I.C.T-V5200H

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T AOI Machine for PCB AI-5146

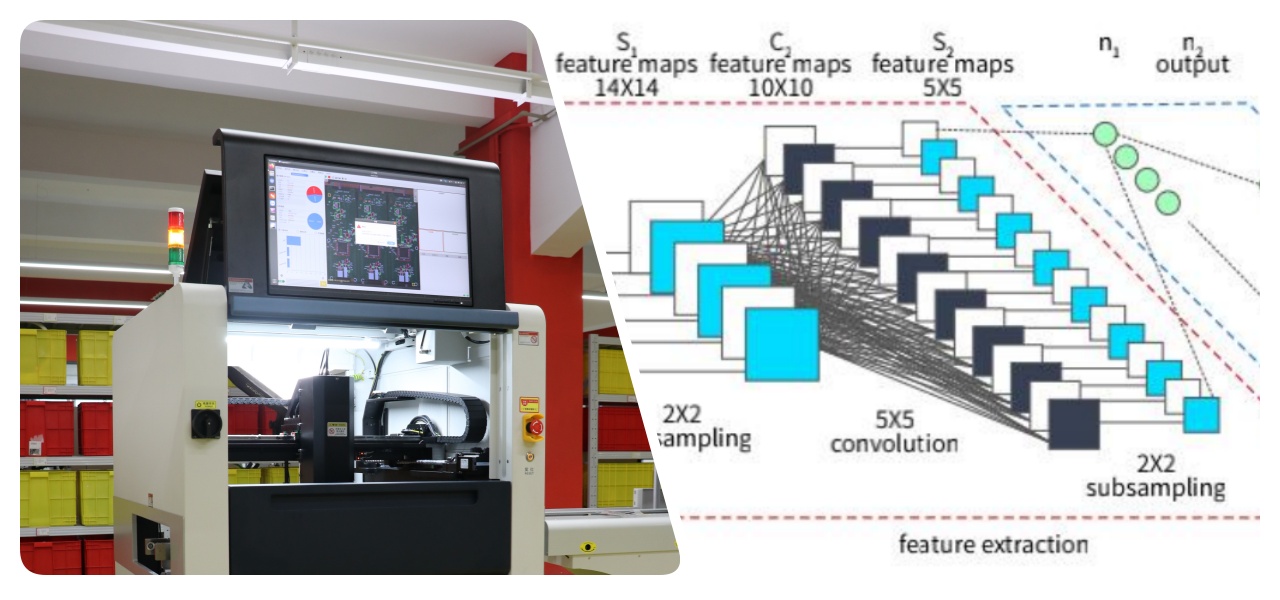

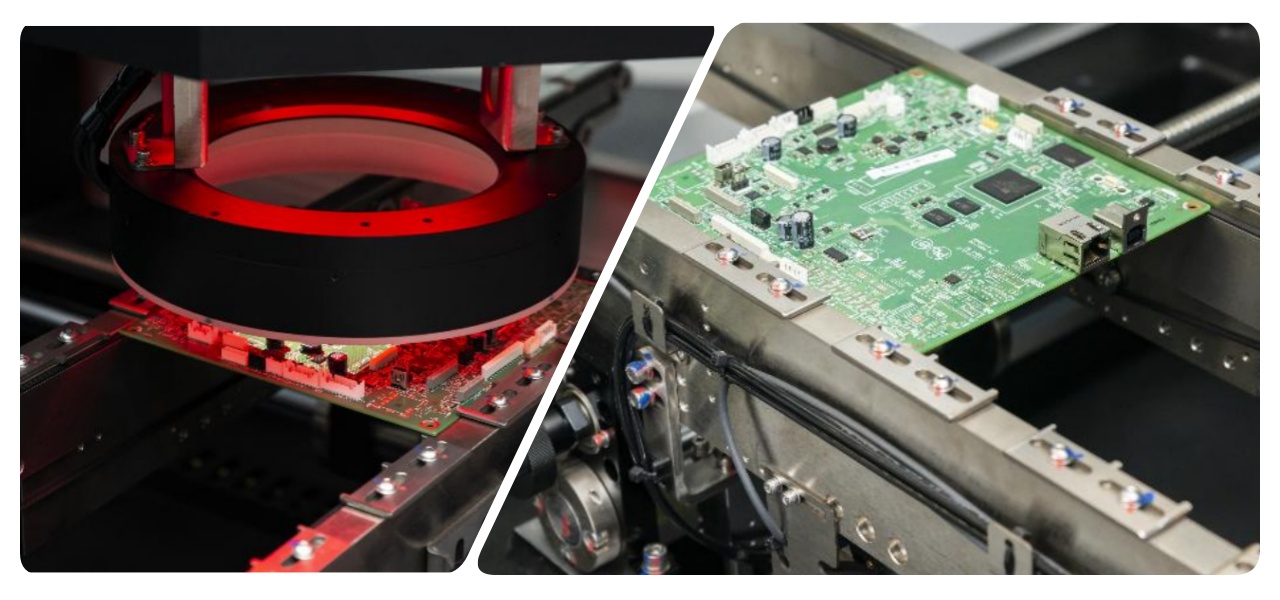

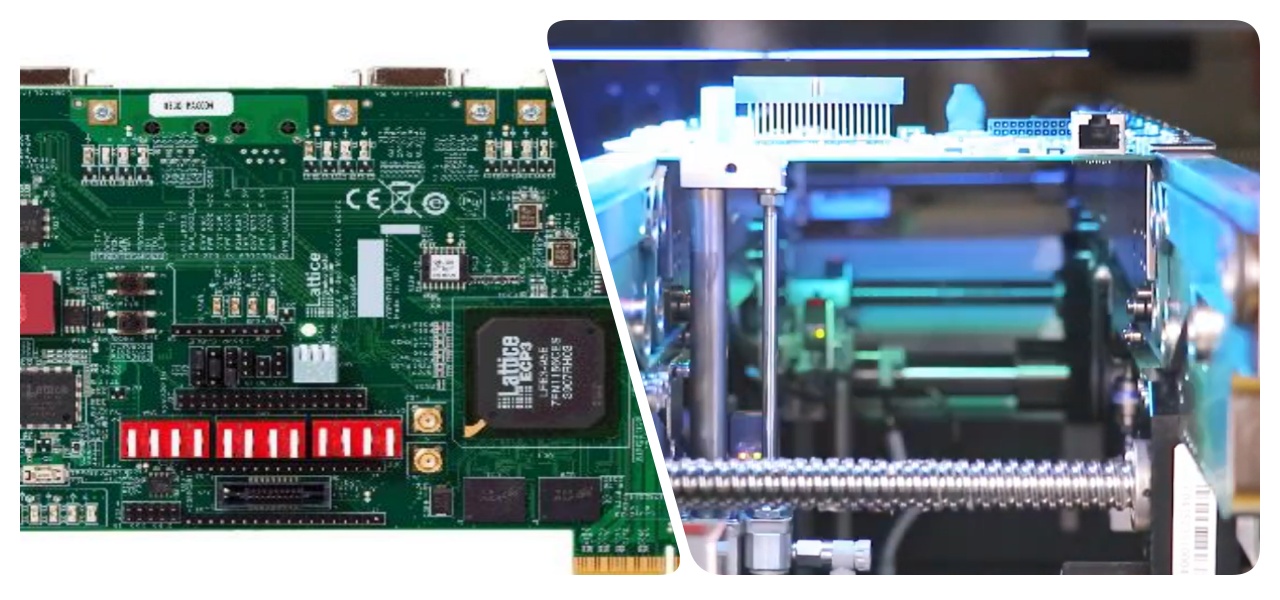

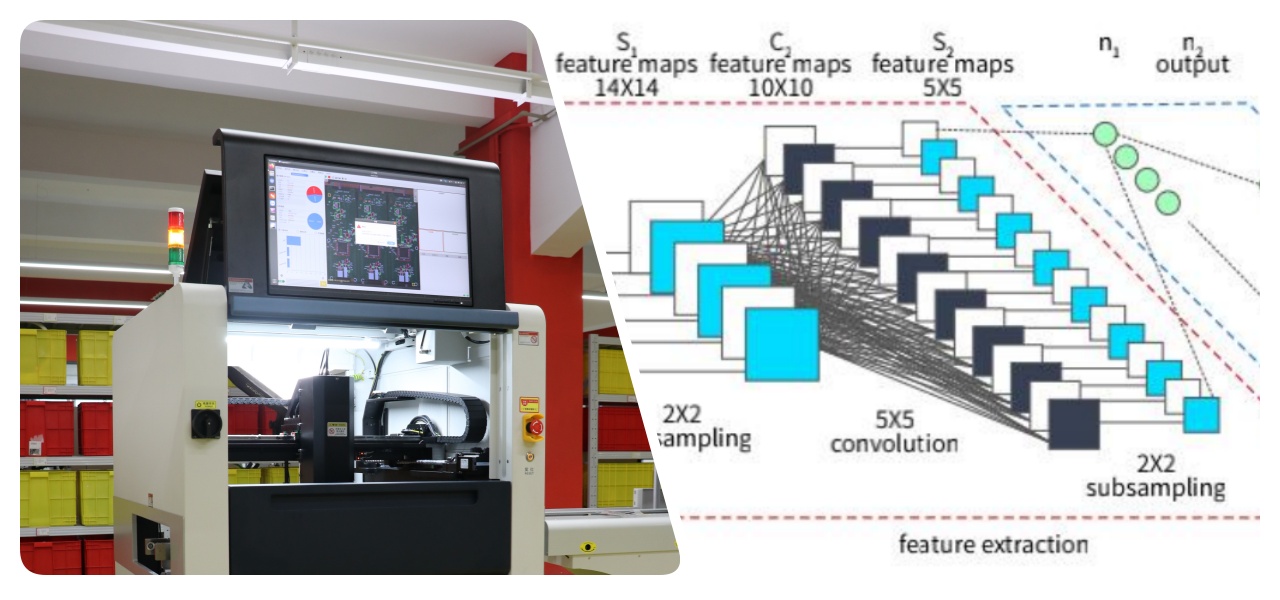

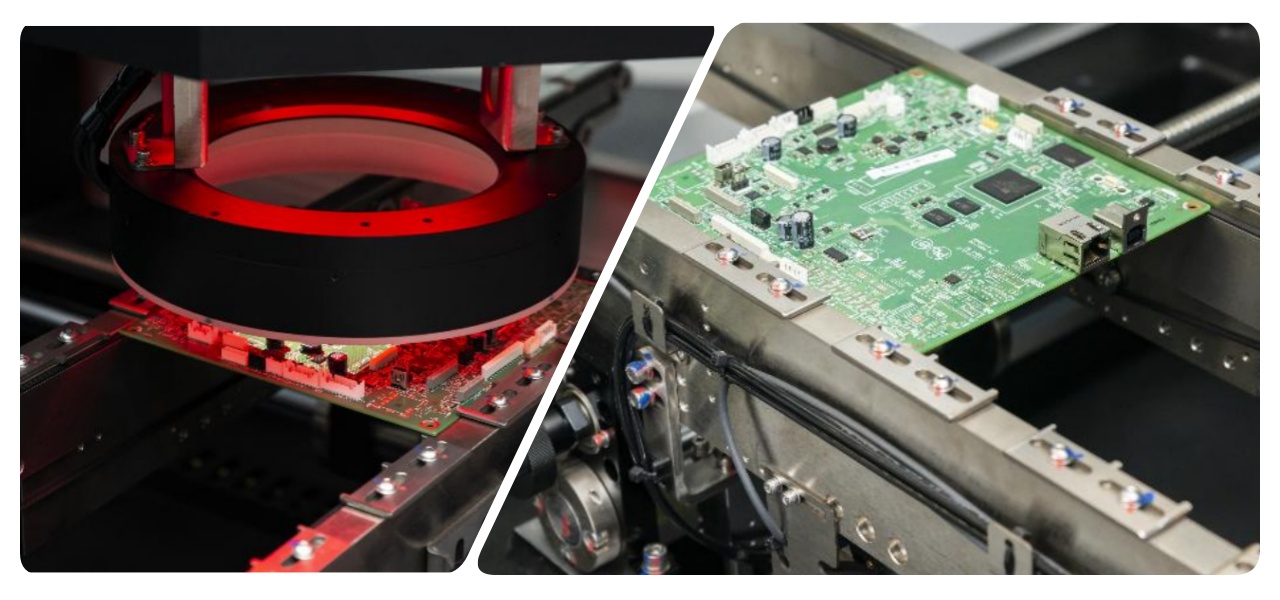

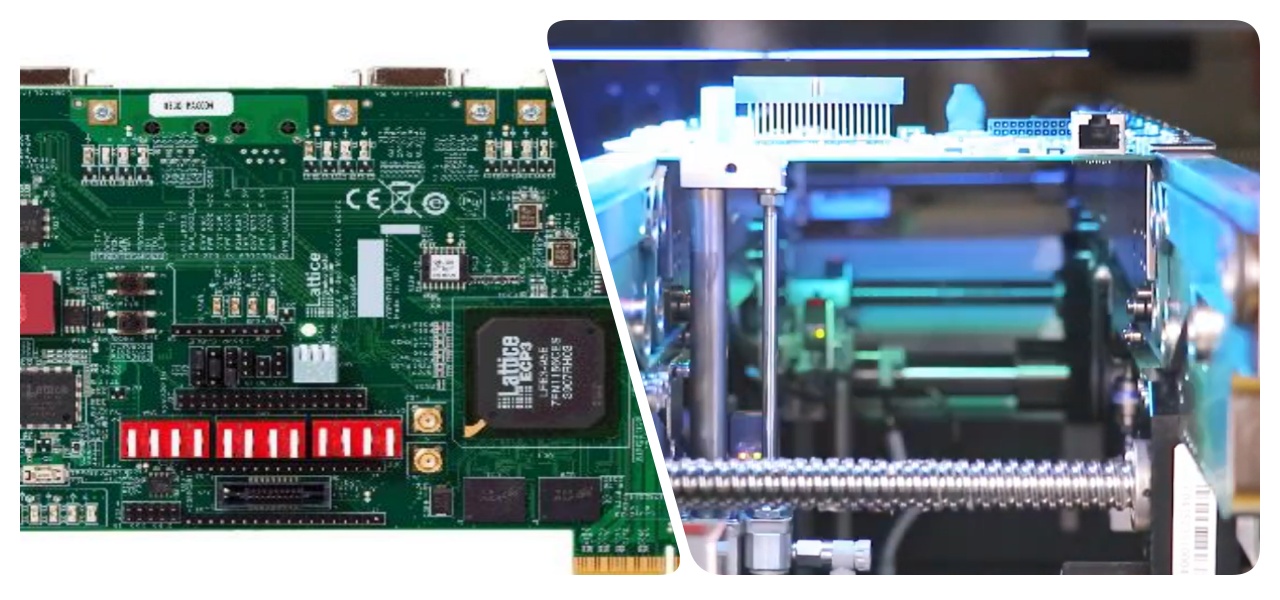

The I.C.T aoi machine for pcb AI-5146 grabs board images live with a top color camera. It uses CNN to spot part and solder issues smartly. This SMT Aoi Optical Inspection Machine works pre-reflow or post-reflow in line. It gives high speed, few wrong alerts, and simple setup. Stable tests show GR&R below 10%. It links to MES for data trace and remote fix. Users boost line yield easily.

| Feature

The aoi machine for pcb applies CNN on big data. It IDs components and solder joints with one click. This cuts long setup time. It lowers high false rates from old ways. Handles fuzzy edges or color shifts well. The aoi inspection equipment works on irregular parts. It keeps accuracy in tough cases.

Camera shoots 0.23 sec per field. Alignment system moves ultra quick. It plans paths auto for best route. Computes next area while shooting current. The aoi machine for pcb fits big boards in high volume. No slow down on busy lines. Users get more boards per hour.

Spots missing, shift, bridge, excess, and more. Auto pin boxes check multi issues. Ignores board color or text change. Handles overhang or small diffs. The aoi machine for pcb keeps low errors in complex setups.

| Specification

| Model | I.C.T SMT AOI AI-5146 | I.C.T SMT AOI AI-5146D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 10um@40*30mm | 15um@40*30mm |

| Camera | 12M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Inspection Algorithm | CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc. | |

| Inspection Item | Component: Absent, Reversed, Mis-alignment, Broken, Extra, Foreign matter, Stained, etc. Solder: Insufficient solder, excessive solder,bridging,pseudo solder etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm Right to left: max 640*460mm) | 50*50mm~510*610mm(Single rail operation) 50*50mm~510*330mm(Dual rail operation) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:80mm | Top:25mm,Bottom:30mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 750Kg | 790Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The I.C.T-5146 marketing video shows the aoi machine for pcb highlights. It opens with clean look and main sells. Inside reveals camera and lights. Machine runs on SMT line, grabs live images. AI program demo does one-click part and solder ID. Shows defects like offset or void. Quick program and remote links. Ends with steady factory run, better speed and quality.

| Service and Training Support

I.C.T gives full help for the aoi machine for pcb. Team does install, tune, and fix. Remote support solves quick. On-site or online classes teach use. Cover program, defect set, data read. Updates keep it fresh. World centers supply parts fast. Builds user know-how and run time.

| Customer Reviews

Users praise engineers for quick help and skill. They like the aoi machine for pcb accuracy and stability. Safe pack during ship. Fast reply to questions. Reliable work lifts their output.

| Certifications and Standards

I.C.T has CE for safe use, RoHS for no harm materials, ISO9001 for quality. Patents on AI tech. These show trust and new ideas.

| About I.C.T Company and Our SMT Factory

I.C.T owns R&D and make in 12,000m² site. 89 staff with 20 engineers. Fast growth serves 1600+ users in 72 lands. Strict checks and quality rules ensure good gear. Global sites give local aid.

| I.C.T AOI Machine for PCB AI-5146

The I.C.T aoi machine for pcb AI-5146 grabs board images live with a top color camera. It uses CNN to spot part and solder issues smartly. This SMT Aoi Optical Inspection Machine works pre-reflow or post-reflow in line. It gives high speed, few wrong alerts, and simple setup. Stable tests show GR&R below 10%. It links to MES for data trace and remote fix. Users boost line yield easily.

| Feature

The aoi machine for pcb applies CNN on big data. It IDs components and solder joints with one click. This cuts long setup time. It lowers high false rates from old ways. Handles fuzzy edges or color shifts well. The aoi inspection equipment works on irregular parts. It keeps accuracy in tough cases.

Camera shoots 0.23 sec per field. Alignment system moves ultra quick. It plans paths auto for best route. Computes next area while shooting current. The aoi machine for pcb fits big boards in high volume. No slow down on busy lines. Users get more boards per hour.

Spots missing, shift, bridge, excess, and more. Auto pin boxes check multi issues. Ignores board color or text change. Handles overhang or small diffs. The aoi machine for pcb keeps low errors in complex setups.

| Specification

| Model | I.C.T SMT AOI AI-5146 | I.C.T SMT AOI AI-5146D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 10um@40*30mm | 15um@40*30mm |

| Camera | 12M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Inspection Algorithm | CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc. | |

| Inspection Item | Component: Absent, Reversed, Mis-alignment, Broken, Extra, Foreign matter, Stained, etc. Solder: Insufficient solder, excessive solder,bridging,pseudo solder etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm Right to left: max 640*460mm) | 50*50mm~510*610mm(Single rail operation) 50*50mm~510*330mm(Dual rail operation) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:80mm | Top:25mm,Bottom:30mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 750Kg | 790Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The I.C.T-5146 marketing video shows the aoi machine for pcb highlights. It opens with clean look and main sells. Inside reveals camera and lights. Machine runs on SMT line, grabs live images. AI program demo does one-click part and solder ID. Shows defects like offset or void. Quick program and remote links. Ends with steady factory run, better speed and quality.

| Service and Training Support

I.C.T gives full help for the aoi machine for pcb. Team does install, tune, and fix. Remote support solves quick. On-site or online classes teach use. Cover program, defect set, data read. Updates keep it fresh. World centers supply parts fast. Builds user know-how and run time.

| Customer Reviews

Users praise engineers for quick help and skill. They like the aoi machine for pcb accuracy and stability. Safe pack during ship. Fast reply to questions. Reliable work lifts their output.

| Certifications and Standards

I.C.T has CE for safe use, RoHS for no harm materials, ISO9001 for quality. Patents on AI tech. These show trust and new ideas.

| About I.C.T Company and Our SMT Factory

I.C.T owns R&D and make in 12,000m² site. 89 staff with 20 engineers. Fast growth serves 1600+ users in 72 lands. Strict checks and quality rules ensure good gear. Global sites give local aid.