I.C.T-MBV360C

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| PCB Depaneling Machine – Efficient and Gentle Board Separation

One cannot but appreciate the steady utility of the PCB Depaneling Machine in the orderly conduct of electronics production. It holds the board firmly fixed during the entire process, allowing the operator to proceed with calm assurance and without risk to delicate parts. The blade's movement remains under direct manual command, its pace adjusted to suit the moment's requirements. Careful regulation of the distance between circular and straight blades accommodates the differing depths of V-grooves, while boards bearing components across the separation line proceed without difficulty.

Most commendably, internal stresses are kept to a modest level, thereby guarding against cracks in solder that might otherwise compromise the whole assembly. In contrast to a Moving Blade PCB Depaneling Machine—which may introduce unnecessary complexity, dust, or heat—this straightforward V-cut method yields cleaner results, operates with greater simplicity, and treats materials with the consideration they deserve, proving itself particularly suitable for those who prize reliability and refinement in their daily work.

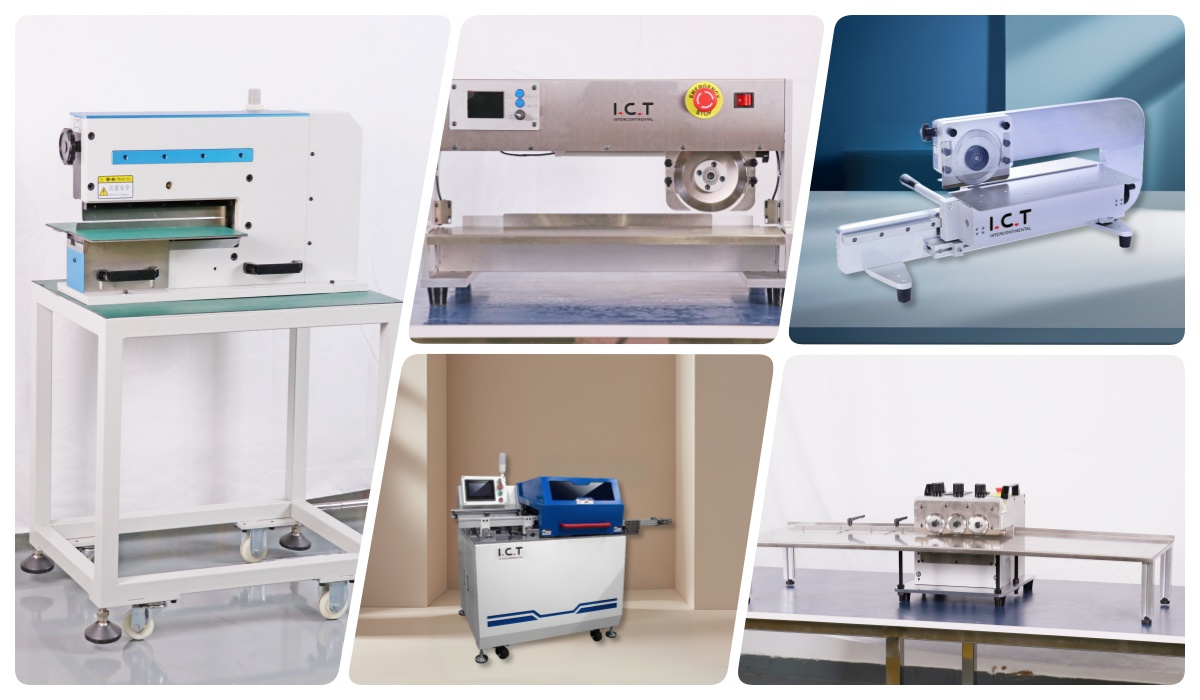

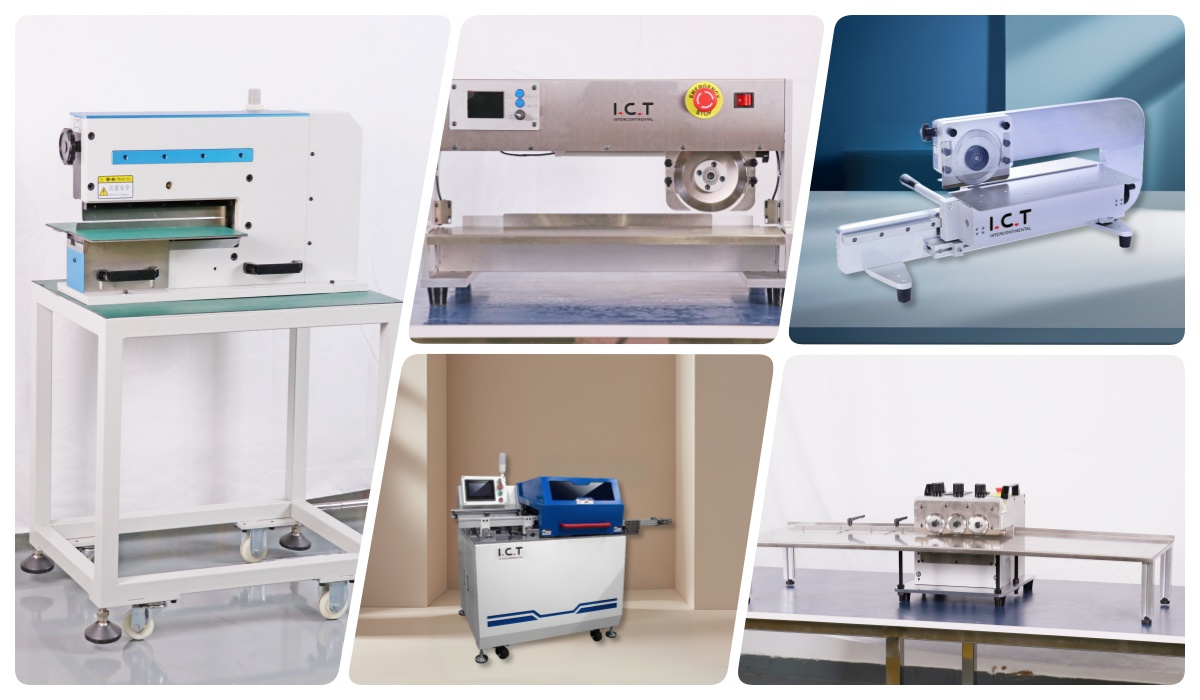

I.C.T presents a well-considered selection of five V-cut machines, each designed to answer particular circumstances with propriety:

The standard manual model provides economical, straightforward service for modest production.

The multi-blades type ensures phased, protective separation for extended LED assemblies.

The guillotine form applies controlled force for firmer boards with dispatch.

The move-blade variety allows adaptable sliding to match groove profiles.

The multi-knife arrangement manages lengthy boards with consistent efficiency.

| Feature

Multi-Blades LED Separator

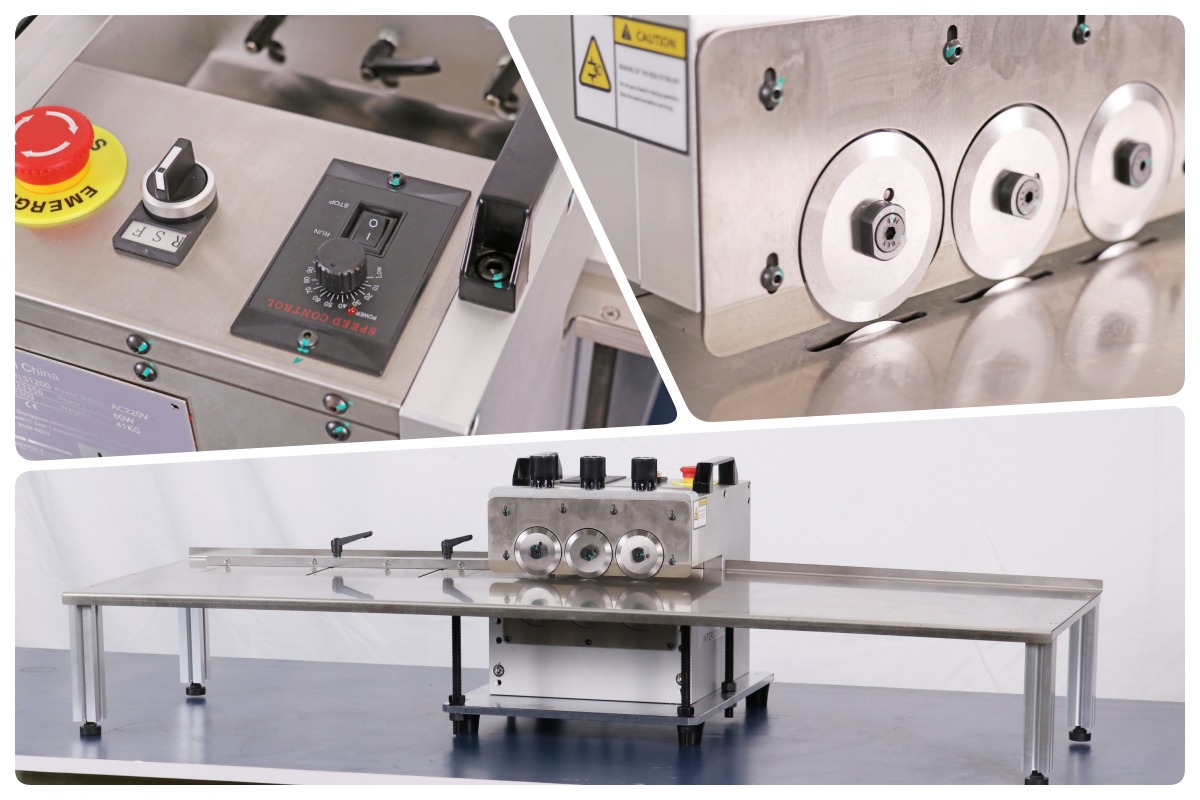

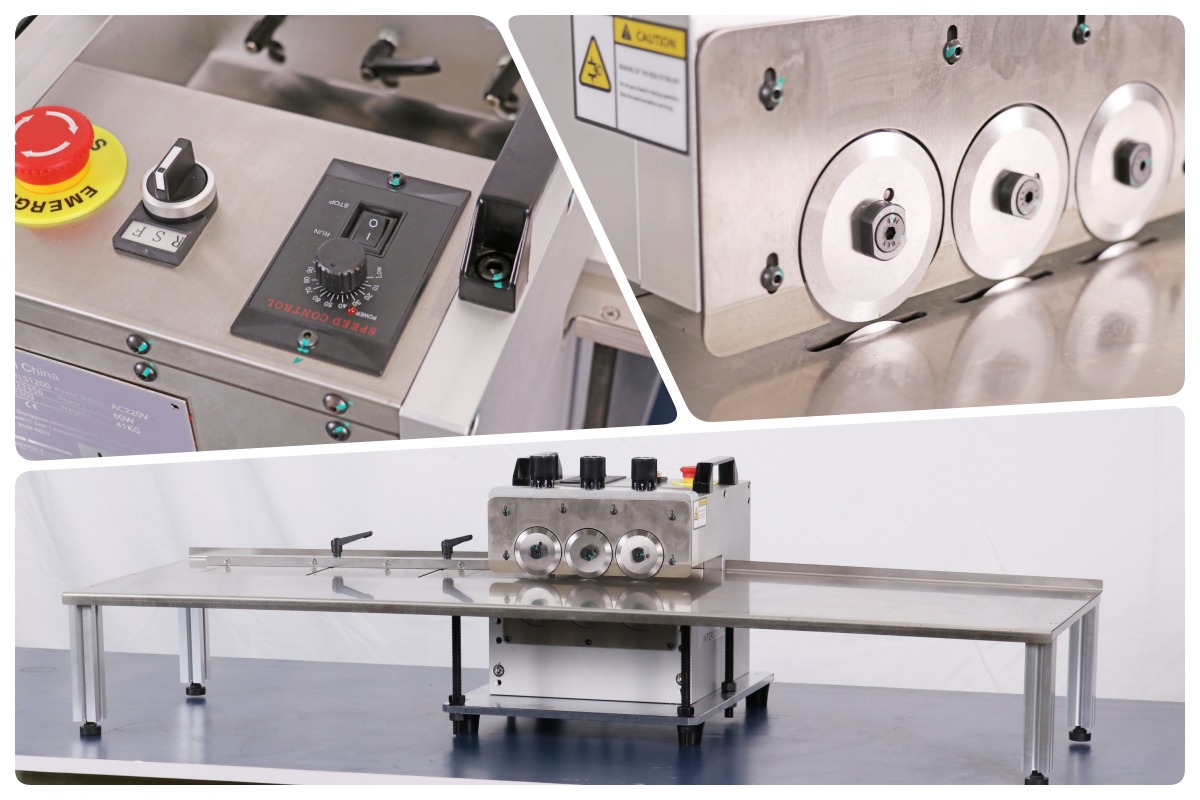

The multi-blades PCB Depaneling Machine exhibits a most commendable arrangement of six circular blades, disposed in three groups that act in concert. The separation proceeds in deliberate stages: the first group accomplishes forty percent of the task along the V-groove, the second advances upon the same line for a further forty percent, and the third concludes the remainder with composure.

By reason of these brief, successive cuts, internal strain diminishes by as much as eighty percent when compared with single, abrupt methods, thereby preserving the integrity and flatness of aluminum substrates and LED strips that might otherwise suffer distortion. The blades, fashioned from reliable Taiwanese stock, maintain their service for more than a twelvemonth and admit of repeated sharpening. Calibration by dual-frequency laser ensures that blade deviation remains within 0.02mm, securing uniform excellence in every instance.

Supplementary stainless platforms of 1.2 or 2.4 meters accommodate greater lengths, while fine adjustments to top and bottom blades, together with custom blocks, render the machine adaptable to boards of varying breadth. It is thus particularly fitted to high-volume LED manufacture, where the preservation of material quality and the steady progress of production are held in esteem.

Guillotine Type V-Cut Machine

The guillotine PCB Depaneling Machine proceeds with a direct, air-assisted descent that confines separation stress to less than 180 microstrain, thereby safeguarding solder connections and adjacent components from injury. It achieves separation precisely at the V-groove edge, permitting a clearance of only 0.3mm to nearby elements while accommodating component heights up to 60mm.

Devoid of rotating motors or frictional drive, it generates neither dust nor carbon residue, and leaves scarcely any metallic trace upon the surface. A single cut completes in one second under foot-pedal command, with the blade's negative activation ensuring safe and predictable control.

The blade endures beyond six million cycles, and simple sanding restores its edge when required. Those engaged in FR4 board processing, or in settings where cleanliness and sharp definition are paramount, find this model most appropriate, for it combines rapidity with a regard for order and the avoidance of contamination.

Move-Blade (Sliding) V-Cut Machine

In the move-blade PCB Depaneling Machine, the operator enjoys full command over the sliding action, regulating both speed and the interval between blades to correspond exactly with the depth of any V-groove. The board remains securely positioned throughout, obviating any displacement that might endanger components of up to 34mm in height crossing the separation path.

This measured procedure keeps pressure to a minimum, preventing cracks in solder or substrate alike. The machine's firm frame ensures constancy, and blade customization stands available for particular needs. It proves well suited to moderate production volumes, to prototype endeavors, or to establishments desiring flexible, economical separation without elaborate mechanisms.

Operators value the direct control it affords, permitting them to address each board's peculiarities with judgment and to achieve separations that are both clean and considerate of quality in routine manufacturing circumstances.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T assembles complete SMT lines wherein loaders, printers, placement machines, reflow ovens, AOI units, conveyors, and PCB Depaneling Machine elements combine in harmonious sequence. Each component is selected and arranged with care, including U-shaped configurations when space constrains the layout. This unified system elevates efficiency, diminishes defects, and sustains consistent output of superior standard across automotive, LED, and consumer electronics applications. Clients receive thorough counsel from initial planning through installation and refinement, enabling their operations to proceed with order and assurance from commencement to completion.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In the early months of 2025, I.C.T engineer Peter undertook a journey to Uzbekistan, devoting sixteen days to careful installation and thorough instruction at the customer's premises. The commission comprised a full SMT line for the production of automotive motors and associated parts, encompassing a 5151 full-automatic printer, mounter, L8 reflow oven, AOI system, NG/OK unloader, BGA rework station, walk-knife depaneling unit, solder paste mixer, translation conveyor, and further necessities. Confronted with restricted factory dimensions, I.C.T devised and executed a U-shaped arrangement that made the most of the available area without sacrifice. Peter conducted the training with patience and clarity, and upon conclusion the customer assumed independent command of the line, commencing steady and satisfactory production forthwith.

| Service and Training Support

I.C.T extends complete service and training for every PCB Depaneling Machine and associated production line. Competent engineers attend sites across the globe to effect proper installation, demonstrate usage, and deliver comprehensive instruction in operation, maintenance, fault resolution, and process improvement. These sessions instill confidence, enabling teams to manage equipment with competence from the outset. Thereafter, prompt channels of communication—telephone, electronic mail, or remote assistance—ensure swift attention to any concern and the preservation of high availability. Such dedication facilitates prompt commencement, enduring performance, and enduring contentment, permitting customers to attend to their principal concerns while technical matters receive attentive and capable management.

| Client Testimonials

Customers in many lands speak with approbation of I.C.T engineers, whose skill, composure, and perseverance during training visits command respect. They express particular satisfaction with the PCB Depaneling Machine for its dependable operation, considerate treatment of boards, and blades that endure long service. The careful packing and secure transport receive frequent commendation, as machines arrive in excellent condition and ready for immediate employment. Rapid and effective replies to inquiries, whether of small adjustment or pressing difficulty, foster continued confidence. Many declare the equipment sound and the support exemplary, sentiments echoed by users in diverse regions.

| Certifications and Standards

The PCB Depaneling Machine bears certifications of CE for safety, RoHS for environmental conformity, and ISO9001 for quality management, together with several patents protecting distinctive innovations in depaneling and related apparatus. These attestations confirm adherence to exacting international norms of performance, safety, and responsible practice. Establishments worldwide accept them with assurance, secure in the knowledge that each machine upholds standards of excellence in construction and function.

| About I.C.T Company and Factory

I.C.T maintains its own research and development division together with a production facility in Dongguan, China, employing 89 persons inclusive of 20 engineers of particular expertise. Since its establishment in 2012, the enterprise has advanced with steadiness, now numbering more than 1600 customers in 72 countries. The 12000m² premises operate under rigorous inspection procedures and a thorough quality management system, ensuring that every machine meets exacting requirements. We furnish comprehensive one-stop solutions—from assessment of needs and planning of lines to installation, training, and continued optimization—assisting partners globally to institute, enhance, and perfect their manufacturing arrangements with confidence and propriety.

| PCB Depaneling Machine – Efficient and Gentle Board Separation

One cannot but appreciate the steady utility of the PCB Depaneling Machine in the orderly conduct of electronics production. It holds the board firmly fixed during the entire process, allowing the operator to proceed with calm assurance and without risk to delicate parts. The blade's movement remains under direct manual command, its pace adjusted to suit the moment's requirements. Careful regulation of the distance between circular and straight blades accommodates the differing depths of V-grooves, while boards bearing components across the separation line proceed without difficulty.

Most commendably, internal stresses are kept to a modest level, thereby guarding against cracks in solder that might otherwise compromise the whole assembly. In contrast to a Moving Blade PCB Depaneling Machine—which may introduce unnecessary complexity, dust, or heat—this straightforward V-cut method yields cleaner results, operates with greater simplicity, and treats materials with the consideration they deserve, proving itself particularly suitable for those who prize reliability and refinement in their daily work.

I.C.T presents a well-considered selection of five V-cut machines, each designed to answer particular circumstances with propriety:

The standard manual model provides economical, straightforward service for modest production.

The multi-blades type ensures phased, protective separation for extended LED assemblies.

The guillotine form applies controlled force for firmer boards with dispatch.

The move-blade variety allows adaptable sliding to match groove profiles.

The multi-knife arrangement manages lengthy boards with consistent efficiency.

| Feature

Multi-Blades LED Separator

The multi-blades PCB Depaneling Machine exhibits a most commendable arrangement of six circular blades, disposed in three groups that act in concert. The separation proceeds in deliberate stages: the first group accomplishes forty percent of the task along the V-groove, the second advances upon the same line for a further forty percent, and the third concludes the remainder with composure.

By reason of these brief, successive cuts, internal strain diminishes by as much as eighty percent when compared with single, abrupt methods, thereby preserving the integrity and flatness of aluminum substrates and LED strips that might otherwise suffer distortion. The blades, fashioned from reliable Taiwanese stock, maintain their service for more than a twelvemonth and admit of repeated sharpening. Calibration by dual-frequency laser ensures that blade deviation remains within 0.02mm, securing uniform excellence in every instance.

Supplementary stainless platforms of 1.2 or 2.4 meters accommodate greater lengths, while fine adjustments to top and bottom blades, together with custom blocks, render the machine adaptable to boards of varying breadth. It is thus particularly fitted to high-volume LED manufacture, where the preservation of material quality and the steady progress of production are held in esteem.

Guillotine Type V-Cut Machine

The guillotine PCB Depaneling Machine proceeds with a direct, air-assisted descent that confines separation stress to less than 180 microstrain, thereby safeguarding solder connections and adjacent components from injury. It achieves separation precisely at the V-groove edge, permitting a clearance of only 0.3mm to nearby elements while accommodating component heights up to 60mm.

Devoid of rotating motors or frictional drive, it generates neither dust nor carbon residue, and leaves scarcely any metallic trace upon the surface. A single cut completes in one second under foot-pedal command, with the blade's negative activation ensuring safe and predictable control.

The blade endures beyond six million cycles, and simple sanding restores its edge when required. Those engaged in FR4 board processing, or in settings where cleanliness and sharp definition are paramount, find this model most appropriate, for it combines rapidity with a regard for order and the avoidance of contamination.

Move-Blade (Sliding) V-Cut Machine

In the move-blade PCB Depaneling Machine, the operator enjoys full command over the sliding action, regulating both speed and the interval between blades to correspond exactly with the depth of any V-groove. The board remains securely positioned throughout, obviating any displacement that might endanger components of up to 34mm in height crossing the separation path.

This measured procedure keeps pressure to a minimum, preventing cracks in solder or substrate alike. The machine's firm frame ensures constancy, and blade customization stands available for particular needs. It proves well suited to moderate production volumes, to prototype endeavors, or to establishments desiring flexible, economical separation without elaborate mechanisms.

Operators value the direct control it affords, permitting them to address each board's peculiarities with judgment and to achieve separations that are both clean and considerate of quality in routine manufacturing circumstances.

| Specification

| Parameter | Manual Single-Blade V-cut Machine | Multi-Blades LED Separator | Guillotine Type V-cut Machine | Move-Blade (Sliding) V-cut Machine | Multi Group Blades PCB V-cut Machine |

|---|---|---|---|---|---|

| Operation Type | Manual (hand sliding) | Manual (hand push) | Manual (pneumatic foot switch) | Manual (adjustable sliding) | Manual (multi-group push) |

| Blade Setup | 1 circular + 1 straight blade | 6 circular blades (3 groups top/bottom) | Single straight guillotine blade | 1 circular + 1 straight (adjustable gap) | Multiple groups of circular blades (custom multi-knife) |

| PCB Length | 0–350 mm | Unlimited (with 1.2m / 2.4m platforms) | 0–330 mm | 0–350 mm (typical) | Unlimited or very long (platform-dependent) |

| PCB Thickness | 0.8–5 mm | 0.2–5 mm | 0.3–5 mm | 0.8–5 mm | 0.2–5 mm (typical for multi-group) |

| Cutting Method | Single pass sliding | 3-phase (40% + 40% + 20%) | One-shot downward cut | Single pass with adjustable depth | Multi-group sequential cutting |

| Best Application | General PCBs, prototypes, medium volume | Long LED strips, aluminum PCBs, high-volume LED | FR4 boards, clean/dust-free edges | Mixed components, flexible V-depth | Extra-long or wide PCBs, high-efficiency separation |

| SMT Line Equipment List

I.C.T assembles complete SMT lines wherein loaders, printers, placement machines, reflow ovens, AOI units, conveyors, and PCB Depaneling Machine elements combine in harmonious sequence. Each component is selected and arranged with care, including U-shaped configurations when space constrains the layout. This unified system elevates efficiency, diminishes defects, and sustains consistent output of superior standard across automotive, LED, and consumer electronics applications. Clients receive thorough counsel from initial planning through installation and refinement, enabling their operations to proceed with order and assurance from commencement to completion.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turnkey Ful-auto SMT assembly line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Customer Success Video

In the early months of 2025, I.C.T engineer Peter undertook a journey to Uzbekistan, devoting sixteen days to careful installation and thorough instruction at the customer's premises. The commission comprised a full SMT line for the production of automotive motors and associated parts, encompassing a 5151 full-automatic printer, mounter, L8 reflow oven, AOI system, NG/OK unloader, BGA rework station, walk-knife depaneling unit, solder paste mixer, translation conveyor, and further necessities. Confronted with restricted factory dimensions, I.C.T devised and executed a U-shaped arrangement that made the most of the available area without sacrifice. Peter conducted the training with patience and clarity, and upon conclusion the customer assumed independent command of the line, commencing steady and satisfactory production forthwith.

| Service and Training Support

I.C.T extends complete service and training for every PCB Depaneling Machine and associated production line. Competent engineers attend sites across the globe to effect proper installation, demonstrate usage, and deliver comprehensive instruction in operation, maintenance, fault resolution, and process improvement. These sessions instill confidence, enabling teams to manage equipment with competence from the outset. Thereafter, prompt channels of communication—telephone, electronic mail, or remote assistance—ensure swift attention to any concern and the preservation of high availability. Such dedication facilitates prompt commencement, enduring performance, and enduring contentment, permitting customers to attend to their principal concerns while technical matters receive attentive and capable management.

| Client Testimonials

Customers in many lands speak with approbation of I.C.T engineers, whose skill, composure, and perseverance during training visits command respect. They express particular satisfaction with the PCB Depaneling Machine for its dependable operation, considerate treatment of boards, and blades that endure long service. The careful packing and secure transport receive frequent commendation, as machines arrive in excellent condition and ready for immediate employment. Rapid and effective replies to inquiries, whether of small adjustment or pressing difficulty, foster continued confidence. Many declare the equipment sound and the support exemplary, sentiments echoed by users in diverse regions.

| Certifications and Standards

The PCB Depaneling Machine bears certifications of CE for safety, RoHS for environmental conformity, and ISO9001 for quality management, together with several patents protecting distinctive innovations in depaneling and related apparatus. These attestations confirm adherence to exacting international norms of performance, safety, and responsible practice. Establishments worldwide accept them with assurance, secure in the knowledge that each machine upholds standards of excellence in construction and function.

| About I.C.T Company and Factory

I.C.T maintains its own research and development division together with a production facility in Dongguan, China, employing 89 persons inclusive of 20 engineers of particular expertise. Since its establishment in 2012, the enterprise has advanced with steadiness, now numbering more than 1600 customers in 72 countries. The 12000m² premises operate under rigorous inspection procedures and a thorough quality management system, ensuring that every machine meets exacting requirements. We furnish comprehensive one-stop solutions—from assessment of needs and planning of lines to installation, training, and continued optimization—assisting partners globally to institute, enhance, and perfect their manufacturing arrangements with confidence and propriety.