I.C.T-SS540

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Selective-Soldering Machine Overview

Engineered and built in China, the I.C.T selective-soldering machine is the go-to SMT selective wave soldering machine for high-mix, high-volume lines. The PCB stays perfectly still while the lightweight cast-aluminum platform—powered by Panasonic servos and precision linear rails—moves flux and solder heads with whisper-quiet speed and pinpoint accuracy. Inline nitrogen heating delivers perfect wetting and almost no dross. Every parameter is dialed in and saved in an easy Windows interface for rock-solid repeatability. Automatic wave calibration, real-time CCD monitoring, German jet valve, and titanium pot keep quality sky-high and rework at zero shift after shift.

| DIP Line Equipment List

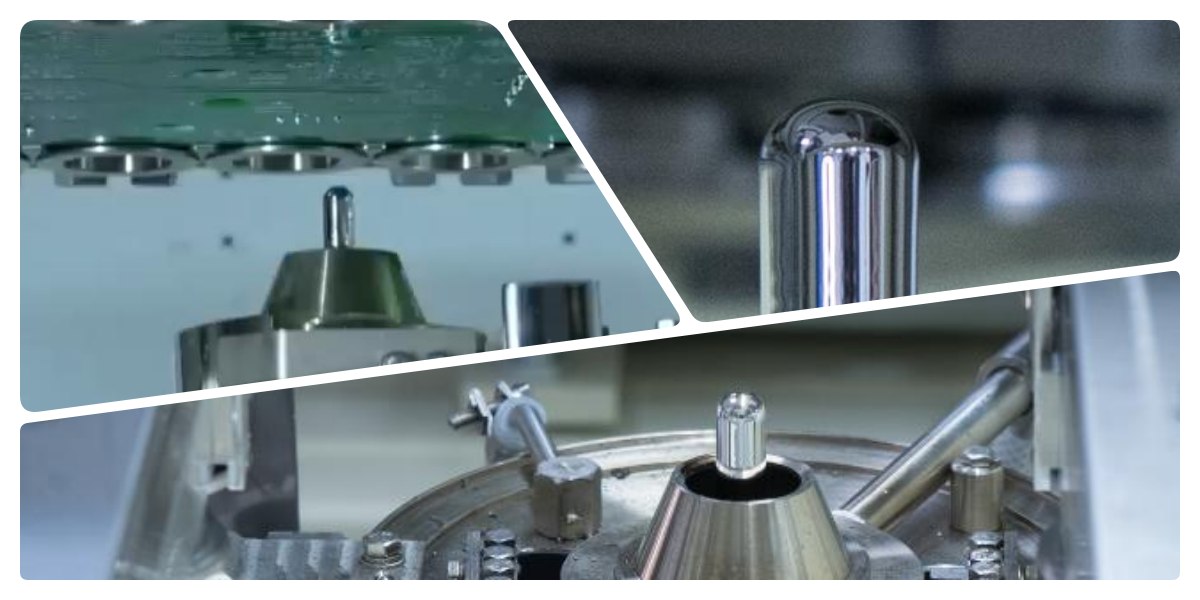

A German high-frequency jet valve shoots tiny, perfect flux dots with solids under 10%. Pressure tank plus precision flow meter keep flow dead-steady no matter the tank level. The nozzle sits on an XY platform repeatable to 0.02 mm. Dropped residue lands in a slide-out tray for instant cleanup. All pneumatics are bulletproof Japanese SMC, gauges right on the surface for quick checks. An automatic pump feeds flux without a hiccup. This system nails clean, repeatable coverage every cycle on the selective-soldering machine.

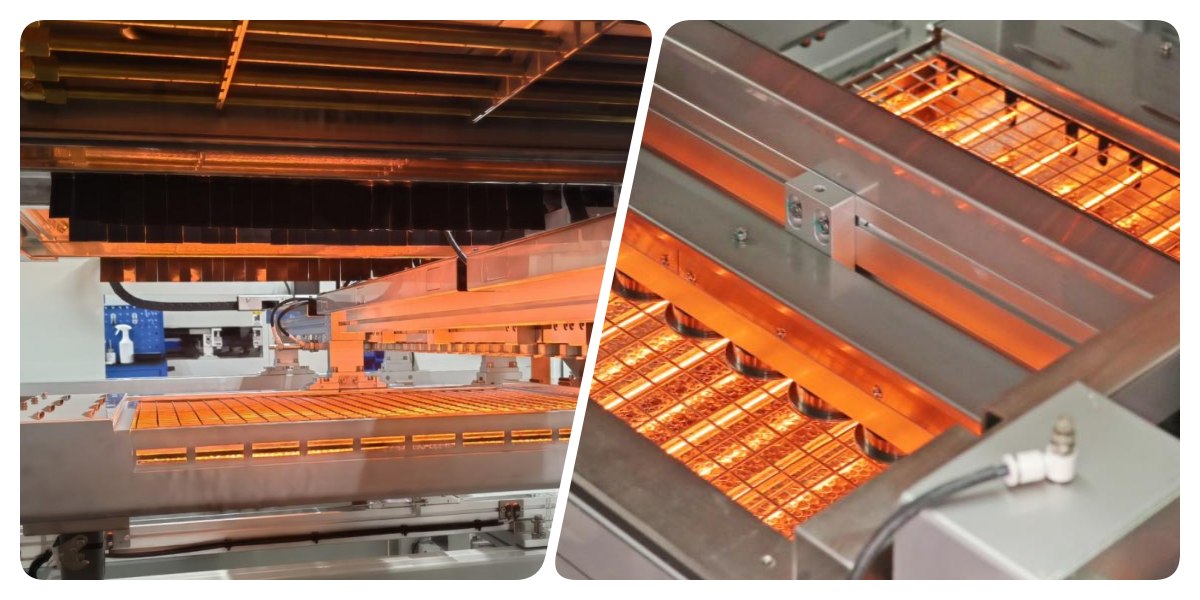

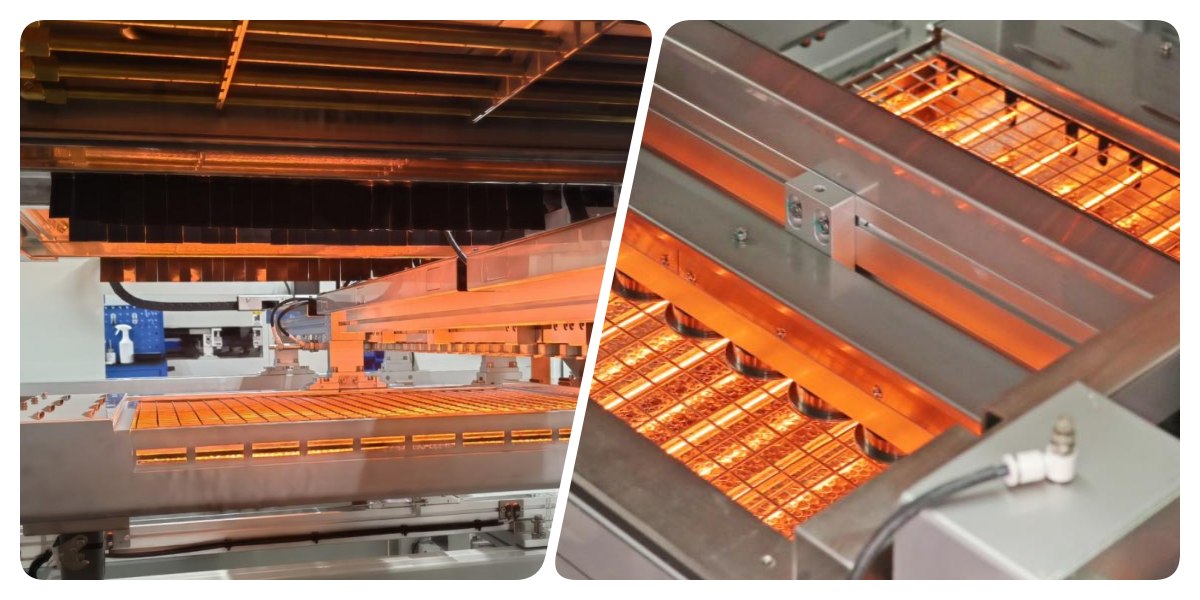

Fully adjustable bottom IR is standard; top IR or hot-air convection optional. Open design spreads heat evenly while thick insulation holds rock-steady temps. Premium elements and motors from global leaders run trouble-free for years. Everything is plug-and-play—no tools needed for service. Boards come out perfectly activated and stress-free, ready for flawless solder joints in the SMT selective wave soldering machine.

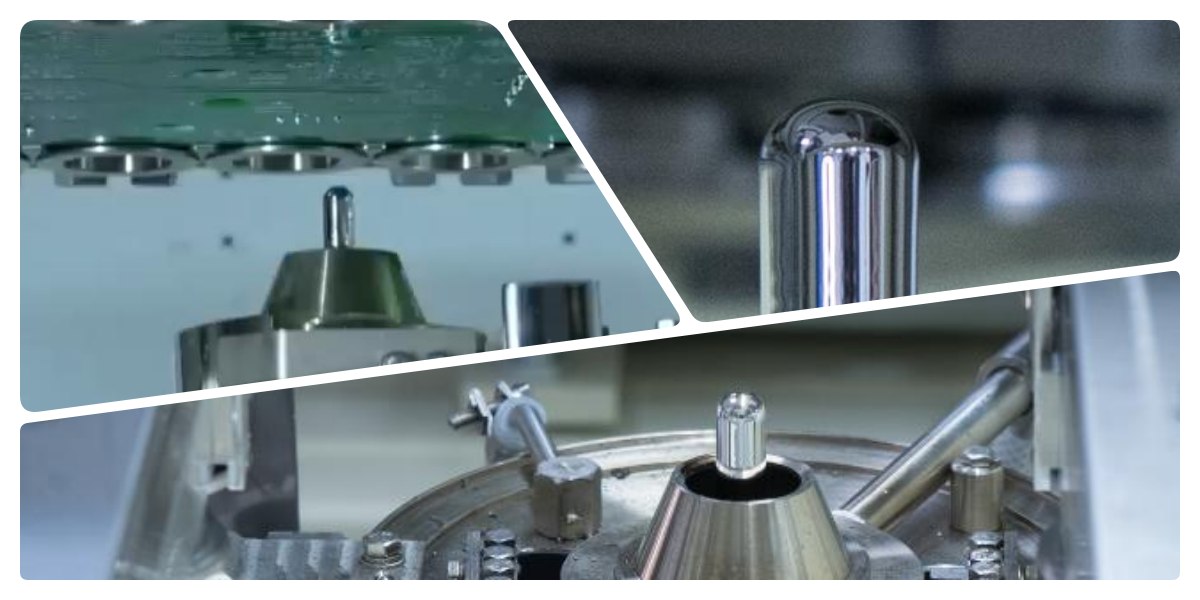

German electromagnetic pump creates an ultra-stable wave peak. Set temperature, N2 flow, height, and auto-calibration straight from the screen. Titanium pot with external cast-iron heater warms fast and never leaks. Inline nitrogen gives shiny joints and virtually zero dross. Real-time CCD records 900 hours of traceable video. Sealed high-speed XYZ axes, laser wave detection, and automatic nozzle cleaning keep the selective-soldering machine humming 24/7.

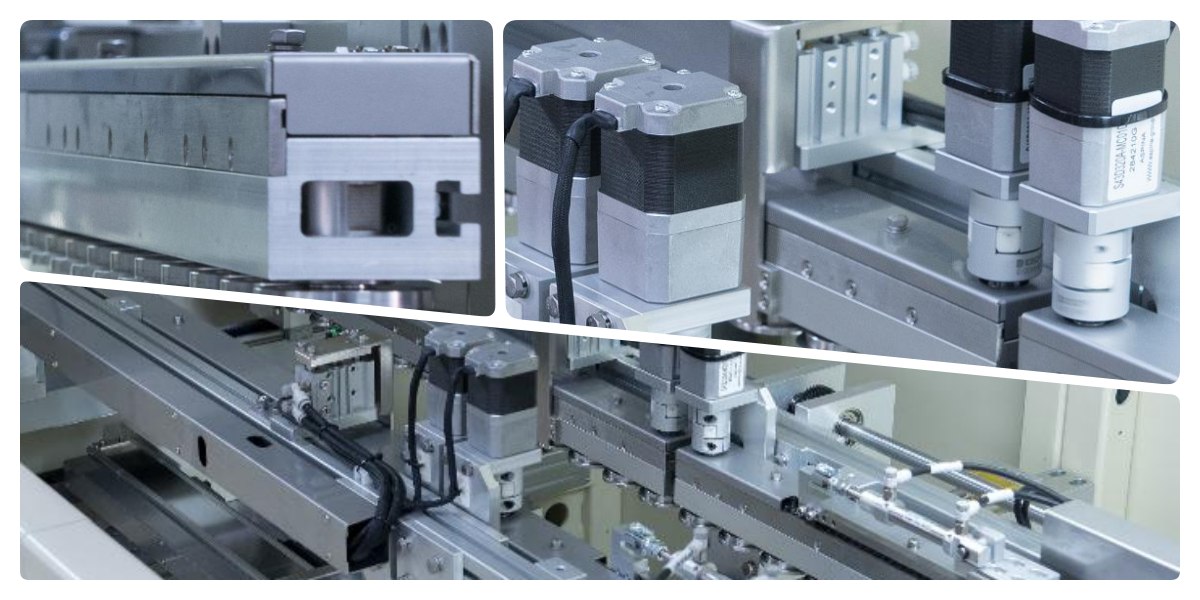

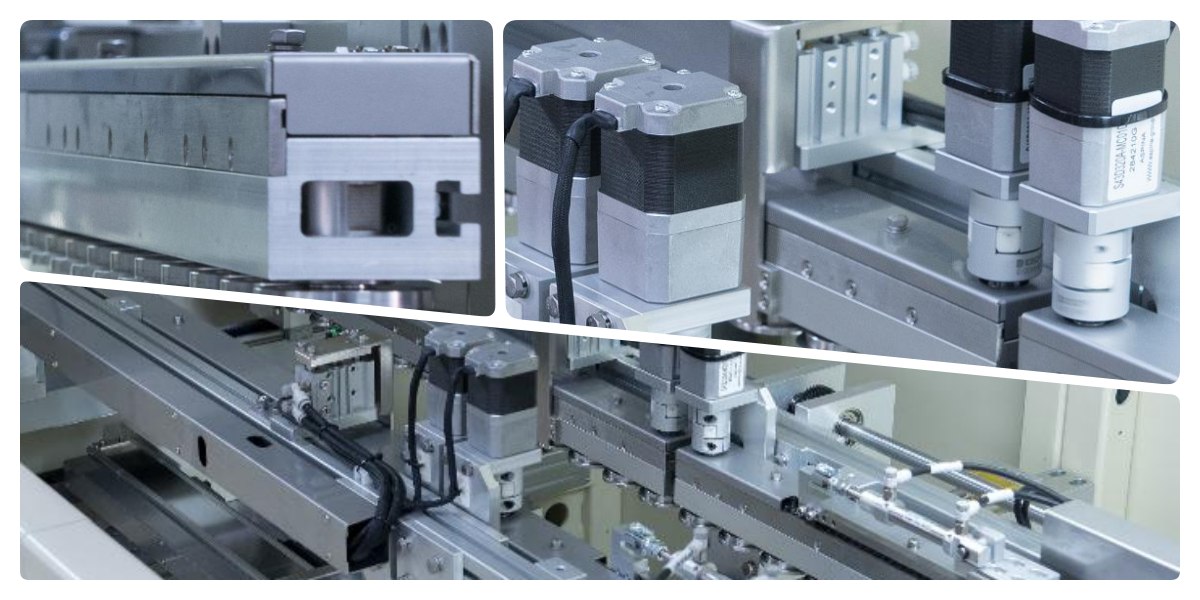

Heavy-duty profiled rails and three-section roller conveyor move boards smoothly. Side and top clamps lock the PCBA dead-still during every step. Thickened rails handle 20 kg loads with ease. Precision drive modules position boards perfectly from flux to solder. The whole transport system is built for nonstop production on the SMT selective wave soldering machine.

CE-certified PLC and high-speed bus architecture meet Industry 4.0 standards. Cat-6 wiring and top-tier electronics deliver lightning-fast response and total reliability. Guided programming, auto nozzle recognition, picture-based edits, one-click live view, and multi-language support make setup a snap. Full traceability keeps quality locked in on every selective-soldering machine.

Step-by-step guided mode, automatic nozzle ID, smart picture correction, real-time dashboards, and one-button live CCD make running the machine a breeze. Supports Chinese, English, Japanese, Russian and more. Built-in MES, Wi-Fi, remote access, voice alerts, and customizable lights keep operators in full control of the SMT selective wave soldering machine.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2025 a Vietnamese customer supplying a world-famous camera brand visited our factory to accept their new selective-soldering machine. Our engineers ran live demos on their actual boards, trained the team on programming, calibration, and daily care, and let them watch perfect joints form in real time on the CCD screen. The hands-on session gave them 100% confidence for a fast, smooth startup back home and proved I.C.T’s real global support.

| Professional Service and Training

From turnkey installation to lifetime maintenance and upgrades, I.C.T has you covered anywhere on earth. Twenty dedicated engineers handle line layout, process tuning, and in-depth training—on-site or remote. Spare-parts hubs on multiple continents and 24-hour response keep your SMT selective wave soldering machine at peak uptime year after year.

| Customer Praise

Customers rave about our patient, expert engineers who train thoroughly at acceptance and startup. They love how the selective-soldering machine nails flux dots, holds perfect wave height, and slashes defects with its dead-simple controls. Bulletproof packing arrives pristine every time, and same-day remote fixes plus lightning-fast on-site support make I.C.T the partner they never worry about.

| Industry Certifications

Every I.C.T selective-soldering machine carries CE for safety, RoHS for eco-compliance, ISO9001 for quality systems, and multiple patents on jet valves, pumps, and laser detection. These globally trusted marks prove you’re getting safe, green, innovative equipment built to the highest standards.

| About I.C.T Company and Factory

Since 2012 we’ve grown fast with full in-house R&D and a 12,000 m² state-of-the-art factory. Eighty-nine team members—including 20 engineers—and eight branch offices serve over 1,600 customers in 72 countries. Strict inspection and complete quality systems back every machine, while true turnkey solutions—planning, equipment, training, optimization—help electronics manufacturers worldwide dominate with the SMT selective wave soldering machine.

| Selective-Soldering Machine Overview

Engineered and built in China, the I.C.T selective-soldering machine is the go-to SMT selective wave soldering machine for high-mix, high-volume lines. The PCB stays perfectly still while the lightweight cast-aluminum platform—powered by Panasonic servos and precision linear rails—moves flux and solder heads with whisper-quiet speed and pinpoint accuracy. Inline nitrogen heating delivers perfect wetting and almost no dross. Every parameter is dialed in and saved in an easy Windows interface for rock-solid repeatability. Automatic wave calibration, real-time CCD monitoring, German jet valve, and titanium pot keep quality sky-high and rework at zero shift after shift.

| DIP Line Equipment List

A German high-frequency jet valve shoots tiny, perfect flux dots with solids under 10%. Pressure tank plus precision flow meter keep flow dead-steady no matter the tank level. The nozzle sits on an XY platform repeatable to 0.02 mm. Dropped residue lands in a slide-out tray for instant cleanup. All pneumatics are bulletproof Japanese SMC, gauges right on the surface for quick checks. An automatic pump feeds flux without a hiccup. This system nails clean, repeatable coverage every cycle on the selective-soldering machine.

Fully adjustable bottom IR is standard; top IR or hot-air convection optional. Open design spreads heat evenly while thick insulation holds rock-steady temps. Premium elements and motors from global leaders run trouble-free for years. Everything is plug-and-play—no tools needed for service. Boards come out perfectly activated and stress-free, ready for flawless solder joints in the SMT selective wave soldering machine.

German electromagnetic pump creates an ultra-stable wave peak. Set temperature, N2 flow, height, and auto-calibration straight from the screen. Titanium pot with external cast-iron heater warms fast and never leaks. Inline nitrogen gives shiny joints and virtually zero dross. Real-time CCD records 900 hours of traceable video. Sealed high-speed XYZ axes, laser wave detection, and automatic nozzle cleaning keep the selective-soldering machine humming 24/7.

Heavy-duty profiled rails and three-section roller conveyor move boards smoothly. Side and top clamps lock the PCBA dead-still during every step. Thickened rails handle 20 kg loads with ease. Precision drive modules position boards perfectly from flux to solder. The whole transport system is built for nonstop production on the SMT selective wave soldering machine.

CE-certified PLC and high-speed bus architecture meet Industry 4.0 standards. Cat-6 wiring and top-tier electronics deliver lightning-fast response and total reliability. Guided programming, auto nozzle recognition, picture-based edits, one-click live view, and multi-language support make setup a snap. Full traceability keeps quality locked in on every selective-soldering machine.

Step-by-step guided mode, automatic nozzle ID, smart picture correction, real-time dashboards, and one-button live CCD make running the machine a breeze. Supports Chinese, English, Japanese, Russian and more. Built-in MES, Wi-Fi, remote access, voice alerts, and customizable lights keep operators in full control of the SMT selective wave soldering machine.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2025 a Vietnamese customer supplying a world-famous camera brand visited our factory to accept their new selective-soldering machine. Our engineers ran live demos on their actual boards, trained the team on programming, calibration, and daily care, and let them watch perfect joints form in real time on the CCD screen. The hands-on session gave them 100% confidence for a fast, smooth startup back home and proved I.C.T’s real global support.

| Professional Service and Training

From turnkey installation to lifetime maintenance and upgrades, I.C.T has you covered anywhere on earth. Twenty dedicated engineers handle line layout, process tuning, and in-depth training—on-site or remote. Spare-parts hubs on multiple continents and 24-hour response keep your SMT selective wave soldering machine at peak uptime year after year.

| Customer Praise

Customers rave about our patient, expert engineers who train thoroughly at acceptance and startup. They love how the selective-soldering machine nails flux dots, holds perfect wave height, and slashes defects with its dead-simple controls. Bulletproof packing arrives pristine every time, and same-day remote fixes plus lightning-fast on-site support make I.C.T the partner they never worry about.

| Industry Certifications

Every I.C.T selective-soldering machine carries CE for safety, RoHS for eco-compliance, ISO9001 for quality systems, and multiple patents on jet valves, pumps, and laser detection. These globally trusted marks prove you’re getting safe, green, innovative equipment built to the highest standards.

| About I.C.T Company and Factory

Since 2012 we’ve grown fast with full in-house R&D and a 12,000 m² state-of-the-art factory. Eighty-nine team members—including 20 engineers—and eight branch offices serve over 1,600 customers in 72 countries. Strict inspection and complete quality systems back every machine, while true turnkey solutions—planning, equipment, training, optimization—help electronics manufacturers worldwide dominate with the SMT selective wave soldering machine.