I.C.T-AI-5146W

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced Automatic PCB AOI Machine AI-5146W

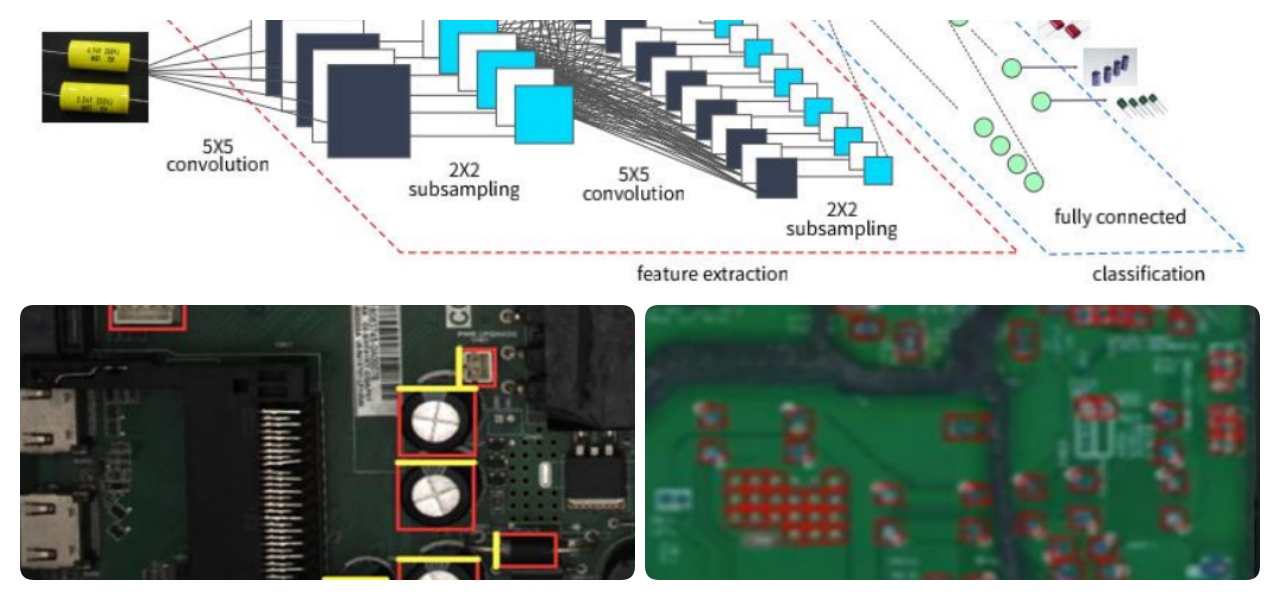

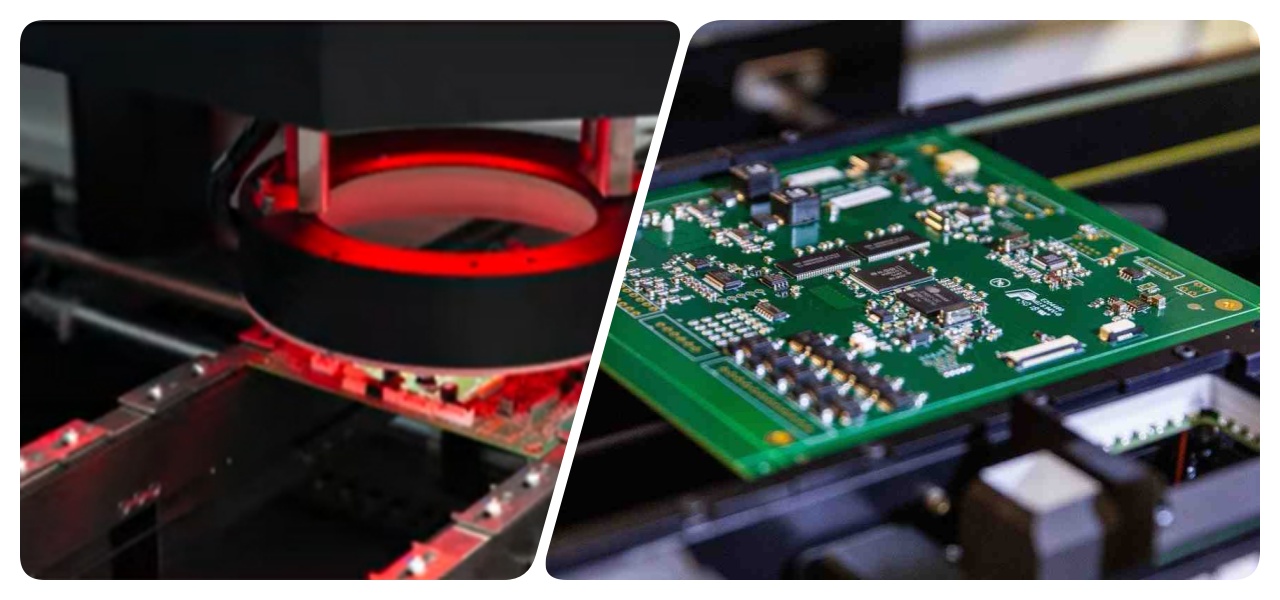

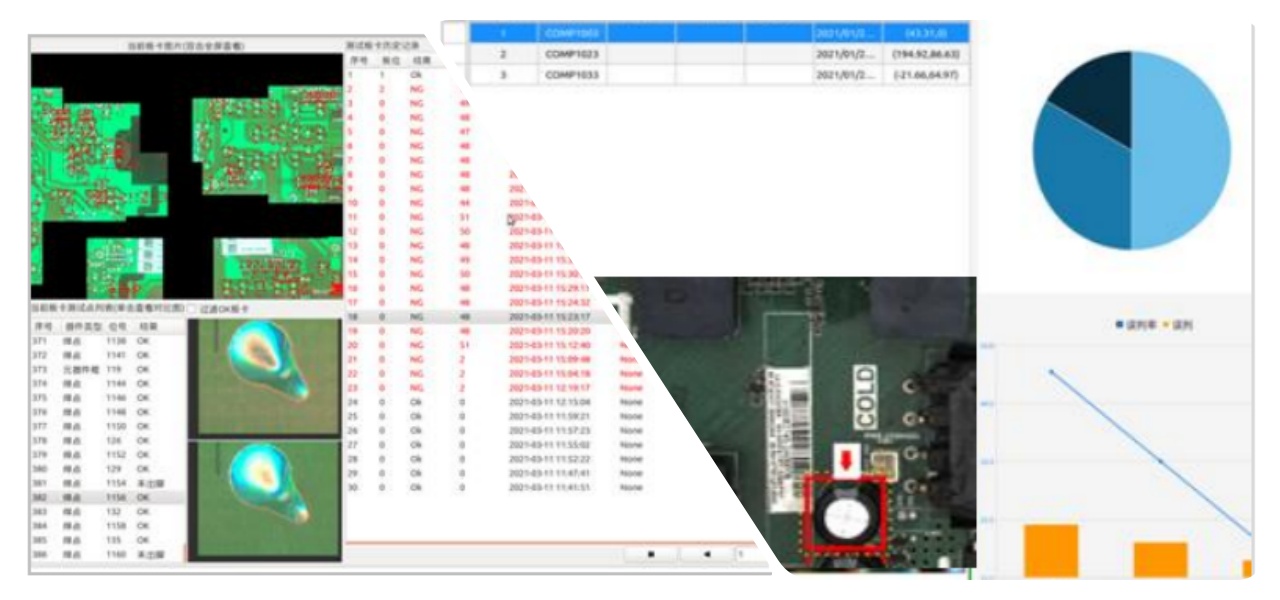

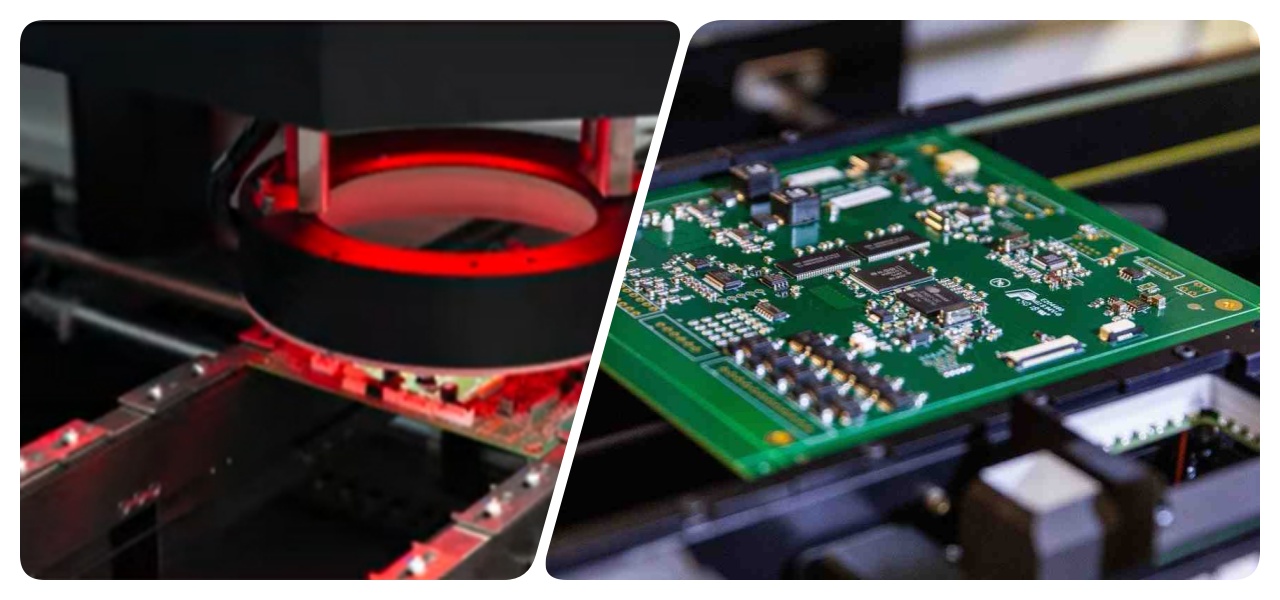

The I.C.T AI-5146W is a cutting-edge online aoi inspection machine designed for dual-side inspection after THT soldering. It uses high-precision color cameras and CNN algorithms to capture and process board images in real time, intelligently judging defects like wrong parts, missing components, or reverse polarity. This automated optical inspection machine boosts production efficiency by spanning over lines without changes, offering quick defect location and control over the production line. With features like remote programming and MES data reports, it ensures traceable data and low false alarms. Ideal for SMT factories, this aoi-optical inspection machine supports various PCB sizes and thicknesses, making it a reliable tool for quality assurance in electronics manufacturing.

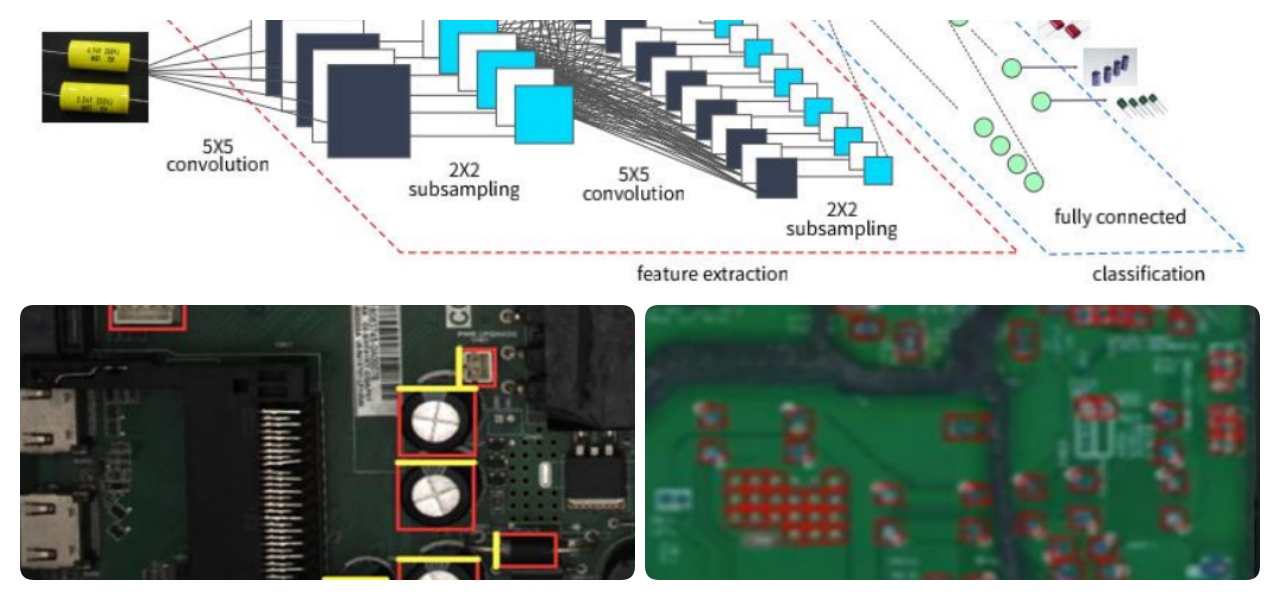

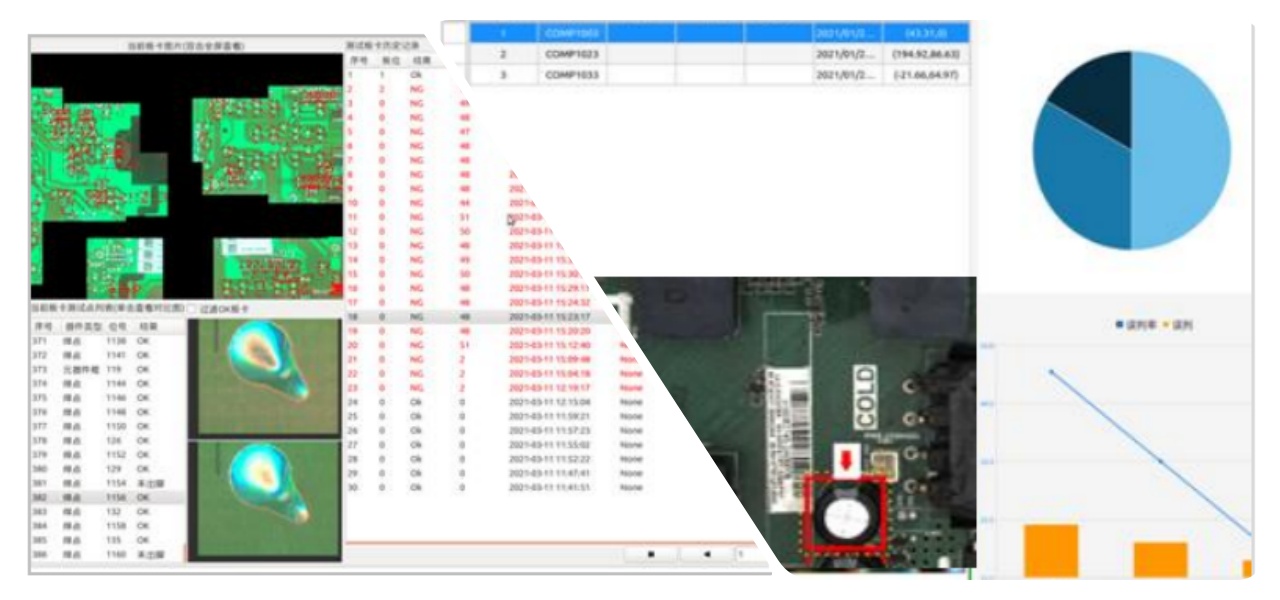

| Feature

The AI-5146W automatic pcb aoi machine employs deep learning through CNN to optimize big data and enable intelligent minimalist programming. It automatically identifies components and solder joints with one-click, solving issues of long programming times and high false alarms common in traditional methods. Trained on vast datasets, it accurately distinguishes NG from OK boards, even with varying solder joint shapes. This reduces miss inspections and enhances generalization for diverse scenarios, like handling component overhangs or pin holes in solder without interference.

This automated optical inspection machine offers flexible programming, allowing online or offline adjustments without halting production. It intelligently checks color ring resistors, capacitors, diodes, and sockets. Programming takes just 10-20 minutes, with quick changeovers by calling existing files. Audible alarms prompt for item numbers, wrong devices, or types, ensuring smooth operations. Short debugging times of 10-15 minutes make it user-friendly for operators.

Supporting multi-board, mixed board, and mixed material inspections, the online aoi inspection machine handles rotations at multiple angles and positions. It includes Bad Mark skipping, enhancing versatility for various production needs without compromising speed or accuracy.

| Specification

| Model | I.C.T DIP On-line Dual side AOI AI-5146W (After THT Soldering) | I.C.T DIP On-line Dual side AOI AI-5146WL (After THT Soldering) |

| FOV | 52.6*44mm | |

| Resolution | 21.5um | |

| Camera | 5M | |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:75mm, Bottom:75mm | |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 750&900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 520W | |

| Communication | SMEMA | |

| Weight | 890Kg | 100Kg |

| Dimension | L1050*W1335*H1650mm | L1050*W1535*H1650mm |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In our featured video, we showcase five advanced AOI models, including the AI-4026, AI-4540, AI-5146W, highlighting their efficient programming features. The video demonstrates one-key programming for quick setup, parameter broadcasting to apply settings across components, automatic detection of bridging solder frames, panel copy programming for replicated boards, and intelligent path planning to optimize inspection routes. This real-world example from a client's SMT line in Mexico illustrates how the AI-5146W automatic pcb aoi machine integrates seamlessly, reducing setup time by up to 50% and improving defect detection accuracy. Engineers on-site provide hands-on service, ensuring smooth installation and training, which helped the client achieve higher throughput and fewer false alarms in their production process.

| Service & Training

I.C.T provides comprehensive service and training to maximize your automatic pcb aoi machine performance. Our global team offers installation, remote debugging, and on-site maintenance, ensuring minimal downtime. Training programs cover operation, programming, and troubleshooting, tailored to your needs. With centralized management, we support one-to-many judgments and quick responses, helping you optimize production. Our long-term partnership approach includes regular updates and technical support, building trust and efficiency for your factory.

| Customer Reviews

Our clients praise I.C.T engineers for their expertise and quick problem-solving during installations. They love the reliable automatic pcb aoi machine performance, noting its accuracy and ease of use. Many highlight our secure packaging and fast shipping that prevent damage. Additionally, customers appreciate our rapid responses to queries, ensuring smooth operations and strong ongoing support.

| Our Certification

I.C.T holds key certifications like CE, RoHS, ISO9001, and various patents, reflecting our commitment to quality and safety. These ensure our automatic pcb aoi machine meets global standards for environmental compliance and reliability. Our patented technologies in AI inspection enhance innovation, while ISO9001 guarantees consistent manufacturing processes, giving clients confidence in product durability and performance.

| About I.C.T & Our Factory

I.C.T is a leading electronics manufacturer with in-house R&D and production, employing over 89 staff in a 12,000m² facility. We've grown rapidly since 2012, serving more than 1,600 customers across 72 countries. Our factories feature strict testing procedures and robust quality management systems, ensuring every automatic pcb aoi machine meets high standards. With 20 engineers and 8 branch offices, we provide global solutions from demand analysis to optimization.

| Advanced Automatic PCB AOI Machine AI-5146W

The I.C.T AI-5146W is a cutting-edge online aoi inspection machine designed for dual-side inspection after THT soldering. It uses high-precision color cameras and CNN algorithms to capture and process board images in real time, intelligently judging defects like wrong parts, missing components, or reverse polarity. This automated optical inspection machine boosts production efficiency by spanning over lines without changes, offering quick defect location and control over the production line. With features like remote programming and MES data reports, it ensures traceable data and low false alarms. Ideal for SMT factories, this aoi-optical inspection machine supports various PCB sizes and thicknesses, making it a reliable tool for quality assurance in electronics manufacturing.

| Feature

The AI-5146W automatic pcb aoi machine employs deep learning through CNN to optimize big data and enable intelligent minimalist programming. It automatically identifies components and solder joints with one-click, solving issues of long programming times and high false alarms common in traditional methods. Trained on vast datasets, it accurately distinguishes NG from OK boards, even with varying solder joint shapes. This reduces miss inspections and enhances generalization for diverse scenarios, like handling component overhangs or pin holes in solder without interference.

This automated optical inspection machine offers flexible programming, allowing online or offline adjustments without halting production. It intelligently checks color ring resistors, capacitors, diodes, and sockets. Programming takes just 10-20 minutes, with quick changeovers by calling existing files. Audible alarms prompt for item numbers, wrong devices, or types, ensuring smooth operations. Short debugging times of 10-15 minutes make it user-friendly for operators.

Supporting multi-board, mixed board, and mixed material inspections, the online aoi inspection machine handles rotations at multiple angles and positions. It includes Bad Mark skipping, enhancing versatility for various production needs without compromising speed or accuracy.

| Specification

| Model | I.C.T DIP On-line Dual side AOI AI-5146W (After THT Soldering) | I.C.T DIP On-line Dual side AOI AI-5146WL (After THT Soldering) |

| FOV | 52.6*44mm | |

| Resolution | 21.5um | |

| Camera | 5M | |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:75mm, Bottom:75mm | |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 750&900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 520W | |

| Communication | SMEMA | |

| Weight | 890Kg | 100Kg |

| Dimension | L1050*W1335*H1650mm | L1050*W1535*H1650mm |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In our featured video, we showcase five advanced AOI models, including the AI-4026, AI-4540, AI-5146W, highlighting their efficient programming features. The video demonstrates one-key programming for quick setup, parameter broadcasting to apply settings across components, automatic detection of bridging solder frames, panel copy programming for replicated boards, and intelligent path planning to optimize inspection routes. This real-world example from a client's SMT line in Mexico illustrates how the AI-5146W automatic pcb aoi machine integrates seamlessly, reducing setup time by up to 50% and improving defect detection accuracy. Engineers on-site provide hands-on service, ensuring smooth installation and training, which helped the client achieve higher throughput and fewer false alarms in their production process.

| Service & Training

I.C.T provides comprehensive service and training to maximize your automatic pcb aoi machine performance. Our global team offers installation, remote debugging, and on-site maintenance, ensuring minimal downtime. Training programs cover operation, programming, and troubleshooting, tailored to your needs. With centralized management, we support one-to-many judgments and quick responses, helping you optimize production. Our long-term partnership approach includes regular updates and technical support, building trust and efficiency for your factory.

| Customer Reviews

Our clients praise I.C.T engineers for their expertise and quick problem-solving during installations. They love the reliable automatic pcb aoi machine performance, noting its accuracy and ease of use. Many highlight our secure packaging and fast shipping that prevent damage. Additionally, customers appreciate our rapid responses to queries, ensuring smooth operations and strong ongoing support.

| Our Certification

I.C.T holds key certifications like CE, RoHS, ISO9001, and various patents, reflecting our commitment to quality and safety. These ensure our automatic pcb aoi machine meets global standards for environmental compliance and reliability. Our patented technologies in AI inspection enhance innovation, while ISO9001 guarantees consistent manufacturing processes, giving clients confidence in product durability and performance.

| About I.C.T & Our Factory

I.C.T is a leading electronics manufacturer with in-house R&D and production, employing over 89 staff in a 12,000m² facility. We've grown rapidly since 2012, serving more than 1,600 customers across 72 countries. Our factories feature strict testing procedures and robust quality management systems, ensuring every automatic pcb aoi machine meets high standards. With 20 engineers and 8 branch offices, we provide global solutions from demand analysis to optimization.