I.C.T-7100

I.C.T

X-RAY machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T X-7100 PCB X-ray Inspection Machine

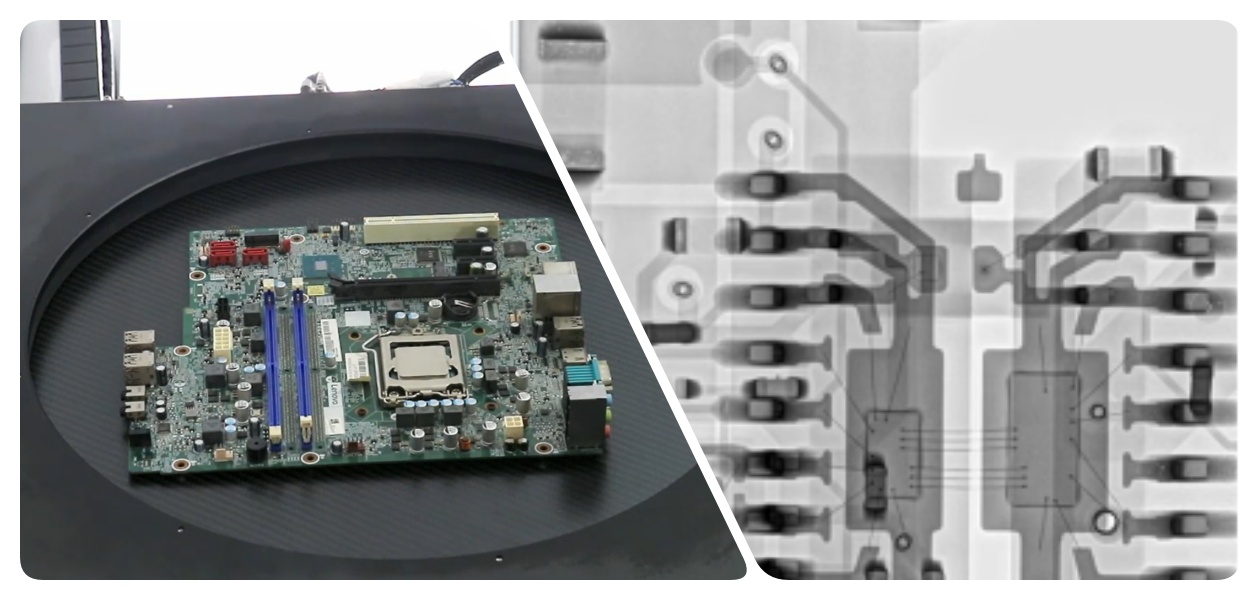

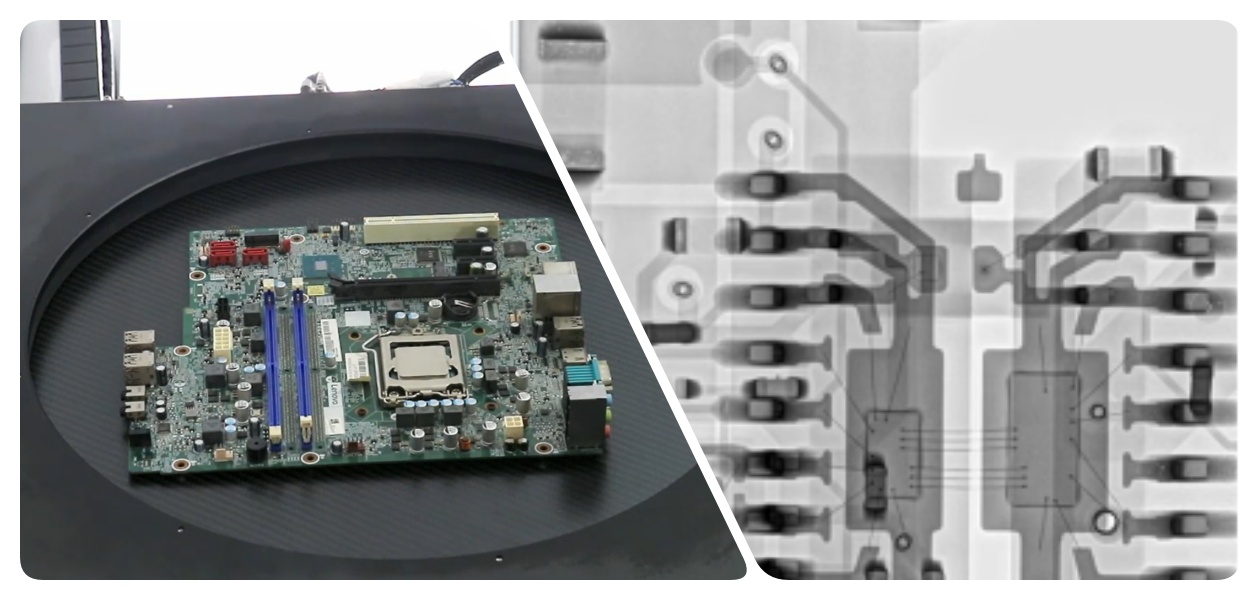

The I.C.T X-7100 serves as an advanced offline X-ray inspection machine tailored for SMT and semiconductor production environments. This SMT X-ray Inspection Machines for PCBs identifies BGA voids, solder joint issues, cracks, missing solder, short circuits, and foreign materials that standard visual inspections overlook. Featuring 1000x magnification, a 60-degree tilt capability, CNC programming for automated scans, and one-button void analysis, it delivers accurate results with minimal operator effort. Radiation levels stay below 1 µSv/h, complying with CE, ISO, and RoHS standards for safe daily use in factories worldwide.

| Feature

Equipped with a high-resolution digital flat-panel detector and Hamamatsu X-ray tube from Japan, the X-ray inspection machine provides real-time image correction and sharp 1536x1536 pixel visuals. Multiple gain modes and built-in temperature sensors ensure consistent performance during prolonged operations. Manufacturers benefit from this SMT X Ray Equipment Solutions by detecting minute defects in solder balls, wire bonds, and semiconductors, preventing costly rework and improving overall product quality in PCBA and battery assembly lines.

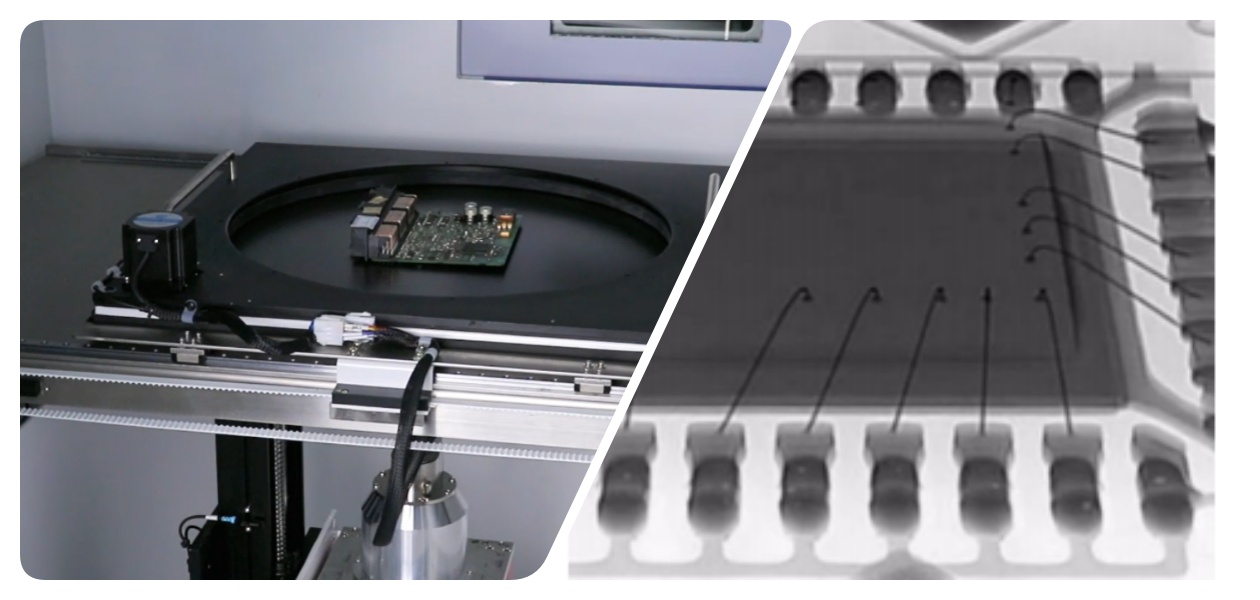

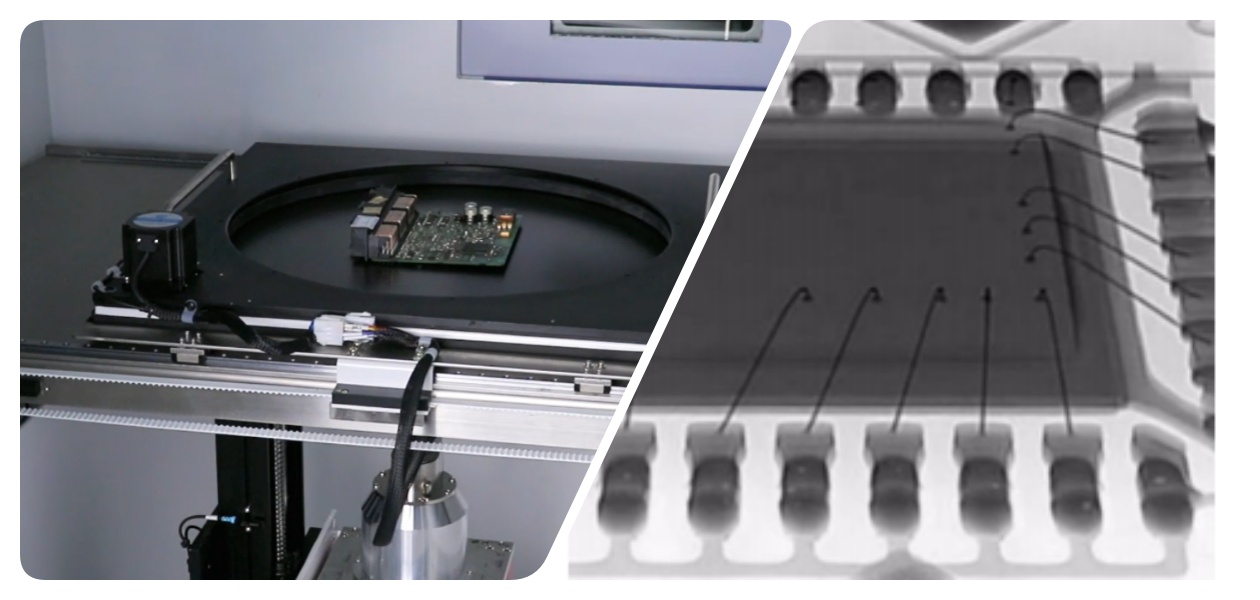

CNC programming enables the X-ray inspection machine to automatically inspect multiple sample positions without manual intervention. Array functions handle fixed-spacing items efficiently, while anti-collision systems protect the equipment. The stage moves precisely in X, Y, and Z directions, making it ideal for high-volume production. This feature in SMT X-ray Inspection Machines for PCBs boosts throughput in automotive electronics, LED manufacturing, and lithium battery testing, reducing errors and operator fatigue significantly.

With one-key functionality, the X-ray inspection machine quickly measures bubble size, void rate, and solder height using color simulation for enhanced visibility. Joystick controls allow real-time adjustments, ensuring accurate analysis of soldering defects. Factories rely on this SMT X Ray Equipment Solutions to meet strict quality standards like IPC, helping identify issues in fuses, displays, and wire harnesses before they impact final products.

| Specification

| Item | Model | I.C.T X-7100 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Cutting Machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The demonstration video highlights the I.C.T X-7100 X-ray inspection machine in a real electronics factory setting. It begins with an exterior tour showcasing the compact design and intuitive controls, then reveals internal components like the Hamamatsu tube and digital detector. Live operations follow, including automatic batch scanning of PCBA boards, instant bubble measurements, 60-degree tilt views of BGA joints, and clear imaging of lithium batteries and wire rods. This footage illustrates how the machine enhances defect detection efficiency, helping clients achieve up to 35% better quality control in their SMT lines.

| Professional Global Training & Support

I.C.T offers complete support for the X-ray inspection machine throughout its lifecycle. Expert engineers provide on-site installation, customized operator training, and calibration with straightforward guides. Remote troubleshooting, 24/7 parts supply, and free software updates prevent downtime. Global service networks and preventive maintenance plans keep equipment optimal, allowing manufacturers to focus on production without worries.

| Customer Feedback

Clients frequently commend I.C.T engineers for their prompt expertise and problem-solving skills. They appreciate the X-ray inspection machine's clear imaging and dependable performance. Secure packaging during shipping avoids damage, while quick responses to inquiries build lasting trust. Many highlight how this support turns I.C.T into a preferred partner.

| Our Certification

I.C.T holds CE, RoHS, ISO9001, and various patents for the X-ray inspection machine. These credentials confirm adherence to international safety, environmental, and quality standards. Factories worldwide trust these marks for reliable equipment approval in their operations.

| About Us and Factory

Established in 2012, I.C.T operates a 12,000 m² R&D and manufacturing facility in Dongguan, China, with nearly 90 staff and 20 engineers. The company has grown rapidly, serving over 1,600 customers in 72 countries through full SMT solutions. Strict testing processes and ISO9001 quality management ensure every product meets high standards, fostering innovation and customer success globally.

| I.C.T X-7100 PCB X-ray Inspection Machine

The I.C.T X-7100 serves as an advanced offline X-ray inspection machine tailored for SMT and semiconductor production environments. This SMT X-ray Inspection Machines for PCBs identifies BGA voids, solder joint issues, cracks, missing solder, short circuits, and foreign materials that standard visual inspections overlook. Featuring 1000x magnification, a 60-degree tilt capability, CNC programming for automated scans, and one-button void analysis, it delivers accurate results with minimal operator effort. Radiation levels stay below 1 µSv/h, complying with CE, ISO, and RoHS standards for safe daily use in factories worldwide.

| Feature

Equipped with a high-resolution digital flat-panel detector and Hamamatsu X-ray tube from Japan, the X-ray inspection machine provides real-time image correction and sharp 1536x1536 pixel visuals. Multiple gain modes and built-in temperature sensors ensure consistent performance during prolonged operations. Manufacturers benefit from this SMT X Ray Equipment Solutions by detecting minute defects in solder balls, wire bonds, and semiconductors, preventing costly rework and improving overall product quality in PCBA and battery assembly lines.

CNC programming enables the X-ray inspection machine to automatically inspect multiple sample positions without manual intervention. Array functions handle fixed-spacing items efficiently, while anti-collision systems protect the equipment. The stage moves precisely in X, Y, and Z directions, making it ideal for high-volume production. This feature in SMT X-ray Inspection Machines for PCBs boosts throughput in automotive electronics, LED manufacturing, and lithium battery testing, reducing errors and operator fatigue significantly.

With one-key functionality, the X-ray inspection machine quickly measures bubble size, void rate, and solder height using color simulation for enhanced visibility. Joystick controls allow real-time adjustments, ensuring accurate analysis of soldering defects. Factories rely on this SMT X Ray Equipment Solutions to meet strict quality standards like IPC, helping identify issues in fuses, displays, and wire harnesses before they impact final products.

| Specification

| Item | Model | I.C.T X-7100 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Cutting Machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The demonstration video highlights the I.C.T X-7100 X-ray inspection machine in a real electronics factory setting. It begins with an exterior tour showcasing the compact design and intuitive controls, then reveals internal components like the Hamamatsu tube and digital detector. Live operations follow, including automatic batch scanning of PCBA boards, instant bubble measurements, 60-degree tilt views of BGA joints, and clear imaging of lithium batteries and wire rods. This footage illustrates how the machine enhances defect detection efficiency, helping clients achieve up to 35% better quality control in their SMT lines.

| Professional Global Training & Support

I.C.T offers complete support for the X-ray inspection machine throughout its lifecycle. Expert engineers provide on-site installation, customized operator training, and calibration with straightforward guides. Remote troubleshooting, 24/7 parts supply, and free software updates prevent downtime. Global service networks and preventive maintenance plans keep equipment optimal, allowing manufacturers to focus on production without worries.

| Customer Feedback

Clients frequently commend I.C.T engineers for their prompt expertise and problem-solving skills. They appreciate the X-ray inspection machine's clear imaging and dependable performance. Secure packaging during shipping avoids damage, while quick responses to inquiries build lasting trust. Many highlight how this support turns I.C.T into a preferred partner.

| Our Certification

I.C.T holds CE, RoHS, ISO9001, and various patents for the X-ray inspection machine. These credentials confirm adherence to international safety, environmental, and quality standards. Factories worldwide trust these marks for reliable equipment approval in their operations.

| About Us and Factory

Established in 2012, I.C.T operates a 12,000 m² R&D and manufacturing facility in Dongguan, China, with nearly 90 staff and 20 engineers. The company has grown rapidly, serving over 1,600 customers in 72 countries through full SMT solutions. Strict testing processes and ISO9001 quality management ensure every product meets high standards, fostering innovation and customer success globally.