Power Supply of electronic devices

The power, also known as a power supply unit (PSU), is an electronic device that provides power to another electronic device or system. It converts the alternating current (AC) power from a wall outlet into the direct current (DC) power that is needed by electronic devices.

Power supplies are used in a wide range of electronic devices and systems, including computers, servers, routers, modems, televisions, home entertainment systems, and many others. They are an essential component of any electronic device or system that requires a stable and reliable power source.

All the Electronic products typically require a power source, which may be a battery, AC power adapter, USB cable, or some other type of power supply. The power source will affect the device's battery life, charging time, and overall usability.

How to produce a power supply with long life and stable performance?

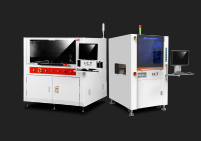

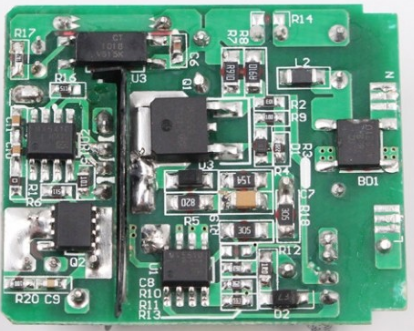

As one of the core components of electronic products, power supply is also produced using SMT process. Here are some of the key steps of the SMT process used in power production:

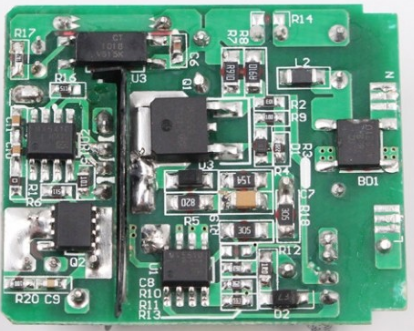

Patch: Put the power circuit board into the Placement machine, and automatically attach the surface mount components (such as capacitors, resistors, chips, etc.) to the circuit board.

Fixed: The surface-mounted components are fixed on the circuit board through reflow soldering or wave welding technology.

Inspection: Automatic or manual inspection of the fixed circuit board to ensure that the position and welding quality of the components meet the requirements.

Test: Test the electrical performance of the circuit board to ensure that the performance and reliability of the power supply meet the standards.

SMT and DIP Process for Power Supply Production:

SMT Process: Solder Paste (Red Glue) Printing --> Components Mounting --> Reflow Soldering --> AOI Optical Inspection

Economical full-auto SMT Line equipment as follows: : 1 person to operate the whole line, 1 person to test AOI, total 2 people.

DIP Process: Plug-in --> Welding --> Maintenance --> PCB Cutting

Economical DIP Line equipment as follows: Personnel are adjusted according to the product, 3-15 people.

Power Supply Production SMT &DIP Solution Data:

| SMT | Capacity Evaluation | 1 set pick and place machine; production capacity 20000-25000CHIP/H |

| Total Power | 59.5 KW | Operating Power | 14.5KW |

| Applicable Product | SMD components within 50pcs, 0201-42mm, max PCB width 350mm

|

| DIP | Capacity Evaluation | Calculated based on the number of componens and the operators |

| Total Power | 16.8 KW

| Operating Power | 5.8 KW |

| Applicable Product | Low capacity requirements or simple products, Max PCB width 350mm |

SMT+ DIP

| Workshop Size | L20m x W15m , total area 300 ㎡

|

This Full-auto SMT Production Line Used to Produce Battery Chargers and Adapters Video for your reference:

I.C.T - Your Reliable Dearest Partner

For you we can provide Full SMT Solution, DIP Solution and Coating Solution with best quality and service.

More information about I.C.T please Contact US at info@smt11.com

English

English