RX-7R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| SMT Chip Pick and Place Machine

In the quiet hum of modern factories, the 6 head SMT machine from Juki stands as a refined tool for building circuit boards. It places surface mount parts with elegant speed and exact care. The design allows modules to join or separate as needs change. Vision systems watch every move closely. Software flows simple and clear for operators. Its slender form slides into busy lines without demand. I.C.T guides each step, from first layout to steady runs, ensuring high output for products that touch everyday lives, from lights to power controls.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

These models offer graceful flexibility for varied work. The RS-1XL handles wide boards to 650×560mm, perfect for larger panels. The RS-1R manages up to 650×370mm with 47,000 CPH and ±35µm precision. The Takumi head adapts smoothly to different shapes. Feeders hold 112 positions for fast switches. Vision catches issues early. Soft force protects fragile surfaces. They blend into lines, balancing custom and volume jobs with quiet efficiency through long hours.

RX-7R / RX-8 Series Features

Pure velocity defines this pair in compact form. The RX-8 reaches 100,000 CPH through the P20 head, while the RX-7R achieves 75,000. Both measure just 998mm wide, leading in output per space. They place 03015 chips with steady hand. Heads coordinate in parallel rhythm. Improved lighting sharpens camera views. Gentle placement guards small parts. Data shares between units on stock and marks. Suited for dense small-component runs in devices that power modern life.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T SMT lines of lasting strength and flow. SMT loader draws boards in clean. Solder Paste Printer spreads paste in even layers. The 6 head SMT machine positions each chip with care. Reflow zones bind solder firm and true. AOI examines every detail closely. Conveyors connect without break. Buffers maintain gentle rhythm. Yield climbs steady, costs remain low. Nothing falters in the chain. These systems serve demanding automotive and board production. Finished pieces emerge ready and strong. We support the entire path.

| Customer Success Video

The video captures a factory crafting car power supplies with quiet purpose. Boards move from vacuum loader, clean and prepared. Paste applies smooth. The SMT chip pick and place machine fills positions swift and sure. Reflow heats connections solid. AOI scans for perfection. Conveyors guide steady, cooling follows calm. DIP wave solders through-hole parts clean. Flippers adjust boards easy. I.C.T confirms function true. The owner notes seamless links, rare pauses, consistent quality. Clear images trace the journey end to end, meeting strict standards without strain.

| Service and Training Support

I.C.T arrives prepared to serve. Engineers set the 6 head SMT machine in place and test thoroughly. Training unfolds patient and practical on the floor. Operators master programming, maintenance, and solutions. Remote access brings swift aid. Scheduled care preserves peak condition across years. We review lines and offer refined paths. Updates integrate smooth. Worldwide centers deliver help near and timely. Production continues strong with minimal interruption. Partnership forms early and endures.

| Customer Feedback

Users share thoughtful words. They commend engineers for deep knowledge and prompt resolution. The 6 head SMT machine gains regard for reliable pace and rare errors. Packing proves careful, arrivals safe. Inquiries receive clear replies often same day. Assistance spans distances yet feels present. Operations extend longer. Results improve steadily. Customers find true worth in equipment and team combined.

| Certifications and Standards

Each 6 head SMT machine bears meaningful standards. CE confirms European safety compliance. RoHS excludes harmful substances. ISO9001 ensures consistent quality control. Patents safeguard innovative heads and vision. These credentials affirm safety for workers, kindness to environment, durability for intensive use. Buyers proceed with quiet assurance. International requirements satisfy fully.

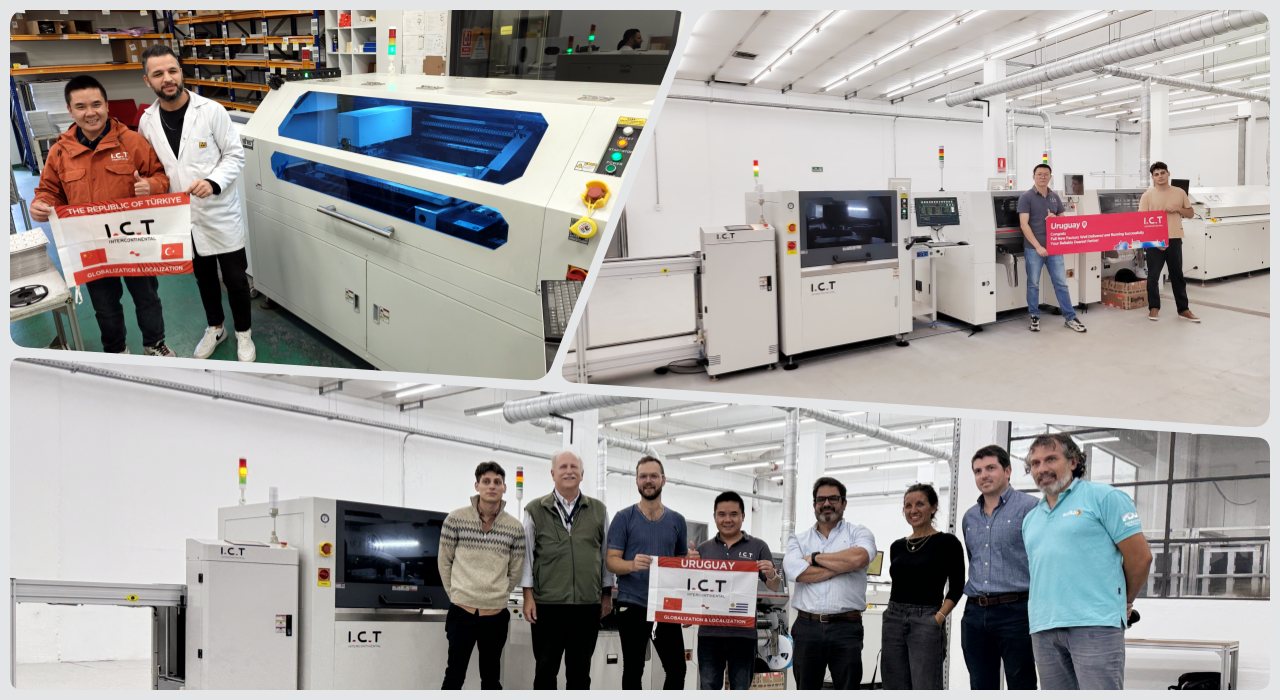

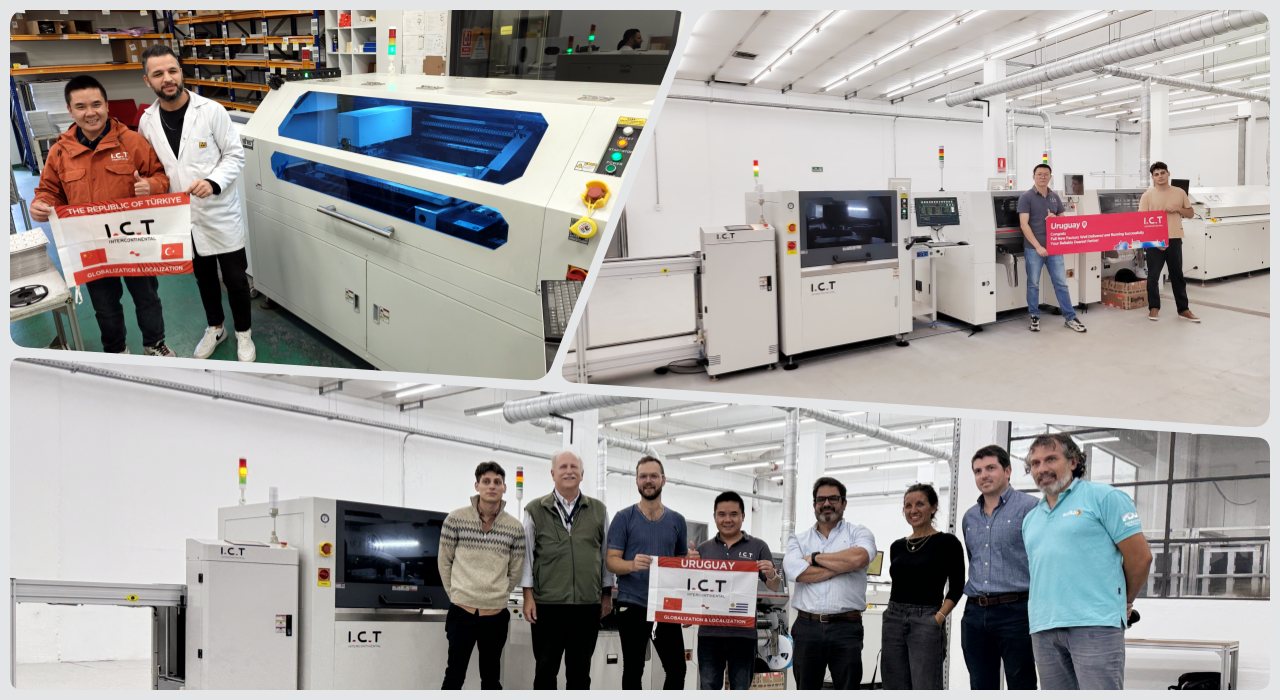

| About I.C.T Company and Factory

I.C.T maintains active research groups transforming concepts into practical machines. Expansive facilities produce with careful oversight at every phase. Teams expand alongside progress. Offices multiply across regions. More than 1600 clients in 72 countries rely on our systems. Advancement stems from dedicated effort and tangible outcomes. Rigorous quality governs all stages. The 6 head SMT machine departs prepared for demanding service. We continue as trusted allies in global electronics assembly.

| SMT Chip Pick and Place Machine

In the quiet hum of modern factories, the 6 head SMT machine from Juki stands as a refined tool for building circuit boards. It places surface mount parts with elegant speed and exact care. The design allows modules to join or separate as needs change. Vision systems watch every move closely. Software flows simple and clear for operators. Its slender form slides into busy lines without demand. I.C.T guides each step, from first layout to steady runs, ensuring high output for products that touch everyday lives, from lights to power controls.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

These models offer graceful flexibility for varied work. The RS-1XL handles wide boards to 650×560mm, perfect for larger panels. The RS-1R manages up to 650×370mm with 47,000 CPH and ±35µm precision. The Takumi head adapts smoothly to different shapes. Feeders hold 112 positions for fast switches. Vision catches issues early. Soft force protects fragile surfaces. They blend into lines, balancing custom and volume jobs with quiet efficiency through long hours.

RX-7R / RX-8 Series Features

Pure velocity defines this pair in compact form. The RX-8 reaches 100,000 CPH through the P20 head, while the RX-7R achieves 75,000. Both measure just 998mm wide, leading in output per space. They place 03015 chips with steady hand. Heads coordinate in parallel rhythm. Improved lighting sharpens camera views. Gentle placement guards small parts. Data shares between units on stock and marks. Suited for dense small-component runs in devices that power modern life.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T SMT lines of lasting strength and flow. SMT loader draws boards in clean. Solder Paste Printer spreads paste in even layers. The 6 head SMT machine positions each chip with care. Reflow zones bind solder firm and true. AOI examines every detail closely. Conveyors connect without break. Buffers maintain gentle rhythm. Yield climbs steady, costs remain low. Nothing falters in the chain. These systems serve demanding automotive and board production. Finished pieces emerge ready and strong. We support the entire path.

| Customer Success Video

The video captures a factory crafting car power supplies with quiet purpose. Boards move from vacuum loader, clean and prepared. Paste applies smooth. The SMT chip pick and place machine fills positions swift and sure. Reflow heats connections solid. AOI scans for perfection. Conveyors guide steady, cooling follows calm. DIP wave solders through-hole parts clean. Flippers adjust boards easy. I.C.T confirms function true. The owner notes seamless links, rare pauses, consistent quality. Clear images trace the journey end to end, meeting strict standards without strain.

| Service and Training Support

I.C.T arrives prepared to serve. Engineers set the 6 head SMT machine in place and test thoroughly. Training unfolds patient and practical on the floor. Operators master programming, maintenance, and solutions. Remote access brings swift aid. Scheduled care preserves peak condition across years. We review lines and offer refined paths. Updates integrate smooth. Worldwide centers deliver help near and timely. Production continues strong with minimal interruption. Partnership forms early and endures.

| Customer Feedback

Users share thoughtful words. They commend engineers for deep knowledge and prompt resolution. The 6 head SMT machine gains regard for reliable pace and rare errors. Packing proves careful, arrivals safe. Inquiries receive clear replies often same day. Assistance spans distances yet feels present. Operations extend longer. Results improve steadily. Customers find true worth in equipment and team combined.

| Certifications and Standards

Each 6 head SMT machine bears meaningful standards. CE confirms European safety compliance. RoHS excludes harmful substances. ISO9001 ensures consistent quality control. Patents safeguard innovative heads and vision. These credentials affirm safety for workers, kindness to environment, durability for intensive use. Buyers proceed with quiet assurance. International requirements satisfy fully.

| About I.C.T Company and Factory

I.C.T maintains active research groups transforming concepts into practical machines. Expansive facilities produce with careful oversight at every phase. Teams expand alongside progress. Offices multiply across regions. More than 1600 clients in 72 countries rely on our systems. Advancement stems from dedicated effort and tangible outcomes. Rigorous quality governs all stages. The 6 head SMT machine departs prepared for demanding service. We continue as trusted allies in global electronics assembly.