Selective wave soldering offers precise and efficient PCB soldering solutions.

a. Fixed PCB plate with moving spray and soldering platform.

b. High soldering quality improves pass rate significantly.

c. Modular SMEMA design supports flexible line formation.

d. Full PC control ensures easy parameter adjustments.

e. Auto wave height calibration maintains stable performance.

f. CCD Mark positioning enhances accurate PCB alignment.

g. Titanium solder pot ensures durable and reliable operation.

I.C.T-SS550

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Selective Wave Soldering Overview

The I.C.T On-line Selective Wave Soldering Machine SS530/550 is a high-performance solution crafted in China, designed for precise PCB soldering. This selective wave soldering system features a fixed PCB plate and moving spray/soldering platform, perfect for high-volume production. With full PC control, it allows easy adjustments for solder temperature, flux type, and N2 temperature, ensuring excellent traceability. Backed by over 25 years of expertise, I.C.T serves more than 1600 customers across 72 countries, delivering reliable equipment to enhance manufacturing efficiency. The titanium solder pot and German jet valves provide stability, making this selective PCB soldering machine a trusted choice globally.

| DIP Line Equipment List

The selective wave soldering machine features a precision flux application system with a German high-frequency pulse injection valve. This technology delivers small flux dots with a solid content less than 10%, ensuring accurate and clean application. The nozzle, mounted on an XY platform with 0.02mm repetition accuracy, minimizes waste and enhances soldering quality. Supported by a pressure tank and SMC pneumatic components, this system maintains stable flux supply, making it ideal for complex PCB soldering tasks.

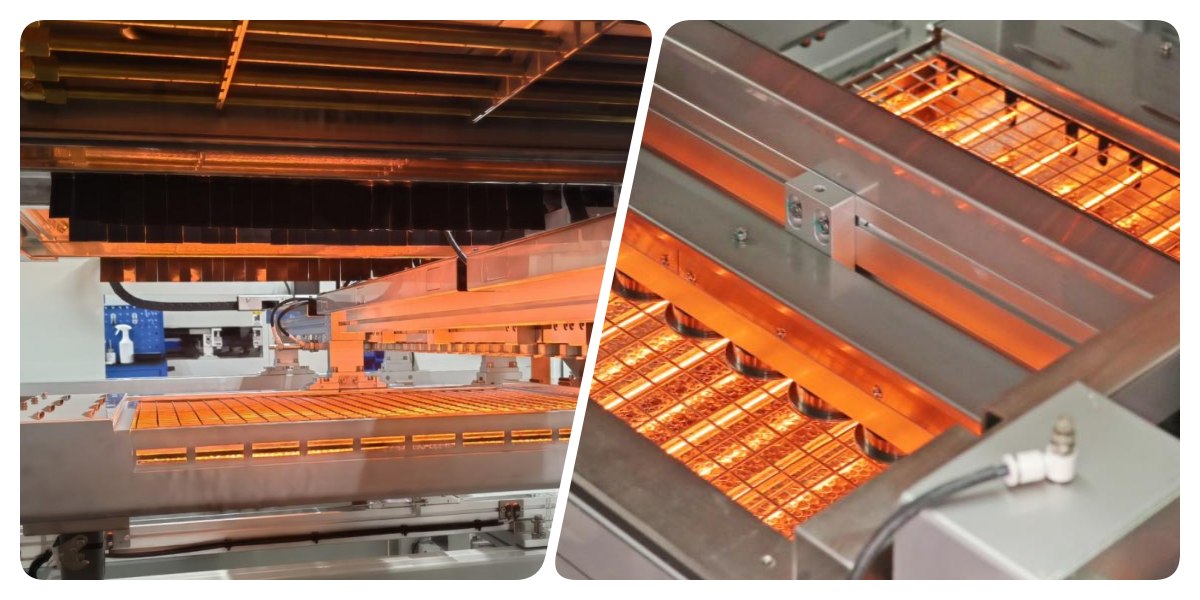

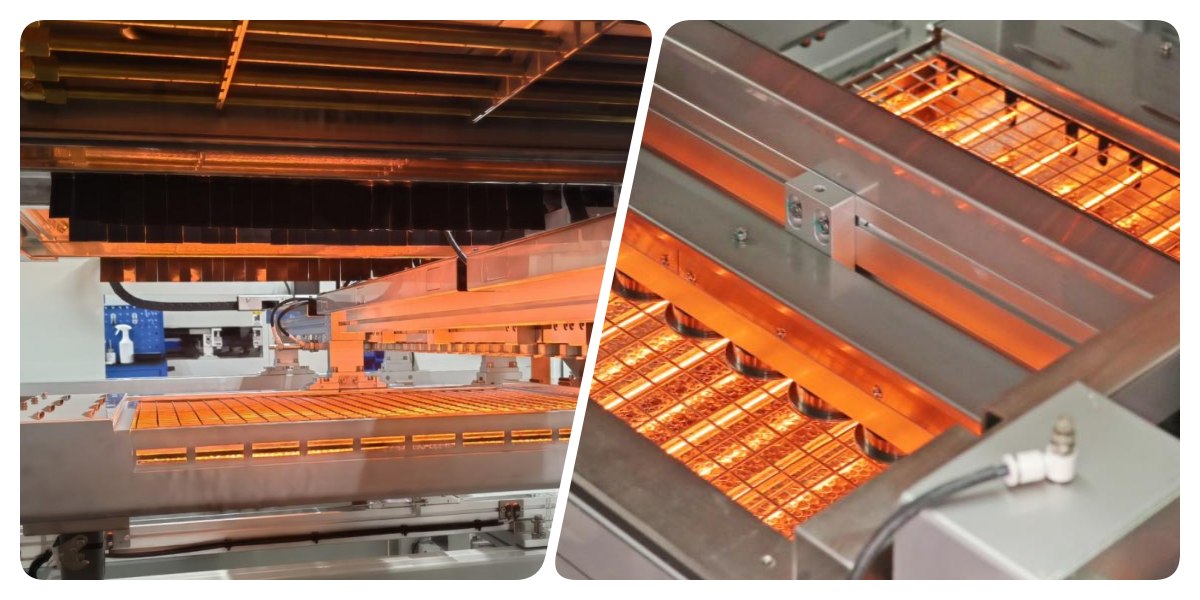

Efficient preheat optimization is a key feature of this selective wave soldering system. Equipped with adjustable bottom preheating and an IR heater on top, the system maximizes the preheating area for uniform heat distribution. The all-round high-temperature cotton design ensures temperature stability, while the maintenance plug-in design allows tool-free servicing. This setup reduces warm-up time to about 15 minutes, boosting productivity for selective PCB soldering machine operations.

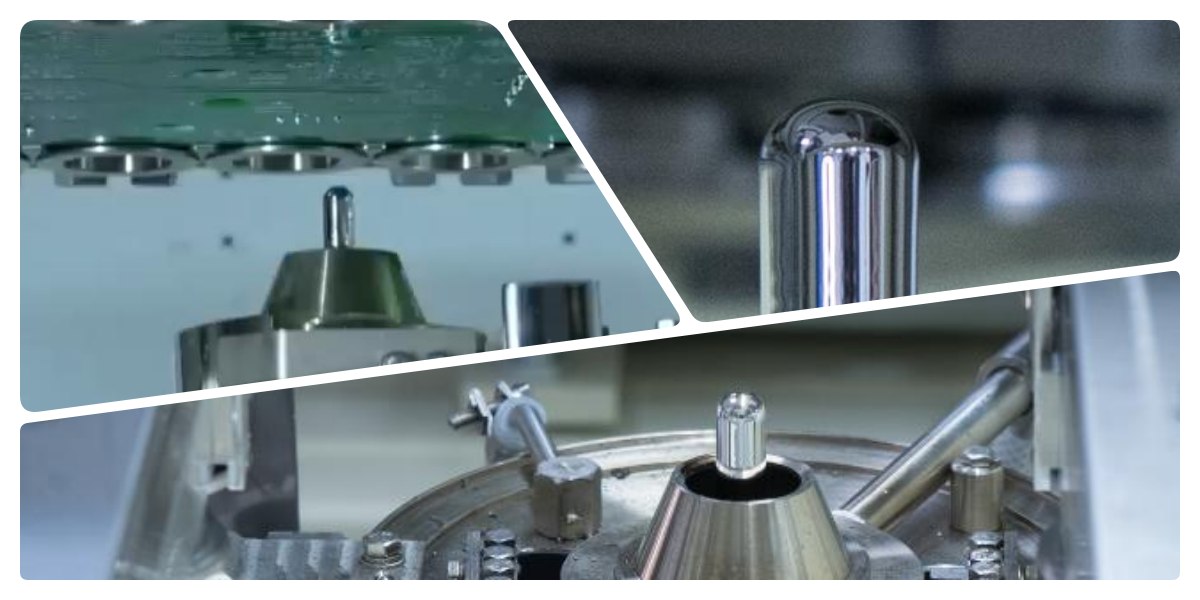

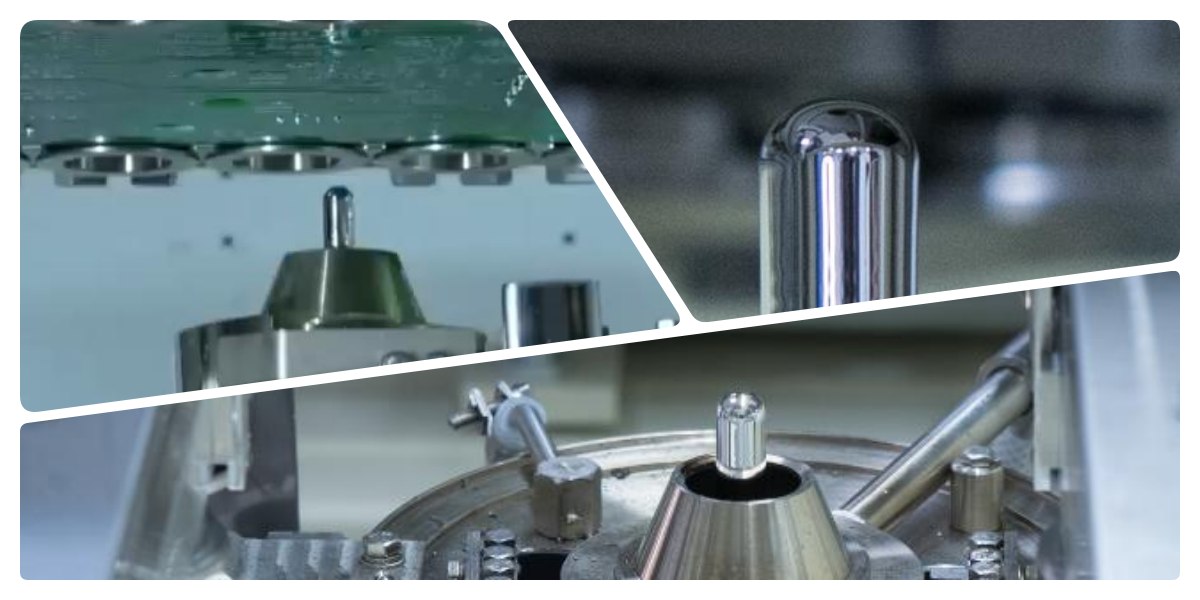

Advanced soldering technology in the selective wave soldering machine ensures top performance. The electromagnetic pump provides stable and reliable solder peaks, while the titanium solder pot prevents leakage and heats up quickly with a cast iron heater. An N2 online heating system improves solder wetting and reduces dross, supported by software-controlled settings for temperature, wave height, and calibration. This technology delivers consistent results for high-volume production.

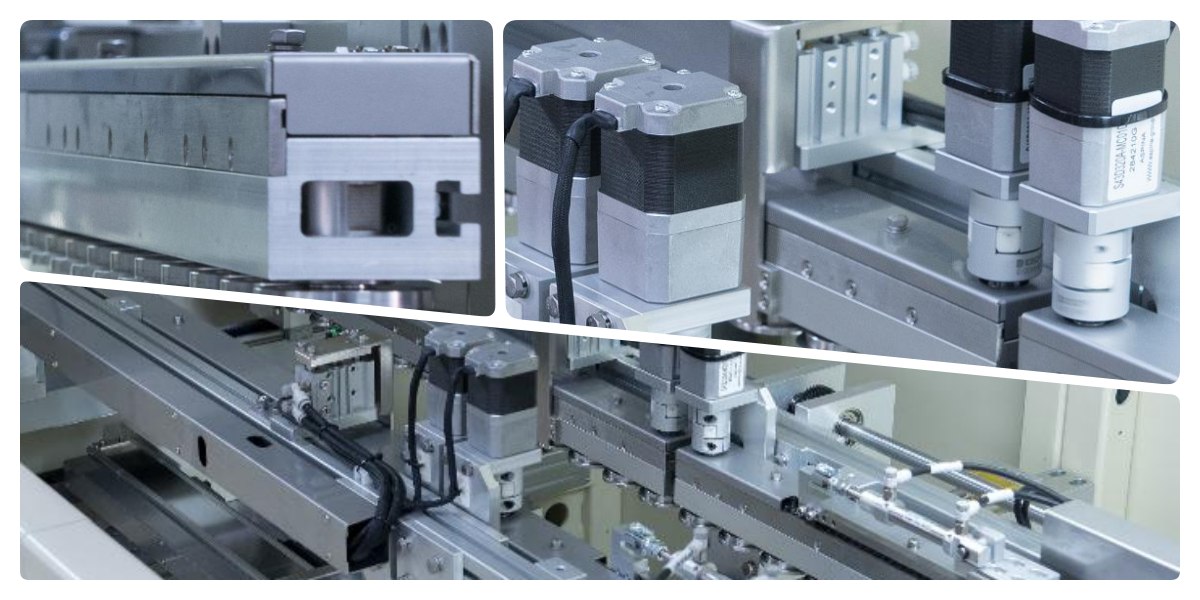

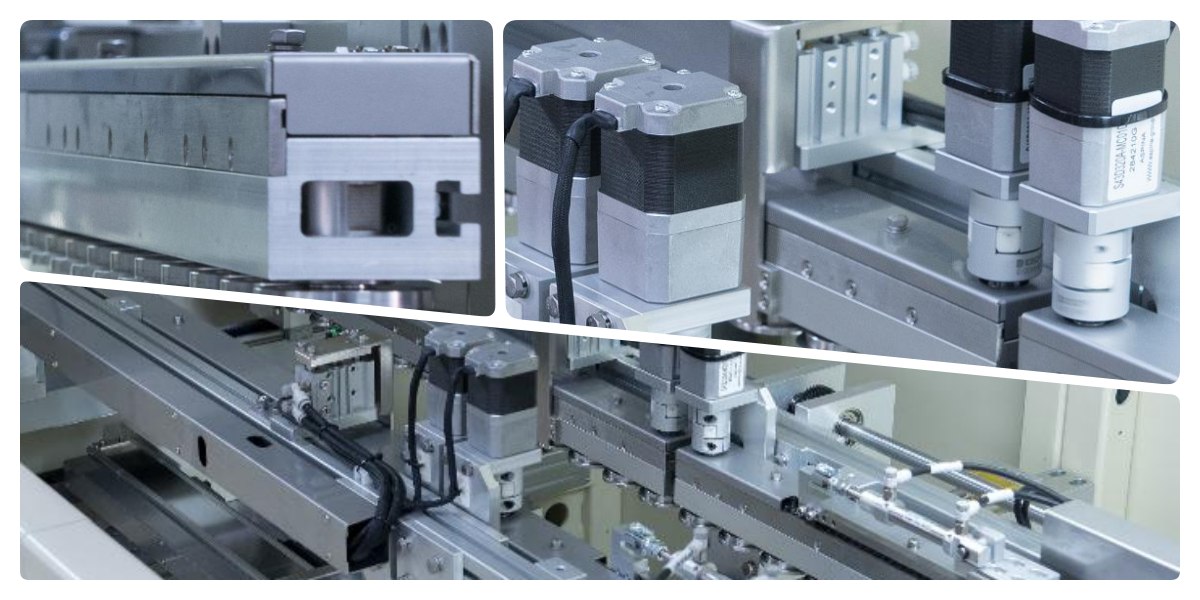

The durable transmission design of this selective PCB soldering machine uses special material profiles and a three-part roller system for stability. Thickened customized rails support up to 20kg loads, with a PCBA side and top clamp system ensuring board stability. Japanese motor and pneumatic components enhance reliability, while a transportation buffer zone prevents collisions, making it a robust choice for long-term manufacturing use.

Reliable control integration is achieved with a PLC+ module high-end bus system in this selective wave soldering machine. This setup ensures stability and scalability, meeting CE standards and supporting Industry 4.0 designs. Global high-quality electrical parts and Cat-6 network cables provide fast communication and sensitive responses, allowing precise control over all soldering parameters for consistent performance.

The user-friendly operating interface of the selective wave soldering system features a guided programming mode with CCD fast programming and auto nozzle identification. It supports multiple languages like Chinese, English, and Japanese, with real-time data visualization and one-button switching to CCD monitoring. This intuitive design, combined with picture programming and intelligent coordinate verification, simplifies operation and improves efficiency for all users.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

I.C.T engineers traveled to Mexico to provide technical support for multiple clients, delivering services for coating lines, wave soldering machines Acrab350/Acrab450, and selective soldering machine SS540. One client, an automotive electronics manufacturer using the Acrab350, produced two different PCBA types with unique fixtures, showcasing the machine’s flexibility. Our team ensured seamless installation and optimized performance, meeting the client’s high standards. A video featuring positive feedback from a selective soldering client highlights their satisfaction with the SS540’s reliability and efficiency, reflecting I.C.T’s commitment to global support and quality service.

| Professional Service and Training

I.C.T offers comprehensive service and training for our selective wave soldering machines. Our team provides installation, maintenance, and technical support to ensure smooth operation. Training sessions cover machine setup, parameter adjustments, and troubleshooting, helping operators maximize efficiency. With over 25 years of experience, we support customers worldwide, offering long-term growth through regular updates and process optimization. Our goal is to provide zero-risk solutions, ensuring your production line runs without worries.

| Customer Praise

Customers love our selective wave soldering machines for their outstanding performance. They praise our engineers for their expert installation and quick problem-solving skills. The equipment’s reliability and soldering quality receive high marks, while the durable packaging ensures safe delivery. Clients also appreciate our fast response to issues, making I.C.T a trusted partner in their manufacturing process.

| Industry Certifications

I.C.T selective wave soldering machines are certified with CE, RoHS, and ISO9001 standards, ensuring top safety and quality. We also hold multiple patents for our innovative designs, reflecting our commitment to excellence. These certifications guarantee that our products meet global manufacturing requirements, providing customers with reliable and eco-friendly solutions.

| About I.C.T Company and Factory

I.C.T is a leading provider of electronic manufacturing solutions with over 25 years of experience. Based in Dongguan, China, our factory spans 12,000m² and employs 89 staff, including 20 engineers. We handle research, development, and production in-house, serving over 1600 customers across 72 countries. Our rapid growth and strict quality control systems ensure high standards. With a $30 million registered fund, we maintain a robust quality management system, delivering reliable selective wave soldering machines globally.

| Selective Wave Soldering Overview

The I.C.T On-line Selective Wave Soldering Machine SS530/550 is a high-performance solution crafted in China, designed for precise PCB soldering. This selective wave soldering system features a fixed PCB plate and moving spray/soldering platform, perfect for high-volume production. With full PC control, it allows easy adjustments for solder temperature, flux type, and N2 temperature, ensuring excellent traceability. Backed by over 25 years of expertise, I.C.T serves more than 1600 customers across 72 countries, delivering reliable equipment to enhance manufacturing efficiency. The titanium solder pot and German jet valves provide stability, making this selective PCB soldering machine a trusted choice globally.

| DIP Line Equipment List

The selective wave soldering machine features a precision flux application system with a German high-frequency pulse injection valve. This technology delivers small flux dots with a solid content less than 10%, ensuring accurate and clean application. The nozzle, mounted on an XY platform with 0.02mm repetition accuracy, minimizes waste and enhances soldering quality. Supported by a pressure tank and SMC pneumatic components, this system maintains stable flux supply, making it ideal for complex PCB soldering tasks.

Efficient preheat optimization is a key feature of this selective wave soldering system. Equipped with adjustable bottom preheating and an IR heater on top, the system maximizes the preheating area for uniform heat distribution. The all-round high-temperature cotton design ensures temperature stability, while the maintenance plug-in design allows tool-free servicing. This setup reduces warm-up time to about 15 minutes, boosting productivity for selective PCB soldering machine operations.

Advanced soldering technology in the selective wave soldering machine ensures top performance. The electromagnetic pump provides stable and reliable solder peaks, while the titanium solder pot prevents leakage and heats up quickly with a cast iron heater. An N2 online heating system improves solder wetting and reduces dross, supported by software-controlled settings for temperature, wave height, and calibration. This technology delivers consistent results for high-volume production.

The durable transmission design of this selective PCB soldering machine uses special material profiles and a three-part roller system for stability. Thickened customized rails support up to 20kg loads, with a PCBA side and top clamp system ensuring board stability. Japanese motor and pneumatic components enhance reliability, while a transportation buffer zone prevents collisions, making it a robust choice for long-term manufacturing use.

Reliable control integration is achieved with a PLC+ module high-end bus system in this selective wave soldering machine. This setup ensures stability and scalability, meeting CE standards and supporting Industry 4.0 designs. Global high-quality electrical parts and Cat-6 network cables provide fast communication and sensitive responses, allowing precise control over all soldering parameters for consistent performance.

The user-friendly operating interface of the selective wave soldering system features a guided programming mode with CCD fast programming and auto nozzle identification. It supports multiple languages like Chinese, English, and Japanese, with real-time data visualization and one-button switching to CCD monitoring. This intuitive design, combined with picture programming and intelligent coordinate verification, simplifies operation and improves efficiency for all users.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

I.C.T engineers traveled to Mexico to provide technical support for multiple clients, delivering services for coating lines, wave soldering machines Acrab350/Acrab450, and selective soldering machine SS540. One client, an automotive electronics manufacturer using the Acrab350, produced two different PCBA types with unique fixtures, showcasing the machine’s flexibility. Our team ensured seamless installation and optimized performance, meeting the client’s high standards. A video featuring positive feedback from a selective soldering client highlights their satisfaction with the SS540’s reliability and efficiency, reflecting I.C.T’s commitment to global support and quality service.

| Professional Service and Training

I.C.T offers comprehensive service and training for our selective wave soldering machines. Our team provides installation, maintenance, and technical support to ensure smooth operation. Training sessions cover machine setup, parameter adjustments, and troubleshooting, helping operators maximize efficiency. With over 25 years of experience, we support customers worldwide, offering long-term growth through regular updates and process optimization. Our goal is to provide zero-risk solutions, ensuring your production line runs without worries.

| Customer Praise

Customers love our selective wave soldering machines for their outstanding performance. They praise our engineers for their expert installation and quick problem-solving skills. The equipment’s reliability and soldering quality receive high marks, while the durable packaging ensures safe delivery. Clients also appreciate our fast response to issues, making I.C.T a trusted partner in their manufacturing process.

| Industry Certifications

I.C.T selective wave soldering machines are certified with CE, RoHS, and ISO9001 standards, ensuring top safety and quality. We also hold multiple patents for our innovative designs, reflecting our commitment to excellence. These certifications guarantee that our products meet global manufacturing requirements, providing customers with reliable and eco-friendly solutions.

| About I.C.T Company and Factory

I.C.T is a leading provider of electronic manufacturing solutions with over 25 years of experience. Based in Dongguan, China, our factory spans 12,000m² and employs 89 staff, including 20 engineers. We handle research, development, and production in-house, serving over 1600 customers across 72 countries. Our rapid growth and strict quality control systems ensure high standards. With a $30 million registered fund, we maintain a robust quality management system, delivering reliable selective wave soldering machines globally.