I.C.T-V5300

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T Automated Optical Inspection Systems AI-5146

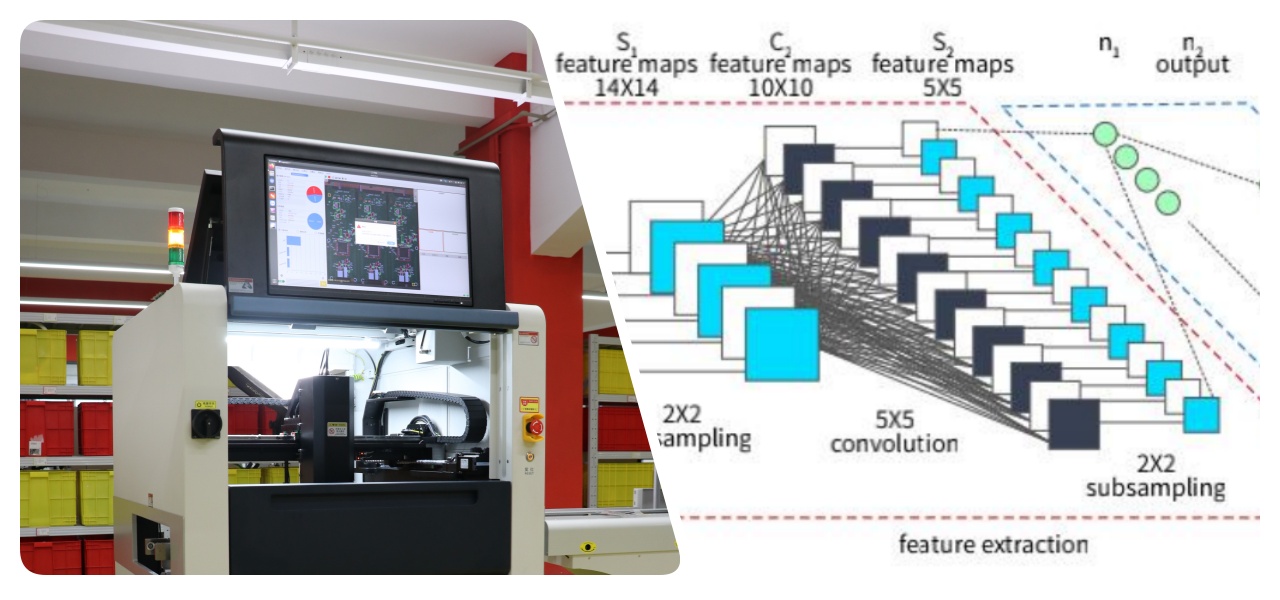

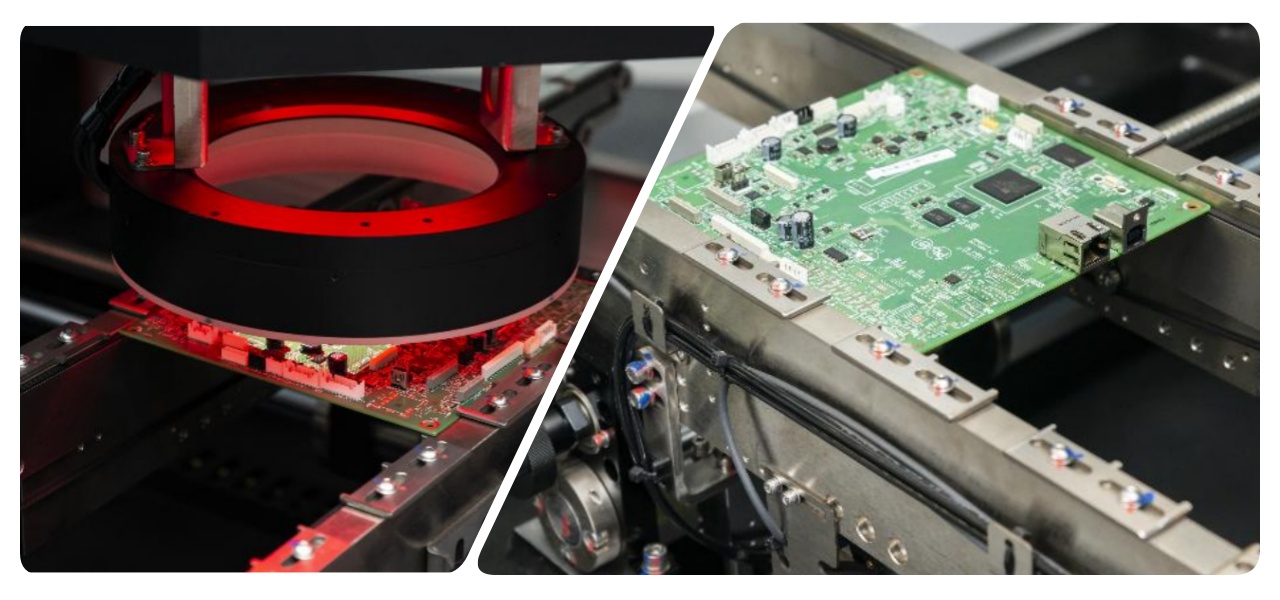

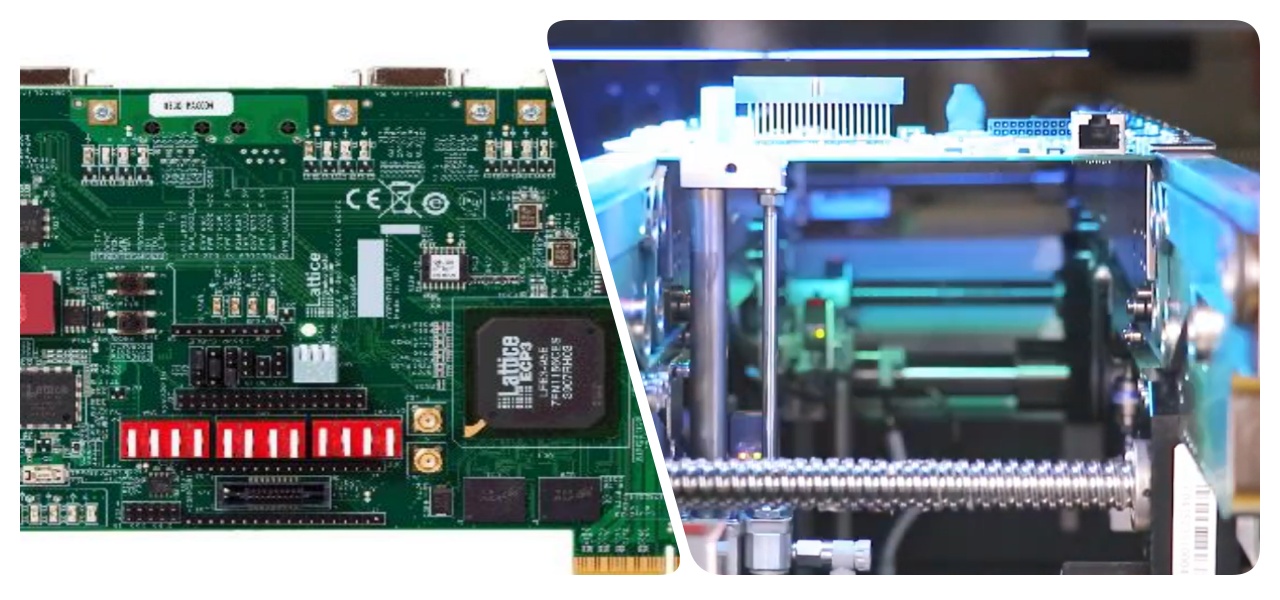

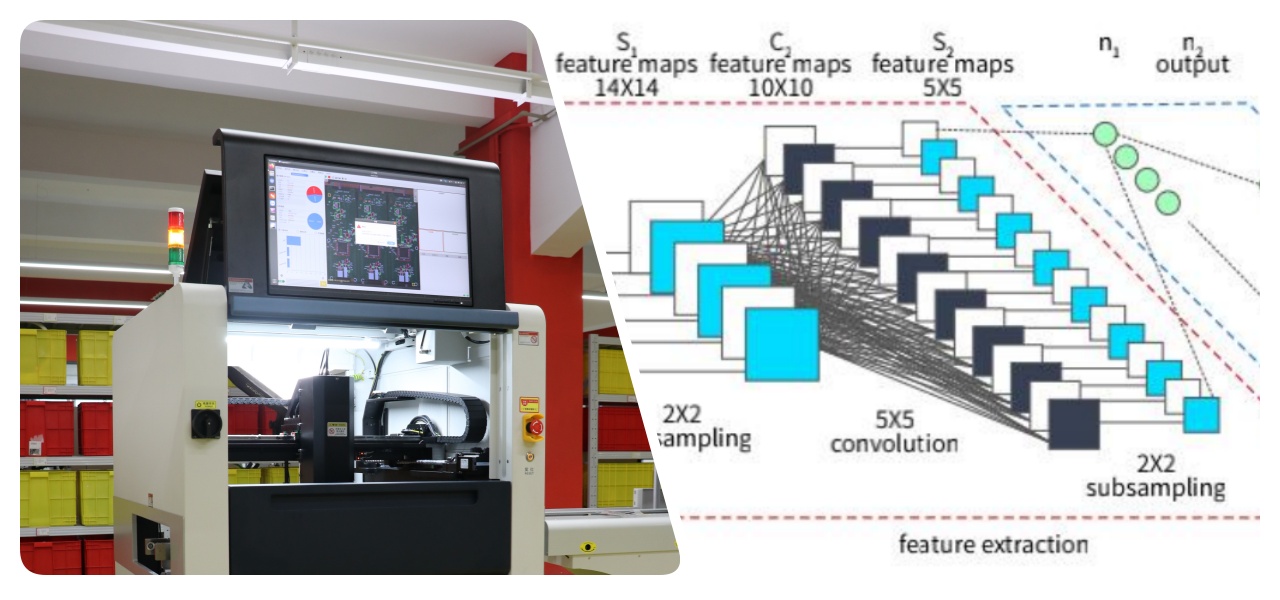

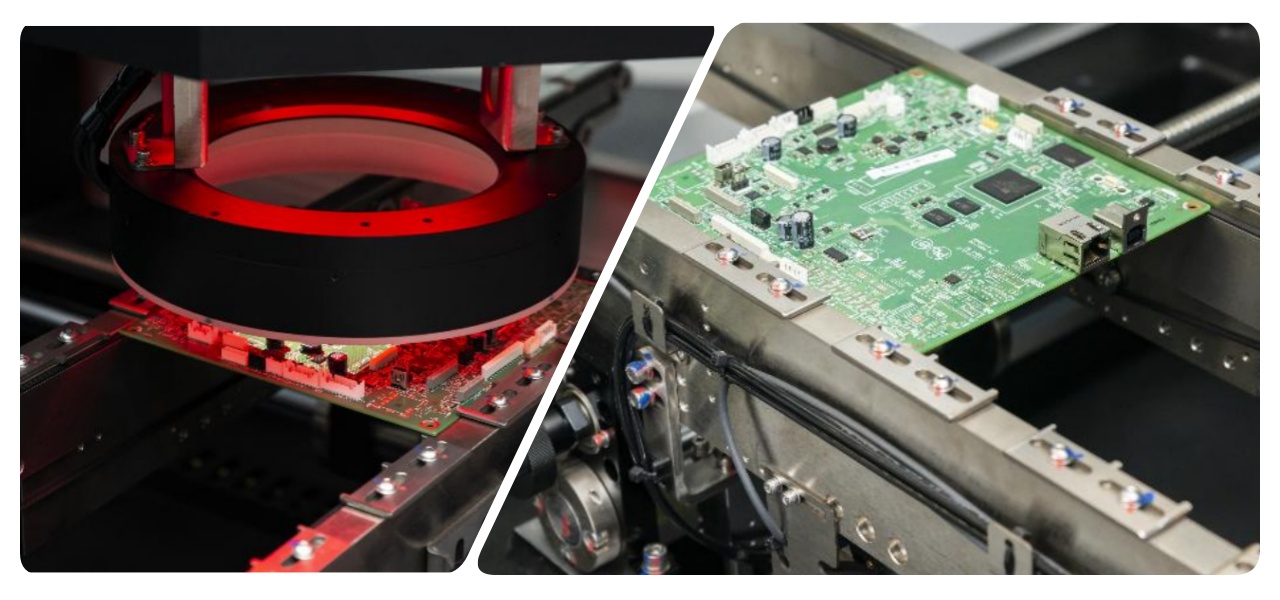

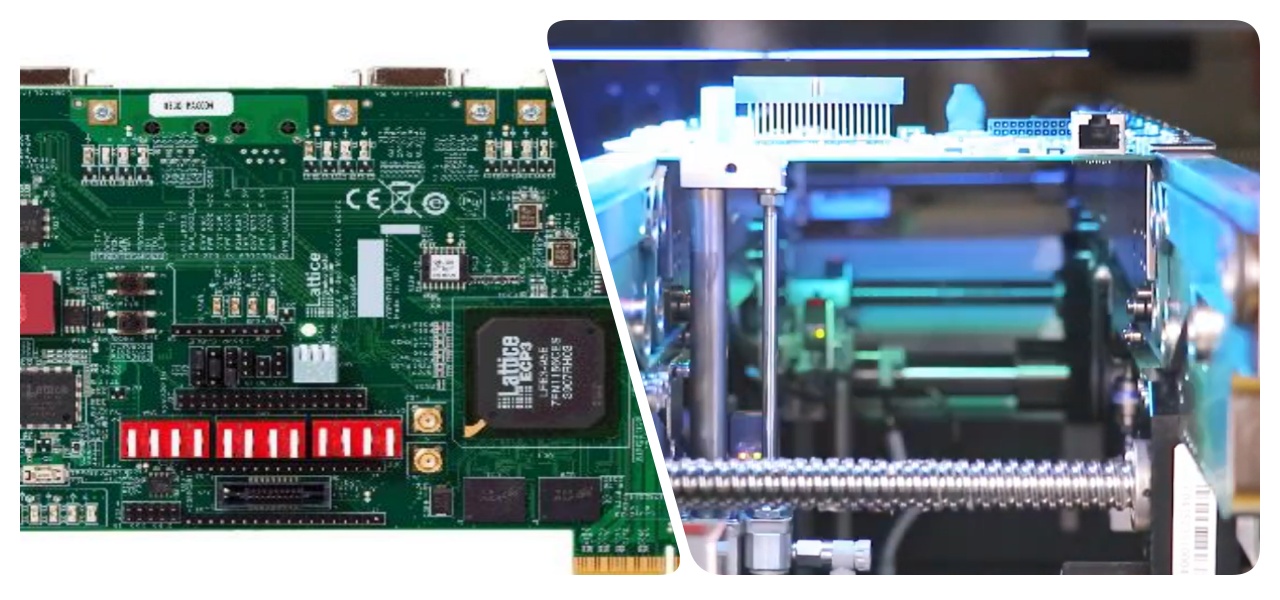

The I.C.T automated optical inspection systems AI-5146 uses a high-res color camera for live PCB images. It applies CNN to judge parts and solder faults smartly. This aoi optical inspection fits pre-reflow and post-reflow inline. It delivers fast checks, low errors, and easy interface. Stability reaches GR&R<10%. It connects to MES for data log and remote debug. Users improve line quality with ease.

| Feature

The automated optical inspection systems use CNN on vast data. One-click IDs components and joints. It shortens program time. Fixes old high false issues. The automated optical inspection pcb handles vague features or colors. It suits odd parts well. Accuracy stays high in hard spots.

Camera at 0.23 sec/FOV. Fast align system. Auto path plan. Computes next while shooting. The automated optical inspection systems manage large PCBs in volume. No lag in full lines. Users raise daily output.

Detects absent, misalign, bridge, excess, etc. Auto boxes multi faults. Ignores color or char shifts. Copes with overhang. The automated optical inspection systems low false in complex.

| Specification

| Model | I.C.T SMT AOI AI-5146 | I.C.T SMT AOI AI-5146D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 10um@40*30mm | 15um@40*30mm |

| Camera | 12M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Inspection Algorithm | CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc. | |

| Inspection Item | Component: Absent, Reversed, Mis-alignment, Broken, Extra, Foreign matter, Stained, etc. Solder: Insufficient solder, excessive solder,bridging,pseudo solder etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm Right to left: max 640*460mm) | 50*50mm~510*610mm(Single rail operation) 50*50mm~510*330mm(Dual rail operation) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:80mm | Top:25mm,Bottom:30mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 750Kg | 790Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The I.C.T-5146 marketing video presents automated optical inspection systems key points. It shows outer design and benefits. Internal camera and lights view. Machine operates on SMT line, live capture. AI setup demo one-click part/solder check. Defect samples like bridge or missing. Fast program, remote connect. Closes with factory steady run, higher yield and pace.

| Service and Training Support

I.C.T provides complete aid for automated optical inspection systems. Install, tune, maintain by team. Remote solve issues quick. Site or web training on ops. Teach program, defects, data. Software updates ongoing. Global spots for parts. Grows user skills and uptime.

| Customer Reviews

Clients praise engineers quick expert help. They like automated optical inspection systems precision and reliability. Secure packing in transit. Fast problem response. Solid performance lifts production.

| Certifications and Standards

I.C.T owns CE safety, RoHS eco, ISO9001 quality. Patents in AI methods. These ensure trust and innovation.

| About I.C.T Company and Our SMT Factory

I.C.T runs own R&D and build in 12,000m² plant. 89 people, 20 engineers. Rapid expand serves 1600+ in 72 nations. Rigorous tests, quality manage top gear. World branches local support.

| I.C.T Automated Optical Inspection Systems AI-5146

The I.C.T automated optical inspection systems AI-5146 uses a high-res color camera for live PCB images. It applies CNN to judge parts and solder faults smartly. This aoi optical inspection fits pre-reflow and post-reflow inline. It delivers fast checks, low errors, and easy interface. Stability reaches GR&R<10%. It connects to MES for data log and remote debug. Users improve line quality with ease.

| Feature

The automated optical inspection systems use CNN on vast data. One-click IDs components and joints. It shortens program time. Fixes old high false issues. The automated optical inspection pcb handles vague features or colors. It suits odd parts well. Accuracy stays high in hard spots.

Camera at 0.23 sec/FOV. Fast align system. Auto path plan. Computes next while shooting. The automated optical inspection systems manage large PCBs in volume. No lag in full lines. Users raise daily output.

Detects absent, misalign, bridge, excess, etc. Auto boxes multi faults. Ignores color or char shifts. Copes with overhang. The automated optical inspection systems low false in complex.

| Specification

| Model | I.C.T SMT AOI AI-5146 | I.C.T SMT AOI AI-5146D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 10um@40*30mm | 15um@40*30mm |

| Camera | 12M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Inspection Algorithm | CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc. | |

| Inspection Item | Component: Absent, Reversed, Mis-alignment, Broken, Extra, Foreign matter, Stained, etc. Solder: Insufficient solder, excessive solder,bridging,pseudo solder etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm Right to left: max 640*460mm) | 50*50mm~510*610mm(Single rail operation) 50*50mm~510*330mm(Dual rail operation) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:80mm | Top:25mm,Bottom:30mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 750Kg | 790Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The I.C.T-5146 marketing video presents automated optical inspection systems key points. It shows outer design and benefits. Internal camera and lights view. Machine operates on SMT line, live capture. AI setup demo one-click part/solder check. Defect samples like bridge or missing. Fast program, remote connect. Closes with factory steady run, higher yield and pace.

| Service and Training Support

I.C.T provides complete aid for automated optical inspection systems. Install, tune, maintain by team. Remote solve issues quick. Site or web training on ops. Teach program, defects, data. Software updates ongoing. Global spots for parts. Grows user skills and uptime.

| Customer Reviews

Clients praise engineers quick expert help. They like automated optical inspection systems precision and reliability. Secure packing in transit. Fast problem response. Solid performance lifts production.

| Certifications and Standards

I.C.T owns CE safety, RoHS eco, ISO9001 quality. Patents in AI methods. These ensure trust and innovation.

| About I.C.T Company and Our SMT Factory

I.C.T runs own R&D and build in 12,000m² plant. 89 people, 20 engineers. Rapid expand serves 1600+ in 72 nations. Rigorous tests, quality manage top gear. World branches local support.