I.C.T-S510

I.C.T

spi machine

| Availability: | |

|---|---|

| Quantity: | |

| 3D SPI Solder Paste Inspection Machine

The I.C.T-S510 online 3D SPI Solder Paste Inspection Machine uses advanced PSLM PMP 3D blue light technology to deliver true three-dimensional measurement of solder paste height, volume, area, and shape. Equipped with a 5M-pixel high-speed camera (12M optional) and professional telecentric lens, it completely solves shadow problems and random reflections that affect traditional inspection. With measurement accuracy reaching 0.67μm and repeatability below 1μm, the S510 helps manufacturers catch insufficient paste, bridging, offset, and other critical defects immediately after printing. Ideal for high-speed, high-precision SMT lines, this 3D SPI Solder Paste Inspection Machine supports Gerber import, fast programming under 10 minutes, and standard SPC reporting, making it the perfect choice for modern electronics manufacturing.

| Feature

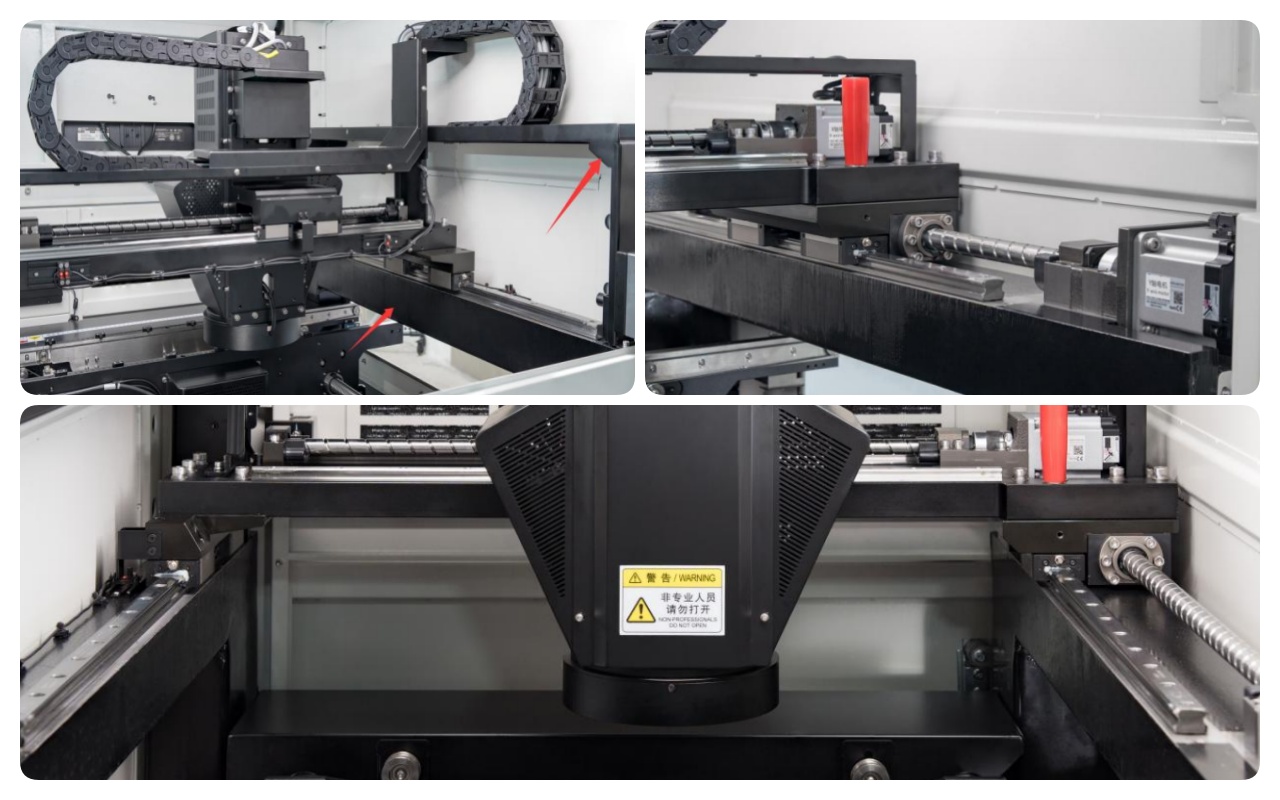

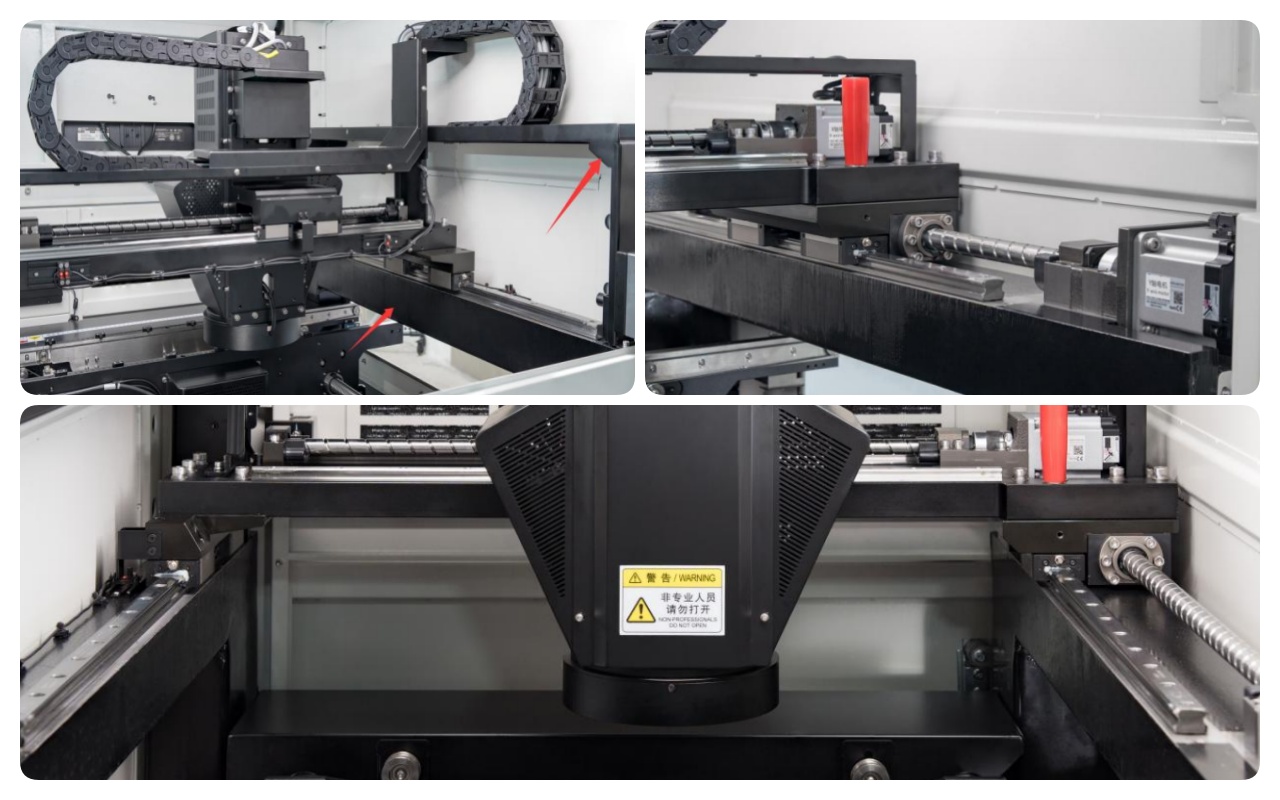

The I.C.T-S510 features an arch bridge suspension design with one-piece casting structure and dual high-precision servo motors controlling X/Y axes independently. Combined with precision slide rails and closed tank chains, this platform guarantees outstanding stability even during high-speed operation. Vibration is minimized, camera positioning remains accurate, and long-term reliability is ensured – giving you a solid foundation for consistent, repeatable 3D inspection results on every board.

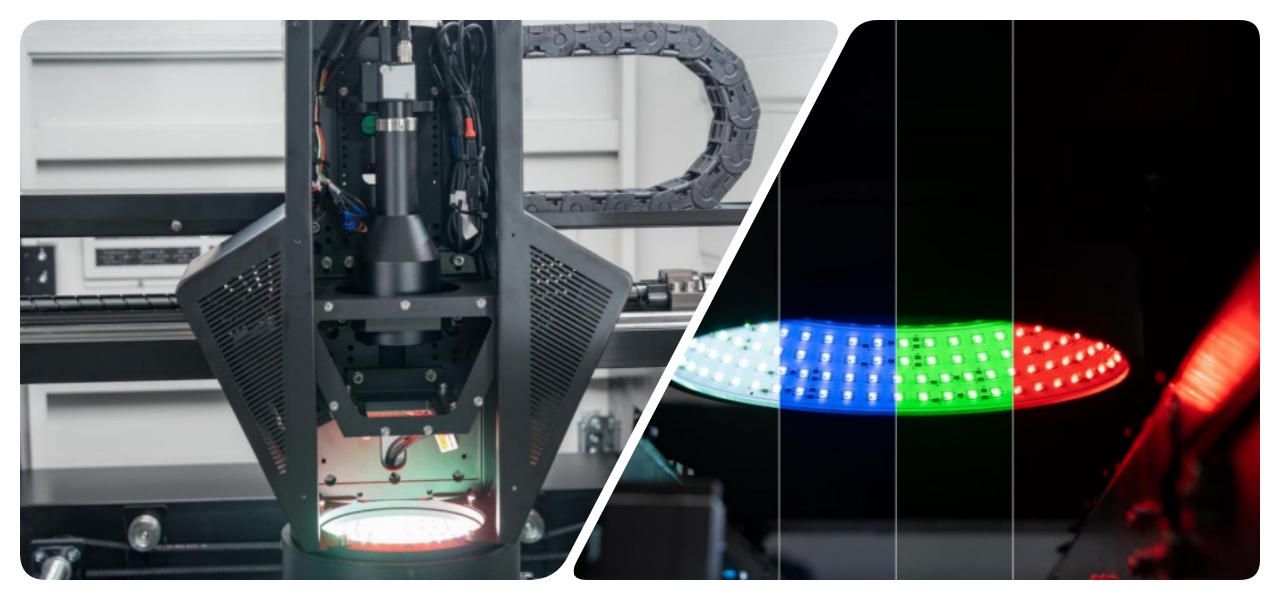

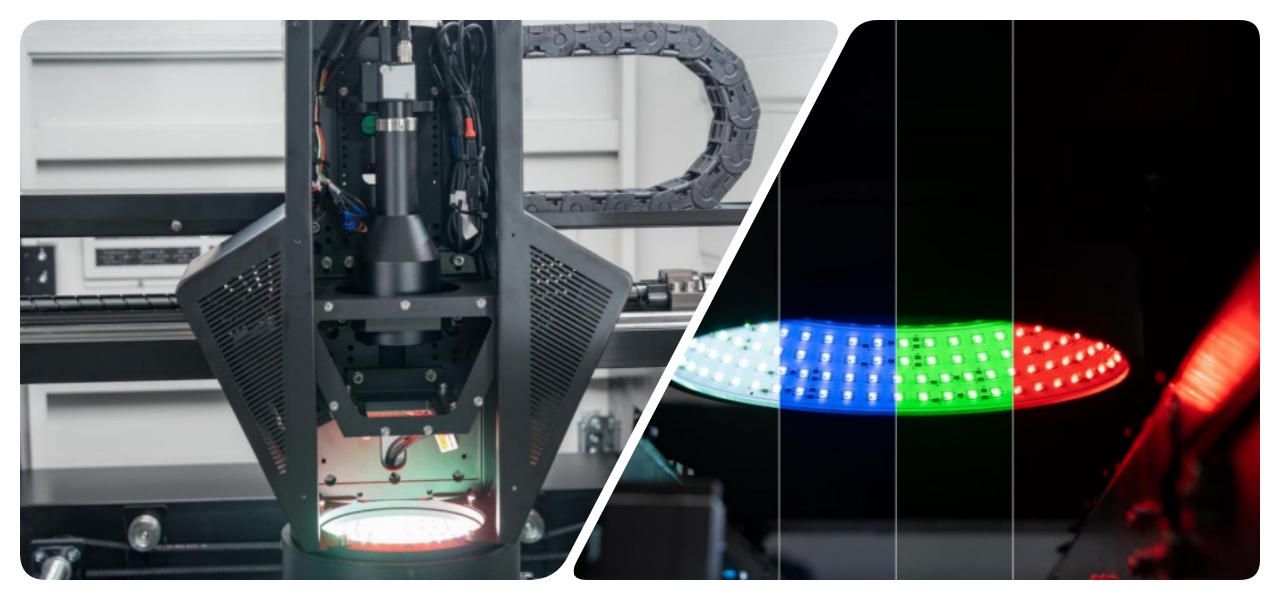

Powered by a 5M-pixel industrial camera and original PSLM (Phase Shift Light Modulation) technology, the vision system projects multi-directional programmable moiré fringes to create accurate 3D reconstructions. All-round adjustable light sources and telecentric optics eliminate color distortion and shadow effects completely. The result is micron-level measurement of height (0-550μm), volume, and shape, even on complex or shiny components, making this one of the most reliable solder paste inspection machines available today.

New programs are created in less than 10 minutes and line changeover takes under 2 minutes. The intuitive Windows 10 interface includes teaching navigation, operation logs, fault analysis, and full SPC reporting. Multi-level user permissions and diagnostic functions keep everything simple and secure, allowing operators of any experience level to achieve maximum efficiency with minimal training.

| Reflow Oven Specification

| Model | I.C.T-S510 | I.C.T-S510D | I.C.T-S1200 |

| PCB Size | 60*50~510*510mm | 50*60~510*310mm Dual rail 50*60~510*580 Single rai | 80*80~1200*500mm |

| PCB Tickness | 0.5 ~ 5.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Manual/automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | W1015*D1195*H1495mm | W1015*D1460*H1495mm | W1840*D1450*H1495mm |

| Weight | 850kg | 950kg | 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT led production line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB loading machine | Automatically loads bare PCBs to the line. |

| Semi Automatic Stencil Printer Solder | Prints solder paste on PCB pads accurately. |

| Hybrid PCB Chip Mounter | Mounts components onto PCBs precisely. |

| china lead-free reflow oven | Melts solder to form solid joints. |

| PCB optical inspection | Inspects solder joints and placement defects. |

| SMT AOI SPI machine | Checks solder paste height and quality. |

| PCB 2d code laser marking machine | Records and tracks production data. |

| Electric Fixture Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB V-groove cutter | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and Soldering robots for efficient SMT assembly. |

| Customer Success Video

I.C.T recently completed overseas installation and FAT support for two complete SMT lines at a leading North American beauty instrument manufacturer. Our engineers successfully deployed and optimized laser marking machines, SMT printers with the I.C.T-S510 3D SPI Solder Paste Inspection Machine, Panasonic placement machines, Heller reflow ovens, AOI systems, conveyors, PCBA cleaning machines, and automatic solder paste storage units. The entire line passed strict factory acceptance testing on the first run, proving once again that I.C.T delivers turnkey solutions that work perfectly from day one.

| Professional Global Training & Support

I.C.T provides complete lifecycle support including on-site installation, professional training, fast spare parts supply, remote diagnostics, and regular process optimization visits anywhere in the world. Our global service team and 8 branch offices ensure response times are measured in hours, not days, so your 3D SPI Solder Paste Inspection Machine stays at peak performance with zero worries.

| Customer Praise

Customers repeatedly praise our engineers for their expertise and quick problem-solving during installation and after-sales support. They love the outstanding detection accuracy of the I.C.T-S510, the careful export packaging that arrives damage-free every time, and our lightning-fast response whenever help is needed.

| Our Certification

| Our Certification

I.C.T holds CE, RoHS, ISO9001 certifications and numerous patents on 3D measurement technology. Every 3D SPI Solder Paste Inspection Machine is built and tested under strict quality management systems to guarantee safety, environmental compliance, and long-term reliability.

| About Us and Factory

Established in 2012, I.C.T owns full R&D and production facilities covering 12,000 m² with 89 staff including 20 experienced engineers. With over $30 million registered capital and rapid annual growth, we proudly serve more than 1,600 customers across 72 countries. Every factory follows rigorous testing procedures and complete quality management systems to deliver world-class SMT solutions you can trust.

| 3D SPI Solder Paste Inspection Machine

The I.C.T-S510 online 3D SPI Solder Paste Inspection Machine uses advanced PSLM PMP 3D blue light technology to deliver true three-dimensional measurement of solder paste height, volume, area, and shape. Equipped with a 5M-pixel high-speed camera (12M optional) and professional telecentric lens, it completely solves shadow problems and random reflections that affect traditional inspection. With measurement accuracy reaching 0.67μm and repeatability below 1μm, the S510 helps manufacturers catch insufficient paste, bridging, offset, and other critical defects immediately after printing. Ideal for high-speed, high-precision SMT lines, this 3D SPI Solder Paste Inspection Machine supports Gerber import, fast programming under 10 minutes, and standard SPC reporting, making it the perfect choice for modern electronics manufacturing.

| Feature

The I.C.T-S510 features an arch bridge suspension design with one-piece casting structure and dual high-precision servo motors controlling X/Y axes independently. Combined with precision slide rails and closed tank chains, this platform guarantees outstanding stability even during high-speed operation. Vibration is minimized, camera positioning remains accurate, and long-term reliability is ensured – giving you a solid foundation for consistent, repeatable 3D inspection results on every board.

Powered by a 5M-pixel industrial camera and original PSLM (Phase Shift Light Modulation) technology, the vision system projects multi-directional programmable moiré fringes to create accurate 3D reconstructions. All-round adjustable light sources and telecentric optics eliminate color distortion and shadow effects completely. The result is micron-level measurement of height (0-550μm), volume, and shape, even on complex or shiny components, making this one of the most reliable solder paste inspection machines available today.

New programs are created in less than 10 minutes and line changeover takes under 2 minutes. The intuitive Windows 10 interface includes teaching navigation, operation logs, fault analysis, and full SPC reporting. Multi-level user permissions and diagnostic functions keep everything simple and secure, allowing operators of any experience level to achieve maximum efficiency with minimal training.

| Reflow Oven Specification

| Model | I.C.T-S510 | I.C.T-S510D | I.C.T-S1200 |

| PCB Size | 60*50~510*510mm | 50*60~510*310mm Dual rail 50*60~510*580 Single rai | 80*80~1200*500mm |

| PCB Tickness | 0.5 ~ 5.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Manual/automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | W1015*D1195*H1495mm | W1015*D1460*H1495mm | W1840*D1450*H1495mm |

| Weight | 850kg | 950kg | 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT led production line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB loading machine | Automatically loads bare PCBs to the line. |

| Semi Automatic Stencil Printer Solder | Prints solder paste on PCB pads accurately. |

| Hybrid PCB Chip Mounter | Mounts components onto PCBs precisely. |

| china lead-free reflow oven | Melts solder to form solid joints. |

| PCB optical inspection | Inspects solder joints and placement defects. |

| SMT AOI SPI machine | Checks solder paste height and quality. |

| PCB 2d code laser marking machine | Records and tracks production data. |

| Electric Fixture Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB V-groove cutter | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and Soldering robots for efficient SMT assembly. |

| Customer Success Video

I.C.T recently completed overseas installation and FAT support for two complete SMT lines at a leading North American beauty instrument manufacturer. Our engineers successfully deployed and optimized laser marking machines, SMT printers with the I.C.T-S510 3D SPI Solder Paste Inspection Machine, Panasonic placement machines, Heller reflow ovens, AOI systems, conveyors, PCBA cleaning machines, and automatic solder paste storage units. The entire line passed strict factory acceptance testing on the first run, proving once again that I.C.T delivers turnkey solutions that work perfectly from day one.

| Professional Global Training & Support

I.C.T provides complete lifecycle support including on-site installation, professional training, fast spare parts supply, remote diagnostics, and regular process optimization visits anywhere in the world. Our global service team and 8 branch offices ensure response times are measured in hours, not days, so your 3D SPI Solder Paste Inspection Machine stays at peak performance with zero worries.

| Customer Praise

Customers repeatedly praise our engineers for their expertise and quick problem-solving during installation and after-sales support. They love the outstanding detection accuracy of the I.C.T-S510, the careful export packaging that arrives damage-free every time, and our lightning-fast response whenever help is needed.

| Our Certification

| Our Certification

I.C.T holds CE, RoHS, ISO9001 certifications and numerous patents on 3D measurement technology. Every 3D SPI Solder Paste Inspection Machine is built and tested under strict quality management systems to guarantee safety, environmental compliance, and long-term reliability.

| About Us and Factory

Established in 2012, I.C.T owns full R&D and production facilities covering 12,000 m² with 89 staff including 20 experienced engineers. With over $30 million registered capital and rapid annual growth, we proudly serve more than 1,600 customers across 72 countries. Every factory follows rigorous testing procedures and complete quality management systems to deliver world-class SMT solutions you can trust.