I.C.T-SS430

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Off-line Selective Wave Soldering Machine

The Off-line Selective Wave Soldering Machine SS550P1, developed by I.C.T in China, is a top-tier solution for through-hole soldering on PCBs. Ideal for DIP and high-reliability needs like automotive electronics, it keeps PCBs fixed while moving the spray and solder platform for precision.

Full PC control allows saving settings like temperature and flux type, ensuring repeatable results. Its modular design adapts to various layouts, with auto wave calibration and CCD alignment boosting quality. As a PCB Selective Wave Soldering Machine, it’s perfect for small to medium shops. I.C.T’s 26 years of expertise back its global trust and performance.

| DIP Line Equipment List

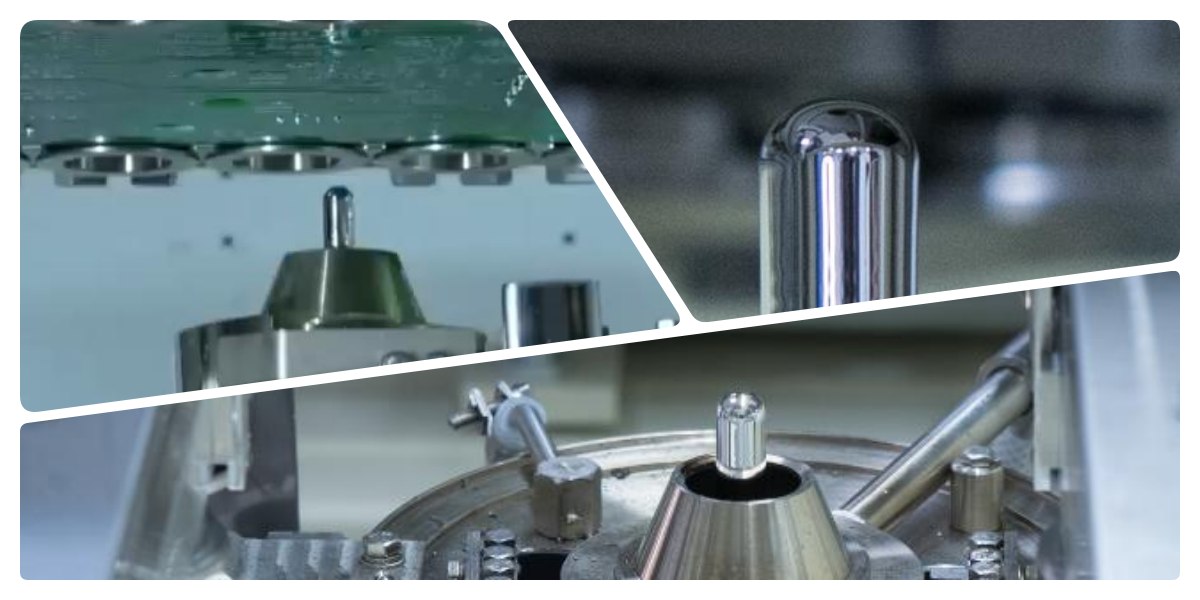

The DIP Selective Wave Soldering Machine features a reliable flux system for accurate application. It uses a German high-frequency pulse valve to spray tiny flux dots with solid content under 10%, minimizing waste. A tray catches residue for easy cleanup, and the nozzle on an XY platform achieves 0.02mm precision. Pressure tanks maintain steady flow, supported by Japanese SMC components. Visible gauges simplify adjustments, making it a go-to for clean, consistent soldering in tight spaces.

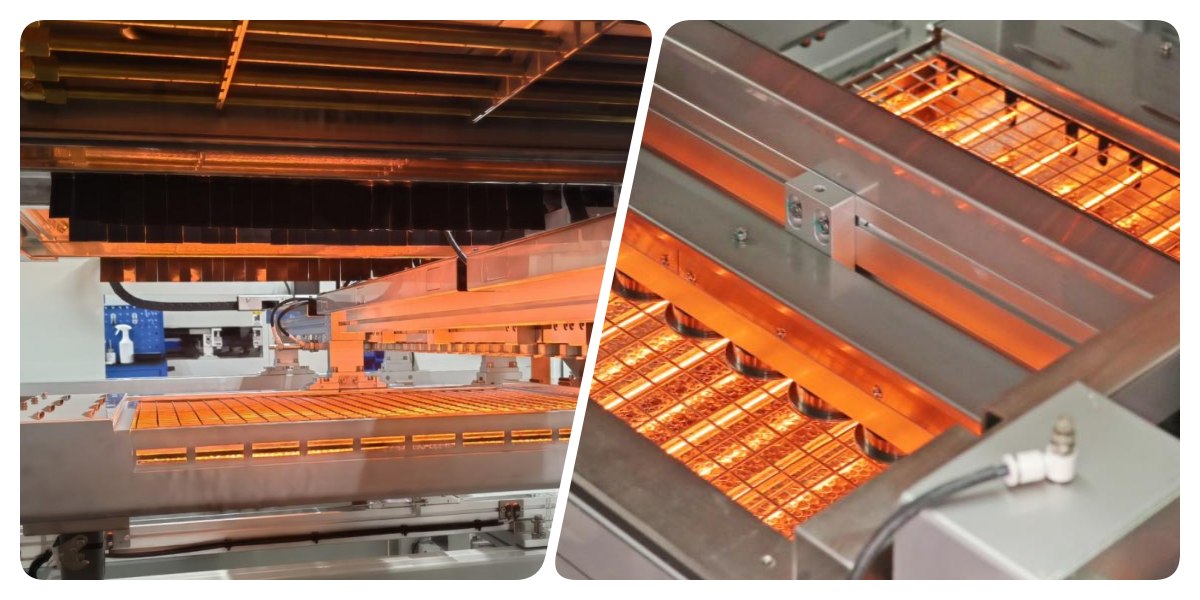

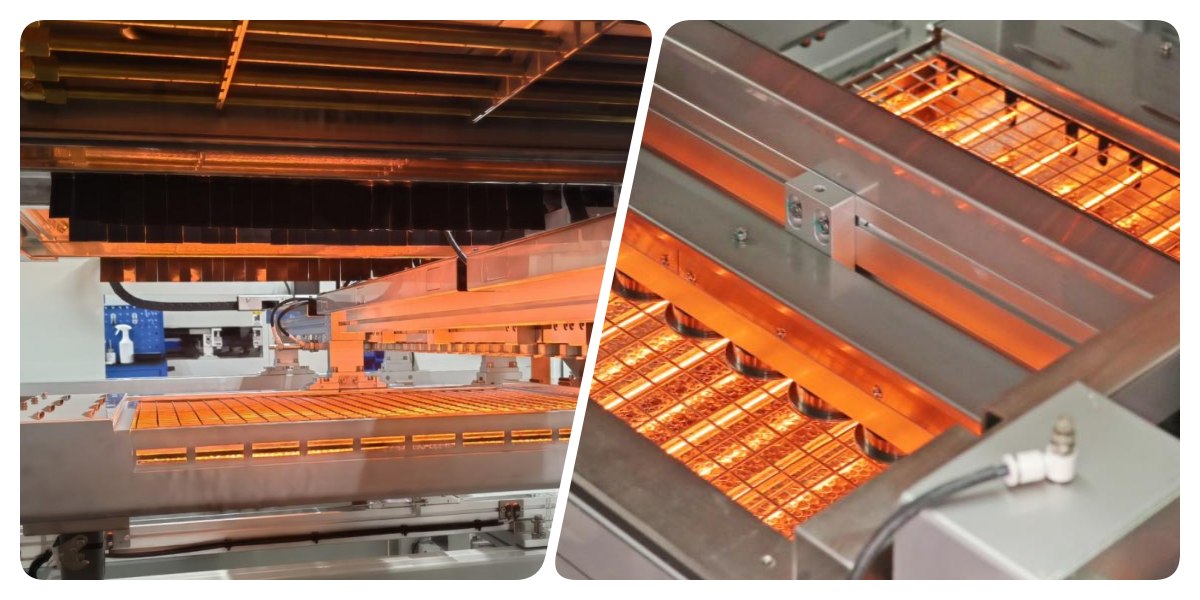

The preheat system in this Off-line Selective Wave Soldering Machine preps boards effectively. It offers adjustable bottom IR heating and top hot air, covering a wide area and reaching 150°C in about 15 minutes. High-temp cotton ensures stable heat, with top-brand parts for durability. The tool-free plug-in design cuts maintenance time. This setup ensures strong welds and reduces errors, ideal for small-scale production.

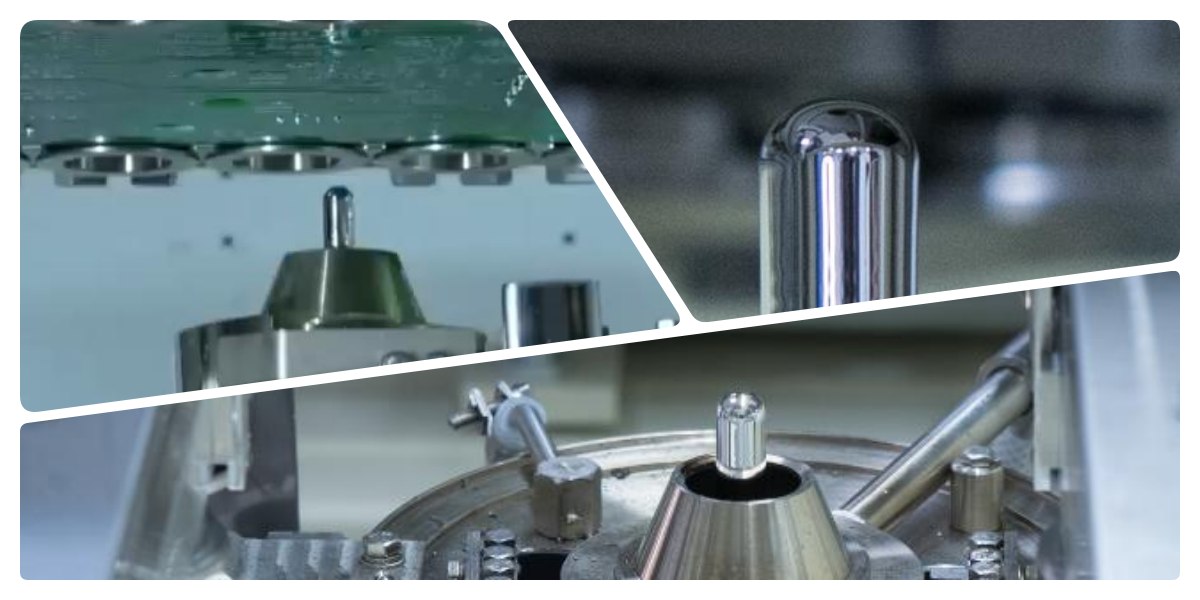

The soldering system excels with advanced features in the PCB Selective Wave Soldering Machine. A Swedish PRECIMETER pump keeps the solder wave stable, with software controlling temps and N2 flow. The stainless steel pot with anti-corrosion coating heats fast with cast iron, while N2 reduces dross for clean joints. It handles complex components, delivering high-quality results for DIP applications.

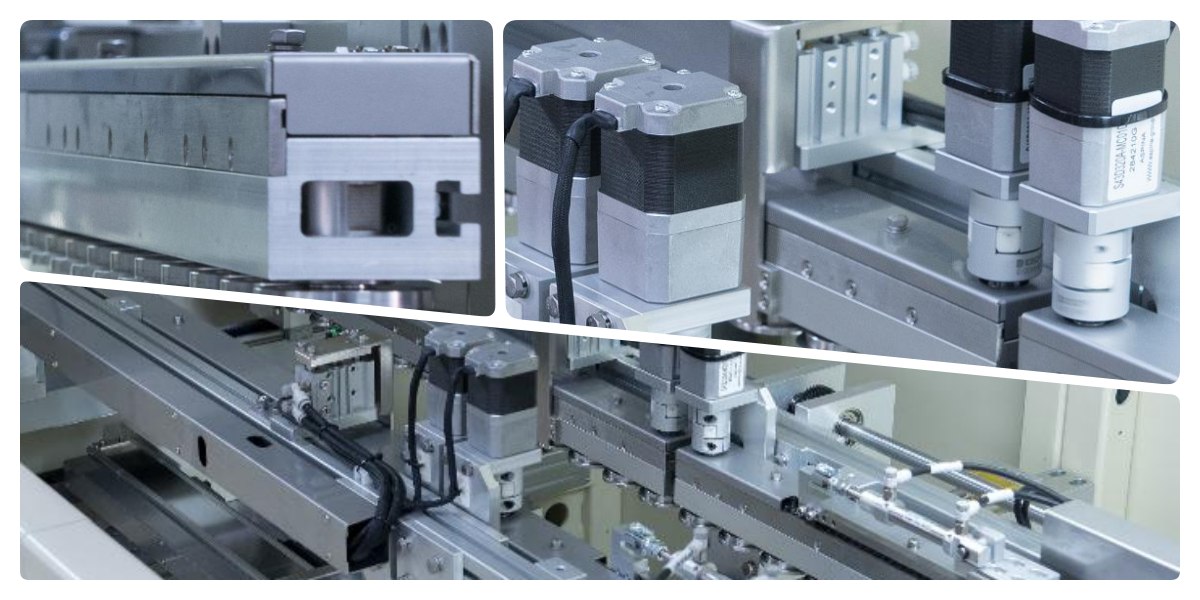

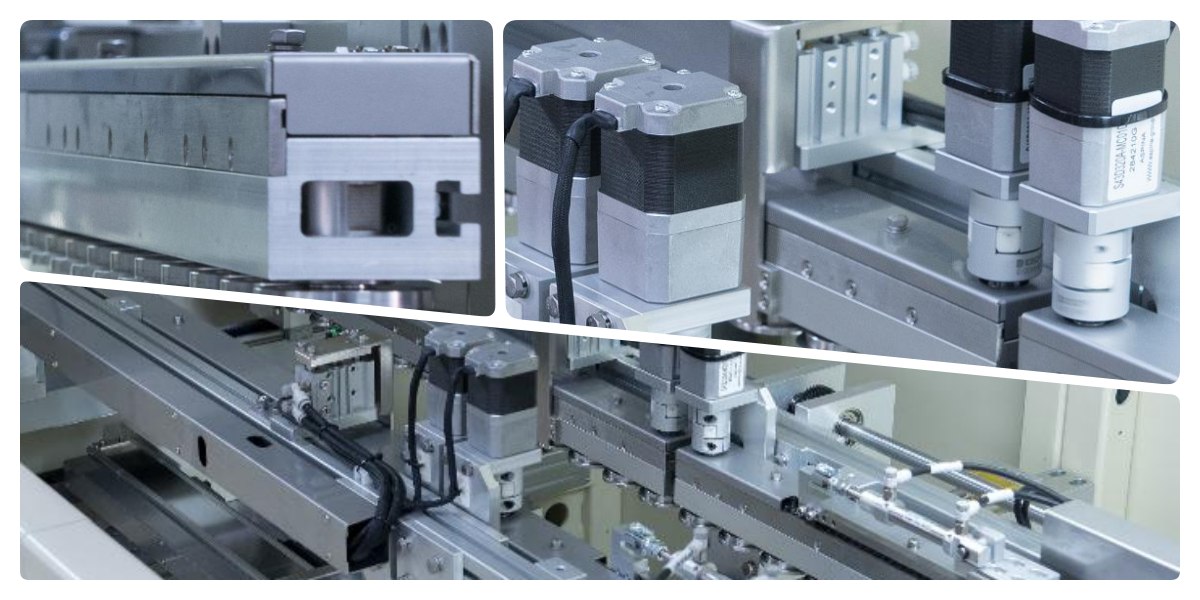

The transmission system ensures smooth PCB handling in this Off-line Selective Wave Soldering Machine. Built with sturdy profiles and rollers, it supports up to 20kg loads with side and top clamps. Japanese motors drive it reliably, fitting modular setups with ease. This compact design suits small workshops, maintaining steady flow for efficient runs.

Control is robust in the DIP Selective Wave Soldering Machine with a Keyence PLC system meeting CE standards. Global parts and Cat-6 cables ensure fast, stable operation, with data tracking for quality checks. It adapts to growing needs, making it a solid choice for small operations seeking precision.

The operating system simplifies use of this Off-line Selective Wave Soldering Machine. Guided CCD programming speeds setup, with picture mode for coordinate verification and real-time monitoring. Choose languages like English or Chinese, with WiFi updates via MES. Data traces each solder point, easing training for new users in compact setups.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2025, I.C.T engineers visited a European client to set up a DIP selective soldering line featuring the JUKI JM100, SS550P1, and OLSR300 machines. The video showcased the full line’s smooth operation, with the Off-line Selective Wave Soldering Machine SS550P1 delivering precise welds. Engineers trained staff and fine-tuned equipment, ensuring seamless production. The client gained confidence in handling high-quality PCB assembly, thanks to I.C.T’s expert support and reliable DIP Selective Wave Soldering Machine performance.

| Professional Service and Training

I.C.T provides comprehensive support for the Off-line Selective Wave Soldering Machine with on-site setup and 24/7 assistance. Our engineers offer training on operation and maintenance, plus remote help to adapt to your needs. With 26 years in SMT, we optimize your line for efficiency. Long-term plans include regular check-ups, ensuring your production stays strong and worry-free.

| Customer Praise

Clients applaud I.C.T engineers for their skilled training and quick fixes on the Off-line Selective Wave Soldering Machine. The machine’s steady soldering and high pass rates impress, with secure packaging ensuring safe delivery. Fast responses to issues keep production on track, earning comments like, "I.C.T’s support is top-notch," building lasting trust.

| Industry Certifications

The Off-line Selective Wave Soldering Machine holds CE, RoHS, and ISO9001 certifications, meeting global safety and quality standards. I.C.T’s patents on wave and flux tech highlight innovation. These credentials assure reliable, eco-friendly equipment you can depend on worldwide.

| About I.C.T Company and Factory

I.C.T leads SMT with in-house R&D and three factories, growing to 89 staff over 26 years. We serve 1600+ clients in 72 countries, offering DIP and PCB solutions with strict testing and quality systems. Our Off-line Selective Wave Soldering Machine fits small spaces, backed by global support. We innovate daily, fostering cross-value partnerships for your factory’s success.

| Off-line Selective Wave Soldering Machine

The Off-line Selective Wave Soldering Machine SS550P1, developed by I.C.T in China, is a top-tier solution for through-hole soldering on PCBs. Ideal for DIP and high-reliability needs like automotive electronics, it keeps PCBs fixed while moving the spray and solder platform for precision.

Full PC control allows saving settings like temperature and flux type, ensuring repeatable results. Its modular design adapts to various layouts, with auto wave calibration and CCD alignment boosting quality. As a PCB Selective Wave Soldering Machine, it’s perfect for small to medium shops. I.C.T’s 26 years of expertise back its global trust and performance.

| DIP Line Equipment List

The DIP Selective Wave Soldering Machine features a reliable flux system for accurate application. It uses a German high-frequency pulse valve to spray tiny flux dots with solid content under 10%, minimizing waste. A tray catches residue for easy cleanup, and the nozzle on an XY platform achieves 0.02mm precision. Pressure tanks maintain steady flow, supported by Japanese SMC components. Visible gauges simplify adjustments, making it a go-to for clean, consistent soldering in tight spaces.

The preheat system in this Off-line Selective Wave Soldering Machine preps boards effectively. It offers adjustable bottom IR heating and top hot air, covering a wide area and reaching 150°C in about 15 minutes. High-temp cotton ensures stable heat, with top-brand parts for durability. The tool-free plug-in design cuts maintenance time. This setup ensures strong welds and reduces errors, ideal for small-scale production.

The soldering system excels with advanced features in the PCB Selective Wave Soldering Machine. A Swedish PRECIMETER pump keeps the solder wave stable, with software controlling temps and N2 flow. The stainless steel pot with anti-corrosion coating heats fast with cast iron, while N2 reduces dross for clean joints. It handles complex components, delivering high-quality results for DIP applications.

The transmission system ensures smooth PCB handling in this Off-line Selective Wave Soldering Machine. Built with sturdy profiles and rollers, it supports up to 20kg loads with side and top clamps. Japanese motors drive it reliably, fitting modular setups with ease. This compact design suits small workshops, maintaining steady flow for efficient runs.

Control is robust in the DIP Selective Wave Soldering Machine with a Keyence PLC system meeting CE standards. Global parts and Cat-6 cables ensure fast, stable operation, with data tracking for quality checks. It adapts to growing needs, making it a solid choice for small operations seeking precision.

The operating system simplifies use of this Off-line Selective Wave Soldering Machine. Guided CCD programming speeds setup, with picture mode for coordinate verification and real-time monitoring. Choose languages like English or Chinese, with WiFi updates via MES. Data traces each solder point, easing training for new users in compact setups.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2025, I.C.T engineers visited a European client to set up a DIP selective soldering line featuring the JUKI JM100, SS550P1, and OLSR300 machines. The video showcased the full line’s smooth operation, with the Off-line Selective Wave Soldering Machine SS550P1 delivering precise welds. Engineers trained staff and fine-tuned equipment, ensuring seamless production. The client gained confidence in handling high-quality PCB assembly, thanks to I.C.T’s expert support and reliable DIP Selective Wave Soldering Machine performance.

| Professional Service and Training

I.C.T provides comprehensive support for the Off-line Selective Wave Soldering Machine with on-site setup and 24/7 assistance. Our engineers offer training on operation and maintenance, plus remote help to adapt to your needs. With 26 years in SMT, we optimize your line for efficiency. Long-term plans include regular check-ups, ensuring your production stays strong and worry-free.

| Customer Praise

Clients applaud I.C.T engineers for their skilled training and quick fixes on the Off-line Selective Wave Soldering Machine. The machine’s steady soldering and high pass rates impress, with secure packaging ensuring safe delivery. Fast responses to issues keep production on track, earning comments like, "I.C.T’s support is top-notch," building lasting trust.

| Industry Certifications

The Off-line Selective Wave Soldering Machine holds CE, RoHS, and ISO9001 certifications, meeting global safety and quality standards. I.C.T’s patents on wave and flux tech highlight innovation. These credentials assure reliable, eco-friendly equipment you can depend on worldwide.

| About I.C.T Company and Factory

I.C.T leads SMT with in-house R&D and three factories, growing to 89 staff over 26 years. We serve 1600+ clients in 72 countries, offering DIP and PCB solutions with strict testing and quality systems. Our Off-line Selective Wave Soldering Machine fits small spaces, backed by global support. We innovate daily, fostering cross-value partnerships for your factory’s success.

FAQ:

Q: What is an Off-line selective Wave Soldering machine?

A: An Off-line selective Wave Soldering machine is a specialized soldering equipment designed for precise soldering of specific components or areas on printed circuit boards (PCBs). It offers controlled soldering solutions, ensuring high-quality results.

Q: How does an Off-line selective Wave Soldering machine differ from other soldering methods?

A: Off-line selective Wave Soldering machines, unlike traditional wave soldering, target specific soldering areas or components on a PCB with precision. This results in reduced solder defects and improved quality control, making it an ideal choice for complex assembly tasks.

Q: What are the benefits of using an Off-line selective Wave Soldering machine in electronics manufacturing?

A: Off-line selective Wave Soldering machines provide advantages such as enhanced soldering precision, reduced rework, and the ability to solder sensitive components accurately. These benefits contribute to improved manufacturing efficiency and product quality.

FAQ:

Q: What is an Off-line selective Wave Soldering machine?

A: An Off-line selective Wave Soldering machine is a specialized soldering equipment designed for precise soldering of specific components or areas on printed circuit boards (PCBs). It offers controlled soldering solutions, ensuring high-quality results.

Q: How does an Off-line selective Wave Soldering machine differ from other soldering methods?

A: Off-line selective Wave Soldering machines, unlike traditional wave soldering, target specific soldering areas or components on a PCB with precision. This results in reduced solder defects and improved quality control, making it an ideal choice for complex assembly tasks.

Q: What are the benefits of using an Off-line selective Wave Soldering machine in electronics manufacturing?

A: Off-line selective Wave Soldering machines provide advantages such as enhanced soldering precision, reduced rework, and the ability to solder sensitive components accurately. These benefits contribute to improved manufacturing efficiency and product quality.