I.C.T-AI4026

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced DIP AOI Inspection System

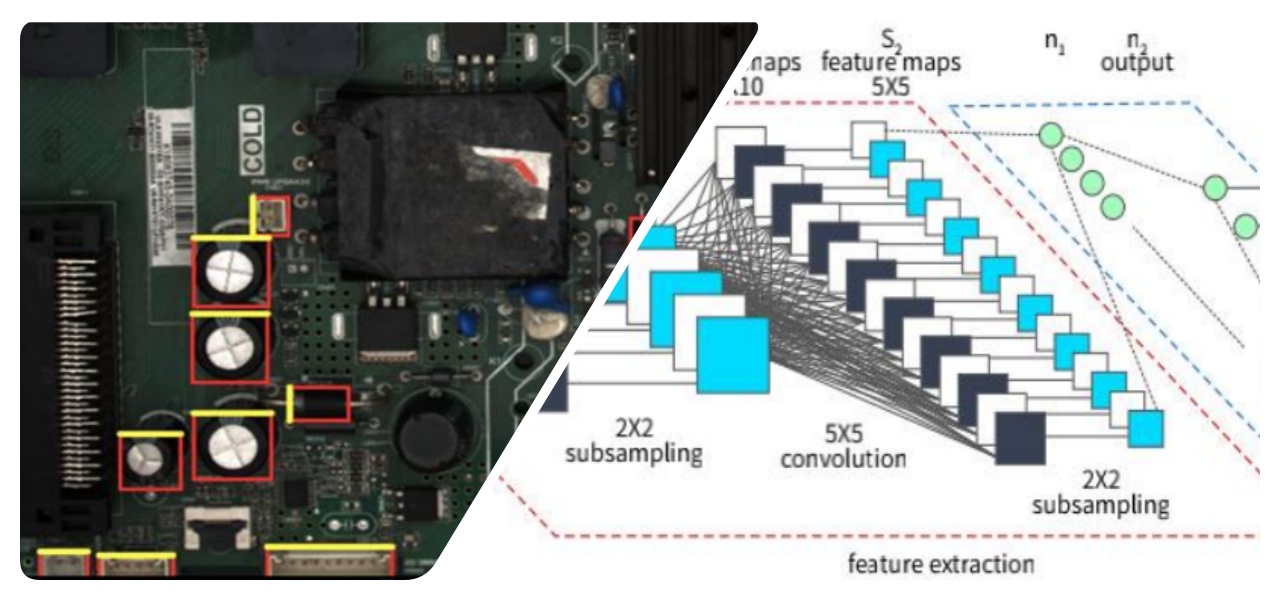

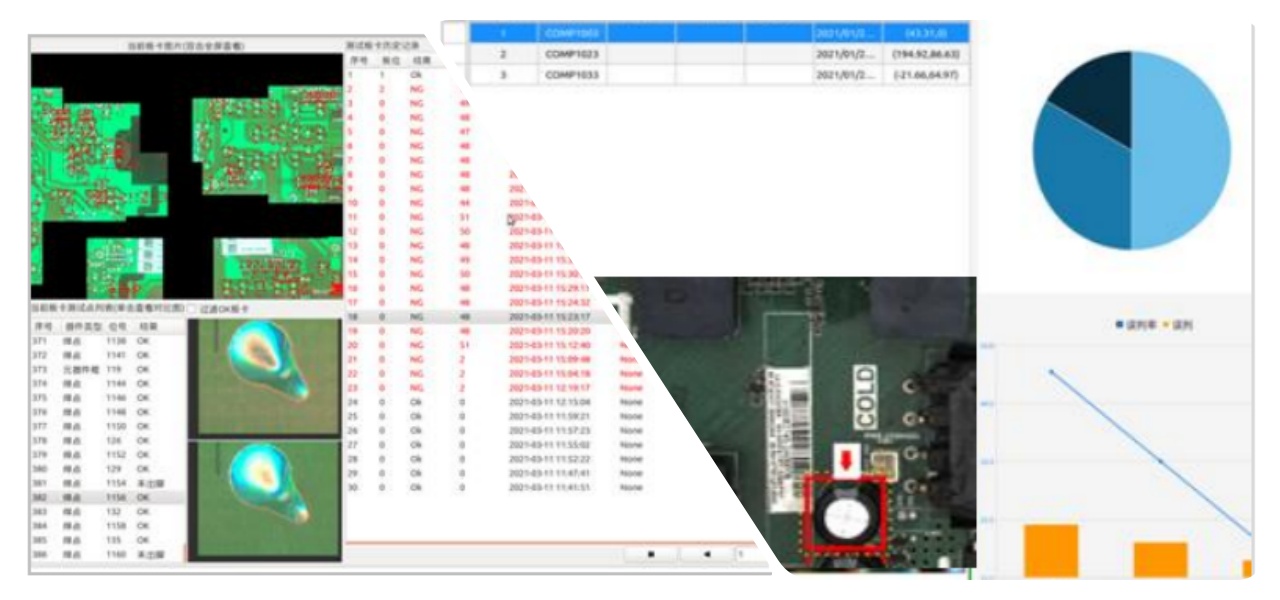

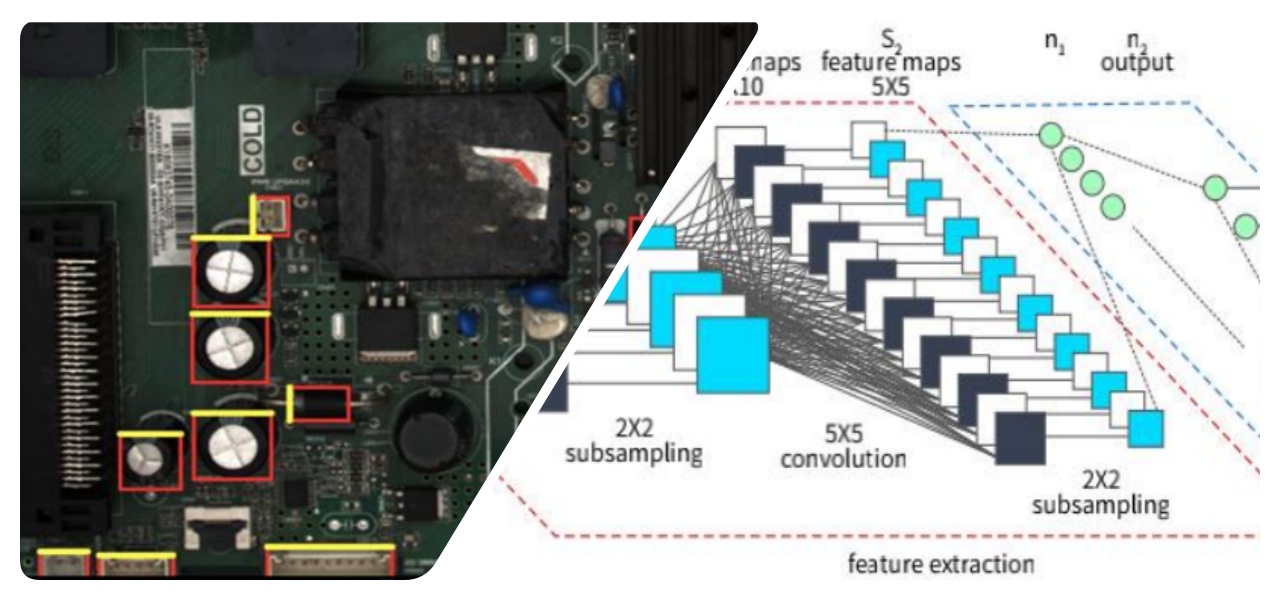

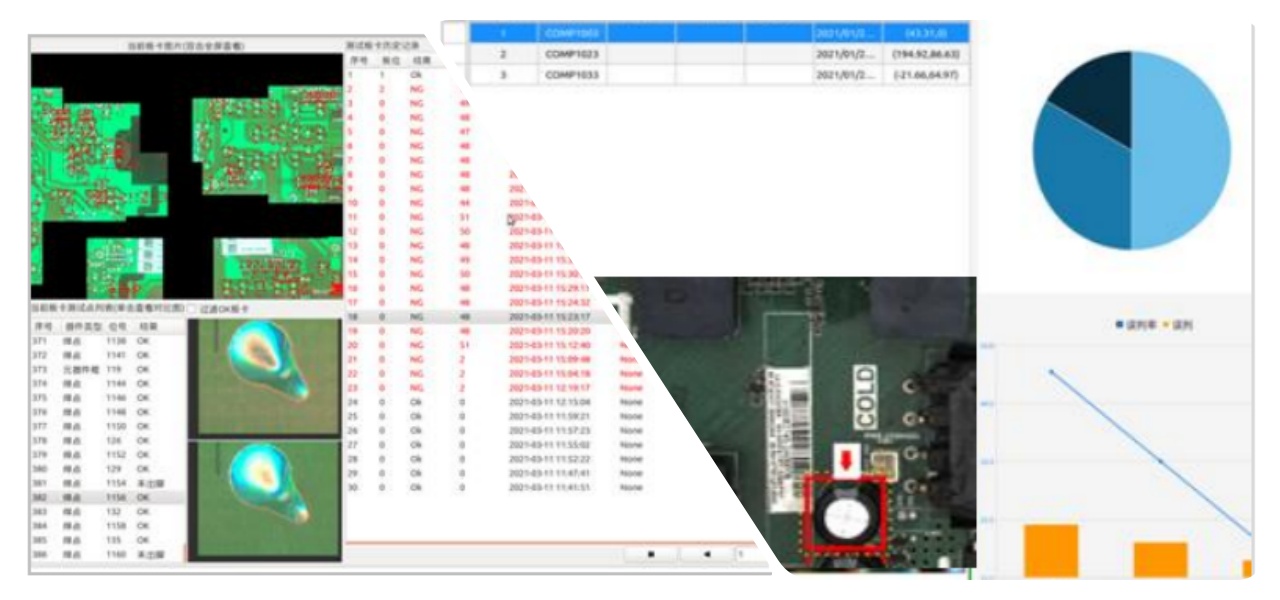

The I.C.T AI-4026 is a reliable aoi optical inspection for PCBA plug-ins before THT soldering. It uses a high-precision color camera to grab images in real time and CNN algorithms to spot defects smartly. This aoi optical inspection checks for wrong parts, missing items, reverse polarity, and other DIP issues like misalignment. With deep learning, it fixes long programming and high false rates in old methods. The system spans lines easily, adjusts height and width, and supports remote debugging. It handles boards up to 520*380mm and connects to MES for reports. Overall, this Aoi Pcb Inspection boosts yield and keeps operations smooth in SMT factories.

| Feature

The AI-4026 aoi optical inspection applies deep learning for one-click component and joint recognition. Trained on big data, it cuts setup time and false alarms effectively. CNN mimics human eyes to handle varied boards. This makes the aoi optical inspection ideal for quick, accurate pre-soldering checks.

This aoi optical inspection allows online or offline setup without stopping the line. Programming takes 10-20 minutes, debugging 10-15 minutes. One-key changes and file calls speed things up. It auto-checks resistors, capacitors, diodes, and sockets. Alarms prompt errors clearly, fitting fast-paced production.

Built for plug-ins, the AI-4026 aoi optical inspection has fuzzy recognition for color rings and polarity. It ignores silkscreen interference and spots black parts on black boards. Same-color detection finds missing or reversed items accurately. Excellent generalization handles diverse materials, reducing misses in aoi machine for pcb tasks.

| Specification

| Model | I.C.T DIP Online AOI AI-4026(Before THT Soldering) | I.C.T DIP Online AOI AI-4026L(Before THT Soldering) |

| FOV | 400*300mm | 520*380mm |

| Resolution | 90um | 80um |

| Camera | 12M | 31M |

| Mixing PCB inspection | Support calling program automatically | |

| PCB Size | 50*50mm ~ 400*300mm | 50*50mm ~ 520*380mm |

| Display | 23.8 inch FHD display | |

| Data output | Autogenerated statistic analysis SPC | |

| Special function | Automatic search of elements and quick programming | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 200W | |

| Compressed Air | 0.4 ~ 0.6Mpa | |

| Communication | SMEMA | |

| Weight | 120Kg | |

| Dimension | L715*W760~1210*H1315~1700mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Service & Training

I.C.T provides complete services for the AI-4026 aoi optical inspection, from install to upkeep. Engineers offer remote help and on-site training on operation and fixes. Sessions last 3-5 days, covering programming and maintenance. We supply parts, updates, and 24-hour responses via global centers. This ensures users get full value from their 3D Aoi Inspection Machine investment with minimal stops.

| Customer Reviews

Users commend our engineers for skilled setup and rapid solutions. The equipment earns praise for precise detection and user-friendly design. Packaging protects during shipping perfectly. Fast query responses, often same-day, build strong trust. This aoi optical inspection exceeds needs in quality and reliability.

| Our Certification

I.C.T has CE for safety, RoHS for green materials, ISO9001 for quality control, and patents on AOI tech. These prove our aoi optical inspection meets world standards for trust and performance.

| About I.C.T & Our Factory

I.C.T handles R&D and production in-house with 89 staff and 20 engineers in 12,000m². Since 2012, we've grown quickly, serving over 1,600 clients in 72 countries. Strict tests and quality systems ensure top products. We cover full SMT solutions, focusing on integrity and sharing for global partnerships.

| Advanced DIP AOI Inspection System

The I.C.T AI-4026 is a reliable aoi optical inspection for PCBA plug-ins before THT soldering. It uses a high-precision color camera to grab images in real time and CNN algorithms to spot defects smartly. This aoi optical inspection checks for wrong parts, missing items, reverse polarity, and other DIP issues like misalignment. With deep learning, it fixes long programming and high false rates in old methods. The system spans lines easily, adjusts height and width, and supports remote debugging. It handles boards up to 520*380mm and connects to MES for reports. Overall, this Aoi Pcb Inspection boosts yield and keeps operations smooth in SMT factories.

| Feature

The AI-4026 aoi optical inspection applies deep learning for one-click component and joint recognition. Trained on big data, it cuts setup time and false alarms effectively. CNN mimics human eyes to handle varied boards. This makes the aoi optical inspection ideal for quick, accurate pre-soldering checks.

This aoi optical inspection allows online or offline setup without stopping the line. Programming takes 10-20 minutes, debugging 10-15 minutes. One-key changes and file calls speed things up. It auto-checks resistors, capacitors, diodes, and sockets. Alarms prompt errors clearly, fitting fast-paced production.

Built for plug-ins, the AI-4026 aoi optical inspection has fuzzy recognition for color rings and polarity. It ignores silkscreen interference and spots black parts on black boards. Same-color detection finds missing or reversed items accurately. Excellent generalization handles diverse materials, reducing misses in aoi machine for pcb tasks.

| Specification

| Model | I.C.T DIP Online AOI AI-4026(Before THT Soldering) | I.C.T DIP Online AOI AI-4026L(Before THT Soldering) |

| FOV | 400*300mm | 520*380mm |

| Resolution | 90um | 80um |

| Camera | 12M | 31M |

| Mixing PCB inspection | Support calling program automatically | |

| PCB Size | 50*50mm ~ 400*300mm | 50*50mm ~ 520*380mm |

| Display | 23.8 inch FHD display | |

| Data output | Autogenerated statistic analysis SPC | |

| Special function | Automatic search of elements and quick programming | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 200W | |

| Compressed Air | 0.4 ~ 0.6Mpa | |

| Communication | SMEMA | |

| Weight | 120Kg | |

| Dimension | L715*W760~1210*H1315~1700mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Service & Training

I.C.T provides complete services for the AI-4026 aoi optical inspection, from install to upkeep. Engineers offer remote help and on-site training on operation and fixes. Sessions last 3-5 days, covering programming and maintenance. We supply parts, updates, and 24-hour responses via global centers. This ensures users get full value from their 3D Aoi Inspection Machine investment with minimal stops.

| Customer Reviews

Users commend our engineers for skilled setup and rapid solutions. The equipment earns praise for precise detection and user-friendly design. Packaging protects during shipping perfectly. Fast query responses, often same-day, build strong trust. This aoi optical inspection exceeds needs in quality and reliability.

| Our Certification

I.C.T has CE for safety, RoHS for green materials, ISO9001 for quality control, and patents on AOI tech. These prove our aoi optical inspection meets world standards for trust and performance.

| About I.C.T & Our Factory

I.C.T handles R&D and production in-house with 89 staff and 20 engineers in 12,000m². Since 2012, we've grown quickly, serving over 1,600 clients in 72 countries. Strict tests and quality systems ensure top products. We cover full SMT solutions, focusing on integrity and sharing for global partnerships.