5146CW

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT AOI Coating Inspector

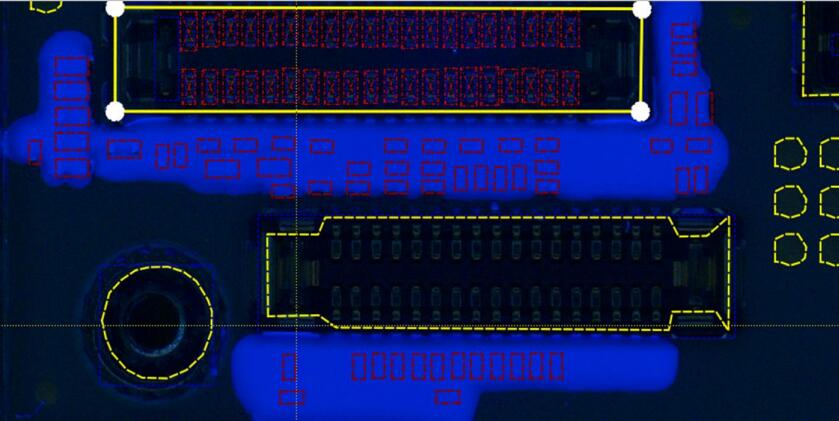

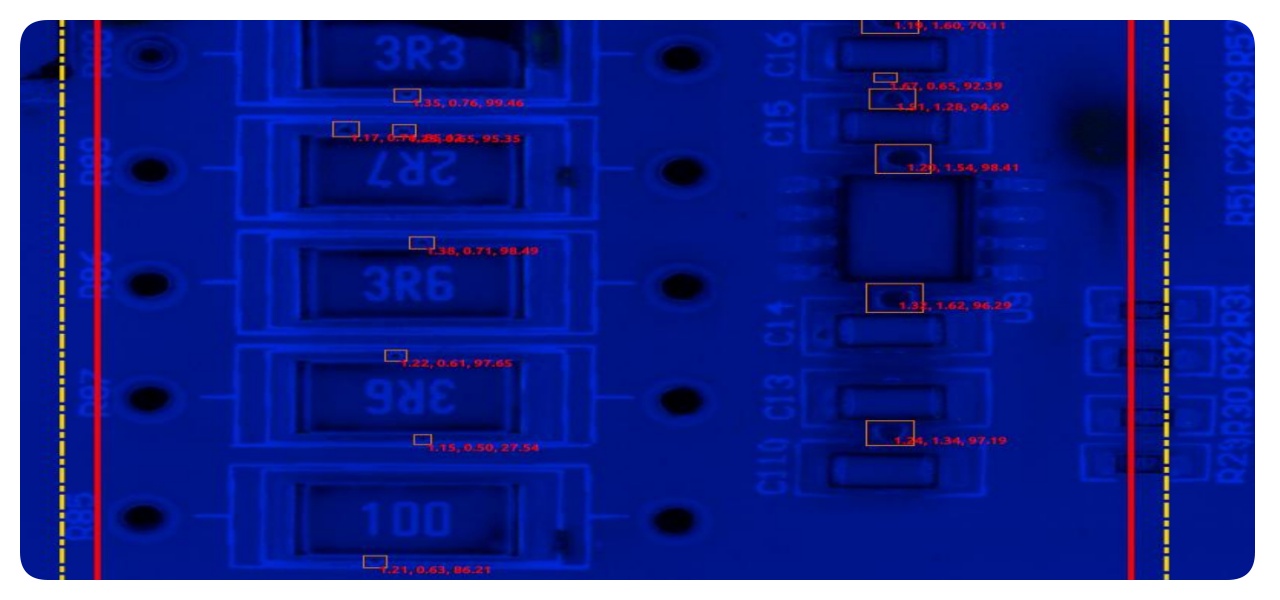

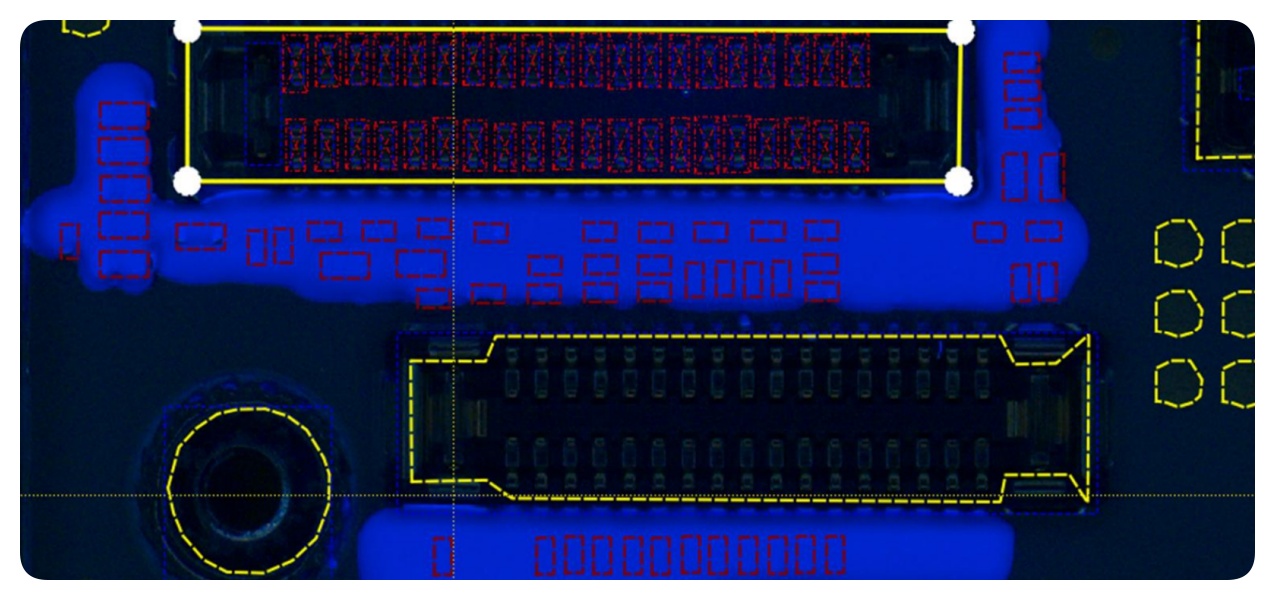

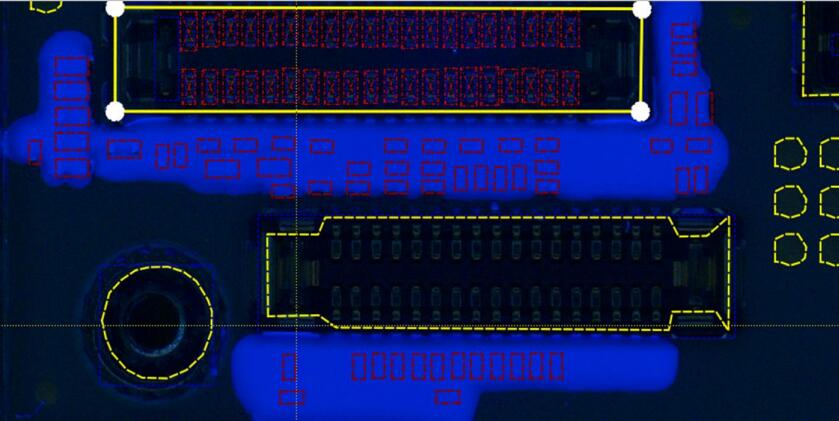

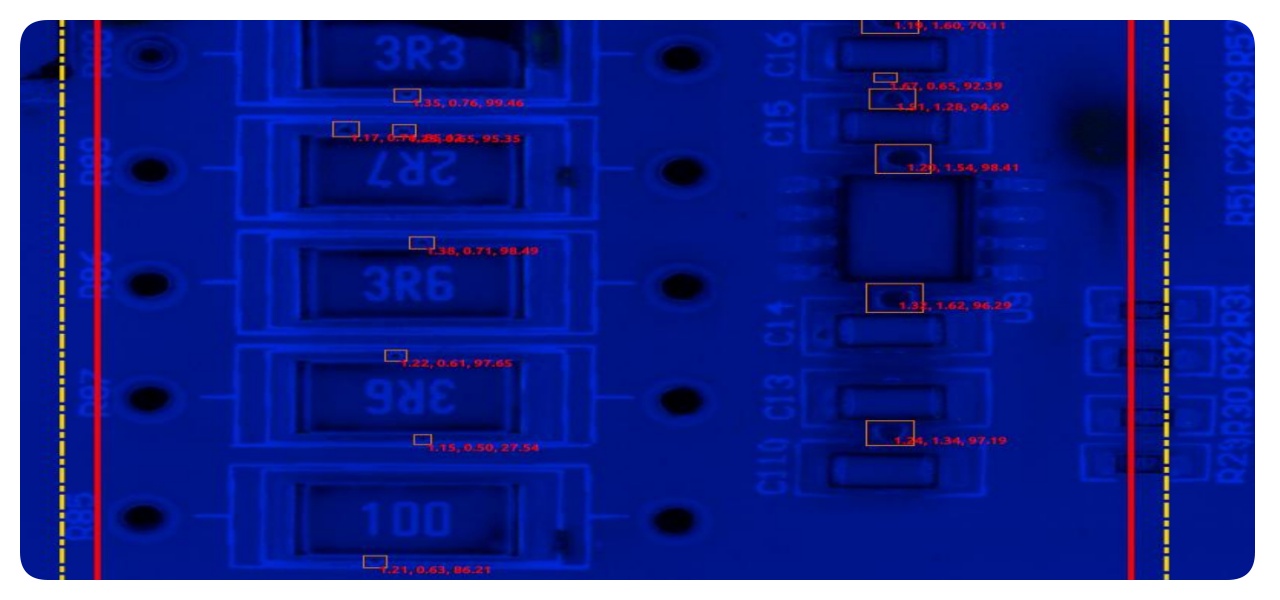

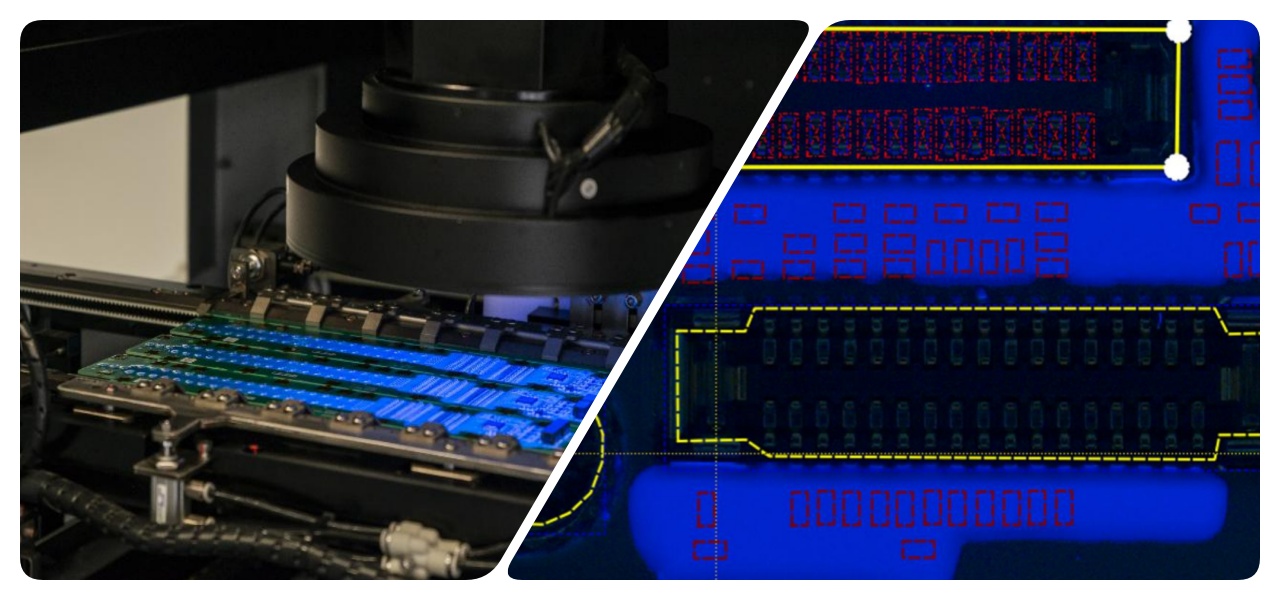

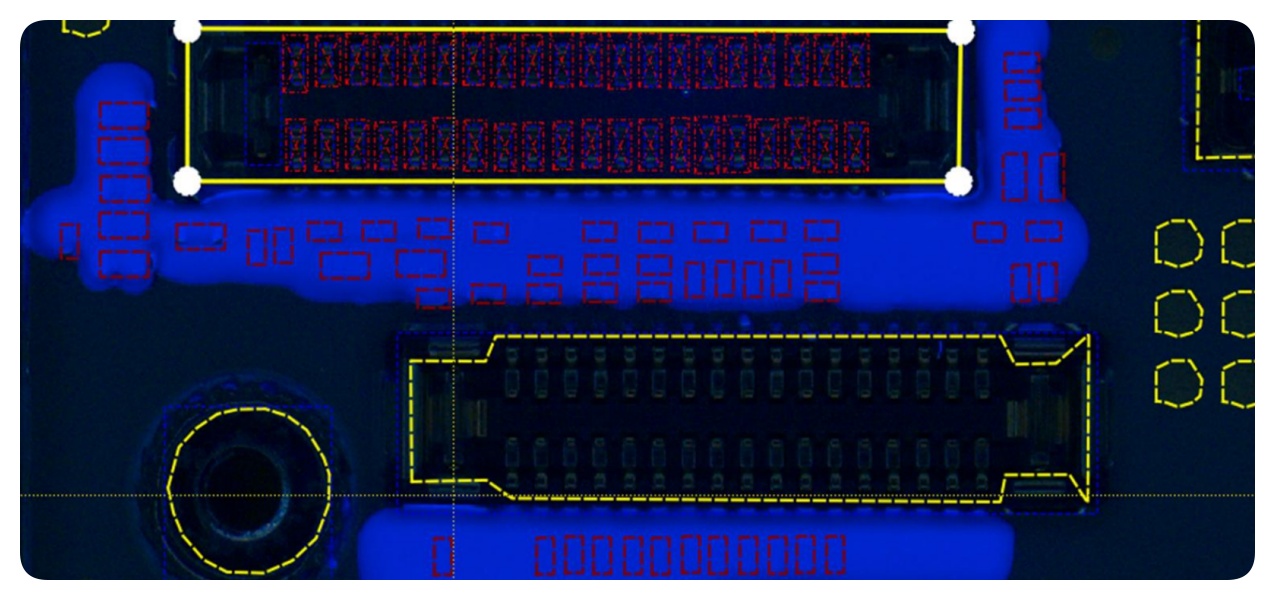

The aoi machine, AI-5146C model, specializes in conformal coating inspection for PCBs. It grabs real-time images with a high-precision color camera and uses CNN algorithms for smart defect analysis. This PCB aoi machine automatically locks coating edges and marks areas without pausing production. It handles various defects like excess glue, shortages, bubbles, or splashes. With UV lights, it highlights phosphorus-based glues clearly. Options include full-board or double-side setups, fitting SMT and DIP needs. Traceable data with SPC alerts and log storage supports quality tracking. This aoi machine enhances factory efficiency and reliability.

| Feature

Our aoi machine employs deep learning to process big data and simplify programming. One-click identification of parts and joints cuts setup time and false alerts. It outperforms old methods by auto-detecting coating zones and generating shapes. Switch lights to inspect SMT, DIP, or solder problems easily. As an automatic optical inspection machine, it manages multi-panel boards and mixed types up to 510x460mm.

The aoi machine uses dedicated tools to detect bubbles as small as 0.05mm and objects like strands without manual tweaks. It displays bubble details and glue widths—min, max, average—for consistent checks. Block non-coated spots with custom frames to skip false positives and reduce rechecks.

Setup takes just 10-15 minutes on this aoi machine with offline or online modes. Select areas flexibly, modify params in batch, and skip bad marks. Rotate detection at multiple angles. Add glue thickness scans for flatness data across the board.

This aoi machine reads barcodes and QR codes automatically for full traceability. Export stats one-click for MES use, covering per-board and summary info. Alarms, warnings, and remote control keep lines running smoothly.

| Specification

| Model | I.C.T Coating Online AOI AI-5146C | I.C.T Coating Online AOI AI-5146CW |

| FOV | 15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm | 21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution | 15um(Standard), 10um | 21.5um(standard) /15um /10um |

| Camera | Single side camera12M | Dual side camera 5M |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:25mm, Bottom:80mm | Top:75mm,Bottom:70mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | 570W |

| Communication | SMEMA | |

| Weight | 750Kg | 890Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

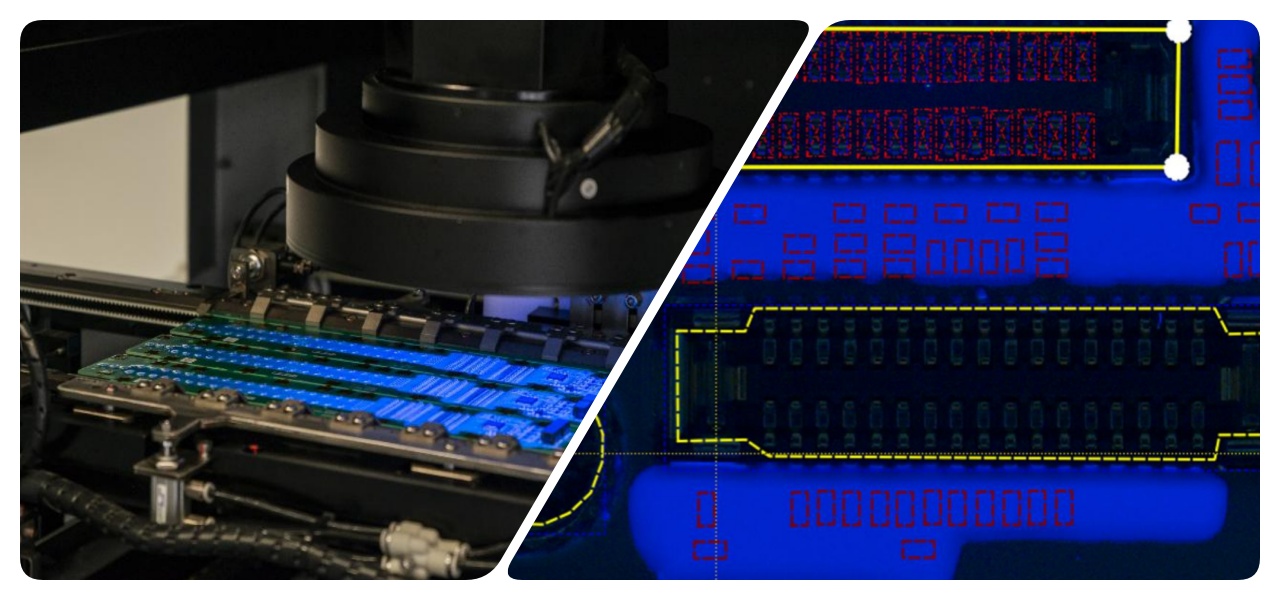

Our double-sided coating line with return system was deployed for an electronics firm. The video covers the complete process from elevator to unloader: coating loader, coater, elevator, aoi machine, IR oven, selector conveyor, flipper, and unloader. It includes bottom jig returns, full barcode reading, and auto top/bottom side recognition to load matching programs. This integration boosted client output with reliable defect spotting via the aoi machine, cutting rework and improving PCB quality overall.

| Service and Training Support

I.C.T offers full service for the aoi machine, from setup to upkeep. Remote debugging, on-site training, and quick maintenance reduce stops. We teach operation, programming, and fixes in simple sessions. Global centers provide fast parts and updates for ongoing success.

| Customer Reviews

Customers love our engineers' fast fixes and knowledge. The aoi machine earns praise for precision and simple interface. Secure packing and quick delivery prevent issues. Rapid query responses strengthen reliable ties.

| Certifications and Standards

I.C.T products like the aoi machine carry CE, RoHS, ISO9001, and patents. These confirm safety, eco-friendliness, and quality via strict tests for worldwide use.

| About I.C.T Company and Our SMT Factory

I.C.T leads in SMT solutions with own R&D and manufacturing. Over 89 team members drive fast growth, serving 1600+ clients in 72 nations. Factories enforce tough checks and quality systems. We build on integrity, openness, and sharing for innovative global electronics gear.

| I.C.T SMT AOI Coating Inspector

The aoi machine, AI-5146C model, specializes in conformal coating inspection for PCBs. It grabs real-time images with a high-precision color camera and uses CNN algorithms for smart defect analysis. This PCB aoi machine automatically locks coating edges and marks areas without pausing production. It handles various defects like excess glue, shortages, bubbles, or splashes. With UV lights, it highlights phosphorus-based glues clearly. Options include full-board or double-side setups, fitting SMT and DIP needs. Traceable data with SPC alerts and log storage supports quality tracking. This aoi machine enhances factory efficiency and reliability.

| Feature

Our aoi machine employs deep learning to process big data and simplify programming. One-click identification of parts and joints cuts setup time and false alerts. It outperforms old methods by auto-detecting coating zones and generating shapes. Switch lights to inspect SMT, DIP, or solder problems easily. As an automatic optical inspection machine, it manages multi-panel boards and mixed types up to 510x460mm.

The aoi machine uses dedicated tools to detect bubbles as small as 0.05mm and objects like strands without manual tweaks. It displays bubble details and glue widths—min, max, average—for consistent checks. Block non-coated spots with custom frames to skip false positives and reduce rechecks.

Setup takes just 10-15 minutes on this aoi machine with offline or online modes. Select areas flexibly, modify params in batch, and skip bad marks. Rotate detection at multiple angles. Add glue thickness scans for flatness data across the board.

This aoi machine reads barcodes and QR codes automatically for full traceability. Export stats one-click for MES use, covering per-board and summary info. Alarms, warnings, and remote control keep lines running smoothly.

| Specification

| Model | I.C.T Coating Online AOI AI-5146C | I.C.T Coating Online AOI AI-5146CW |

| FOV | 15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm | 21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution | 15um(Standard), 10um | 21.5um(standard) /15um /10um |

| Camera | Single side camera12M | Dual side camera 5M |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:25mm, Bottom:80mm | Top:75mm,Bottom:70mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | 570W |

| Communication | SMEMA | |

| Weight | 750Kg | 890Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

Our double-sided coating line with return system was deployed for an electronics firm. The video covers the complete process from elevator to unloader: coating loader, coater, elevator, aoi machine, IR oven, selector conveyor, flipper, and unloader. It includes bottom jig returns, full barcode reading, and auto top/bottom side recognition to load matching programs. This integration boosted client output with reliable defect spotting via the aoi machine, cutting rework and improving PCB quality overall.

| Service and Training Support

I.C.T offers full service for the aoi machine, from setup to upkeep. Remote debugging, on-site training, and quick maintenance reduce stops. We teach operation, programming, and fixes in simple sessions. Global centers provide fast parts and updates for ongoing success.

| Customer Reviews

Customers love our engineers' fast fixes and knowledge. The aoi machine earns praise for precision and simple interface. Secure packing and quick delivery prevent issues. Rapid query responses strengthen reliable ties.

| Certifications and Standards

I.C.T products like the aoi machine carry CE, RoHS, ISO9001, and patents. These confirm safety, eco-friendliness, and quality via strict tests for worldwide use.

| About I.C.T Company and Our SMT Factory

I.C.T leads in SMT solutions with own R&D and manufacturing. Over 89 team members drive fast growth, serving 1600+ clients in 72 nations. Factories enforce tough checks and quality systems. We build on integrity, openness, and sharing for innovative global electronics gear.