I.C.T-W2

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| W-Series Lead-Free Dual Wave Soldering Machine

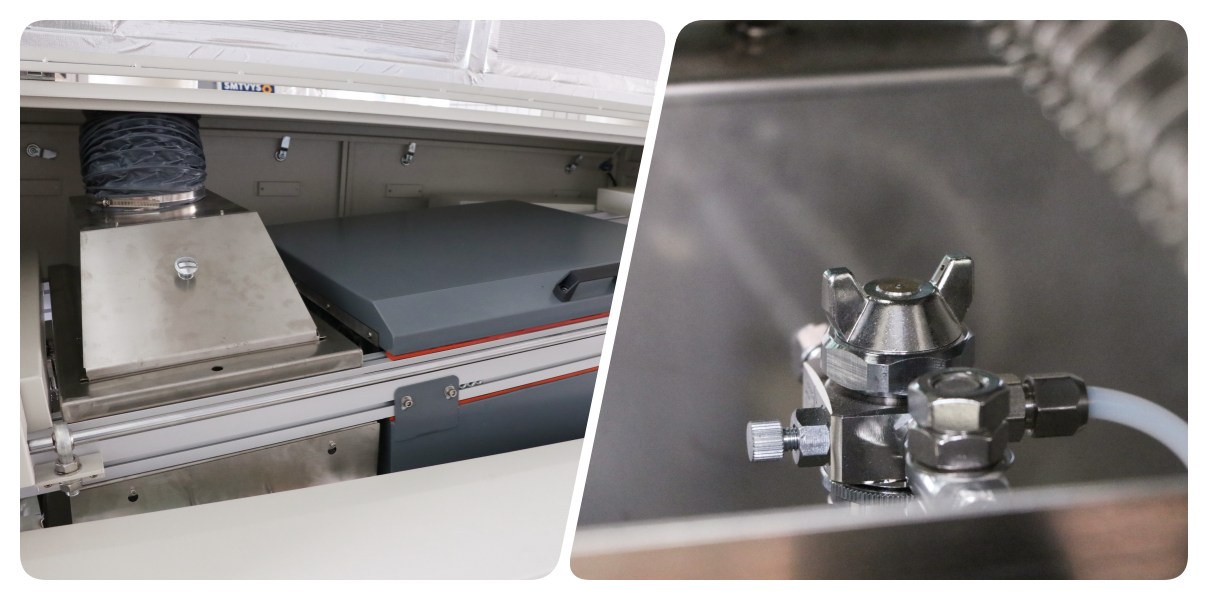

The W-Series Lead-Free Dual Wave Soldering Machine from I.C.T is a mature product, refined through extensive market testing and trusted by customers worldwide. This DIP Dual Wave Soldering Equipment excels with its dual-wave technology, offering precise soldering for complex PCBs while maintaining superior heating performance and temperature control.

With a maximum PCB size of 400mm, a solder pot capacity of 180kg, and a transmission height of 750±20mm, it is ideal for lead-free DIP dual wave soldering. Its energy-saving design reduces costs, and it complies with CE, CCC, and UL standards. I.C.T provides global installation, maintenance, and training, ensuring optimal performance for your production line.

| Feature

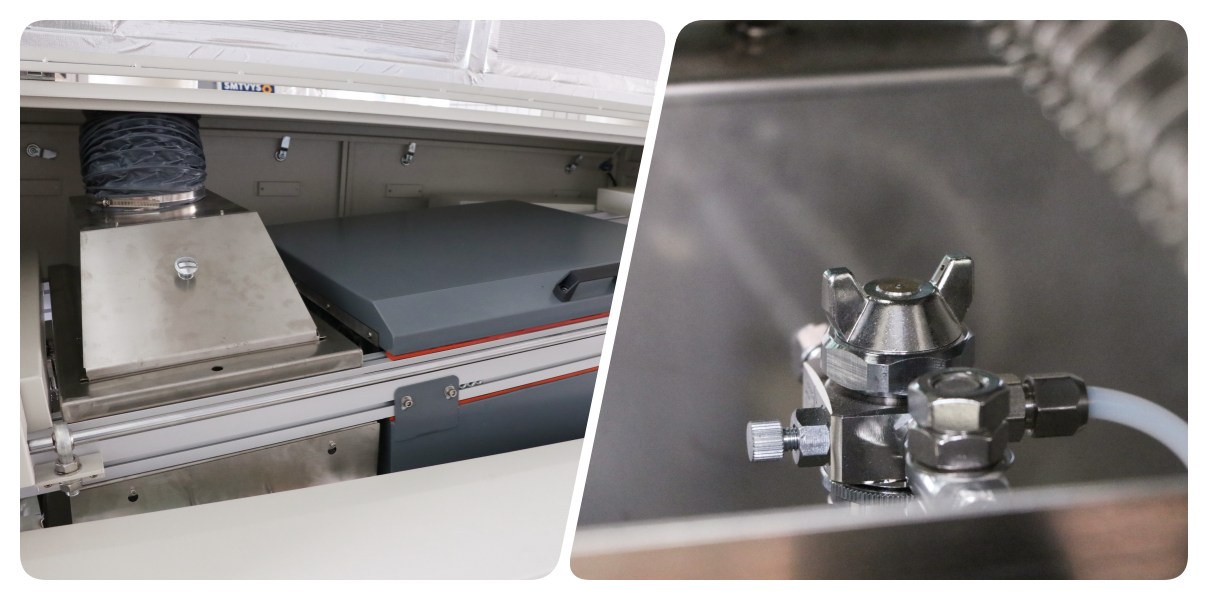

Equipped with Japan Kuroda nozzles, this Lead-free DIP Dual Wave Soldering system offers adjustable atomization for uniform and reliable spray. PLC control allows precise management of spray time, speed, and FLUX flow, with digital settings for flow and width that can be recorded. This system minimizes waste and supports eco-friendly operations.

The Dual Wave Soldering Machine features a unique dual-wave system, enabling precise soldering for through-hole and surface-mount components. This design ensures high-quality joints on complex PCBs, making it an excellent choice for dip soldering machine applications. The adjustable waves adapt to various board sizes, enhancing versatility and efficiency in production.

Safety is prioritized with third-party over-temperature protection and multiple safety layers, ensuring secure operation of the DIP Dual Wave Soldering Equipment. The horizontal heating design prevents interference between zones, providing a stable temperature curve, which is critical for sensitive electronic assemblies.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

n 2024, two I.C.T engineers traveled to Uruguay to assist a smart meter manufacturer, as featured in a video with positive customer feedback. The video showcases equipment including board loaders, placement machines 471 and 481, Lyra622, AOI, corner conveyors, W2 Dual Wave Soldering Machine, junction stations, material frame belt lines, roller lines, and bullseye workbenches. Clients praised the engineers’ expertise and the machine’s reliable performance, noting improved production efficiency for smart meters.

| Expert Services and Training

I.C.T offers extensive services and training for the Dual Wave Soldering Machine, including installation, maintenance, and operational guidance. Our global network of engineers, spanning 72 countries, provides on-site support and customized training to maximize efficiency. With 25 years of experience and a team of 20 engineers, we deliver technical upgrades and process optimizations. Based in our 12,000m² Dongguan facility, we ensure timely assistance, making I.C.T a reliable partner for Lead-free DIP Dual Wave Soldering needs.

| Customer Testimonials

Customers highly value I.C.T engineers for their professional skills and quick responses, especially during overseas support in Uruguay. The Dual Wave Soldering Machine is praised for its consistent welding quality and efficiency, a key asset for dip soldering machine tasks. Our sturdy packaging ensures safe delivery, while our rapid response to technical issues—often resolved within hours—earns high marks. Clients appreciate our innovative solutions and view I.C.T as a trusted partner in global electronics manufacturing.

| Quality Certifications

I.C.T’s Dual Wave Soldering Machine holds CE, RoHS, ISO9001, and multiple patents, reflecting compliance with global safety and quality standards. These certifications, validated in our advanced 12,000m² factory, ensure the reliability of DIP Dual Wave Soldering Equipment. Our patented technologies enhance durability and performance, giving customers confidence in choosing I.C.T for their production needs.

| About I.C.T Company and Factory

I.C.T is a leader in electronics manufacturing with in-house R&D and production, employing a large team that has grown rapidly over 25 years. Serving over 1,600 clients across 72 countries, our 12,000m² industrial park in Dongguan features strict quality control and a robust management system, producing top-tier Dual Wave Soldering Machine units. With eight branch offices and a $30 million registered fund, we deliver innovative solutions globally. Our commitment to excellence supports clients from setup to optimization, making I.C.T a trusted name in the industry.

| W-Series Lead-Free Dual Wave Soldering Machine

The W-Series Lead-Free Dual Wave Soldering Machine from I.C.T is a mature product, refined through extensive market testing and trusted by customers worldwide. This DIP Dual Wave Soldering Equipment excels with its dual-wave technology, offering precise soldering for complex PCBs while maintaining superior heating performance and temperature control.

With a maximum PCB size of 400mm, a solder pot capacity of 180kg, and a transmission height of 750±20mm, it is ideal for lead-free DIP dual wave soldering. Its energy-saving design reduces costs, and it complies with CE, CCC, and UL standards. I.C.T provides global installation, maintenance, and training, ensuring optimal performance for your production line.

| Feature

Equipped with Japan Kuroda nozzles, this Lead-free DIP Dual Wave Soldering system offers adjustable atomization for uniform and reliable spray. PLC control allows precise management of spray time, speed, and FLUX flow, with digital settings for flow and width that can be recorded. This system minimizes waste and supports eco-friendly operations.

The Dual Wave Soldering Machine features a unique dual-wave system, enabling precise soldering for through-hole and surface-mount components. This design ensures high-quality joints on complex PCBs, making it an excellent choice for dip soldering machine applications. The adjustable waves adapt to various board sizes, enhancing versatility and efficiency in production.

Safety is prioritized with third-party over-temperature protection and multiple safety layers, ensuring secure operation of the DIP Dual Wave Soldering Equipment. The horizontal heating design prevents interference between zones, providing a stable temperature curve, which is critical for sensitive electronic assemblies.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

n 2024, two I.C.T engineers traveled to Uruguay to assist a smart meter manufacturer, as featured in a video with positive customer feedback. The video showcases equipment including board loaders, placement machines 471 and 481, Lyra622, AOI, corner conveyors, W2 Dual Wave Soldering Machine, junction stations, material frame belt lines, roller lines, and bullseye workbenches. Clients praised the engineers’ expertise and the machine’s reliable performance, noting improved production efficiency for smart meters.

| Expert Services and Training

I.C.T offers extensive services and training for the Dual Wave Soldering Machine, including installation, maintenance, and operational guidance. Our global network of engineers, spanning 72 countries, provides on-site support and customized training to maximize efficiency. With 25 years of experience and a team of 20 engineers, we deliver technical upgrades and process optimizations. Based in our 12,000m² Dongguan facility, we ensure timely assistance, making I.C.T a reliable partner for Lead-free DIP Dual Wave Soldering needs.

| Customer Testimonials

Customers highly value I.C.T engineers for their professional skills and quick responses, especially during overseas support in Uruguay. The Dual Wave Soldering Machine is praised for its consistent welding quality and efficiency, a key asset for dip soldering machine tasks. Our sturdy packaging ensures safe delivery, while our rapid response to technical issues—often resolved within hours—earns high marks. Clients appreciate our innovative solutions and view I.C.T as a trusted partner in global electronics manufacturing.

| Quality Certifications

I.C.T’s Dual Wave Soldering Machine holds CE, RoHS, ISO9001, and multiple patents, reflecting compliance with global safety and quality standards. These certifications, validated in our advanced 12,000m² factory, ensure the reliability of DIP Dual Wave Soldering Equipment. Our patented technologies enhance durability and performance, giving customers confidence in choosing I.C.T for their production needs.

| About I.C.T Company and Factory

I.C.T is a leader in electronics manufacturing with in-house R&D and production, employing a large team that has grown rapidly over 25 years. Serving over 1,600 clients across 72 countries, our 12,000m² industrial park in Dongguan features strict quality control and a robust management system, producing top-tier Dual Wave Soldering Machine units. With eight branch offices and a $30 million registered fund, we deliver innovative solutions globally. Our commitment to excellence supports clients from setup to optimization, making I.C.T a trusted name in the industry.

FAQ:

Q: What is Dual Wave Soldering Equipment?

A: Dual Wave Soldering Equipment is an advanced solution for electronics manufacturing, known for its precision in soldering through-hole components.

Q: How does Dual Wave Soldering Equipment work?

A: This equipment utilizes innovative technology to create two distinct solder waves, ensuring exceptional soldering quality in the manufacturing process.

Q: What sets Dual Wave Soldering Equipment apart from others?

A: Dual Wave Soldering Equipment is distinguished by its cutting-edge dual-wave technology, precise temperature control, and comprehensive quality assurance measures.

Q: Can Dual Wave Soldering Equipment handle a variety of PCB sizes?

A: Yes, it offers versatility, accommodating various PCB sizes to meet different manufacturing needs.

FAQ:

Q: What is Dual Wave Soldering Equipment?

A: Dual Wave Soldering Equipment is an advanced solution for electronics manufacturing, known for its precision in soldering through-hole components.

Q: How does Dual Wave Soldering Equipment work?

A: This equipment utilizes innovative technology to create two distinct solder waves, ensuring exceptional soldering quality in the manufacturing process.

Q: What sets Dual Wave Soldering Equipment apart from others?

A: Dual Wave Soldering Equipment is distinguished by its cutting-edge dual-wave technology, precise temperature control, and comprehensive quality assurance measures.

Q: Can Dual Wave Soldering Equipment handle a variety of PCB sizes?

A: Yes, it offers versatility, accommodating various PCB sizes to meet different manufacturing needs.