I.C.T DIP Inverted Camera Online AOI AI-4540 enhances PCB quality control after THT soldering with precise defect detection and minimal downtime.

a. Spots defects in components fast.

b. Applies deep learning for smart judgments.

c. Checks boards without halting lines.

d. Simple programming with quick setups.

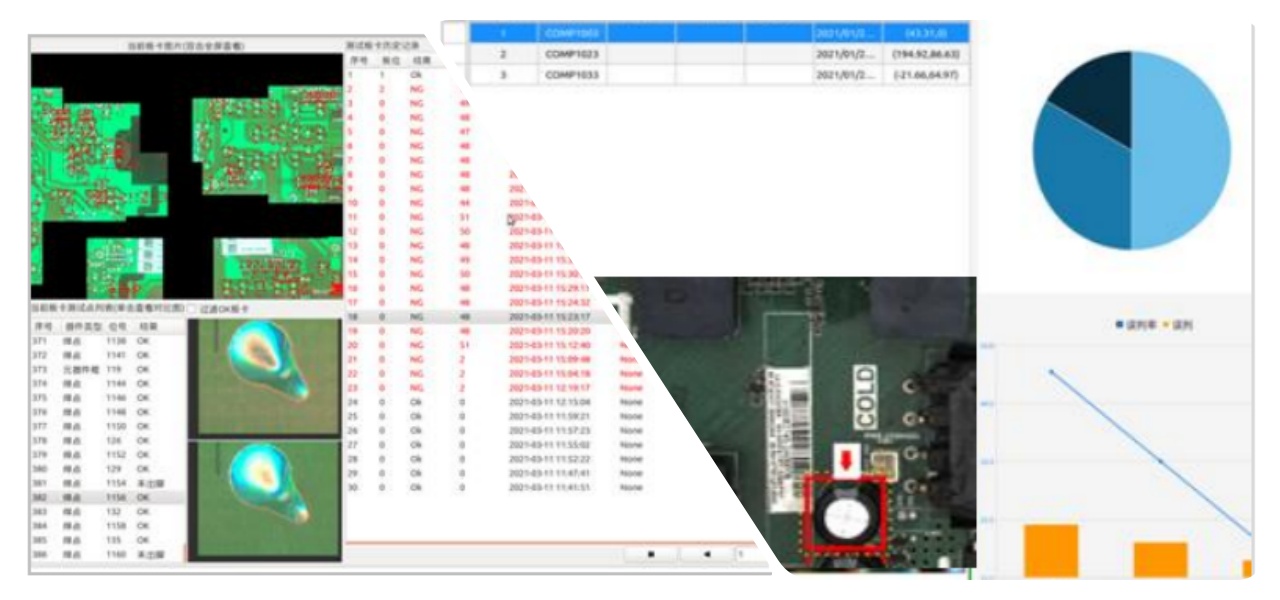

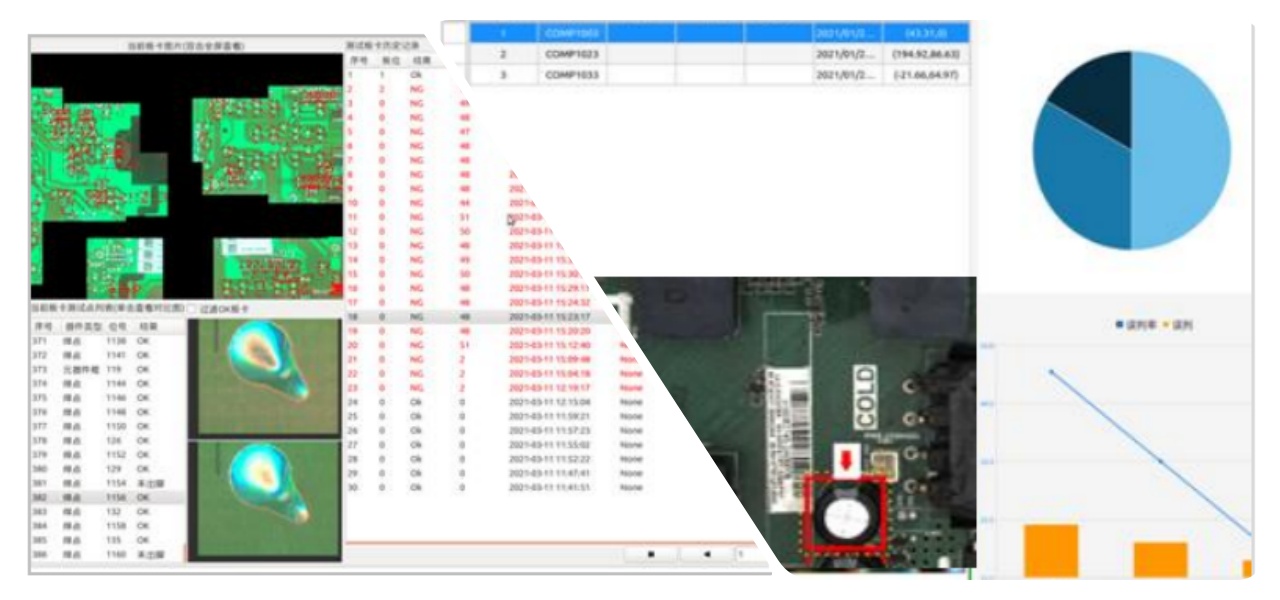

e. Enables remote management and data tracking.

f. Fits various PCB sizes easily.

g. Integrates with factory systems smoothly.

I.C.T- AI-4026

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Discover AI-4540 AOI Machines

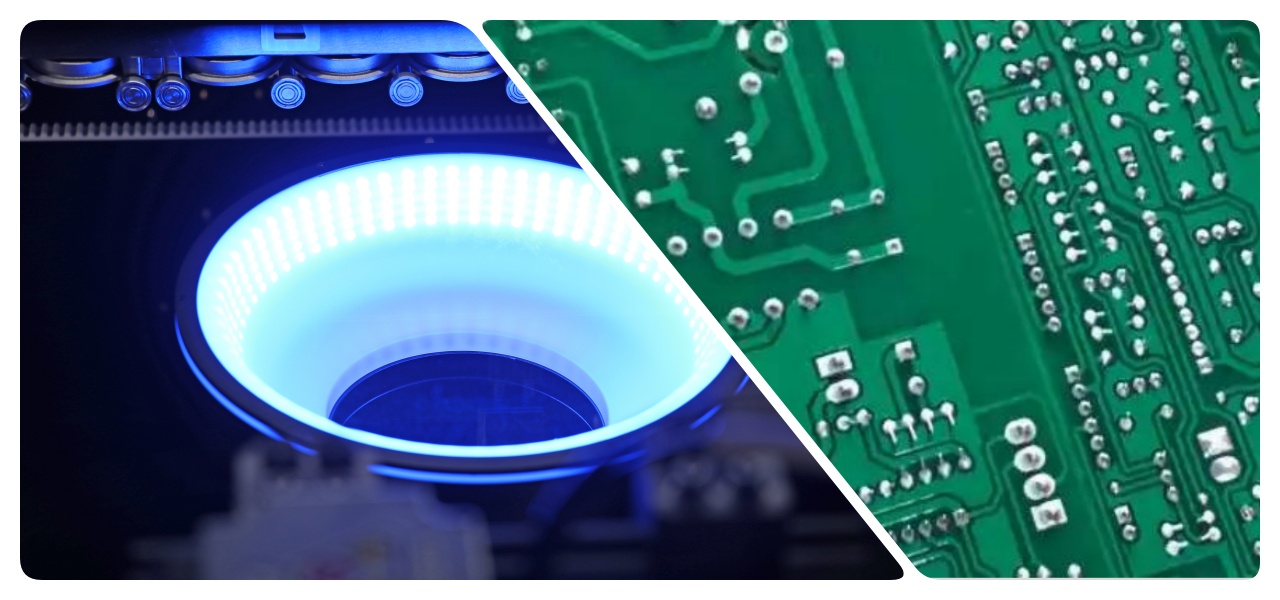

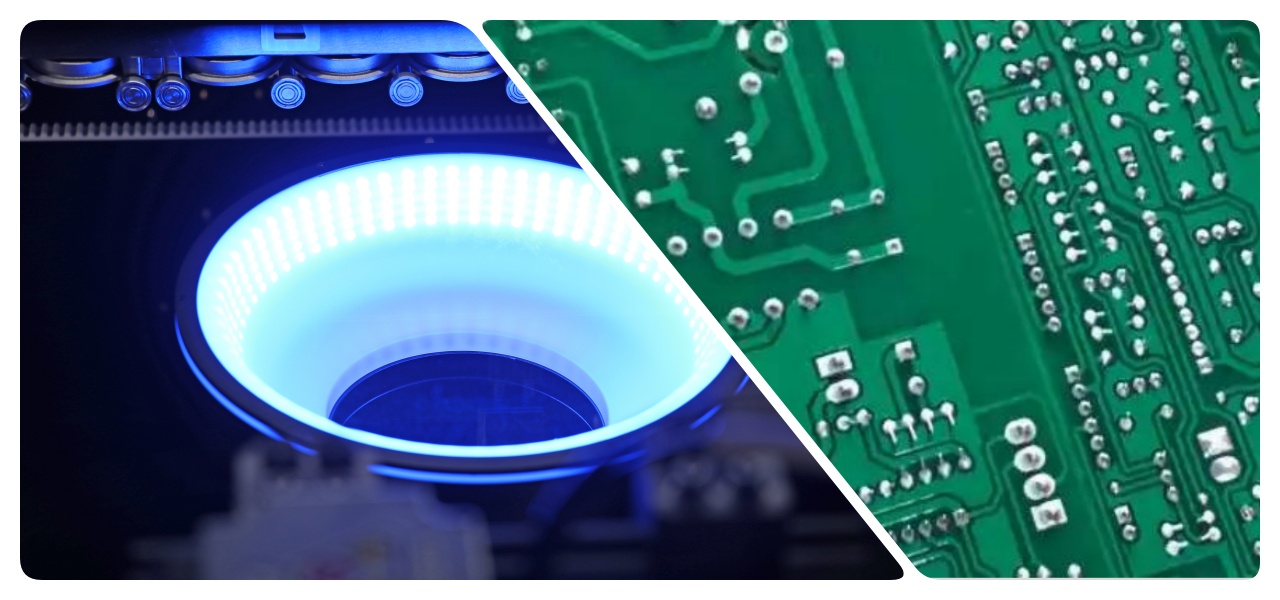

The I.C.T DIP Inverted Camera Online AOI AI-4540 is an advanced inspection tool for PCBA after THT soldering. It captures real-time images using a high-precision color camera and processes them with Convolution Neural Network (CNN) algorithms to detect defects intelligently. This automatic pcb aoi machine identifies issues like wrong parts, missing components, reverse polarity, and solder defects such as bridges, voids, or insufficient solder in elements like resistors, capacitors, diodes, and sockets. With high detection rates and low false alarms, it installs over production lines without modifications, allowing continuous operation. Easy to adjust in height and width, it supports central control for multiple units. Data traceability includes SPC alarms, automatic log storage, NG warnings, and remote programming. This boosts factory efficiency and quality in SMT processes.

| Feature

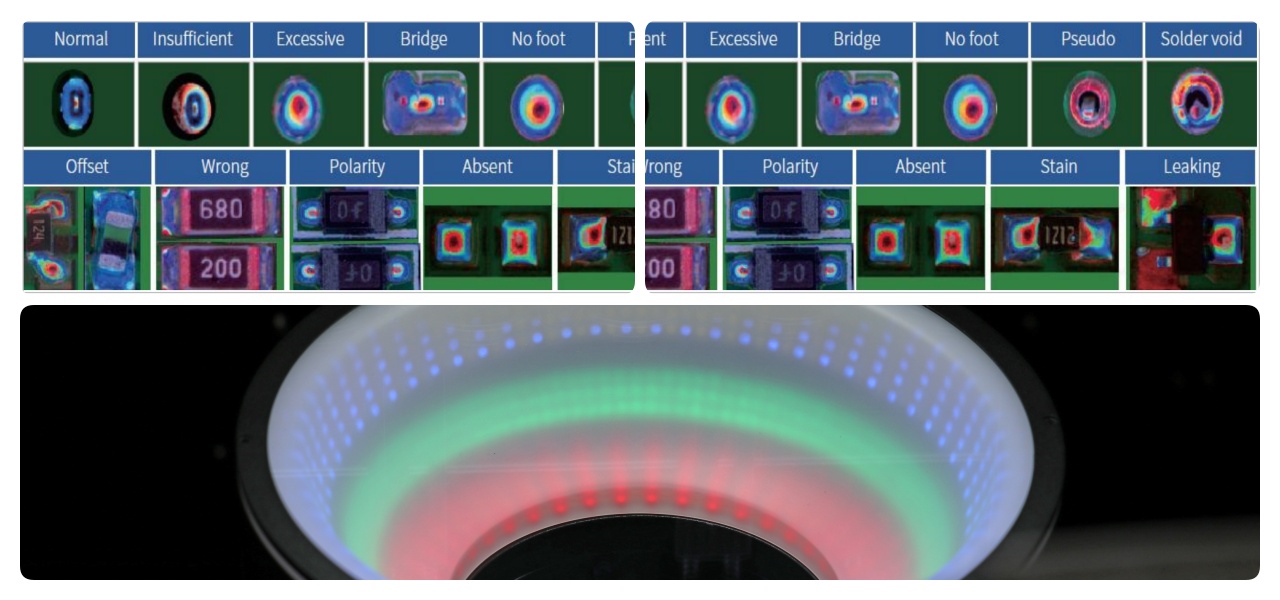

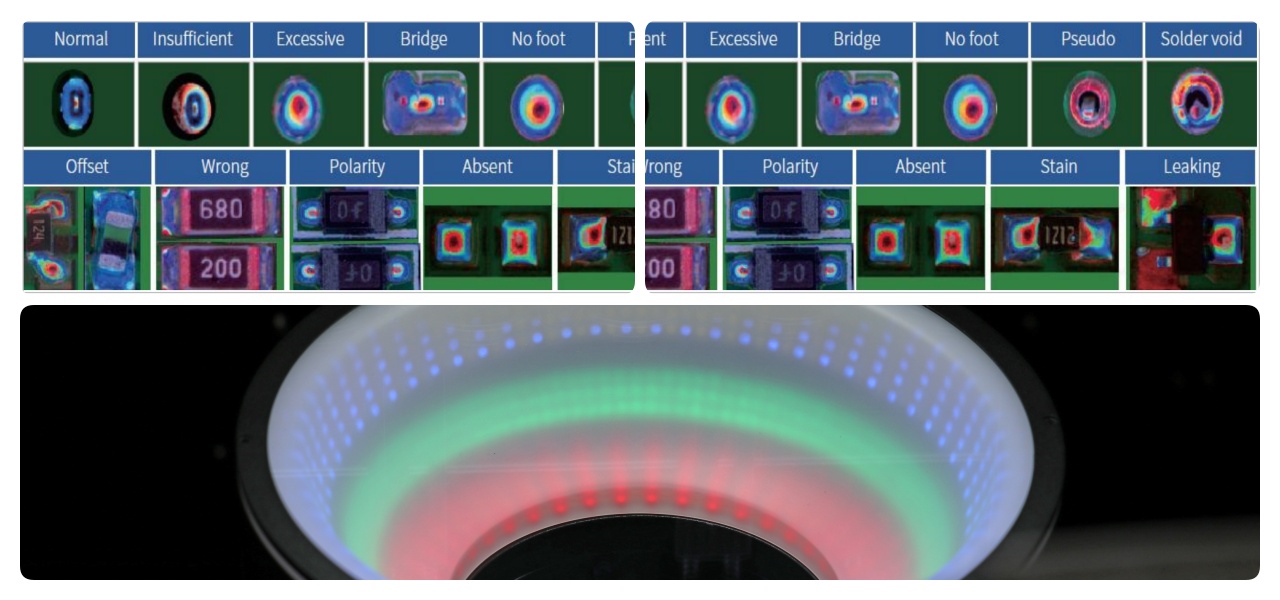

AI-4540 aoi machines use deep learning with big data optimization for industrial checks. It identifies components and solder joints automatically with one-click, cutting long programming times and high false alarms from traditional methods. Trained on large datasets, it handles bottom-side variations after wave soldering, ensuring no missed defects. It reduces false calls from overhanging parts or slight color differences. CNN mimics human-like judgment for diverse scenarios, like detecting fuzzy pin holes in solder without pin or device interference. This leads to strong generalization, high accuracy, and reliable inspections for complex boards.

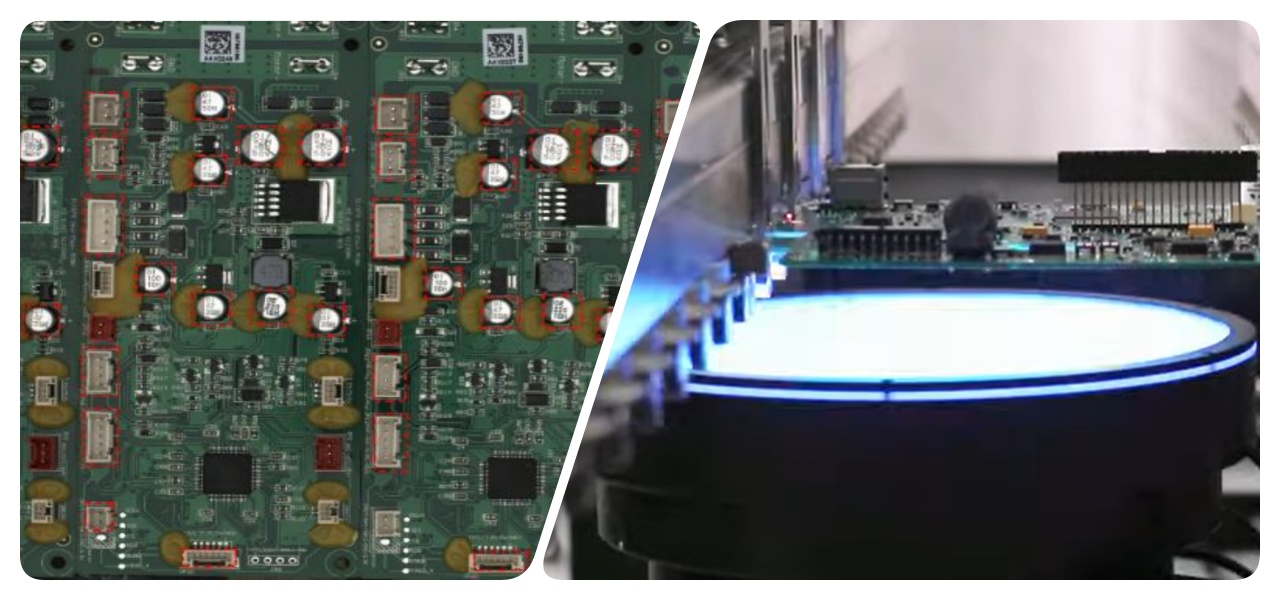

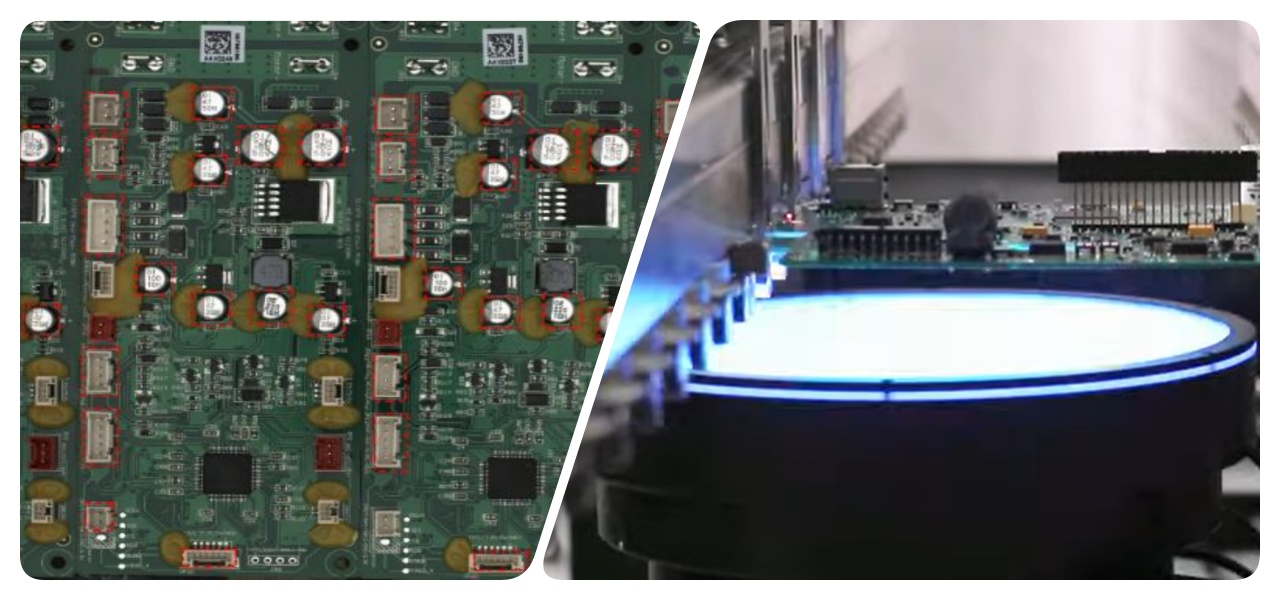

This online aoi inspection machine offers smart, adaptable processes for smooth use. It checks color ring resistors, capacitors, diodes, and sockets intelligently, online or offline, without stopping lines. Programming takes 10-20 minutes, debugging 10-15 minutes, with short changeovers using existing files. Batch parameter changes happen with one key. Audible alarms alert for wrong items or types. This simplifies operations, optimizes equipment settings quickly, and reduces downtime for better production flow.

AI-4540 aoi machines achieve fast checks with genetic algorithm path planning. It reduces FOV counts by skipping non-weld areas, shortens paths, and picks ideal imaging spots to avoid solder at edges. GPU parallel processing speeds data handling. At 0.23 seconds per FOV, it suits high-volume lines. As an inspection system on line smt aoi machine, it maintains flow while ensuring precise results.

Supports multi-board, mixed-board, and mixed-material checks. Identifies rotations at various angles and positions. Skips bad marks automatically. This flexibility fits different PCB setups for thorough, efficient inspections without extra steps.

| Specification

| Model | I.C.T DIP Inverted Camera Online AOI AI-4540 (After THT Soldering) | I.C.T DIP Inverted Camera Online AOI AI-4540L (After THT Soldering) |

| FOV | 49*41mm | |

| Resolution | 20um | |

| Camera | 5M | |

| Light | RGB + W light, 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Mixing PCB inspection | Support calling program automatically. | |

| PCB Size | Three section track: 50*50-350*400mm Single section track: 50*50-450*400mm | 50*50~550*650mm |

| PCB Height | Top:110mm(150mm optional), Bottom:25mm | |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 750&900±20mm | |

| Display | 23.8 inch FHD display | |

| Data output | Autogenerated statistic analysis SPC | |

| Special function | Automatic search of elements and quick programming | |

| Power | AC220 50/60Hz,5A | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

Our marketing video for the AI-4540 aoi machines showcases its sleek exterior design, highlighting the three-section track for flexible PCB handling. It dives into the internal structure, demonstrating the high-precision camera and lighting system. The electrical box is displayed, emphasizing reliable components for stable operation. Key selling points are featured, such as real-time defect detection and low false alarms. Various programming highlights are shown, including one-click identification, quick setups, and batch modifications. This video illustrates how the machine integrates seamlessly into lines, optimizes efficiency, and ensures high-quality outputs for electronics manufacturers worldwide.

| Service & Training

I.C.T offers comprehensive service and training for AI-4540 aoi machines. Our global team handles installation, maintenance, and remote assistance to minimize downtime. Training includes hands-on sessions on programming, operation, and troubleshooting, available on-site or online. We focus on quick responses to queries, ensuring your staff gains skills fast. This support helps factories run smoothly, improve quality, and adapt to production needs effectively.

| Customer Reviews

Clients praise I.C.T aoi machines for their precision and reliability. They commend our engineers for expert setups and fast fixes. Secure packaging and timely shipping prevent damage, earning high marks. Quick responses to issues build strong trust and partnerships.

| Our Certification

I.C.T holds CE, RoHS, ISO9001, and various patents. These ensure safety, environmental compliance, and quality standards. Our aoi machines meet global rules for dependable performance. Patents protect innovations like deep learning tech, providing advanced, protected solutions.

| About I.C.T & Our Factory

I.C.T is a leading electronics firm with in-house R&D and production. Our team of over 89 staff, including 20 engineers, drives rapid growth over 12 years. We serve 1600 customers in 72 countries with full SMT solutions. Our 12,000m² factory uses strict testing and ISO9001 systems to maintain high product quality.

| Discover AI-4540 AOI Machines

The I.C.T DIP Inverted Camera Online AOI AI-4540 is an advanced inspection tool for PCBA after THT soldering. It captures real-time images using a high-precision color camera and processes them with Convolution Neural Network (CNN) algorithms to detect defects intelligently. This automatic pcb aoi machine identifies issues like wrong parts, missing components, reverse polarity, and solder defects such as bridges, voids, or insufficient solder in elements like resistors, capacitors, diodes, and sockets. With high detection rates and low false alarms, it installs over production lines without modifications, allowing continuous operation. Easy to adjust in height and width, it supports central control for multiple units. Data traceability includes SPC alarms, automatic log storage, NG warnings, and remote programming. This boosts factory efficiency and quality in SMT processes.

| Feature

AI-4540 aoi machines use deep learning with big data optimization for industrial checks. It identifies components and solder joints automatically with one-click, cutting long programming times and high false alarms from traditional methods. Trained on large datasets, it handles bottom-side variations after wave soldering, ensuring no missed defects. It reduces false calls from overhanging parts or slight color differences. CNN mimics human-like judgment for diverse scenarios, like detecting fuzzy pin holes in solder without pin or device interference. This leads to strong generalization, high accuracy, and reliable inspections for complex boards.

This online aoi inspection machine offers smart, adaptable processes for smooth use. It checks color ring resistors, capacitors, diodes, and sockets intelligently, online or offline, without stopping lines. Programming takes 10-20 minutes, debugging 10-15 minutes, with short changeovers using existing files. Batch parameter changes happen with one key. Audible alarms alert for wrong items or types. This simplifies operations, optimizes equipment settings quickly, and reduces downtime for better production flow.

AI-4540 aoi machines achieve fast checks with genetic algorithm path planning. It reduces FOV counts by skipping non-weld areas, shortens paths, and picks ideal imaging spots to avoid solder at edges. GPU parallel processing speeds data handling. At 0.23 seconds per FOV, it suits high-volume lines. As an inspection system on line smt aoi machine, it maintains flow while ensuring precise results.

Supports multi-board, mixed-board, and mixed-material checks. Identifies rotations at various angles and positions. Skips bad marks automatically. This flexibility fits different PCB setups for thorough, efficient inspections without extra steps.

| Specification

| Model | I.C.T DIP Inverted Camera Online AOI AI-4540 (After THT Soldering) | I.C.T DIP Inverted Camera Online AOI AI-4540L (After THT Soldering) |

| FOV | 49*41mm | |

| Resolution | 20um | |

| Camera | 5M | |

| Light | RGB + W light, 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Mixing PCB inspection | Support calling program automatically. | |

| PCB Size | Three section track: 50*50-350*400mm Single section track: 50*50-450*400mm | 50*50~550*650mm |

| PCB Height | Top:110mm(150mm optional), Bottom:25mm | |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 750&900±20mm | |

| Display | 23.8 inch FHD display | |

| Data output | Autogenerated statistic analysis SPC | |

| Special function | Automatic search of elements and quick programming | |

| Power | AC220 50/60Hz,5A | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

Our marketing video for the AI-4540 aoi machines showcases its sleek exterior design, highlighting the three-section track for flexible PCB handling. It dives into the internal structure, demonstrating the high-precision camera and lighting system. The electrical box is displayed, emphasizing reliable components for stable operation. Key selling points are featured, such as real-time defect detection and low false alarms. Various programming highlights are shown, including one-click identification, quick setups, and batch modifications. This video illustrates how the machine integrates seamlessly into lines, optimizes efficiency, and ensures high-quality outputs for electronics manufacturers worldwide.

| Service & Training

I.C.T offers comprehensive service and training for AI-4540 aoi machines. Our global team handles installation, maintenance, and remote assistance to minimize downtime. Training includes hands-on sessions on programming, operation, and troubleshooting, available on-site or online. We focus on quick responses to queries, ensuring your staff gains skills fast. This support helps factories run smoothly, improve quality, and adapt to production needs effectively.

| Customer Reviews

Clients praise I.C.T aoi machines for their precision and reliability. They commend our engineers for expert setups and fast fixes. Secure packaging and timely shipping prevent damage, earning high marks. Quick responses to issues build strong trust and partnerships.

| Our Certification

I.C.T holds CE, RoHS, ISO9001, and various patents. These ensure safety, environmental compliance, and quality standards. Our aoi machines meet global rules for dependable performance. Patents protect innovations like deep learning tech, providing advanced, protected solutions.

| About I.C.T & Our Factory

I.C.T is a leading electronics firm with in-house R&D and production. Our team of over 89 staff, including 20 engineers, drives rapid growth over 12 years. We serve 1600 customers in 72 countries with full SMT solutions. Our 12,000m² factory uses strict testing and ISO9001 systems to maintain high product quality.