I.C.T-7900

I.C.T

X-RAY machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T X-7900 PCB X-ray Inspection Machine

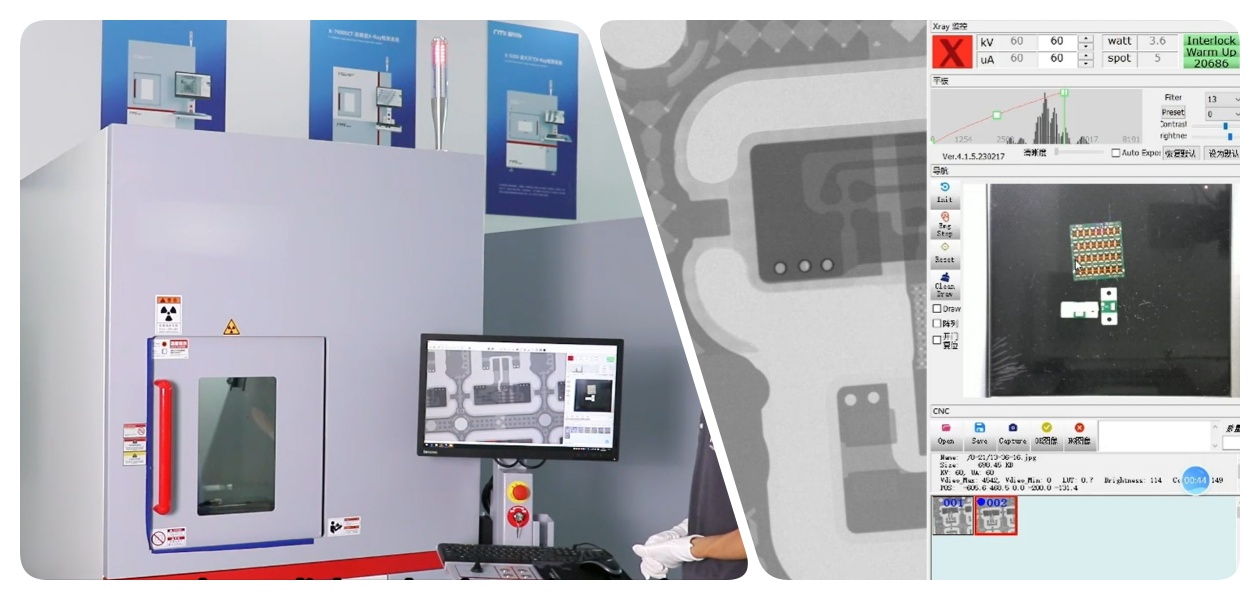

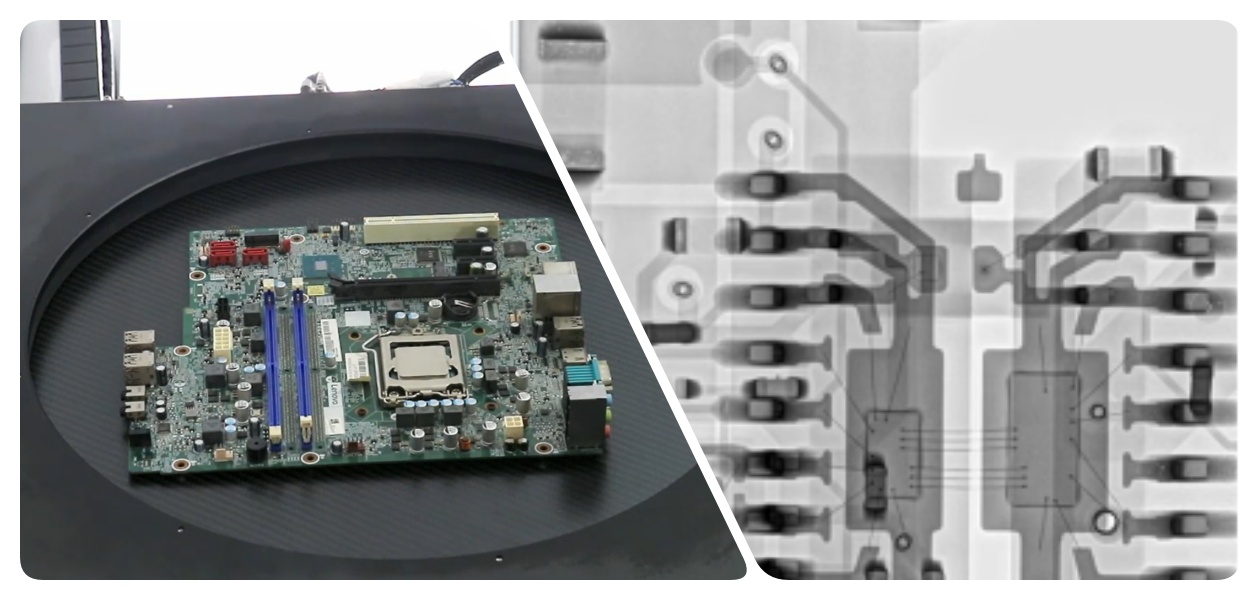

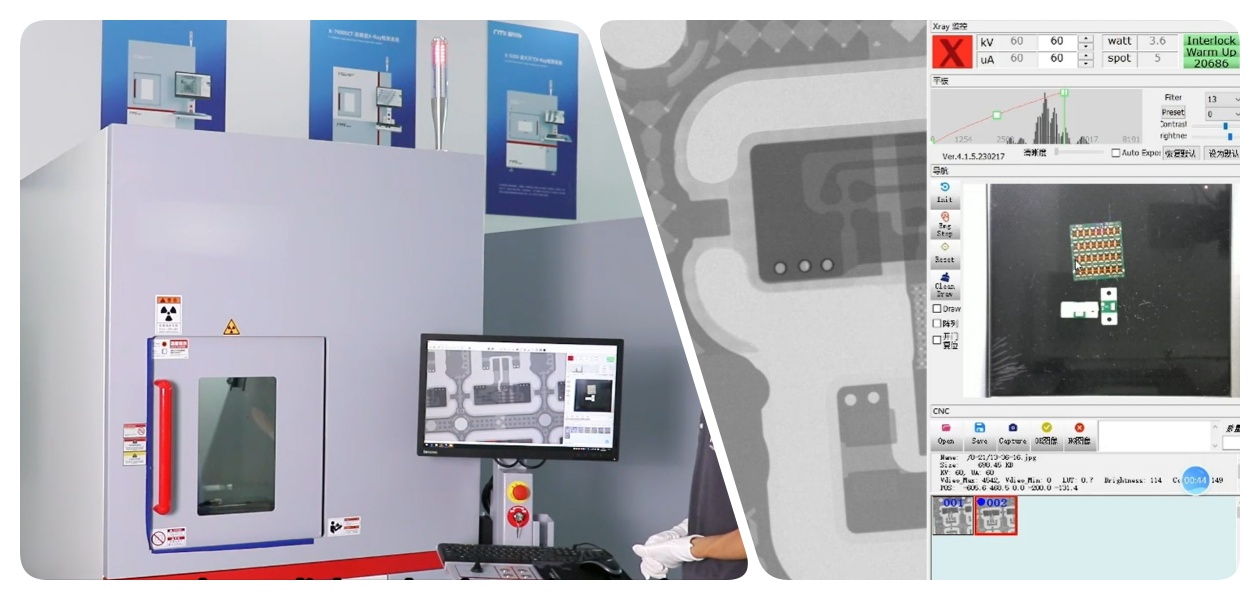

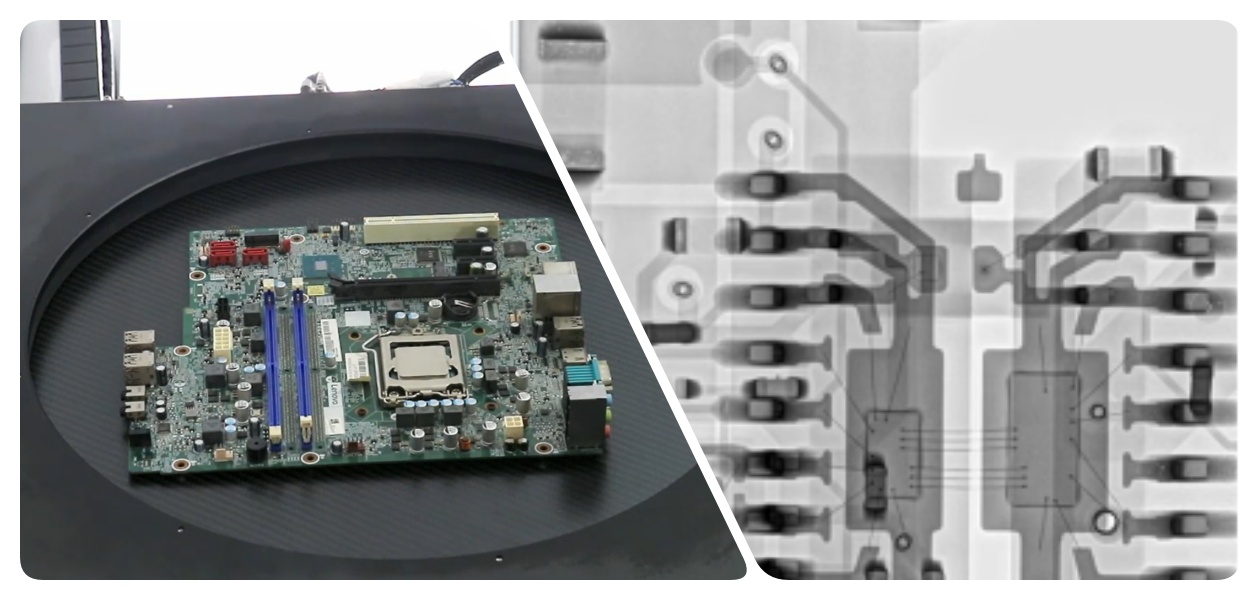

The I.C.T X-7900 is a high-performance offline PCB Xray Inspection SMT Machine built for modern SMT factories. It quickly reveals BGA voids, cold joints, cracks, missing solder, wire-bonding issues, and internal contaminants that normal AOI can’t see. With 1000× system magnification, 60° tilt observation, one-click void analysis, and full CNC programming, operators get crystal-clear, repeatable results with almost no training. This pcb xray inspection machine stays ultra-safe at <1 µSv/h and carries CE, ISO9001, and RoHS certifications.

| Feature

At the core of this PCB Xray Inspection SMT Machine is a high-resolution 1536×1536 digital flat-panel detector plus a premium Hamamatsu closed X-ray tube from Japan. Real-time correction and adjustable gain deliver razor-sharp images of tiny solder balls and gold wires. Built-in cooling and temperature monitoring keep everything stable during long runs. SMT engineers love how this Smt Pcb Xray Inspection Machine turns complex internal checks into simple, reliable decisions every shift.

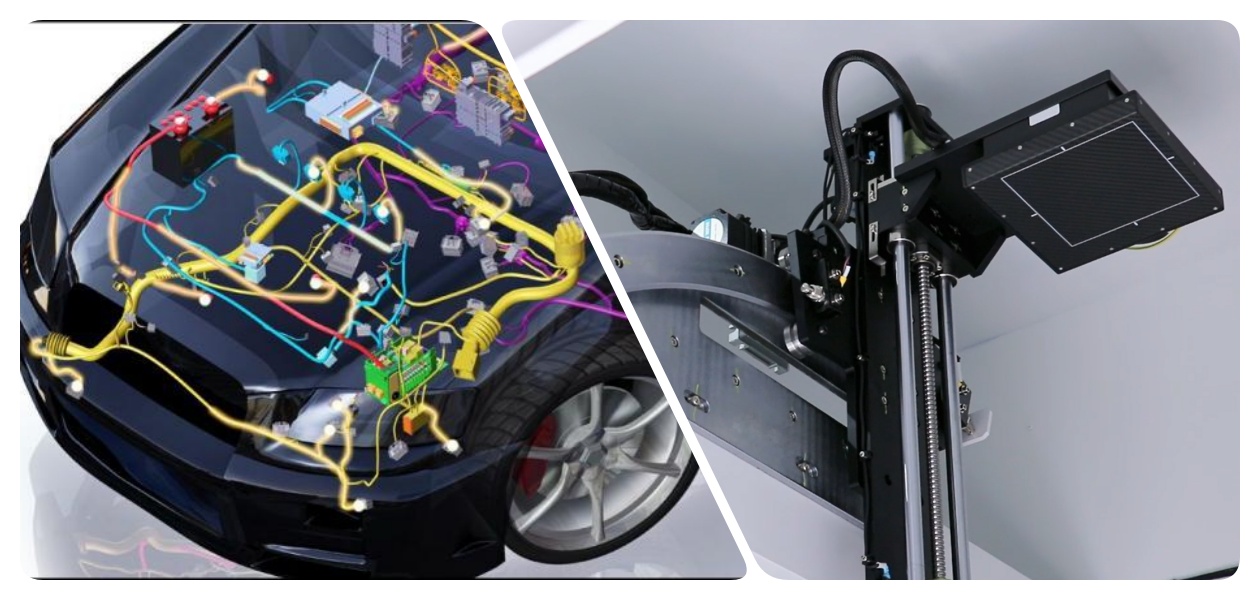

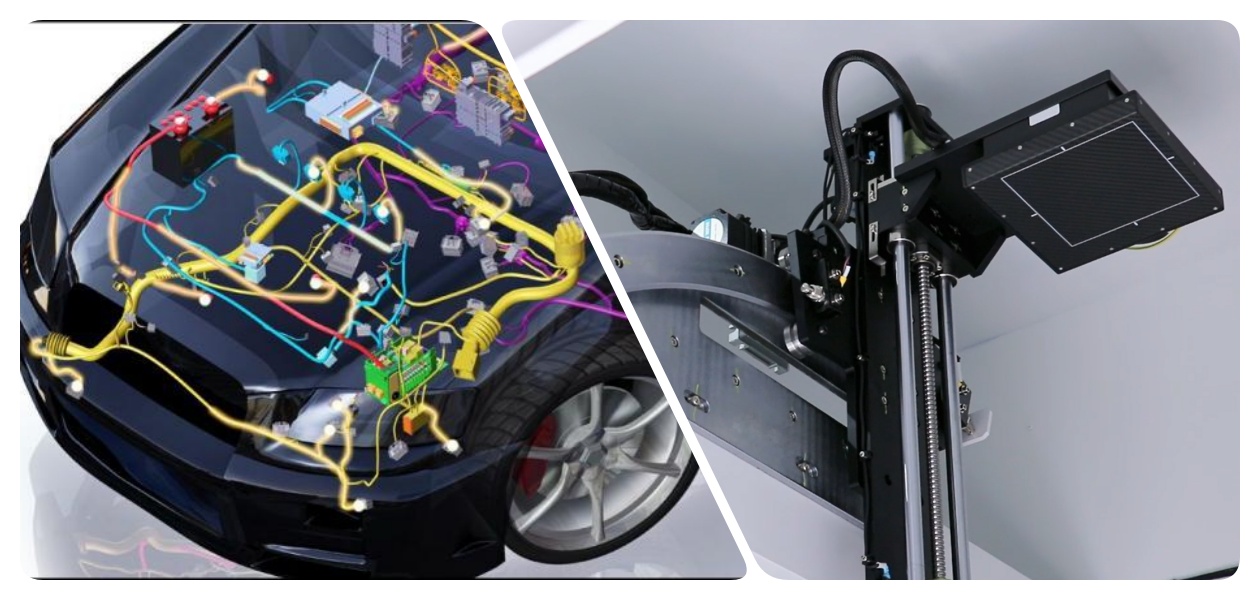

Set it once and watch the PCB Xray Inspection SMT Machine scan hundreds of boards automatically using CNC paths or array mode. Mouse-click programming, anti-collision protection, and smooth X-Y-Z movement make setup a breeze. The 60° tilting detector catches defects from every angle. Perfect for high-volume PCBA, lithium battery, automotive, and LED lines that demand speed and zero escapes. This pcb xray inspection machine boosts throughput without sacrificing accuracy..

Just hit one button and the PCB Xray Inspection SMT Machine instantly calculates bubble size, void rate, and solder climb height. Color simulation makes problems pop on screen so operators spot issues in seconds. Combined with intuitive joystick control and visual navigation, it turns tough quality checks into fast pass/fail calls. Factories worldwide trust this Smt Pcb Xray Inspection Machine to meet strict IPC standards every day.

| Specification

| Item | Model | I.C.T X-7900 |

| X-Ray Tube | Type | Enclosed reflective target microfocus X-ray source |

| Voltage | 130kV | |

| Electric current | 300uA | |

| Focal spot size | 3μm | |

| Maximum input power | 39W | |

| X-ray beam angle (cone) | 105 degree | |

| Distance from focus to object | 10mm | |

| Flat panel | Imaging area | 160mm*160mm |

| Photosensitive unit size | 85μm | |

| Resolution | 1644*1648px | |

| Detector tilt angle | 0-60° | |

| Image frame rate (1×1) | 30fps | |

| Platform | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | 10kg | |

| Platform rotation | 360° platform rotation (Optional) | |

| Machine | Inner lead sheet | 5mm thick lead plate (isolation radiation) |

| Dimension | 1110mm(L)*1350mm(W)*2000mm(H) | |

| Weight | 1050KG | |

| Computer | 24-inch widescreen LCD monitor/I5 processor/4G memory/250G hard disk | |

| Power | AC110/220V, 10A, 1300W |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T turnkey SMT production line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT magazine loader | Automatically loads bare PCBs to the line. |

| SMT Stencil Printer Solder | Prints solder paste on PCB pads accurately. |

| PCB Pick n Place Machine | Mounts components onto PCBs precisely. |

| Reflow circuit board oven | Melts solder to form solid joints. |

| AOI for SMT line | Inspects solder joints and placement defects. |

| SMT SPI machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| PCB Stencil Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB V-groove cutting machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: PCBA laser marking machines/Label Mounter/Inkjet Printer |

| Customer Success Story

Our video walks you through the sleek exterior design and key selling points of the I.C.T X-7900 PCB Xray Inspection SMT Machine. It opens the doors to reveal the premium Hamamatsu tube and digital detector inside. Then it shows live operation: automatic batch scanning of PCBA boards, instant void measurement, smooth 60° tilt views of BGA joints, and crystal-clear imaging in real factory conditions. Customers see exactly how fast and easy defect detection becomes.

| Professional Training & Support

I.C.T delivers complete support for every PCB Xray Inspection SMT Machine. Our engineers handle professional on-site installation, detailed operator training, and fast calibration. 24/7 spare parts, remote diagnostics, and free lifetime software updates keep downtime near zero. Regular maintenance plans and global service centers guarantee your machine runs like new for years. We make sure you get maximum value from day one.

| Customer Praise

Customers keep telling us how much they love our quick-response engineers and rock-solid equipment. They praise the sharp images, easy operation, bullet-proof export packing, and lightning-fast technical support of the PCB Xray Inspection SMT Machine. Many say our friendly service and reliable performance turned them into long-term I.C.T partners. Five-star reviews keep coming in!

| Our Certification

Every I.C.T PCB Xray Inspection SMT Machine carries CE, RoHS, ISO9001, AERB radiation certification, and multiple innovation patents. These globally respected marks prove our dedication to safety, environmental care, and cutting-edge technology. Factories in Europe, USA, and Asia accept them without question when approving new equipment for their SMT lines.

| About I.C.T and Our Factory

Since 2012, I.C.T has grown rapidly with our own 12,000 m² R&D and manufacturing campus in Dongguan, China. Nearly 90 team members and 20 engineers design, build, and rigorously test every machine under strict quality systems. We already power over 1,600 customers in 72 countries with complete SMT solutions. Partner with I.C.T and join a proven global leader focused on your success.

| I.C.T X-7900 PCB X-ray Inspection Machine

The I.C.T X-7900 is a high-performance offline PCB Xray Inspection SMT Machine built for modern SMT factories. It quickly reveals BGA voids, cold joints, cracks, missing solder, wire-bonding issues, and internal contaminants that normal AOI can’t see. With 1000× system magnification, 60° tilt observation, one-click void analysis, and full CNC programming, operators get crystal-clear, repeatable results with almost no training. This pcb xray inspection machine stays ultra-safe at <1 µSv/h and carries CE, ISO9001, and RoHS certifications.

| Feature

At the core of this PCB Xray Inspection SMT Machine is a high-resolution 1536×1536 digital flat-panel detector plus a premium Hamamatsu closed X-ray tube from Japan. Real-time correction and adjustable gain deliver razor-sharp images of tiny solder balls and gold wires. Built-in cooling and temperature monitoring keep everything stable during long runs. SMT engineers love how this Smt Pcb Xray Inspection Machine turns complex internal checks into simple, reliable decisions every shift.

Set it once and watch the PCB Xray Inspection SMT Machine scan hundreds of boards automatically using CNC paths or array mode. Mouse-click programming, anti-collision protection, and smooth X-Y-Z movement make setup a breeze. The 60° tilting detector catches defects from every angle. Perfect for high-volume PCBA, lithium battery, automotive, and LED lines that demand speed and zero escapes. This pcb xray inspection machine boosts throughput without sacrificing accuracy..

Just hit one button and the PCB Xray Inspection SMT Machine instantly calculates bubble size, void rate, and solder climb height. Color simulation makes problems pop on screen so operators spot issues in seconds. Combined with intuitive joystick control and visual navigation, it turns tough quality checks into fast pass/fail calls. Factories worldwide trust this Smt Pcb Xray Inspection Machine to meet strict IPC standards every day.

| Specification

| Item | Model | I.C.T X-7900 |

| X-Ray Tube | Type | Enclosed reflective target microfocus X-ray source |

| Voltage | 130kV | |

| Electric current | 300uA | |

| Focal spot size | 3μm | |

| Maximum input power | 39W | |

| X-ray beam angle (cone) | 105 degree | |

| Distance from focus to object | 10mm | |

| Flat panel | Imaging area | 160mm*160mm |

| Photosensitive unit size | 85μm | |

| Resolution | 1644*1648px | |

| Detector tilt angle | 0-60° | |

| Image frame rate (1×1) | 30fps | |

| Platform | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | 10kg | |

| Platform rotation | 360° platform rotation (Optional) | |

| Machine | Inner lead sheet | 5mm thick lead plate (isolation radiation) |

| Dimension | 1110mm(L)*1350mm(W)*2000mm(H) | |

| Weight | 1050KG | |

| Computer | 24-inch widescreen LCD monitor/I5 processor/4G memory/250G hard disk | |

| Power | AC110/220V, 10A, 1300W |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

I.C.T turnkey SMT production line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT magazine loader | Automatically loads bare PCBs to the line. |

| SMT Stencil Printer Solder | Prints solder paste on PCB pads accurately. |

| PCB Pick n Place Machine | Mounts components onto PCBs precisely. |

| Reflow circuit board oven | Melts solder to form solid joints. |

| AOI for SMT line | Inspects solder joints and placement defects. |

| SMT SPI machine | Checks solder paste height and quality. |

Inspects internal solder joint integrity and detects hidden defects. | |

| PCB Stencil Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB V-groove cutting machine | Cut the PCBA into the final product |

| Traceability Equipment | Records and tracks production data: PCBA laser marking machines/Label Mounter/Inkjet Printer |

| Customer Success Story

Our video walks you through the sleek exterior design and key selling points of the I.C.T X-7900 PCB Xray Inspection SMT Machine. It opens the doors to reveal the premium Hamamatsu tube and digital detector inside. Then it shows live operation: automatic batch scanning of PCBA boards, instant void measurement, smooth 60° tilt views of BGA joints, and crystal-clear imaging in real factory conditions. Customers see exactly how fast and easy defect detection becomes.

| Professional Training & Support

I.C.T delivers complete support for every PCB Xray Inspection SMT Machine. Our engineers handle professional on-site installation, detailed operator training, and fast calibration. 24/7 spare parts, remote diagnostics, and free lifetime software updates keep downtime near zero. Regular maintenance plans and global service centers guarantee your machine runs like new for years. We make sure you get maximum value from day one.

| Customer Praise

Customers keep telling us how much they love our quick-response engineers and rock-solid equipment. They praise the sharp images, easy operation, bullet-proof export packing, and lightning-fast technical support of the PCB Xray Inspection SMT Machine. Many say our friendly service and reliable performance turned them into long-term I.C.T partners. Five-star reviews keep coming in!

| Our Certification

Every I.C.T PCB Xray Inspection SMT Machine carries CE, RoHS, ISO9001, AERB radiation certification, and multiple innovation patents. These globally respected marks prove our dedication to safety, environmental care, and cutting-edge technology. Factories in Europe, USA, and Asia accept them without question when approving new equipment for their SMT lines.

| About I.C.T and Our Factory

Since 2012, I.C.T has grown rapidly with our own 12,000 m² R&D and manufacturing campus in Dongguan, China. Nearly 90 team members and 20 engineers design, build, and rigorously test every machine under strict quality systems. We already power over 1,600 customers in 72 countries with complete SMT solutions. Partner with I.C.T and join a proven global leader focused on your success.