I.C.T VL-M | SMT Automatic PCB Translational Vacuum Loader

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Reliable PCB Vacuum Loader for Modern SMT Lines

The I.C.T PCB Vacuum Loader is an upgraded automatic handling solution specially designed for SMT production. Using strong vacuum suction, it gently takes bare PCBs from magazine racks and smoothly sends them to the next machine. Whether standard or CE version, this PCB Vacuum Loader offers higher stability and longer service life. Advanced hardware, electrical parts and smart control system reduce downtime and increase production efficiency. The SMT Automatic PCB Translational Vacuum Loader works perfectly with all major SMT brands and easily connects to smart factory systems.

| Detailed Product Features

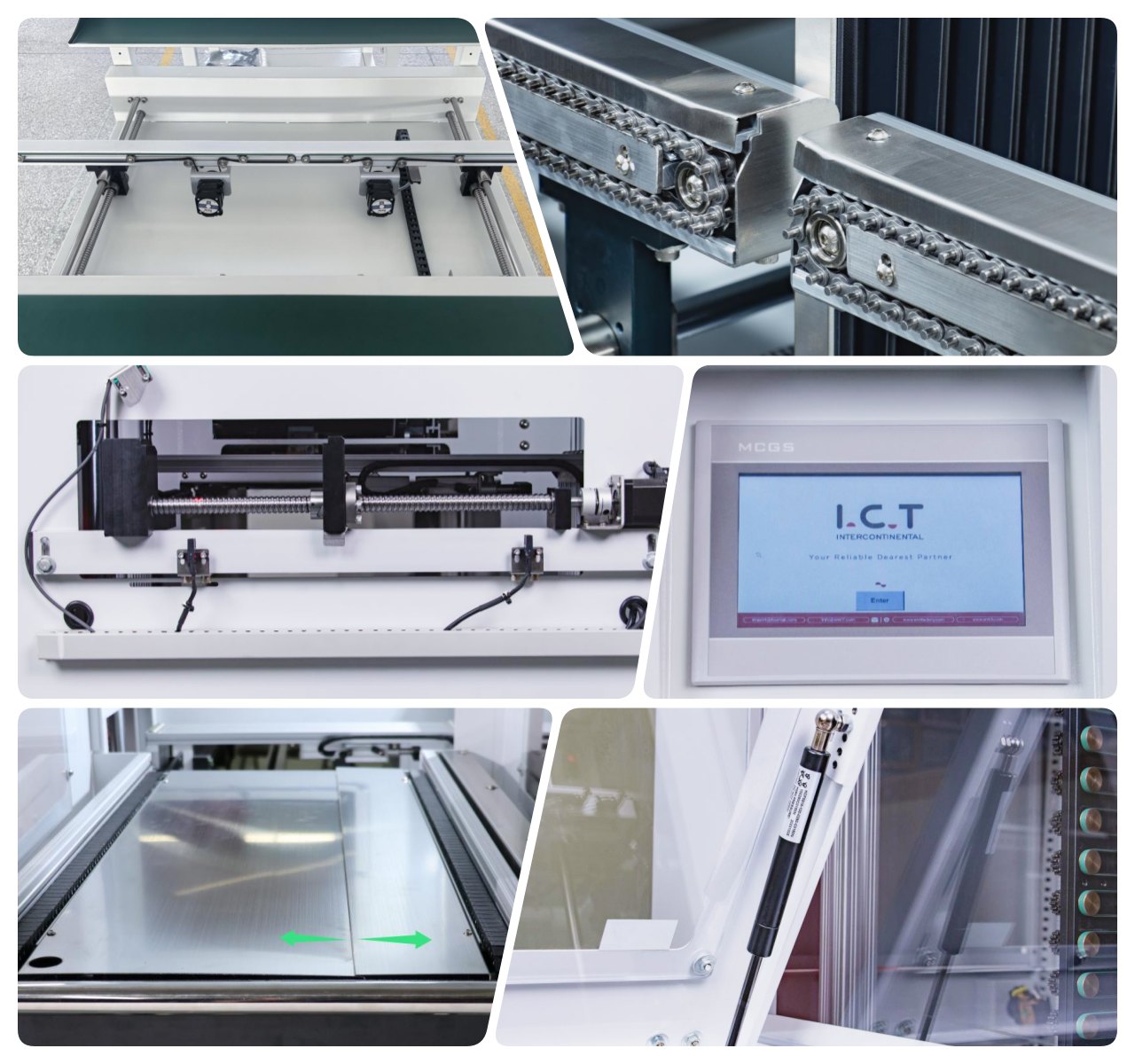

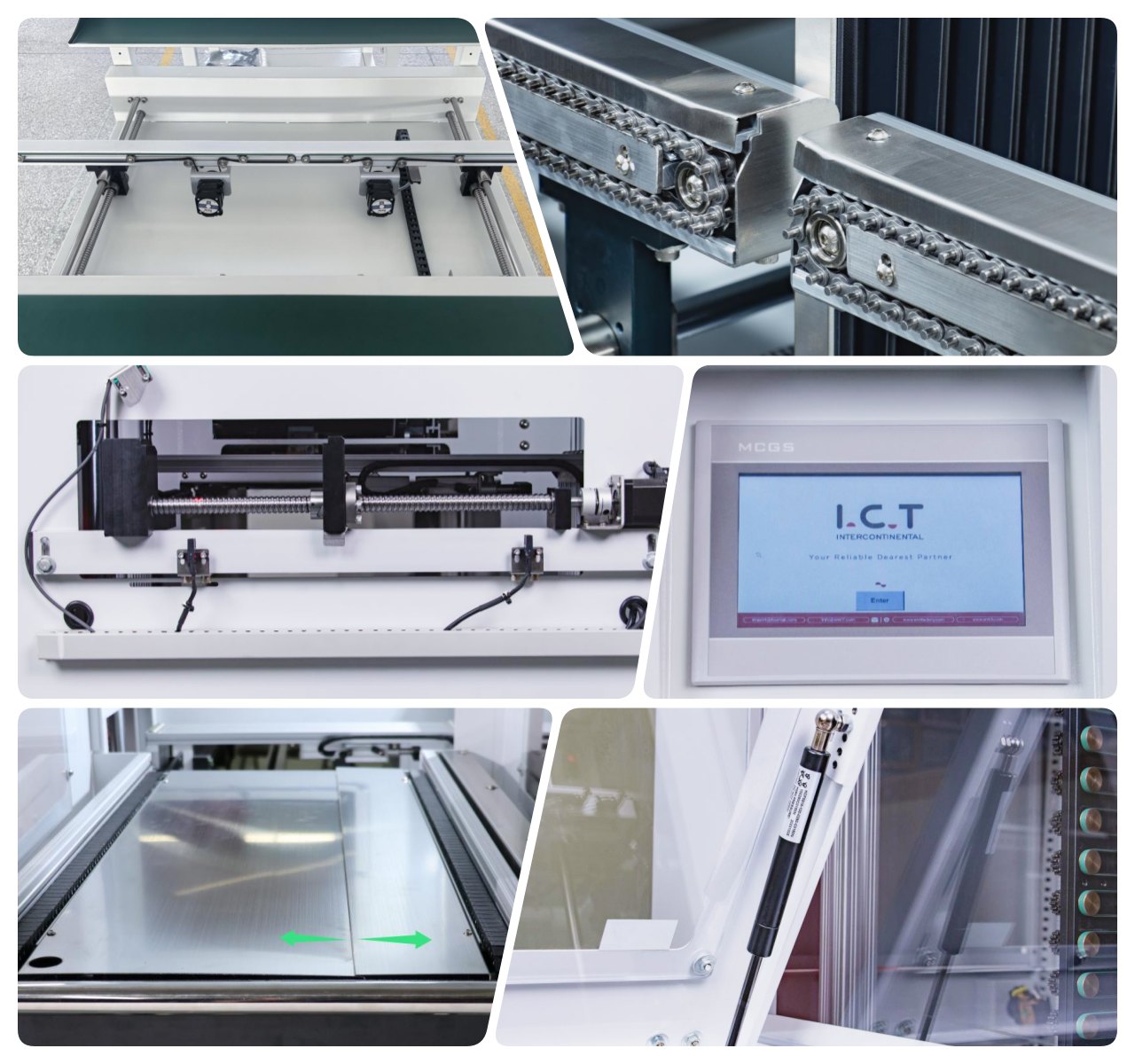

Every part of the PCB Vacuum Loader uses higher-level materials. Installation and maintenance follow strict ISO and CE rules. The ergonomic design and stronger base make the machine run stably for many years and very easy for workers to operate every day.

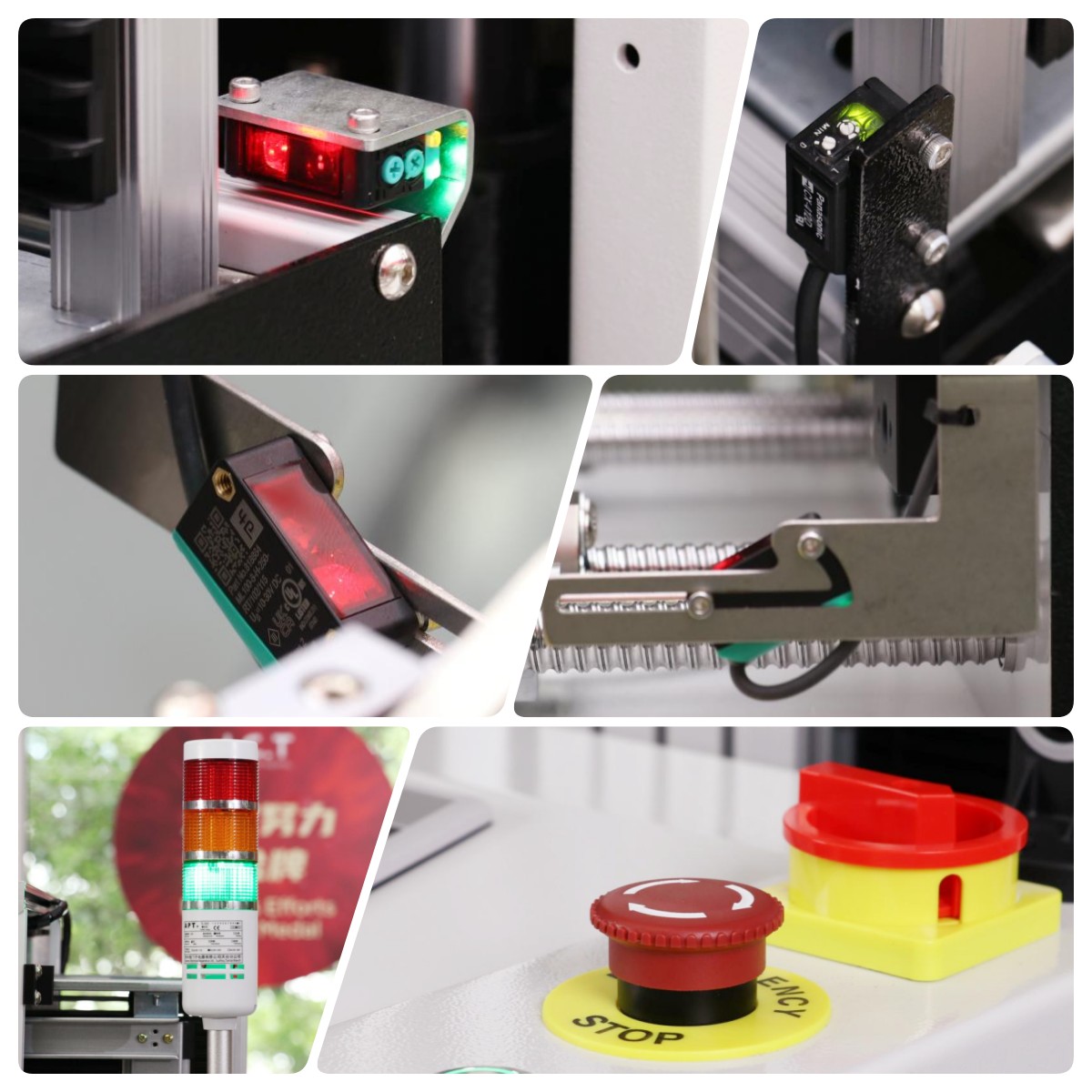

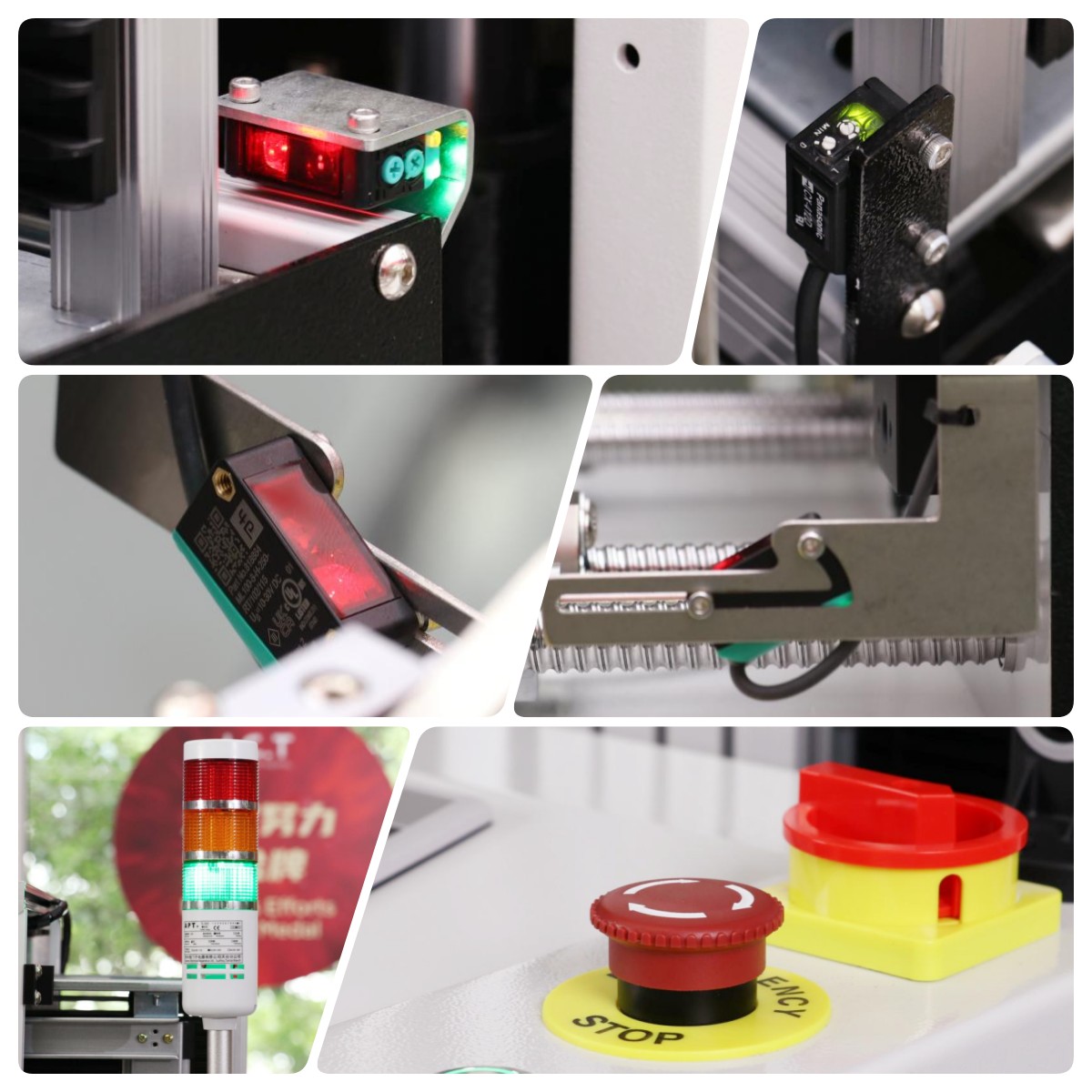

Top-quality electrical components and sensitive sensors give the PCB Vacuum Loader precise control. High-frequency buttons and clear status lights meet the needs of different production speeds and help operators see machine status quickly.

The control system supports Industry 4.0 standards. It is easy to upgrade and expand. The PCB Vacuum Loader can connect to IPC-CFX, Hermes, and SEMI SMT-ELS protocols (optional), so it works perfectly in modern smart factories.

Special vacuum system provides strong and stable suction force. It safely handles different PCB sizes without scratches or position errors. The translational conveyor moves boards smoothly to the next process.

Optional smart communication modules let the PCB Vacuum Loader connect quickly with upstream and downstream machines. This helps build a fully automatic SMT line with minimum manual work.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality SMT Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T overseas engineers flew to Finland to build a fully automatic LED Panel production line for a well-known lighting customer. The complete SMT line includes PCB Vacuum Loader, 1.5m fully automatic printer, SM482PLUS pick-and-place machine, L8 reflow oven, vertical cooling buffer, linking conveyors, board splitter, and solder paste mixer. Our engineers finished installation and debugging in only five days. After professional training, the customer’s operators could run the whole line smoothly and reached designed speed on the first day of official production. The customer was very satisfied with the stable performance of the PCB Vacuum Loader and the perfect connection between all machines, and successfully passed the strict European customer audit. This SMT Automatic PCB Translational Vacuum Loader once again proved its excellent reliability in high-end LED applications.

| Professional Training & Support

I.C.T provides complete service: online or on-site installation, free operator and engineer training, 24-hour technical support, regular maintenance plans, and fast spare parts delivery worldwide. Our experienced team makes sure your PCB Vacuum Loader always runs at best condition.

| Customer Praise

“Engineers arrived the next day after we called – super fast!” “The PCB Vacuum Loader is very stable, almost zero failure in one year.” “Packing is extremely safe; every machine arrived perfectly.” “Response speed is the fastest among all suppliers we have.”

| Our Certification

I.C.T PCB Vacuum Loader has passed CE, RoHS, ISO9001 certifications and owns many technical patents. Every machine goes through strict testing before shipment to guarantee top quality and safety for customers worldwide.

| About Us and Factory

I.C.T was established in 2012 and now has nearly 90 employees and 12,000 m² modern factory. We have our own R&D team, full production lines, and strict quality control system. For more than 10 years we grew very fast and now serve over 1600 customers in 72 countries. From PCB Vacuum Loader to complete SMT turnkey solutions, I.C.T is your trusted long-term partner.

| Reliable PCB Vacuum Loader for Modern SMT Lines

The I.C.T PCB Vacuum Loader is an upgraded automatic handling solution specially designed for SMT production. Using strong vacuum suction, it gently takes bare PCBs from magazine racks and smoothly sends them to the next machine. Whether standard or CE version, this PCB Vacuum Loader offers higher stability and longer service life. Advanced hardware, electrical parts and smart control system reduce downtime and increase production efficiency. The SMT Automatic PCB Translational Vacuum Loader works perfectly with all major SMT brands and easily connects to smart factory systems.

| Detailed Product Features

Every part of the PCB Vacuum Loader uses higher-level materials. Installation and maintenance follow strict ISO and CE rules. The ergonomic design and stronger base make the machine run stably for many years and very easy for workers to operate every day.

Top-quality electrical components and sensitive sensors give the PCB Vacuum Loader precise control. High-frequency buttons and clear status lights meet the needs of different production speeds and help operators see machine status quickly.

The control system supports Industry 4.0 standards. It is easy to upgrade and expand. The PCB Vacuum Loader can connect to IPC-CFX, Hermes, and SEMI SMT-ELS protocols (optional), so it works perfectly in modern smart factories.

Special vacuum system provides strong and stable suction force. It safely handles different PCB sizes without scratches or position errors. The translational conveyor moves boards smoothly to the next process.

Optional smart communication modules let the PCB Vacuum Loader connect quickly with upstream and downstream machines. This helps build a fully automatic SMT line with minimum manual work.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality SMT Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T overseas engineers flew to Finland to build a fully automatic LED Panel production line for a well-known lighting customer. The complete SMT line includes PCB Vacuum Loader, 1.5m fully automatic printer, SM482PLUS pick-and-place machine, L8 reflow oven, vertical cooling buffer, linking conveyors, board splitter, and solder paste mixer. Our engineers finished installation and debugging in only five days. After professional training, the customer’s operators could run the whole line smoothly and reached designed speed on the first day of official production. The customer was very satisfied with the stable performance of the PCB Vacuum Loader and the perfect connection between all machines, and successfully passed the strict European customer audit. This SMT Automatic PCB Translational Vacuum Loader once again proved its excellent reliability in high-end LED applications.

| Professional Training & Support

I.C.T provides complete service: online or on-site installation, free operator and engineer training, 24-hour technical support, regular maintenance plans, and fast spare parts delivery worldwide. Our experienced team makes sure your PCB Vacuum Loader always runs at best condition.

| Customer Praise

“Engineers arrived the next day after we called – super fast!” “The PCB Vacuum Loader is very stable, almost zero failure in one year.” “Packing is extremely safe; every machine arrived perfectly.” “Response speed is the fastest among all suppliers we have.”

| Our Certification

I.C.T PCB Vacuum Loader has passed CE, RoHS, ISO9001 certifications and owns many technical patents. Every machine goes through strict testing before shipment to guarantee top quality and safety for customers worldwide.

| About Us and Factory

I.C.T was established in 2012 and now has nearly 90 employees and 12,000 m² modern factory. We have our own R&D team, full production lines, and strict quality control system. For more than 10 years we grew very fast and now serve over 1600 customers in 72 countries. From PCB Vacuum Loader to complete SMT turnkey solutions, I.C.T is your trusted long-term partner.