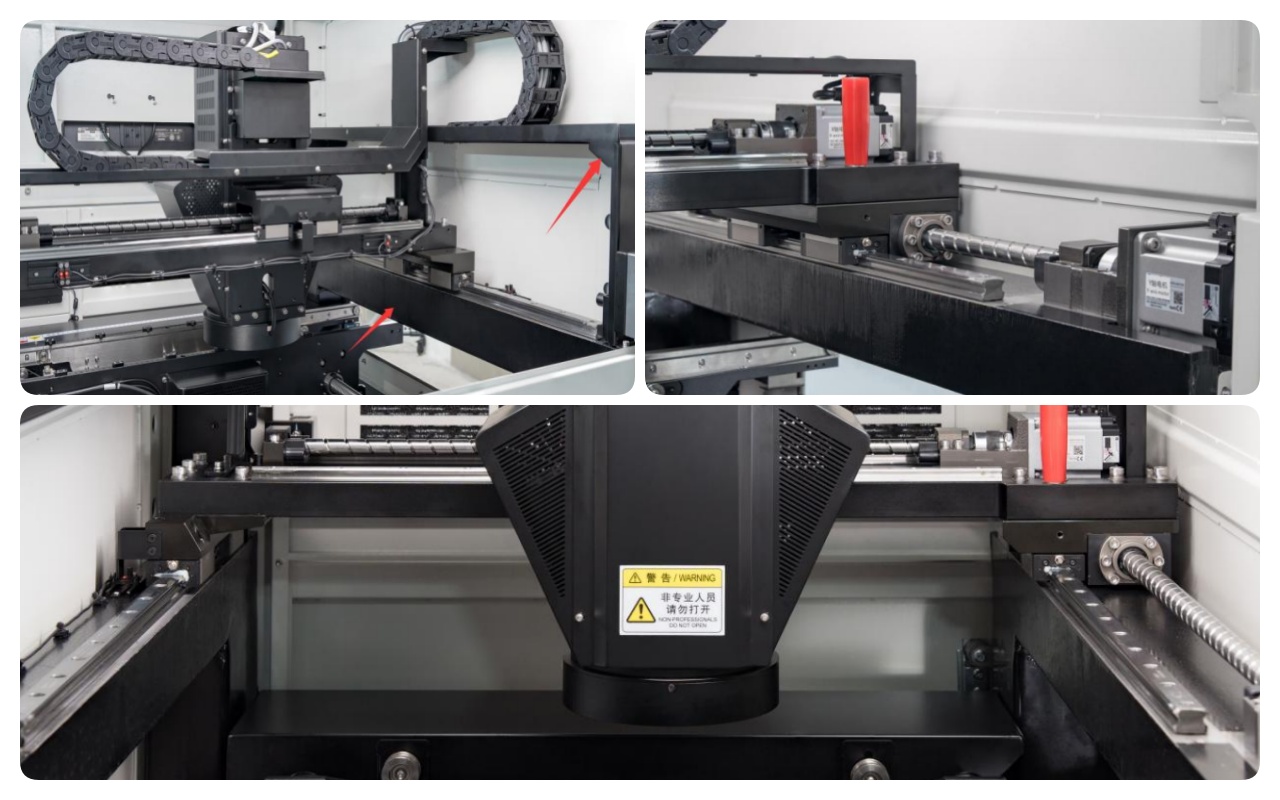

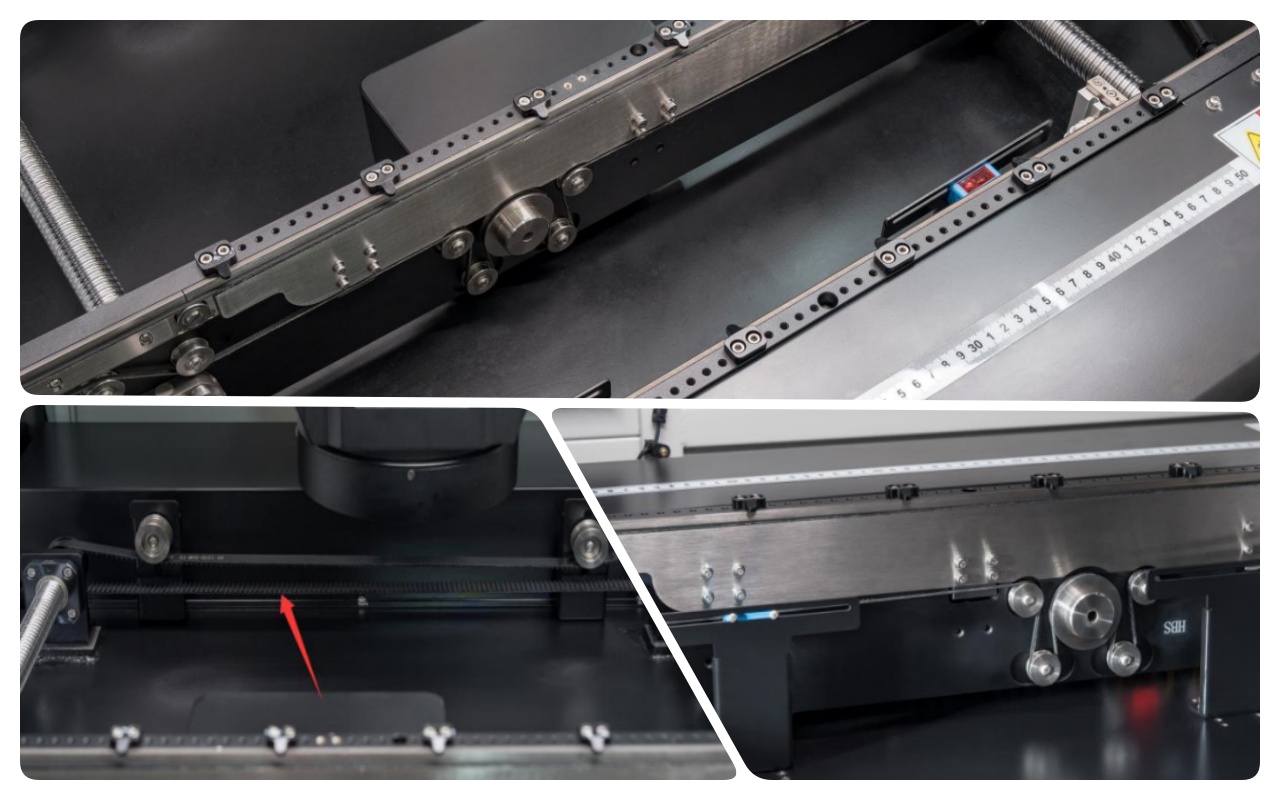

| Feature

Built around an arch-bridge suspended frame and one-piece cast base, the S510D platform uses two independent high-precision servo motors for X/Y motion and precision slide rails to keep everything perfectly stable—even at full dual-lane speed. Flexible closed tank chains and heavy-duty components eliminate vibration, ensuring the camera stays locked in position shot after shot. This rock-solid foundation delivers repeatable, trustworthy 3D inspection results day in and day out, no matter how demanding your production schedule gets.

New programs take less than 10 minutes to create and line changeover is done in under 2 minutes. The clean Windows 10 interface offers step-by-step teaching wizards, multi-level user permissions, full operation logs, fault diagnostics, and built-in SPC reporting. Original PSLM software simulates perfect grating cycles for maximum accuracy across all board types. Even new operators feel confident immediately, while engineers get all the detailed data they need to optimize the process in record time.

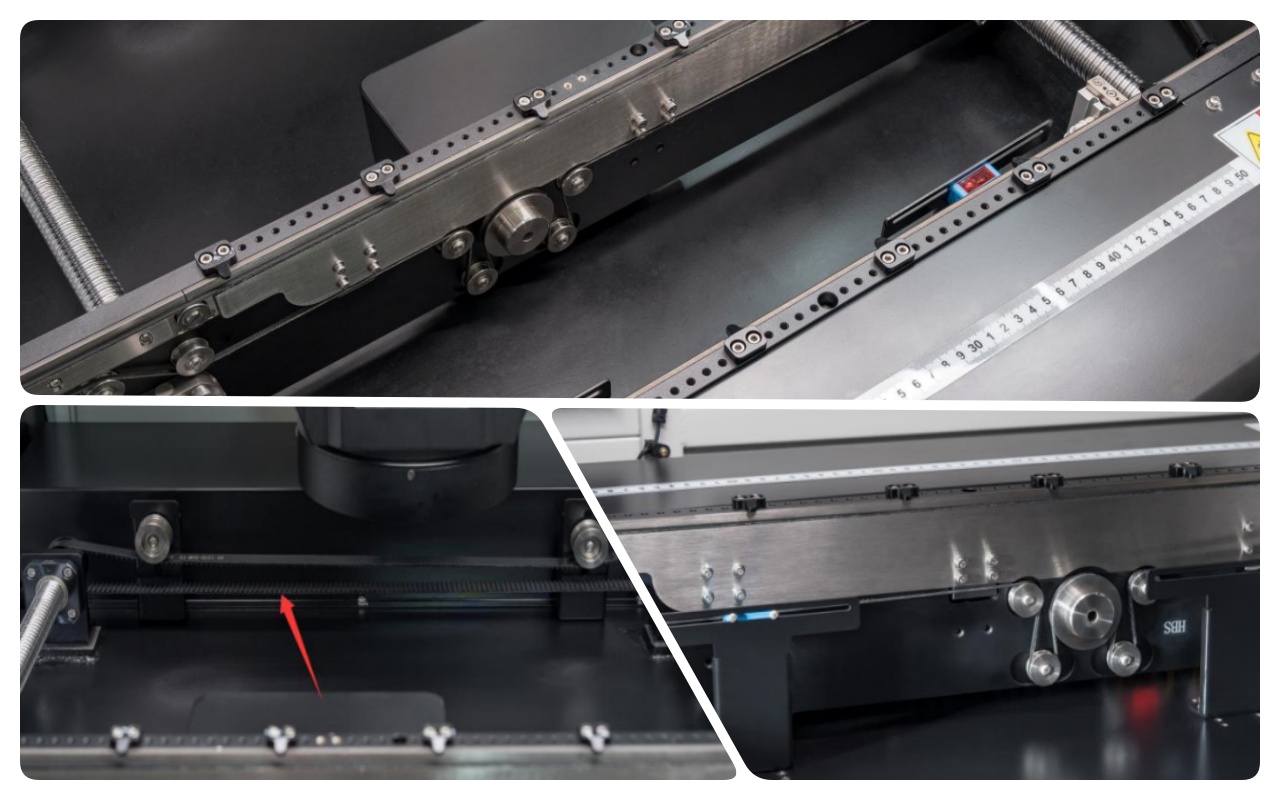

The smart conveyor system automatically adjusts rail width via ball screw, guarantees perfect parallelism, and stops every board in exactly the right spot using double sensors and cylinders. Operators can switch between inspection mode and pass-through mode with password protection. Deceleration sensors plus backup stop sensors prevent jams completely, so boards glide through smoothly even during non-stop dual-lane operation. Changeover between single and dual-lane is fast and foolproof—keeping your line moving and your uptime sky-high.

| Reflow Oven Specification

| Model | I.C.T-S510 | I.C.T-S510D | I.C.T-S1200 |

| PCB Size | 60*50~510*510mm | 50*60~510*310mm Dual rail 50*60~510*580 Single rai | 80*80~1200*500mm |

| PCB Tickness | 0.5 ~ 5.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Manual/automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | W1015*D1195*H1495mm | W1015*D1460*H1495mm | W1840*D1450*H1495mm |

| Weight | 850kg | 950kg | 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB board assembly Line | Turkey Fully Automated Traceable High-End SMT Line. |

| SMT Magazine Loader | Automatically loads bare PCBs to the line. |

| SMT PCB printer | Prints solder paste on PCB pads accurately. |

| PCB Mounting Machine | Mounts components onto PCBs precisely. |

| Nitrogen Reflow Oven | Melts solder to form solid joints. |

| Online AOI machine | Inspects solder joints and placement defects. |

| 3D solder paste inspection | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data like PCBA laser marking machines |

| Aqueous stencil cleaning machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB separator cutting machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| Robotic Soldering Machine | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Video

I.C.T recently completed the successful overseas installation and Factory Acceptance Test (FAT) support for two SMT production lines at a North American beauty device manufacturer. The project involved deploying advanced equipment, including laser marking machines for precise component identification, SMT printers paired with our SMT SPI Solder Paste Inspection Machine to ensure flawless paste application, Panasonic pick-and-place machines for high-speed component mounting, Heller reflow ovens for reliable soldering, AOI detection systems for post-assembly quality checks, PCB conveyors for seamless material flow, PCBA cleaning machines to remove residues, and automatic solder paste storage warmers to maintain material integrity. Our engineers provided on-site training and optimization, leading to smooth production acceptance. This case highlights I.C.T's commitment to delivering turnkey solutions that enhance efficiency and product quality in global markets.

| Professional Global Training & Support

From installation and on-site training to lifetime spare parts and remote diagnostics, I.C.T provides true end-to-end support anywhere in the world. Our eight branch offices and rapid-response engineers keep your SPI SMT machine running at peak performance with almost zero downtime. Regular process optimization visits and 24/7 hotline access come standard—because we believe your success is our success.

| Customer Praise

Customers constantly tell us how impressed they are with our engineers’ expertise and lightning-fast support, the incredible accuracy of the S510D 3D solder paste inspection machine, our bulletproof export packaging that arrives flawless every time, and how quickly we solve any question—usually within hours.

| Our Certification

Every I.C.T-S510D carries CE, RoHS, ISO9001 certifications plus multiple patents on 3D measurement technology. Strict in-house testing and full quality management systems guarantee safety, environmental compliance, and rock-solid reliability you can count on for the long haul.

| About Us and Factory

Founded in 2012, I.C.T owns complete R&D and 12,000 m² production facilities with 89 talented people including 20 experienced engineers. Backed by $30 million registered capital and growing fast every year, we proudly serve over 1,600 customers across 72 countries through our global network and rigorous quality processes.

| High-Throughput Dual-Lane SPI SMT Machine

The I.C.T-S510D is a powerful dual-lane online SPI SMT machine built for high-volume electronics manufacturing. Using genuine 3D blue-light PSLM PMP technology and a 5M-pixel high-speed camera (12M optional), this advanced solder paste inspection machine measures height, volume, area, and shape with micron-level precision while running two boards in parallel. It completely removes shadow problems and random reflections that plague traditional systems, supports PCB sizes from 50×60mm up to 510×310mm per lane, and programs new products in under 10 minutes via Gerber import or graphical editing. Perfect for customers who need maximum output with zero compromise on quality, the S510D is the ultimate 3D solder paste inspection solution for modern SMT factories.

| Feature

Built around an arch-bridge suspended frame and one-piece cast base, the S510D platform uses two independent high-precision servo motors for X/Y motion and precision slide rails to keep everything perfectly stable—even at full dual-lane speed. Flexible closed tank chains and heavy-duty components eliminate vibration, ensuring the camera stays locked in position shot after shot. This rock-solid foundation delivers repeatable, trustworthy 3D inspection results day in and day out, no matter how demanding your production schedule gets.

New programs take less than 10 minutes to create and line changeover is done in under 2 minutes. The clean Windows 10 interface offers step-by-step teaching wizards, multi-level user permissions, full operation logs, fault diagnostics, and built-in SPC reporting. Original PSLM software simulates perfect grating cycles for maximum accuracy across all board types. Even new operators feel confident immediately, while engineers get all the detailed data they need to optimize the process in record time.

The smart conveyor system automatically adjusts rail width via ball screw, guarantees perfect parallelism, and stops every board in exactly the right spot using double sensors and cylinders. Operators can switch between inspection mode and pass-through mode with password protection. Deceleration sensors plus backup stop sensors prevent jams completely, so boards glide through smoothly even during non-stop dual-lane operation. Changeover between single and dual-lane is fast and foolproof—keeping your line moving and your uptime sky-high.

| Reflow Oven Specification

| Model | I.C.T-S510 | I.C.T-S510D | I.C.T-S1200 |

| PCB Size | 60*50~510*510mm | 50*60~510*310mm Dual rail 50*60~510*580 Single rai | 80*80~1200*500mm |

| PCB Tickness | 0.5 ~ 5.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Manual/automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | W1015*D1195*H1495mm | W1015*D1460*H1495mm | W1840*D1450*H1495mm |

| Weight | 850kg | 950kg | 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB board assembly Line | Turkey Fully Automated Traceable High-End SMT Line. |

| SMT Magazine Loader | Automatically loads bare PCBs to the line. |

| SMT PCB printer | Prints solder paste on PCB pads accurately. |

| PCB Mounting Machine | Mounts components onto PCBs precisely. |

| Nitrogen Reflow Oven | Melts solder to form solid joints. |

| Online AOI machine | Inspects solder joints and placement defects. |

| 3D solder paste inspection | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data like PCBA laser marking machines |

| Aqueous stencil cleaning machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB separator cutting machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| Robotic Soldering Machine | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Video

I.C.T recently completed the successful overseas installation and Factory Acceptance Test (FAT) support for two SMT production lines at a North American beauty device manufacturer. The project involved deploying advanced equipment, including laser marking machines for precise component identification, SMT printers paired with our SMT SPI Solder Paste Inspection Machine to ensure flawless paste application, Panasonic pick-and-place machines for high-speed component mounting, Heller reflow ovens for reliable soldering, AOI detection systems for post-assembly quality checks, PCB conveyors for seamless material flow, PCBA cleaning machines to remove residues, and automatic solder paste storage warmers to maintain material integrity. Our engineers provided on-site training and optimization, leading to smooth production acceptance. This case highlights I.C.T's commitment to delivering turnkey solutions that enhance efficiency and product quality in global markets.

| Professional Global Training & Support

From installation and on-site training to lifetime spare parts and remote diagnostics, I.C.T provides true end-to-end support anywhere in the world. Our eight branch offices and rapid-response engineers keep your SPI SMT machine running at peak performance with almost zero downtime. Regular process optimization visits and 24/7 hotline access come standard—because we believe your success is our success.

| Customer Praise

Customers constantly tell us how impressed they are with our engineers’ expertise and lightning-fast support, the incredible accuracy of the S510D 3D solder paste inspection machine, our bulletproof export packaging that arrives flawless every time, and how quickly we solve any question—usually within hours.

| Our Certification

Every I.C.T-S510D carries CE, RoHS, ISO9001 certifications plus multiple patents on 3D measurement technology. Strict in-house testing and full quality management systems guarantee safety, environmental compliance, and rock-solid reliability you can count on for the long haul.

| About Us and Factory

Founded in 2012, I.C.T owns complete R&D and 12,000 m² production facilities with 89 talented people including 20 experienced engineers. Backed by $30 million registered capital and growing fast every year, we proudly serve over 1,600 customers across 72 countries through our global network and rigorous quality processes.