X9300

I.C.T

X-ray inspection machine

| Availability: | |

|---|---|

| Quantity: | |

In the dynamic realm of Surface Mount Technology (SMT), precision and quality are non-negotiable. Enter the I.C.T X-9300 X-Ray Machine, a technological marvel that has been meticulously engineered to redefine quality control in your SMT plant. With a sharp focus on accuracy, versatility, and ease of use, the X-9300 promises to be your trusted ally in ensuring impeccable SMT processes.

Unraveling the X-9300's Excellence:

High-Resolution Imaging:

At the heart of the X-9300 lies a high-resolution digital X-ray flat panel. With an unrivaled imaging accuracy of 76μm and a remarkable resolution as low as 1μm, this machine unveils the finest details with unmatched clarity. Every component, every connection – scrutinized with precision.

Versatility Beyond Compare:

Whether you're dealing with integrated circuits, BGA, flip-chip, or PCBA component welding, the X-9300 has you covered. It seamlessly transitions between various inspection needs, making it a versatile powerhouse in your SMT arsenal.

360-Degree Inspection:

The X-9300 features a spacious platform that can accommodate a variety of sample sizes. What sets it apart is the option for 360-degree stage rotation. No blind spots, no compromise on inspection thoroughness. It ensures that every angle is scrutinized, every detail revealed.

Tilted Observation:

Take advantage of the machine's ability to tilt up to 60 degrees for a comprehensive view. This unique feature enables you to evaluate your components from different angles, enhancing defect detection.

Bubble Analysis Simplified:

Efficiency is the name of the game, and the X-9300 understands that. With the one-key bubble measurement function, analyzing bubble size, void rate, and tin climbing height becomes a breeze. Precise and swift, it streamlines quality control in your SMT processes.

Smart X-Ray Control:

Automating your workflow, the X-9300 allows for automatic ON/OFF control of the X-ray light tube during batch inspections. Say goodbye to manual intervention and hello to optimized efficiency.

Certified Safety and Reliability:

Safety is paramount, and the X-9300 delivers. With certifications including the EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray, you can trust in its adherence to stringent safety standards.

Elevate Your SMT Processes with the X-9300:

In today's fiercely competitive electronics industry, quality and precision are the keys to success. The X-9300 X-Ray Machine has been designed to meet these demands head-on. It empowers your SMT plant with cutting-edge technology, unmatched versatility, and a commitment to safety and excellence.

Trust the X-9300 to revolutionize your quality control efforts, streamline your manufacturing processes, and ensure the highest standards of precision in your SMT plant. Make the smart choice and elevate your SMT processes with the X-9300.

When it comes to ensuring the utmost quality and safety in your SMT plant, the I.C.T X-9300 X-Ray Machine shines as a beacon of excellence. Let's delve into its standout features that elevate it to a class of its own:

At the core of the X-9300 lies a high-resolution digital X-ray flat panel. With an extraordinary imaging accuracy of 76μm and a remarkable resolution as low as 1μm, it unveils the tiniest of details with unmatched clarity. This feature empowers you to scrutinize every component and connection with precision, setting new standards for quality control in your SMT processes.

Adaptability is key in the world of SMT. The X-9300 understands this need and boasts a spacious stage that can comfortably accommodate a variety of sample sizes. Whether you're inspecting smaller components or larger assemblies, this machine is up to the task.

The X-9300 takes versatility to the next level with its optional 360° stage rotation capability. This feature ensures that no corner goes unexamined, no detail remains hidden. Say goodbye to blind spots and hello to thorough inspections.

Safety is non-negotiable, and the X-9300 is committed to delivering the highest level of safety and reliability. It proudly carries certifications including the EU CE Certificate, International Quality Management System ISO, and the AERB Certificate for X-ray. These certifications underscore its compliance with stringent safety standards, providing peace of mind to your SMT operations.

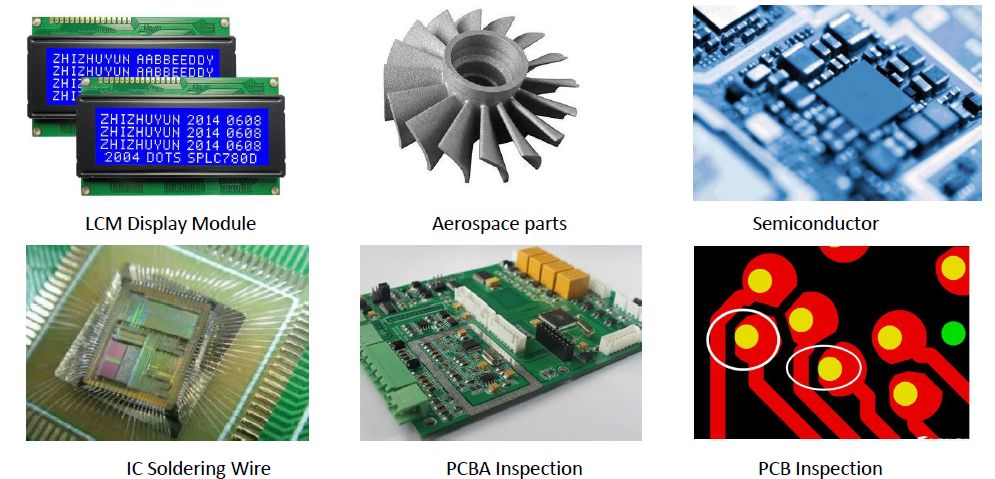

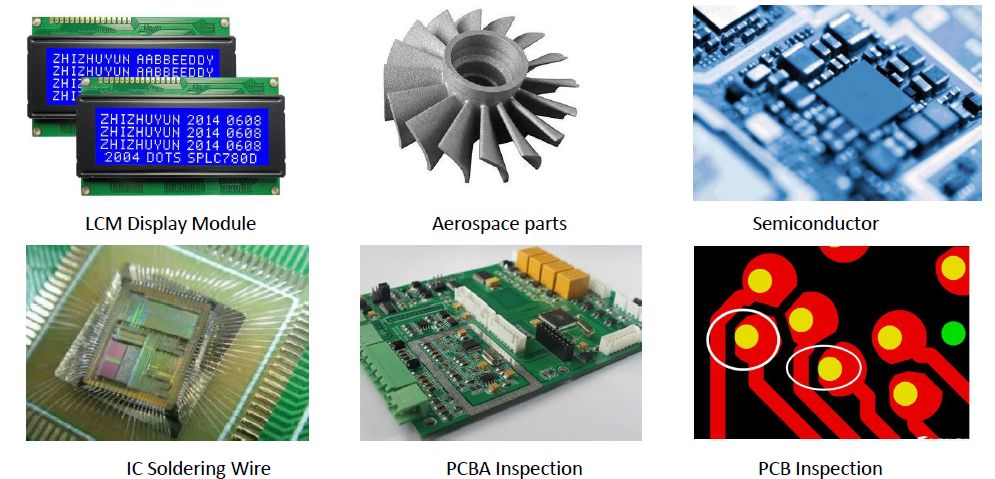

SMT, BGA, CSP, LGA, POP, SIP, Flip Chip, LED, IGBT, Semiconductor, Packaging components, Battery, Electronic components, Automotive parts,

LCM display module, other special industries.

| Item | Model | I.C.T X-9300 |

| X-Ray Tube | Type | Transmissive Light Tube |

| Voltage | 100kv/110kv, 200μA/300μA | |

| Spatial resolution | 1μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 76μm | |

| A/D conversion quantized density value | 16bit | |

| Resolution | 1648*1644px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 2500x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1800W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 690*685mm |

| Max. Inspection area | 670*665mm | |

| Max. Loading weight | ≤20kg | |

| Platform rotation angle | 60° | |

| Dimension | 1510*1770*1850mm | |

| Weight | 1800kg | |

| Platform movement | Manual/Auto |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

In the dynamic realm of Surface Mount Technology (SMT), precision and quality are non-negotiable. Enter the I.C.T X-9300 X-Ray Machine, a technological marvel that has been meticulously engineered to redefine quality control in your SMT plant. With a sharp focus on accuracy, versatility, and ease of use, the X-9300 promises to be your trusted ally in ensuring impeccable SMT processes.

Unraveling the X-9300's Excellence:

High-Resolution Imaging:

At the heart of the X-9300 lies a high-resolution digital X-ray flat panel. With an unrivaled imaging accuracy of 76μm and a remarkable resolution as low as 1μm, this machine unveils the finest details with unmatched clarity. Every component, every connection – scrutinized with precision.

Versatility Beyond Compare:

Whether you're dealing with integrated circuits, BGA, flip-chip, or PCBA component welding, the X-9300 has you covered. It seamlessly transitions between various inspection needs, making it a versatile powerhouse in your SMT arsenal.

360-Degree Inspection:

The X-9300 features a spacious platform that can accommodate a variety of sample sizes. What sets it apart is the option for 360-degree stage rotation. No blind spots, no compromise on inspection thoroughness. It ensures that every angle is scrutinized, every detail revealed.

Tilted Observation:

Take advantage of the machine's ability to tilt up to 60 degrees for a comprehensive view. This unique feature enables you to evaluate your components from different angles, enhancing defect detection.

Bubble Analysis Simplified:

Efficiency is the name of the game, and the X-9300 understands that. With the one-key bubble measurement function, analyzing bubble size, void rate, and tin climbing height becomes a breeze. Precise and swift, it streamlines quality control in your SMT processes.

Smart X-Ray Control:

Automating your workflow, the X-9300 allows for automatic ON/OFF control of the X-ray light tube during batch inspections. Say goodbye to manual intervention and hello to optimized efficiency.

Certified Safety and Reliability:

Safety is paramount, and the X-9300 delivers. With certifications including the EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray, you can trust in its adherence to stringent safety standards.

Elevate Your SMT Processes with the X-9300:

In today's fiercely competitive electronics industry, quality and precision are the keys to success. The X-9300 X-Ray Machine has been designed to meet these demands head-on. It empowers your SMT plant with cutting-edge technology, unmatched versatility, and a commitment to safety and excellence.

Trust the X-9300 to revolutionize your quality control efforts, streamline your manufacturing processes, and ensure the highest standards of precision in your SMT plant. Make the smart choice and elevate your SMT processes with the X-9300.

When it comes to ensuring the utmost quality and safety in your SMT plant, the I.C.T X-9300 X-Ray Machine shines as a beacon of excellence. Let's delve into its standout features that elevate it to a class of its own:

At the core of the X-9300 lies a high-resolution digital X-ray flat panel. With an extraordinary imaging accuracy of 76μm and a remarkable resolution as low as 1μm, it unveils the tiniest of details with unmatched clarity. This feature empowers you to scrutinize every component and connection with precision, setting new standards for quality control in your SMT processes.

Adaptability is key in the world of SMT. The X-9300 understands this need and boasts a spacious stage that can comfortably accommodate a variety of sample sizes. Whether you're inspecting smaller components or larger assemblies, this machine is up to the task.

The X-9300 takes versatility to the next level with its optional 360° stage rotation capability. This feature ensures that no corner goes unexamined, no detail remains hidden. Say goodbye to blind spots and hello to thorough inspections.

Safety is non-negotiable, and the X-9300 is committed to delivering the highest level of safety and reliability. It proudly carries certifications including the EU CE Certificate, International Quality Management System ISO, and the AERB Certificate for X-ray. These certifications underscore its compliance with stringent safety standards, providing peace of mind to your SMT operations.

SMT, BGA, CSP, LGA, POP, SIP, Flip Chip, LED, IGBT, Semiconductor, Packaging components, Battery, Electronic components, Automotive parts,

LCM display module, other special industries.

| Item | Model | I.C.T X-9300 |

| X-Ray Tube | Type | Transmissive Light Tube |

| Voltage | 100kv/110kv, 200μA/300μA | |

| Spatial resolution | 1μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 76μm | |

| A/D conversion quantized density value | 16bit | |

| Resolution | 1648*1644px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 2500x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1800W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 690*685mm |

| Max. Inspection area | 670*665mm | |

| Max. Loading weight | ≤20kg | |

| Platform rotation angle | 60° | |

| Dimension | 1510*1770*1850mm | |

| Weight | 1800kg | |

| Platform movement | Manual/Auto |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT