I.C.T-5600

I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T-5600 Offline PCBA Cleaning Machine

The I.C.T-5600 offline PCBA cleaning machine is a compact, energy-efficient solution designed for batch cleaning of assembled boards. It effectively eliminates rosin flux, water-soluble flux, no-clean flux, solder paste residues, and other organic or inorganic contaminants from SMT and THT PCBA. This machine is especially suitable for industries such as aviation, medical devices, automotive electronics, new energy, and instrumentation, where small-scale or multi-variety production is common. A large observation window allows clear visibility of the entire cleaning process. Heated detergent combined with multi-directional sprays delivers excellent results, while intelligent recycling features help reduce chemical consumption. The user-friendly interface supports quick parameter setup and includes password protection for secure operation. For comparison, the online I.C.T-6300 uses a belt conveyor and high-pressure spray system for continuous high-volume cleaning in full SMT lines.

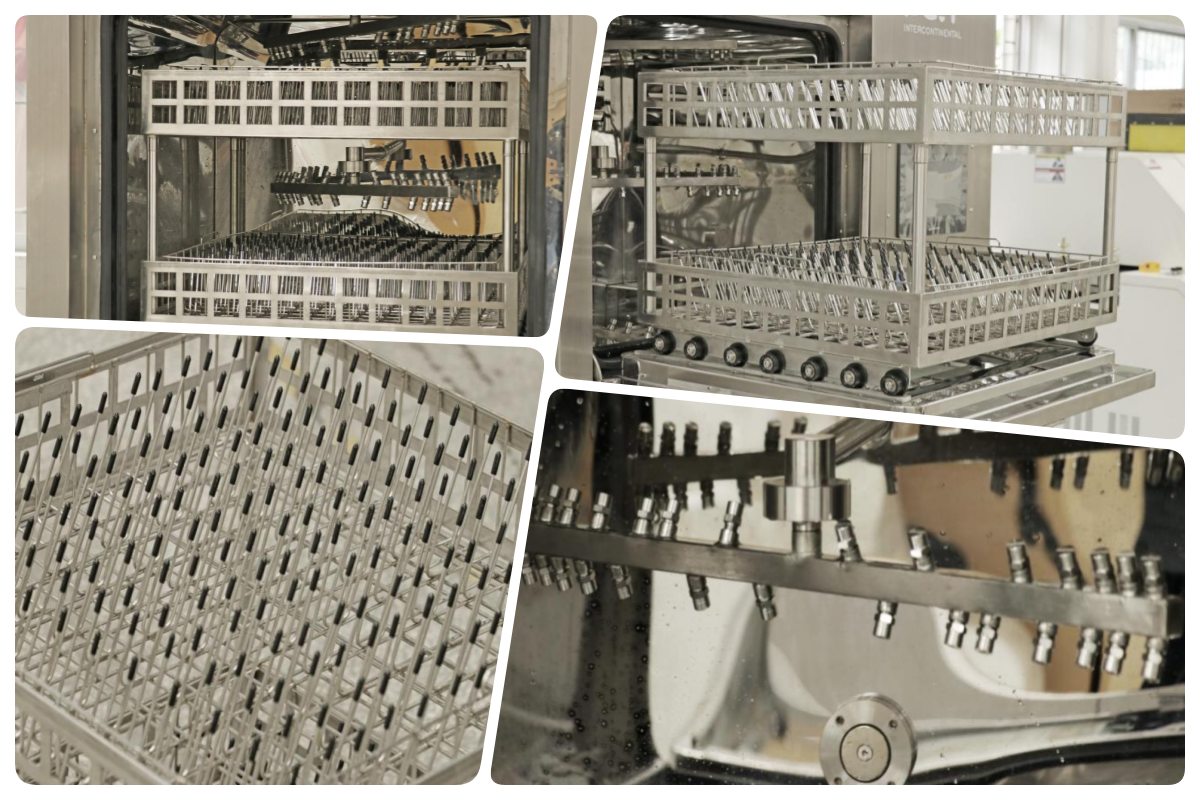

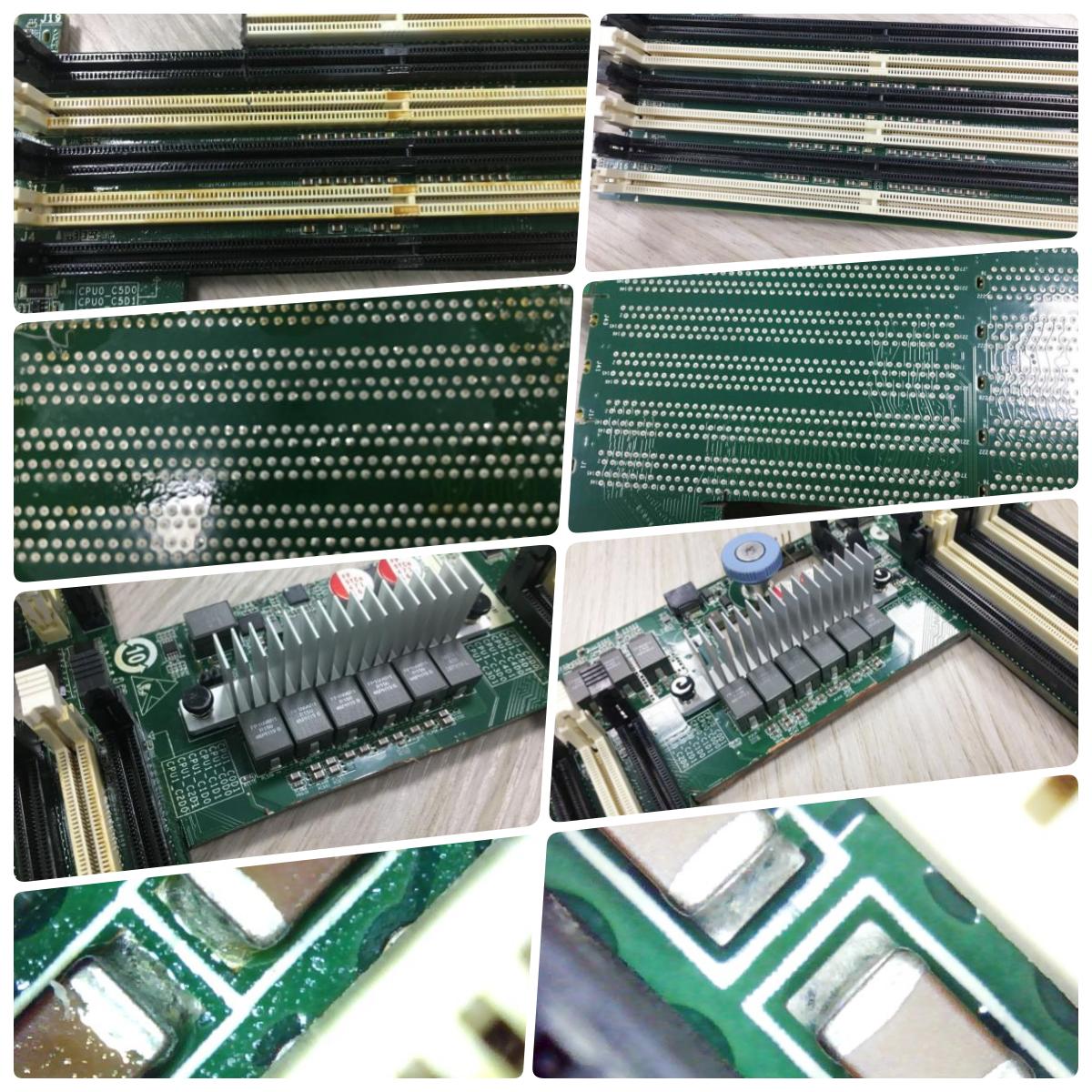

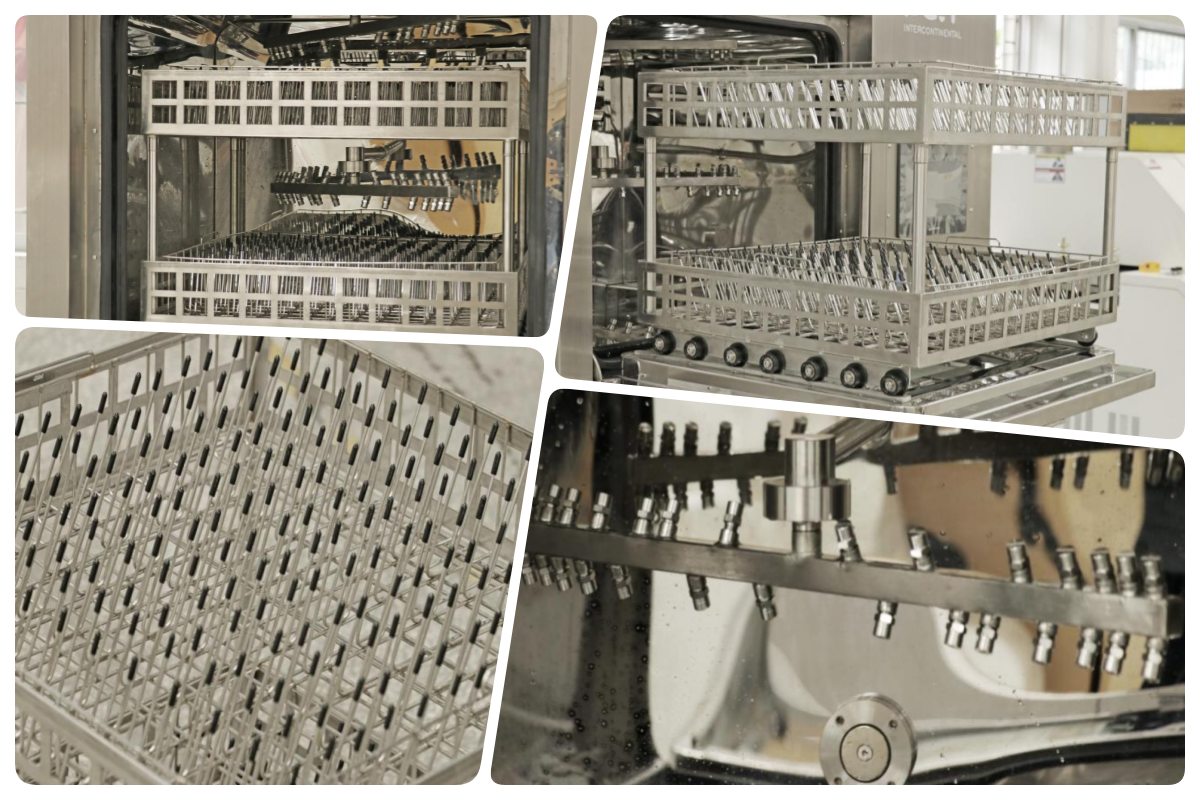

| Feature

Engineers constructed the cleaning room from 100% SUS304 stainless steel, ensuring strong resistance to chemicals and a long operational life. Multiple spray channels provide uniform coverage of cleaning liquid across every board surface. The standard double-layer basket increases throughput, while universal fixtures come equipped with flexible plastic sleeves to prevent scratching delicate PCBA components. When the door opens, it serves as a convenient temporary platform with slides and small wheels for easy loading and unloading. The tilted bottom, combined with dense filter nets, directs liquid flow and avoids water pooling in the tank. A retractable magnetic push rod moves the basket back and forth during cycles, allowing sprays to reach hidden areas more completely. Unique nozzle spacing ensures full coverage and eliminates dead corners. This thoughtful design balances board protection with superior cleaning performance.

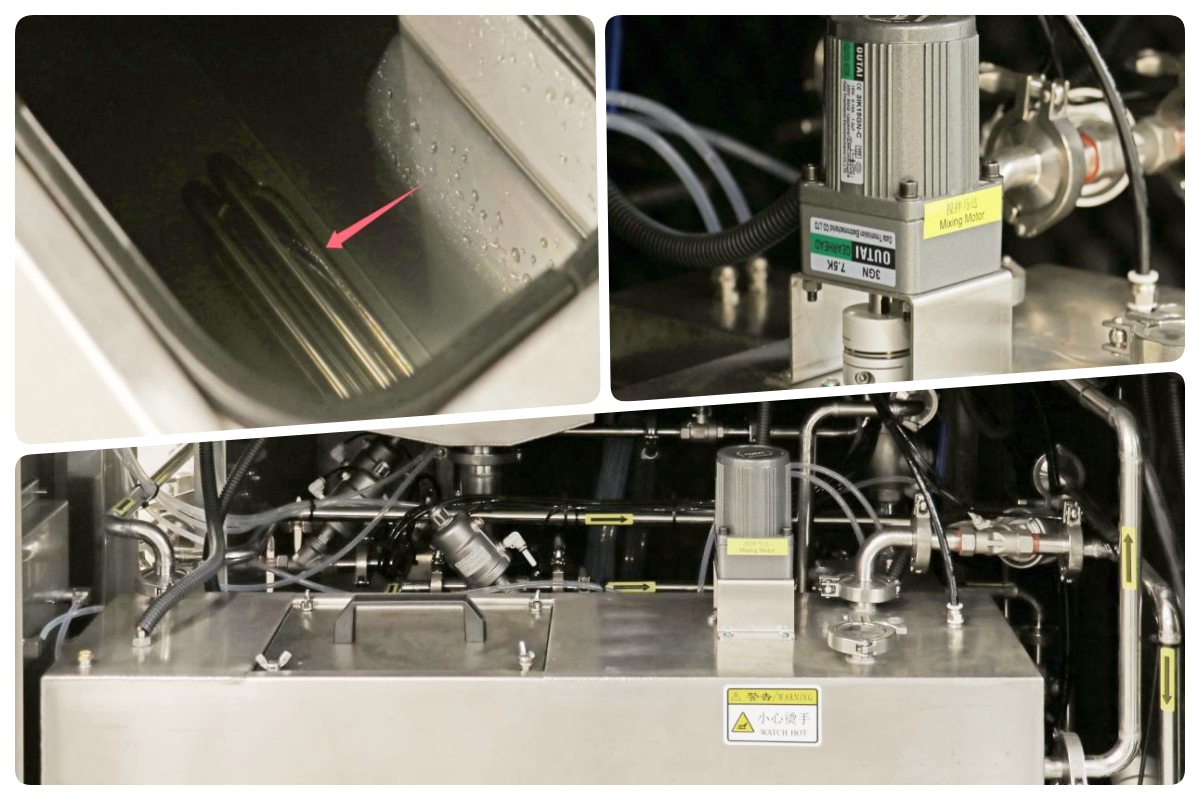

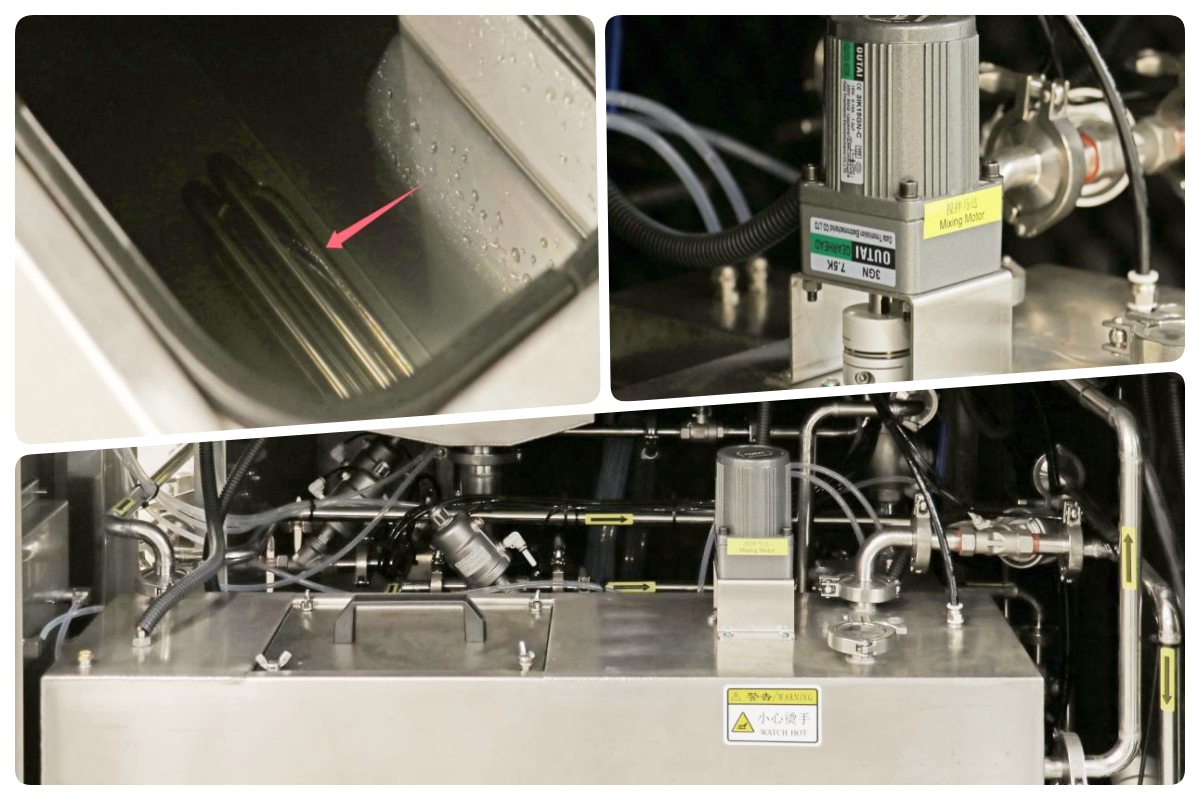

The circulation pipe system was developed internally to deliver both high efficiency and a compact layout. A high-power diaphragm pump generates strong, reliable flow to support consistent cleaning results. The carefully planned pipeline route recycles detergent effectively while minimizing the space required inside the machine. Integrated filters capture contaminants, enabling repeated use of the solution without quality degradation. Durable, corrosion-resistant materials maintain stable performance during extended operation. The air blow function clears residual liquid from pipes and pumps, returning it to the tank and reducing waste significantly. This smart design lowers running costs and promotes environmentally friendly practices. For production environments with frequent board changes, the circulation system ensures predictable, high-quality outcomes batch after batch.

Dual tanks—a 60L diluent tank and a 30L concentrate tank—maintain a steady supply of cleaning solution throughout operation. The rapid heating system brings detergent to optimal temperature quickly, reducing overall cycle time and improving cleaning efficiency. An inner filter supports repeated use of the liquid while maintaining performance. Real-time DI water resistivity monitoring provides immediate insight into cleaning effectiveness. After each run, compressed air blows remaining detergent from pipes and pumps back to the tank, saving up to 50% of fluid. All tank components are constructed from SUS304 stainless steel for excellent chemical resistance and easy maintenance. This reliable setup supports stable, consistent performance even in demanding production schedules.

Although the primary focus remains on powerful spray cleaning, the I.C.T-5600 manages residual moisture effectively through integrated air blow and thorough rinsing stages. Boards emerge from the process clean and sufficiently dry for immediate downstream steps such as inspection, coating, or assembly. The design minimizes issues like water spots or trapped contaminants that could affect quality later. In batch mode, natural drying after complete rinsing meets required standards without additional equipment. Ionic contamination levels stay well below IPC Class I specifications. Operators gain confidence from reliable board preparation for subsequent processes. In contrast, the online I.C.T-6300 features dedicated multi-stage hot air drying sections optimized for faster, continuous throughput.

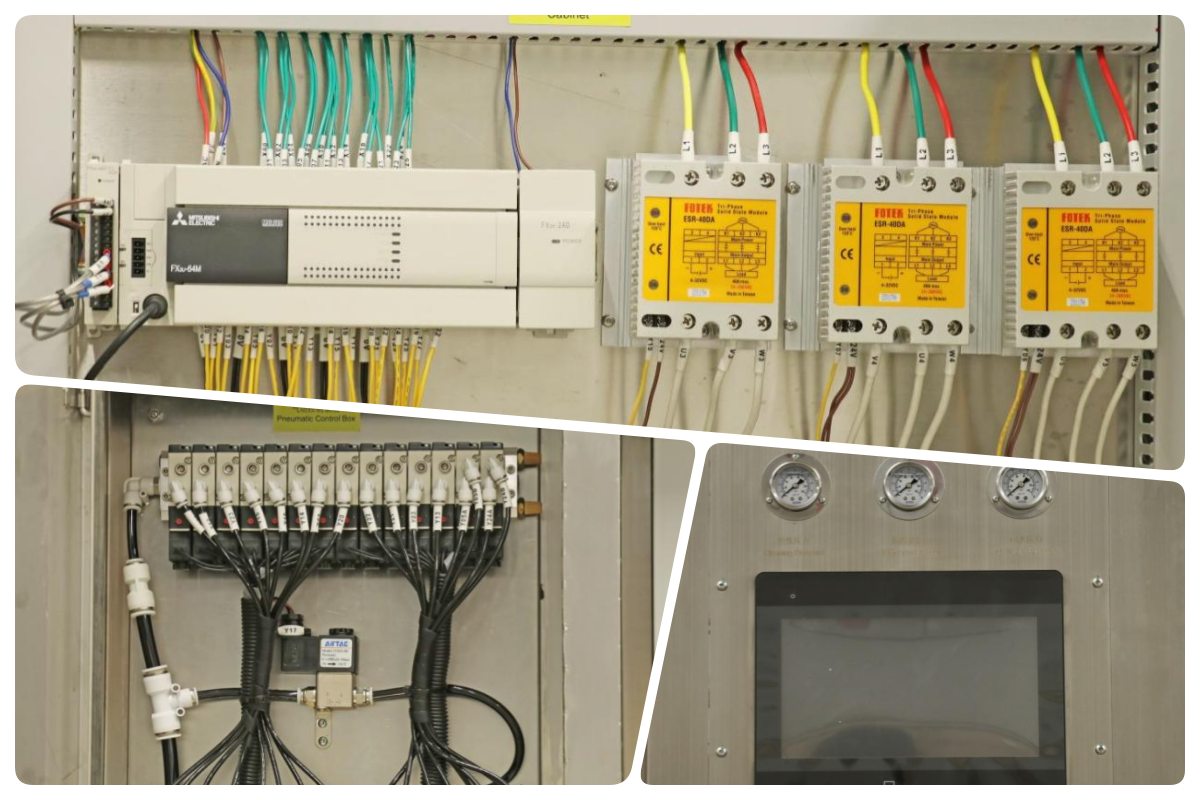

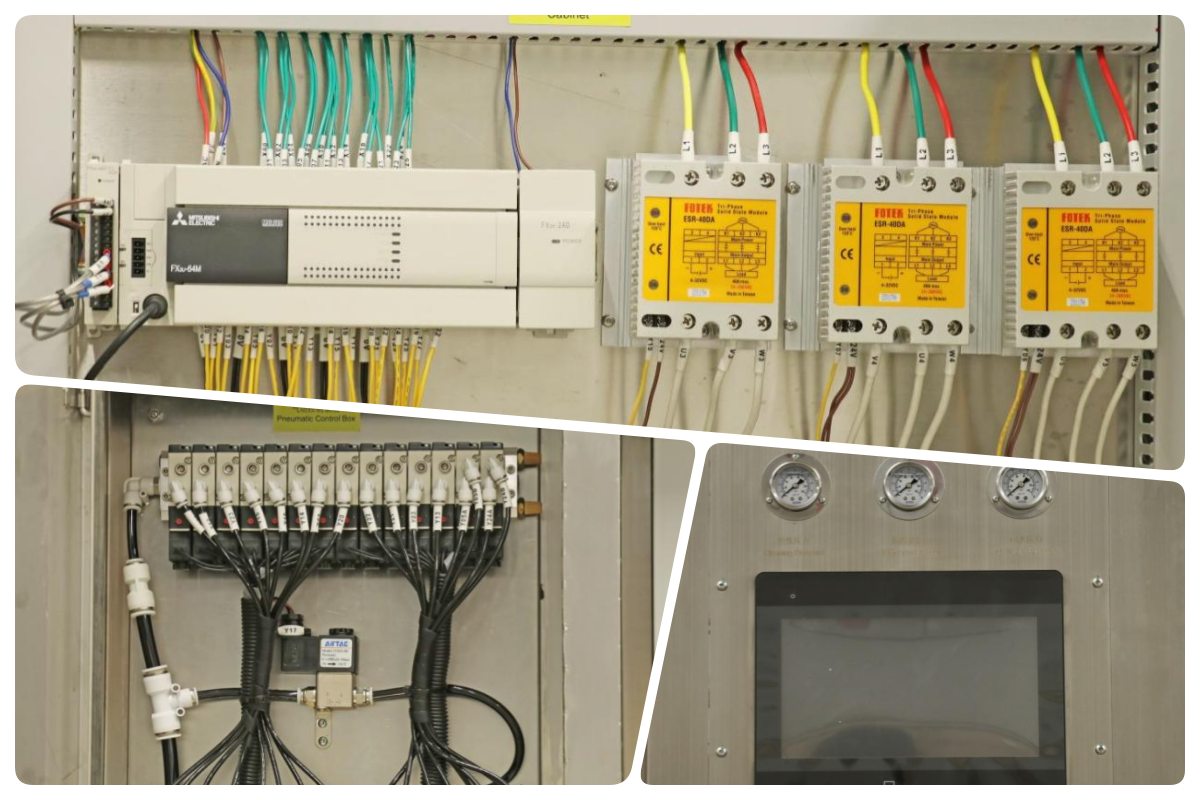

The control system features a straightforward touch interface that lets operators adjust parameters quickly and easily. Settings for temperature, time, and cycles can be changed with minimal effort, while password protection secures the system against unauthorized modifications. The panel displays live resistivity readings and process status for clear monitoring at a glance. Built-in alarms alert users promptly to conditions such as low liquid levels or other anomalies. This simple yet effective design shortens training time and helps prevent operational errors. Reliable electronics ensure repeatable, consistent performance over many production cycles. Traceability options support documentation needs in regulated industries. These controls deliver dependable management and operational peace of mind.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

I.C.T successfully completed overseas installation and Factory Acceptance Testing (FAT) for two full SMT production lines at a North American beauty instrument manufacturer. The lines incorporated laser marking machines, SMT printers with SPI, Panasonic mounters, Heller reflow ovens, AOI inspection equipment, PCB conveyors, PCBA cleaning machines, and fully automatic solder paste storage and thawing boxes. Our engineers managed on-site installation, debugging, operator training, and performance verification. The customer passed production acceptance smoothly and transitioned directly into full-scale manufacturing. This project showcases I.C.T’s expertise in delivering turnkey SMT solutions, handling international logistics, and providing dependable support for clients in high-demand industries.

| Service and Training

I.C.T offers complete service and training programs to ensure customers achieve maximum value from day one. Experienced engineers provide on-site installation, precise commissioning, and thorough operator training. Training covers parameter adjustment, daily maintenance routines, basic troubleshooting, and safety protocols. Remote support is available for rapid resolution of questions or technical issues. We supply detailed manuals, instructional videos, and continued guidance to support long-term success. Process optimization recommendations help improve efficiency over time. This comprehensive support package minimizes startup delays, reduces unplanned downtime, and extends equipment lifespan. Customers rely on our responsive global team to maintain smooth, productive operations.

| Customer Reviews

Customers regularly commend our engineers for their strong technical knowledge, clear communication, and fast response during installation and training visits. The PCBA cleaning machine receives high praise for its reliable cleaning performance and robust construction that withstands daily production demands. Intelligent features like detergent recovery are appreciated for delivering noticeable cost savings. Packaging and international shipping are frequently highlighted for secure, damage-free delivery even over long distances. Quick email responses and effective remote diagnostics strengthen trust in our commitment to customer satisfaction. Overall, clients see I.C.T as a dependable partner offering high-quality equipment and outstanding after-sales support.

| Our Certification

I.C.T machines carry key international certifications that confirm safety, environmental responsibility, and manufacturing excellence. CE certification verifies compliance with European safety requirements, RoHS restricts the use of hazardous substances, and ISO9001 demonstrates a comprehensive quality management system. Multiple patents protect innovative cleaning technologies and design improvements. These credentials provide assurance for use in strictly regulated sectors such as medical, automotive, and aerospace. Customers select our PCBA cleaning machine with confidence, knowing it passes rigorous testing and meets global standards. Our certifications reflect a deep commitment to safe, sustainable, and high-quality production practices.

| About I.C.T and SMT Factory

I.C.T maintains its own R&D and production facilities in Dongguan, China, allowing complete control over design, manufacturing, and quality. Established in 2012, the company has grown rapidly, now employing 89 staff members—including 20 skilled engineers—across 12,000 square meters of space. We serve more than 1,600 customers in 72 countries with full SMT, DIP, and coating solutions. Strict inspection procedures occur at every production stage, supported by a robust quality management system that ensures consistent product reliability. Eight branch offices strengthen our global service network. I.C.T focuses on innovation, customer needs, and reliable support to help manufacturers build and optimize their production systems effectively.

| I.C.T-5600 Offline PCBA Cleaning Machine

The I.C.T-5600 offline PCBA cleaning machine is a compact, energy-efficient solution designed for batch cleaning of assembled boards. It effectively eliminates rosin flux, water-soluble flux, no-clean flux, solder paste residues, and other organic or inorganic contaminants from SMT and THT PCBA. This machine is especially suitable for industries such as aviation, medical devices, automotive electronics, new energy, and instrumentation, where small-scale or multi-variety production is common. A large observation window allows clear visibility of the entire cleaning process. Heated detergent combined with multi-directional sprays delivers excellent results, while intelligent recycling features help reduce chemical consumption. The user-friendly interface supports quick parameter setup and includes password protection for secure operation. For comparison, the online I.C.T-6300 uses a belt conveyor and high-pressure spray system for continuous high-volume cleaning in full SMT lines.

| Feature

Engineers constructed the cleaning room from 100% SUS304 stainless steel, ensuring strong resistance to chemicals and a long operational life. Multiple spray channels provide uniform coverage of cleaning liquid across every board surface. The standard double-layer basket increases throughput, while universal fixtures come equipped with flexible plastic sleeves to prevent scratching delicate PCBA components. When the door opens, it serves as a convenient temporary platform with slides and small wheels for easy loading and unloading. The tilted bottom, combined with dense filter nets, directs liquid flow and avoids water pooling in the tank. A retractable magnetic push rod moves the basket back and forth during cycles, allowing sprays to reach hidden areas more completely. Unique nozzle spacing ensures full coverage and eliminates dead corners. This thoughtful design balances board protection with superior cleaning performance.

The circulation pipe system was developed internally to deliver both high efficiency and a compact layout. A high-power diaphragm pump generates strong, reliable flow to support consistent cleaning results. The carefully planned pipeline route recycles detergent effectively while minimizing the space required inside the machine. Integrated filters capture contaminants, enabling repeated use of the solution without quality degradation. Durable, corrosion-resistant materials maintain stable performance during extended operation. The air blow function clears residual liquid from pipes and pumps, returning it to the tank and reducing waste significantly. This smart design lowers running costs and promotes environmentally friendly practices. For production environments with frequent board changes, the circulation system ensures predictable, high-quality outcomes batch after batch.

Dual tanks—a 60L diluent tank and a 30L concentrate tank—maintain a steady supply of cleaning solution throughout operation. The rapid heating system brings detergent to optimal temperature quickly, reducing overall cycle time and improving cleaning efficiency. An inner filter supports repeated use of the liquid while maintaining performance. Real-time DI water resistivity monitoring provides immediate insight into cleaning effectiveness. After each run, compressed air blows remaining detergent from pipes and pumps back to the tank, saving up to 50% of fluid. All tank components are constructed from SUS304 stainless steel for excellent chemical resistance and easy maintenance. This reliable setup supports stable, consistent performance even in demanding production schedules.

Although the primary focus remains on powerful spray cleaning, the I.C.T-5600 manages residual moisture effectively through integrated air blow and thorough rinsing stages. Boards emerge from the process clean and sufficiently dry for immediate downstream steps such as inspection, coating, or assembly. The design minimizes issues like water spots or trapped contaminants that could affect quality later. In batch mode, natural drying after complete rinsing meets required standards without additional equipment. Ionic contamination levels stay well below IPC Class I specifications. Operators gain confidence from reliable board preparation for subsequent processes. In contrast, the online I.C.T-6300 features dedicated multi-stage hot air drying sections optimized for faster, continuous throughput.

The control system features a straightforward touch interface that lets operators adjust parameters quickly and easily. Settings for temperature, time, and cycles can be changed with minimal effort, while password protection secures the system against unauthorized modifications. The panel displays live resistivity readings and process status for clear monitoring at a glance. Built-in alarms alert users promptly to conditions such as low liquid levels or other anomalies. This simple yet effective design shortens training time and helps prevent operational errors. Reliable electronics ensure repeatable, consistent performance over many production cycles. Traceability options support documentation needs in regulated industries. These controls deliver dependable management and operational peace of mind.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

I.C.T successfully completed overseas installation and Factory Acceptance Testing (FAT) for two full SMT production lines at a North American beauty instrument manufacturer. The lines incorporated laser marking machines, SMT printers with SPI, Panasonic mounters, Heller reflow ovens, AOI inspection equipment, PCB conveyors, PCBA cleaning machines, and fully automatic solder paste storage and thawing boxes. Our engineers managed on-site installation, debugging, operator training, and performance verification. The customer passed production acceptance smoothly and transitioned directly into full-scale manufacturing. This project showcases I.C.T’s expertise in delivering turnkey SMT solutions, handling international logistics, and providing dependable support for clients in high-demand industries.

| Service and Training

I.C.T offers complete service and training programs to ensure customers achieve maximum value from day one. Experienced engineers provide on-site installation, precise commissioning, and thorough operator training. Training covers parameter adjustment, daily maintenance routines, basic troubleshooting, and safety protocols. Remote support is available for rapid resolution of questions or technical issues. We supply detailed manuals, instructional videos, and continued guidance to support long-term success. Process optimization recommendations help improve efficiency over time. This comprehensive support package minimizes startup delays, reduces unplanned downtime, and extends equipment lifespan. Customers rely on our responsive global team to maintain smooth, productive operations.

| Customer Reviews

Customers regularly commend our engineers for their strong technical knowledge, clear communication, and fast response during installation and training visits. The PCBA cleaning machine receives high praise for its reliable cleaning performance and robust construction that withstands daily production demands. Intelligent features like detergent recovery are appreciated for delivering noticeable cost savings. Packaging and international shipping are frequently highlighted for secure, damage-free delivery even over long distances. Quick email responses and effective remote diagnostics strengthen trust in our commitment to customer satisfaction. Overall, clients see I.C.T as a dependable partner offering high-quality equipment and outstanding after-sales support.

| Our Certification

I.C.T machines carry key international certifications that confirm safety, environmental responsibility, and manufacturing excellence. CE certification verifies compliance with European safety requirements, RoHS restricts the use of hazardous substances, and ISO9001 demonstrates a comprehensive quality management system. Multiple patents protect innovative cleaning technologies and design improvements. These credentials provide assurance for use in strictly regulated sectors such as medical, automotive, and aerospace. Customers select our PCBA cleaning machine with confidence, knowing it passes rigorous testing and meets global standards. Our certifications reflect a deep commitment to safe, sustainable, and high-quality production practices.

| About I.C.T and SMT Factory

I.C.T maintains its own R&D and production facilities in Dongguan, China, allowing complete control over design, manufacturing, and quality. Established in 2012, the company has grown rapidly, now employing 89 staff members—including 20 skilled engineers—across 12,000 square meters of space. We serve more than 1,600 customers in 72 countries with full SMT, DIP, and coating solutions. Strict inspection procedures occur at every production stage, supported by a robust quality management system that ensures consistent product reliability. Eight branch offices strengthen our global service network. I.C.T focuses on innovation, customer needs, and reliable support to help manufacturers build and optimize their production systems effectively.