Smt Led Module Manufacturing Assembly Line

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| SMT LED Module Production Line

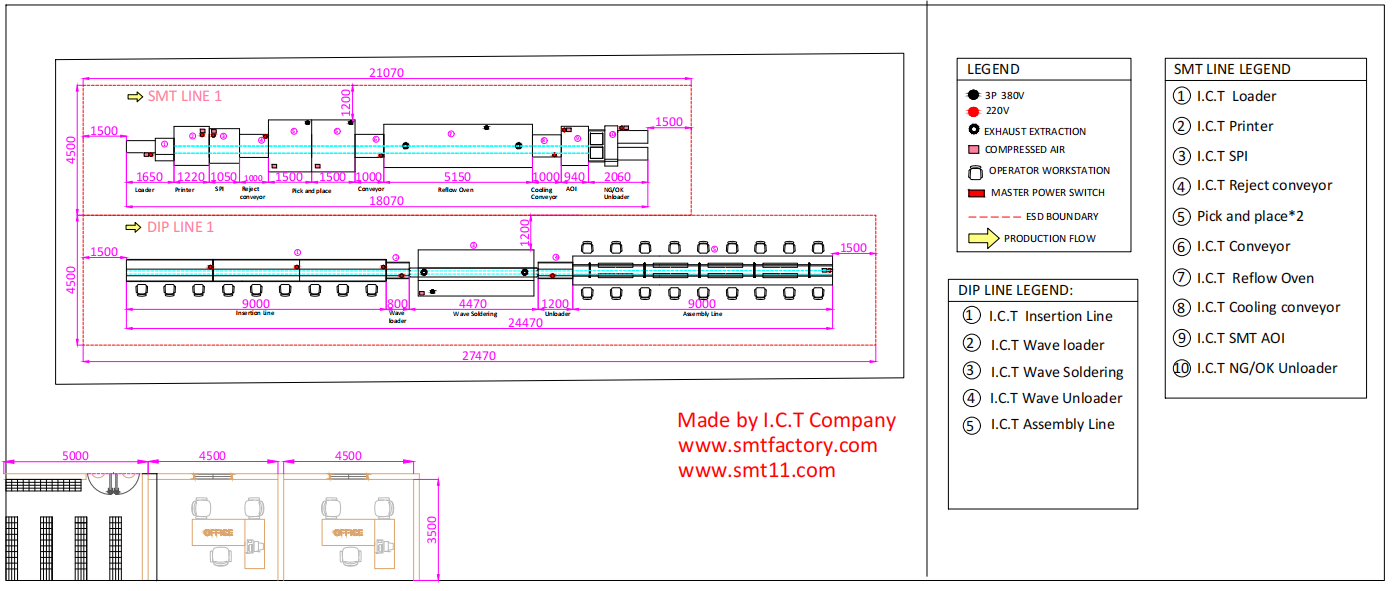

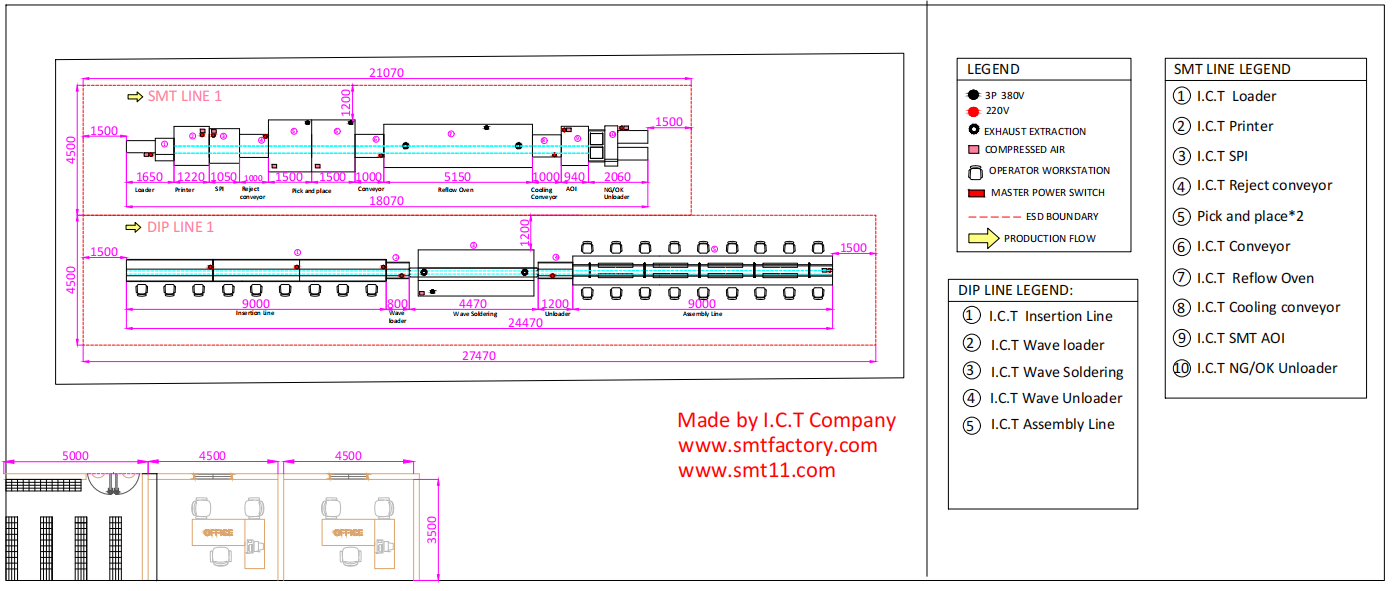

I.C.T brings you a turnkey smt led module Production Line backed by three company-owned factories and over 22 years of real-world SMT experience. We handle everything from factory layout and planning to labor needs and ROI forecasts for LED module makers. Choose semi-auto or full-auto setups with loaders, printers, placers, reflow ovens, AOI, and unloaders. One operator runs the whole shift. Power stays low at 18Kw/H. We help LED display and lighting companies worldwide. Installation takes only 3 days, including air, power, exhaust, lighting, and 23±0.9°C checks. Training lasts 7-15 days covering software, upkeep, safety, and fixes. Our 15-year global service keeps things running. This complete package gets your LED module factory up fast, grows with you, and cuts risk for new or big players in the lighting world with solid support and proven results.

| Detailed Product Features

Seamless Automation Flow

The smt led module Production Line links all machines with smart software for live data and higher yields on LED modules. Loaders take different board sizes. Printers put paste exactly using cameras on LED chips and drivers. Placers drop tiny 01005 parts super fast. Reflow holds ±0.9°C for strong solder. AOI finds problems with AI. Unloaders sort boards. Yields jump over 25% in smt led module manufacturing assembly line. Works for small or big modules. Buffers keep steady pace, remote tools let you watch anywhere, auto recipes switch quick, and tracking watches every part for mix jobs with less stop, full rules, and better speed in big runs.

Accurate Paste System

Printers on the smt led module Production Line lock stencils with super accuracy and fit frames for module sizes. Quick changes cut down time. Auto fill and clean keep prints perfect. 3D checks measure paste to stop early bad prints. This is key for packed LED layouts or fine lines. It handles many paste kinds, low-heat for soft parts. The squeegee changes pressure for even cover on bumpy boards, lifts print quality, drops waste, lets fast design changes in new LED work with steady good, more speed, less fix, and bigger count each shift.

Component Placement Module

Placers in the smt led module Production Line use JUKI power for quick, spot-on LED chip drops on modules. They take 01005 to big parts no problem. Cameras guide every place for no mistakes. Multi-heads push speed to thousands an hour. Feeders reload auto for non-stop work. Software fits module types for easy start. This cuts errors in full LED setups, boosts line speed, handles mix module sizes in one run with simple switch, smart set, and sure repeat for daily high-volume module making.

Reliable Reflow Process

Ovens have 12+ zones with own air flow for even heat in the smt led module Production Line. Nitrogen makes tough joints for LED power or lights. Profiles fit board needs auto. Cooling stops bend in big modules. Heat save gets 18Kw/H. Touch screens hold many profiles. Must for LED last long. Conveyors link software for right speed, easy change, built checks to no stop in long runs, safe hand off, help big make non-stop, and green power.

Smart Inspection Tools

AOI grabs 8K pics fast, spots wrong or solder bad in modules. AI gets smarter from work. It sends fix to placers quick. Drops bad in smt led module Production Line. Gives reports for better ways. Auto bad go side no stop, save info for look and fast fix in many kinds with less down, good track, and auto notes.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality SMT Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

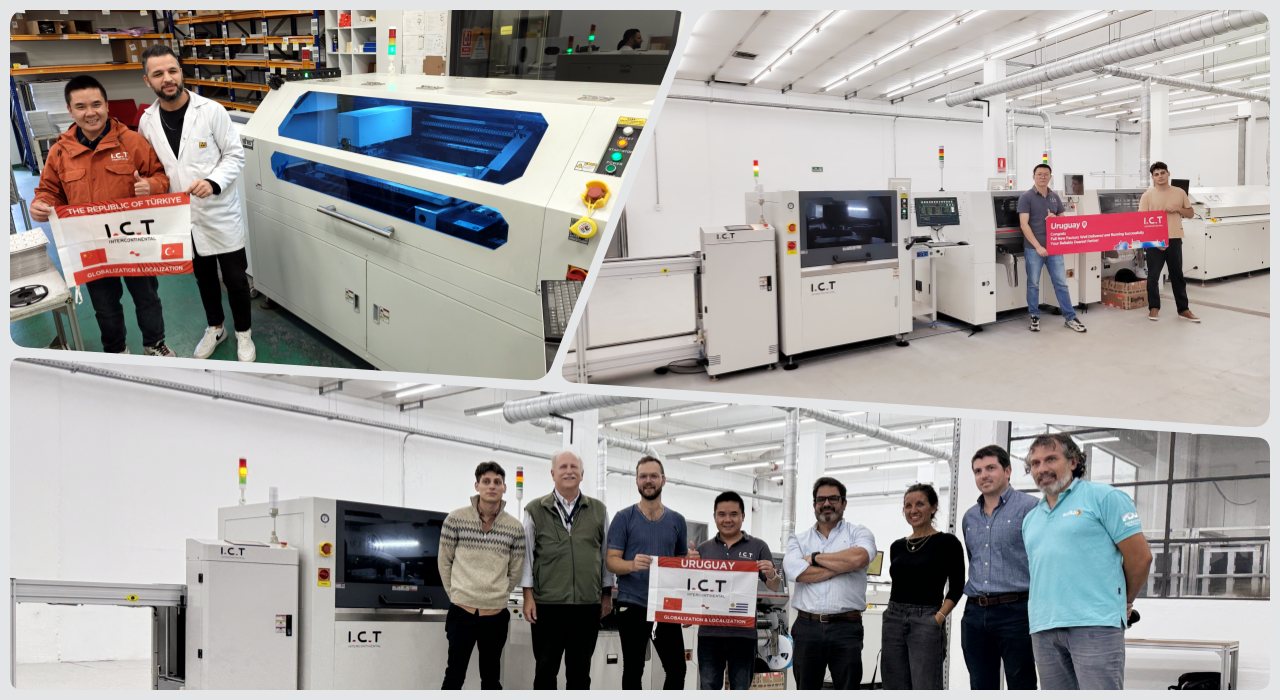

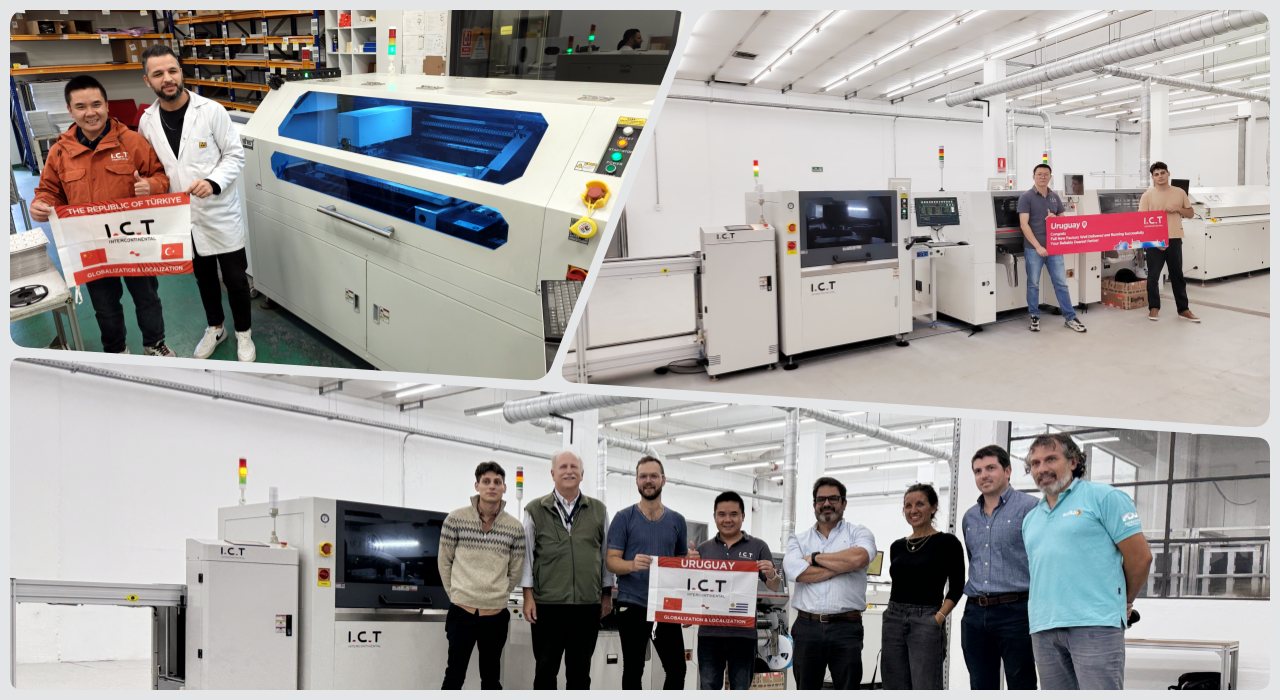

Our Algerian client making phones came to our factory for acceptance test. They brought more than ten PCBs and materials. We ran live production to show how it works. Full-auto printer put paste perfect. SPI checked every spot. RX-8 did small parts fast. RS-1R placed big ones right. Tray feeder gave shields no stop. Reflow soldered strong. AOI found nothing wrong. 5700 cut panels clean. Full run was smooth and quick. This demo shows how smt led module Production Line fits phone or LED work. Client loved speed and quality. They approved boards and plan same line at home.

| End-to-End Support System

I.C.T gives full help for the smt led module Production Line from day one to years later. Our team sets up in 3 days with all checks. Engineers train your people 7-15 days on machines and software. We share upkeep tips, upgrades, and parts fast. Service covers the world with 15 years know-how. Managers fix problems quick by phone or visit. Assistants make sure nothing missed. We help make lines better over time for faster run and less stop. Remote help works instant. Yearly visits keep gear fresh with new tips and changes.

| User Feedback Highlights

Customers like our engineers' quick help overseas for the smt led module Production Line. They say equipment runs steady with little down time. Packing keeps machines safe in ship. Fast answers fix issues in hours. Lines work good with high make every day. Training gets new staff ready quick.

| Quality Standards Met

I.C.T holds CE for safe work, RoHS for no bad stuff, ISO9001 for quality way, and patents for new ideas. These show our smt led module Production Line is good and safe all over world. We test every machine full before send.

| About I.C.T Company and Factory

I.C.T has own R&D and three factories with lots staff and 20 engineers. We grow quick over 25 years and help 1600 clients in 72 countries. Factories big 12000m² with hard tests and quality rules every step. We give full help worldwide for LED. Own make means fast send and good price. Come see our real work any time.

| SMT LED Module Production Line

I.C.T brings you a turnkey smt led module Production Line backed by three company-owned factories and over 22 years of real-world SMT experience. We handle everything from factory layout and planning to labor needs and ROI forecasts for LED module makers. Choose semi-auto or full-auto setups with loaders, printers, placers, reflow ovens, AOI, and unloaders. One operator runs the whole shift. Power stays low at 18Kw/H. We help LED display and lighting companies worldwide. Installation takes only 3 days, including air, power, exhaust, lighting, and 23±0.9°C checks. Training lasts 7-15 days covering software, upkeep, safety, and fixes. Our 15-year global service keeps things running. This complete package gets your LED module factory up fast, grows with you, and cuts risk for new or big players in the lighting world with solid support and proven results.

| Detailed Product Features

Seamless Automation Flow

The smt led module Production Line links all machines with smart software for live data and higher yields on LED modules. Loaders take different board sizes. Printers put paste exactly using cameras on LED chips and drivers. Placers drop tiny 01005 parts super fast. Reflow holds ±0.9°C for strong solder. AOI finds problems with AI. Unloaders sort boards. Yields jump over 25% in smt led module manufacturing assembly line. Works for small or big modules. Buffers keep steady pace, remote tools let you watch anywhere, auto recipes switch quick, and tracking watches every part for mix jobs with less stop, full rules, and better speed in big runs.

Accurate Paste System

Printers on the smt led module Production Line lock stencils with super accuracy and fit frames for module sizes. Quick changes cut down time. Auto fill and clean keep prints perfect. 3D checks measure paste to stop early bad prints. This is key for packed LED layouts or fine lines. It handles many paste kinds, low-heat for soft parts. The squeegee changes pressure for even cover on bumpy boards, lifts print quality, drops waste, lets fast design changes in new LED work with steady good, more speed, less fix, and bigger count each shift.

Component Placement Module

Placers in the smt led module Production Line use JUKI power for quick, spot-on LED chip drops on modules. They take 01005 to big parts no problem. Cameras guide every place for no mistakes. Multi-heads push speed to thousands an hour. Feeders reload auto for non-stop work. Software fits module types for easy start. This cuts errors in full LED setups, boosts line speed, handles mix module sizes in one run with simple switch, smart set, and sure repeat for daily high-volume module making.

Reliable Reflow Process

Ovens have 12+ zones with own air flow for even heat in the smt led module Production Line. Nitrogen makes tough joints for LED power or lights. Profiles fit board needs auto. Cooling stops bend in big modules. Heat save gets 18Kw/H. Touch screens hold many profiles. Must for LED last long. Conveyors link software for right speed, easy change, built checks to no stop in long runs, safe hand off, help big make non-stop, and green power.

Smart Inspection Tools

AOI grabs 8K pics fast, spots wrong or solder bad in modules. AI gets smarter from work. It sends fix to placers quick. Drops bad in smt led module Production Line. Gives reports for better ways. Auto bad go side no stop, save info for look and fast fix in many kinds with less down, good track, and auto notes.

| Factory Layout Requirements

| Category | Projects | Details |

|---|---|---|

| Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

| SMT Line Equipment List

I.C.T High Quality SMT Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| PCB Conveyor | Conveyor transports PCBs during manufacturing. |

| Pick and Place Machine | Mounts components onto PCB precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

| Customer Success Video

Our Algerian client making phones came to our factory for acceptance test. They brought more than ten PCBs and materials. We ran live production to show how it works. Full-auto printer put paste perfect. SPI checked every spot. RX-8 did small parts fast. RS-1R placed big ones right. Tray feeder gave shields no stop. Reflow soldered strong. AOI found nothing wrong. 5700 cut panels clean. Full run was smooth and quick. This demo shows how smt led module Production Line fits phone or LED work. Client loved speed and quality. They approved boards and plan same line at home.

| End-to-End Support System

I.C.T gives full help for the smt led module Production Line from day one to years later. Our team sets up in 3 days with all checks. Engineers train your people 7-15 days on machines and software. We share upkeep tips, upgrades, and parts fast. Service covers the world with 15 years know-how. Managers fix problems quick by phone or visit. Assistants make sure nothing missed. We help make lines better over time for faster run and less stop. Remote help works instant. Yearly visits keep gear fresh with new tips and changes.

| User Feedback Highlights

Customers like our engineers' quick help overseas for the smt led module Production Line. They say equipment runs steady with little down time. Packing keeps machines safe in ship. Fast answers fix issues in hours. Lines work good with high make every day. Training gets new staff ready quick.

| Quality Standards Met

I.C.T holds CE for safe work, RoHS for no bad stuff, ISO9001 for quality way, and patents for new ideas. These show our smt led module Production Line is good and safe all over world. We test every machine full before send.

| About I.C.T Company and Factory

I.C.T has own R&D and three factories with lots staff and 20 engineers. We grow quick over 25 years and help 1600 clients in 72 countries. Factories big 12000m² with hard tests and quality rules every step. We give full help worldwide for LED. Own make means fast send and good price. Come see our real work any time.