I.C.T-400

I.C.T

PCB Laser Marking

| Availability: | |

|---|---|

| Quantity: | |

| Reliable Fiber Laser Marking Solution for Modern SMT Lines

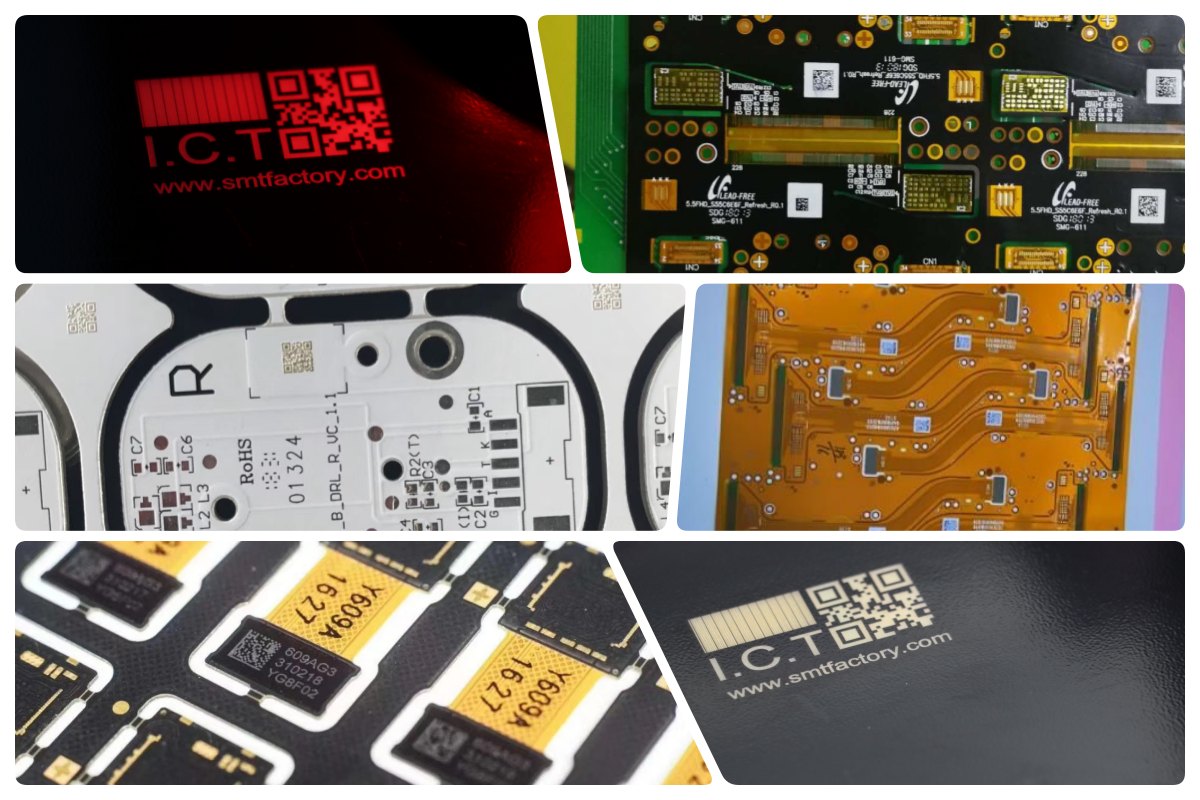

In today's fast-moving electronics assembly, the fiber laser marking machine stands out as a smart choice for adding permanent codes, text, and graphics to PCBs. With models sized for PCBs up to 510×460 mm, it achieves ±0.05 mm accuracy and speeds under 7000 mm/s. Customers pick from fiber, CO₂, UV, or green lasers depending on board type—FR4, metals, plastics, or sensitive coatings. Built-in anti-reprint logic prevents duplicate marks, while automatic code verification saves data and flags issues instantly. Seamless MES linkage pulls batch info and pushes results back online. No inks, labels, or solvents needed means less waste and downtime. Factories gain durable traceability that holds up through reflow, cleaning, and testing. This Co2 UV Laser Marking Machine variant fits perfectly into high-volume lines, boosting quality control and compliance without slowing production.

| Feature

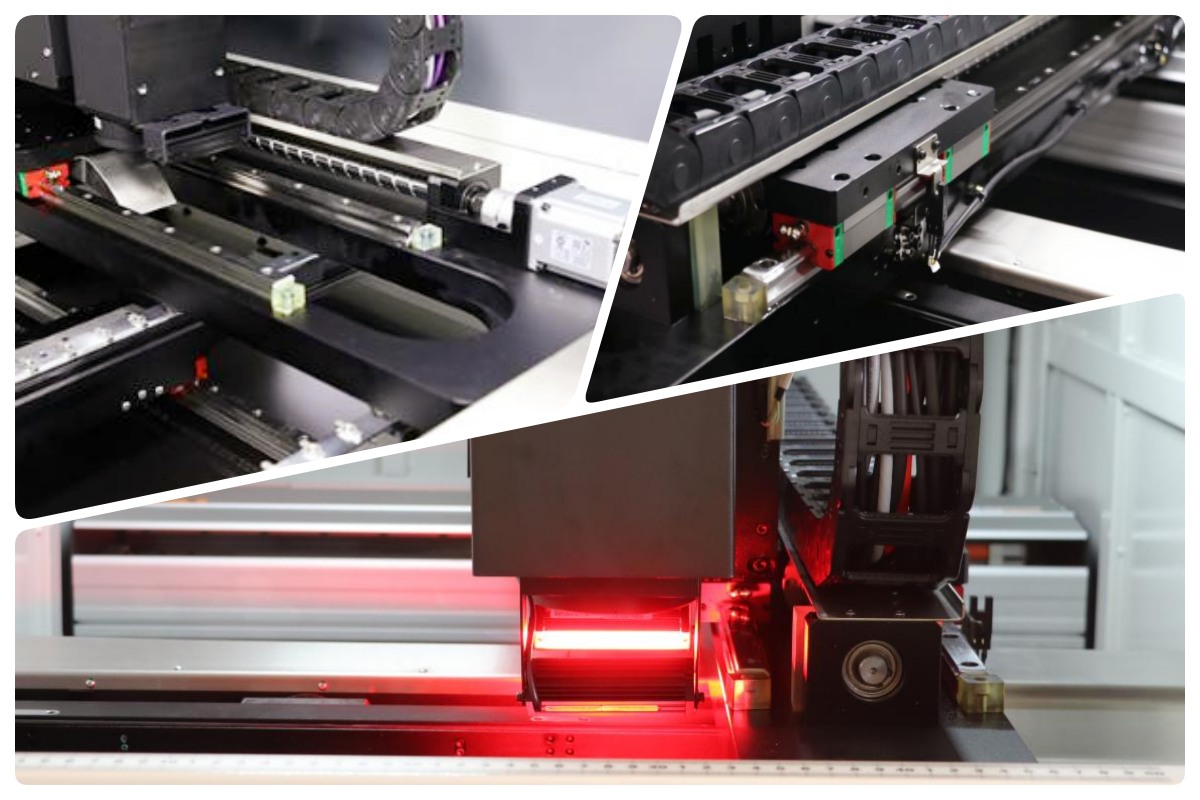

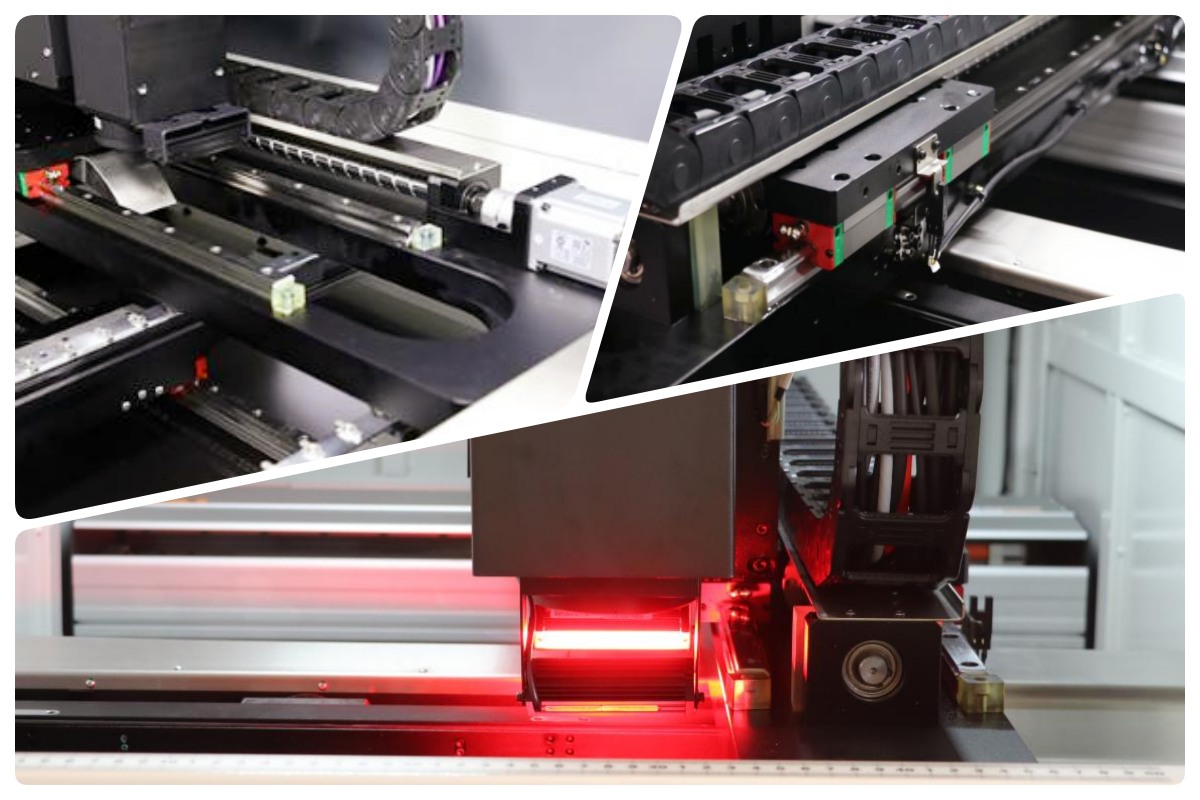

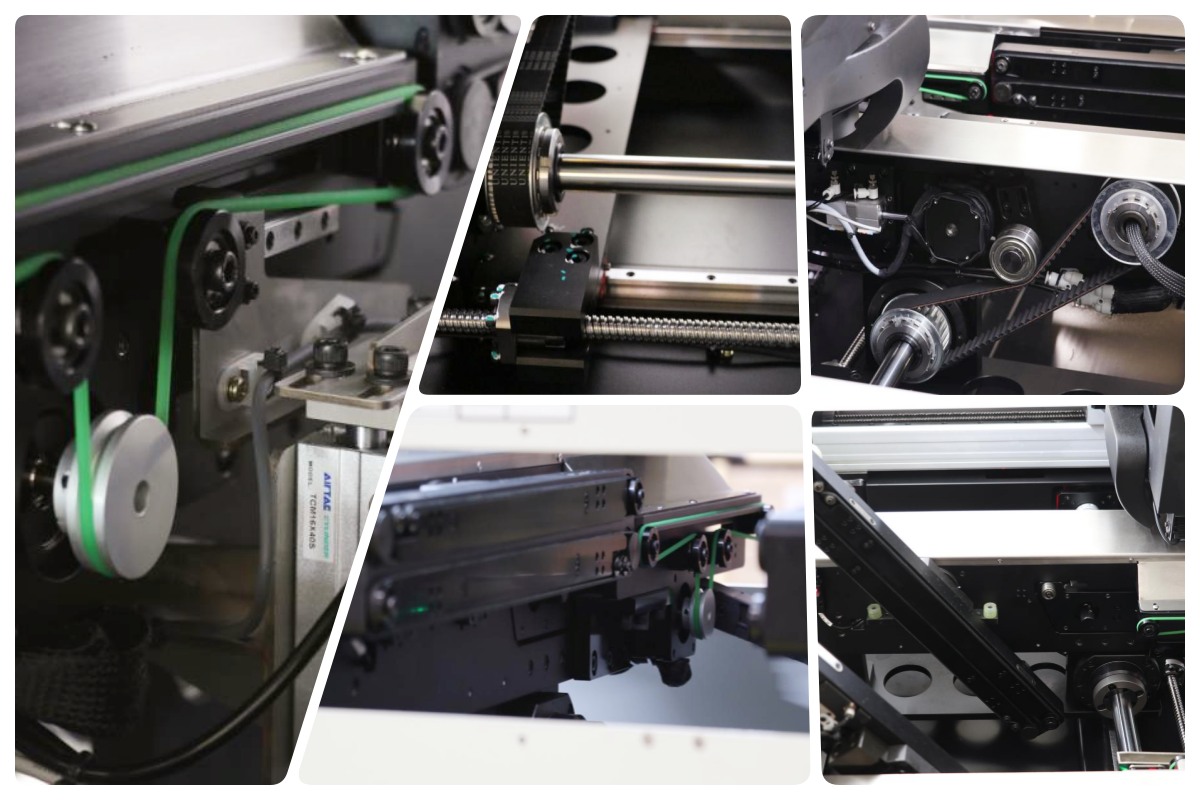

Advanced Driving System

The driving system uses an arch bridge suspension with heavy-duty ball screws and linear guides from trusted brands like TBI and HIWIN. Two separate high-precision servo motors control the X and Y axes independently for smooth, accurate motion. Flexible closed tank chains and protective profiles keep everything running without interruption. A special dust cover design cuts down on cleaning time and repair frequency. This solid structure handles heavy use in busy SMT factories while keeping positioning exact and maintenance simple over many years of operation.

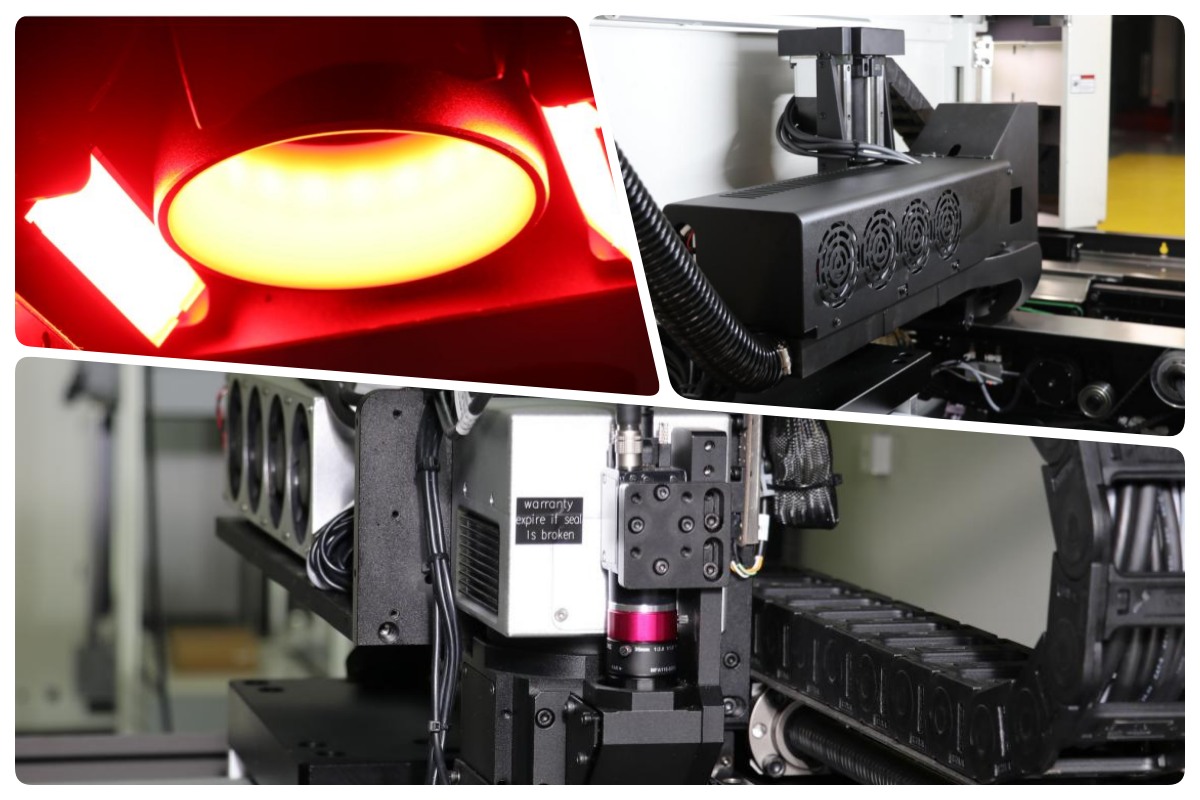

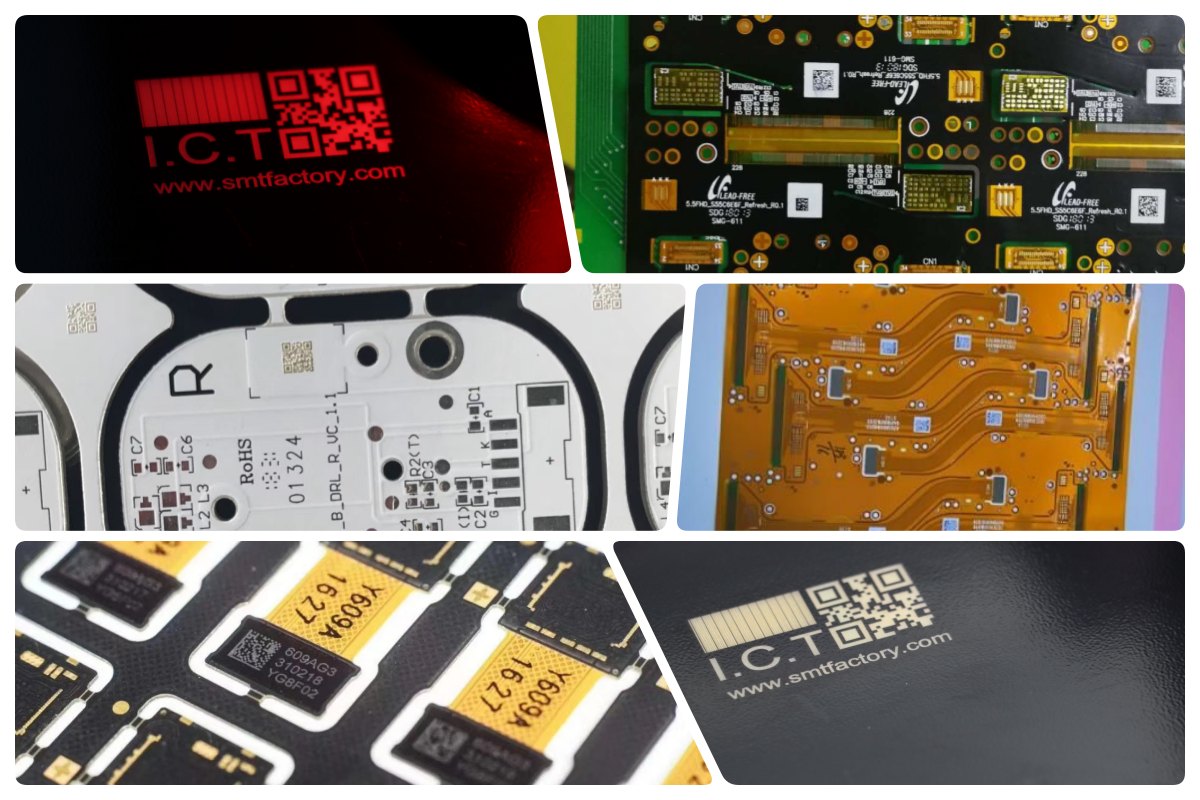

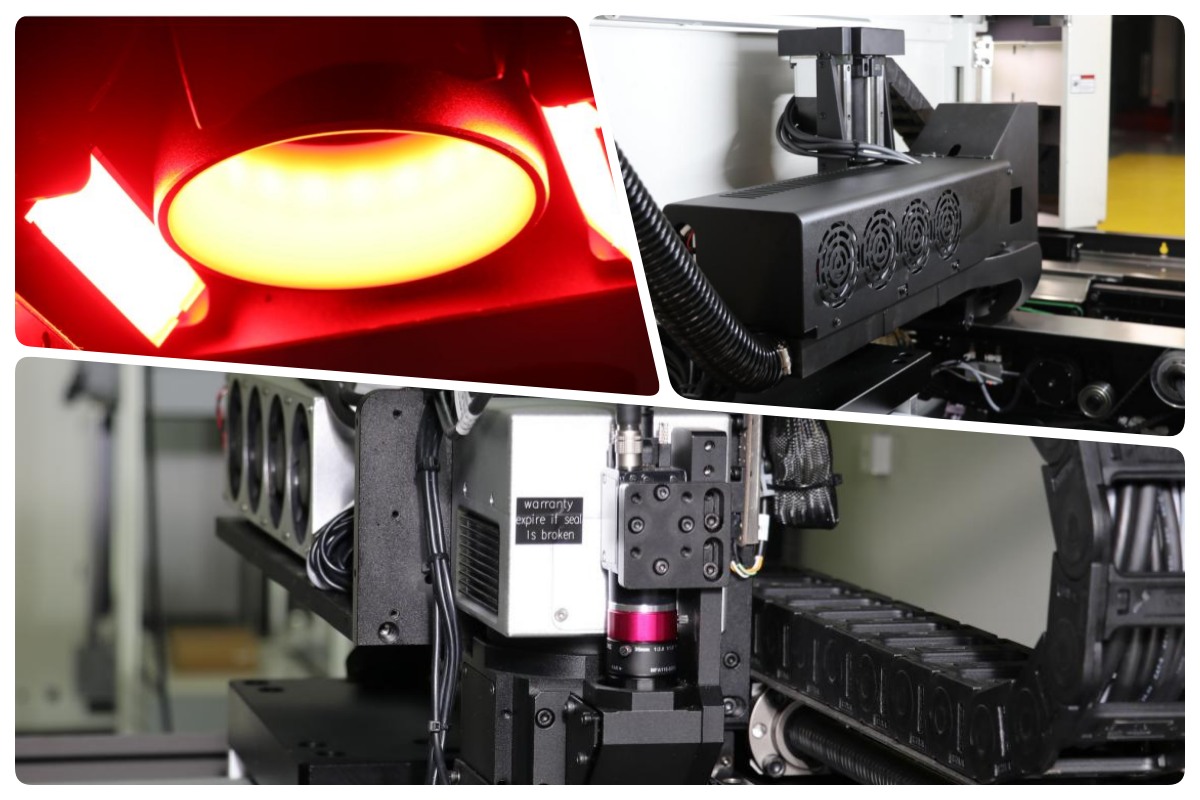

Reliable Marking System

Select the best laser—UV, green, fiber, or CO₂—to match your exact PCB material and requirements. All lasers deliver stable wavelength output, long working life, and tight focus. The focal length comes pre-calibrated from the factory, so no manual adjustment is needed; the Z axis moves automatically. Proper cooling systems keep each laser type running at peak performance. Different beam shapes and options handle complex surfaces and tight tolerances. This setup ensures consistent, high-quality marks on every board, even in high-volume production.

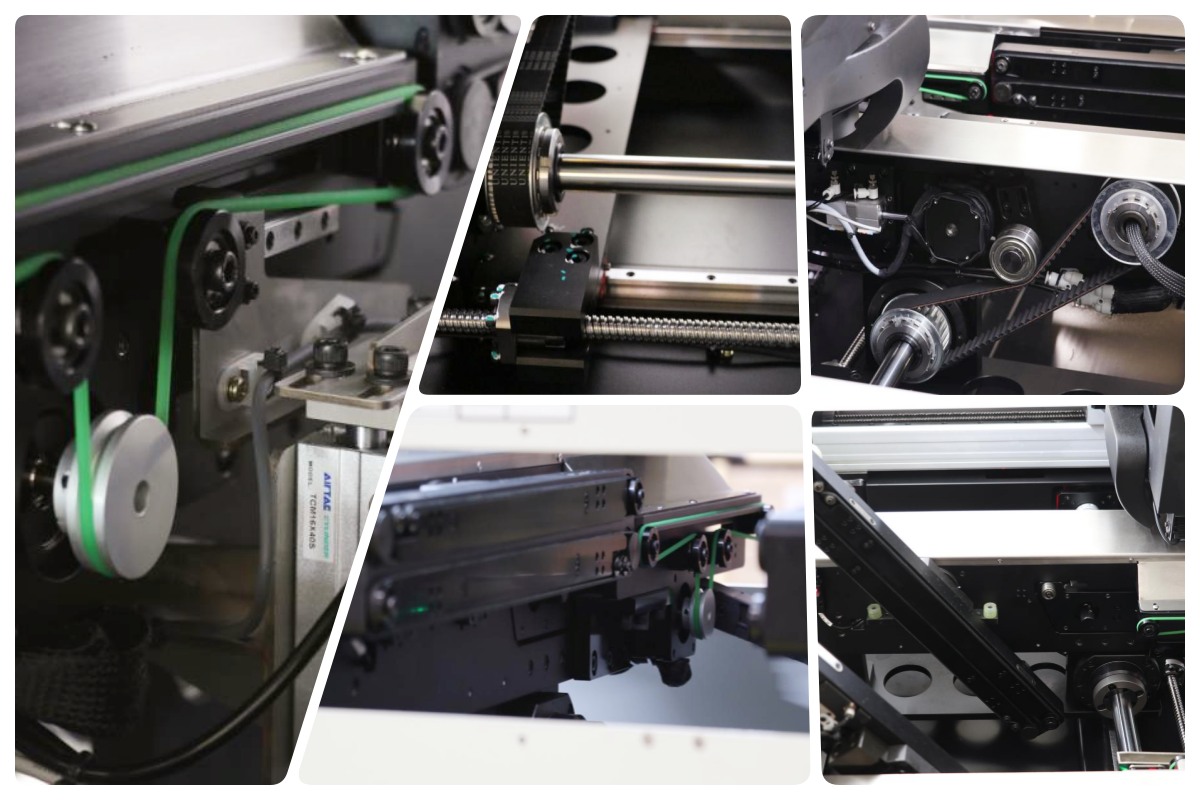

Efficient Transport System

A built-in flip mechanism handles double-sided PCBs in one pass when required. Segmented guide rails use ESD-safe belts to prevent static damage during movement. High-strength synchronous belts allow adjustable speed for perfect line balance. Special tension devices keep belts tight and aligned at all times. Ball screws and rigid shafts adjust rail width evenly, maintaining front-to-back parallelism. Cylinder stops with fine-tuning provide accurate board positioning. This transport design moves PCBs safely and reliably through the marking process.

Stable Control System

The control layout follows clean, standardized wiring for fast inspection and easy repairs. High-precision servo motors and drives deliver stable, repeatable performance. Smart air convection cooling prevents overheating during long runs. Our in-house integrated control board runs reliably with minimal troubleshooting. A separate leakage protection switch adds extra safety and meets international CE and UL standards. This thoughtful engineering keeps the machine dependable in demanding 24/7 SMT environments.

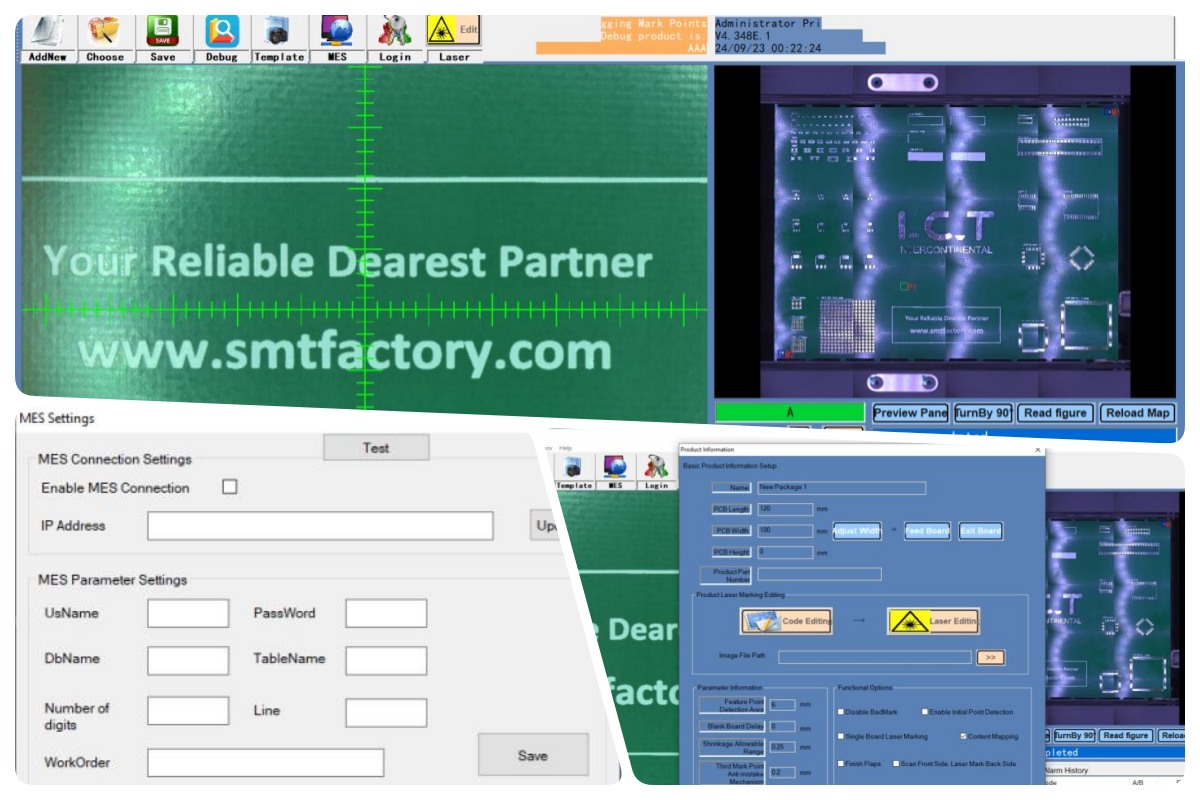

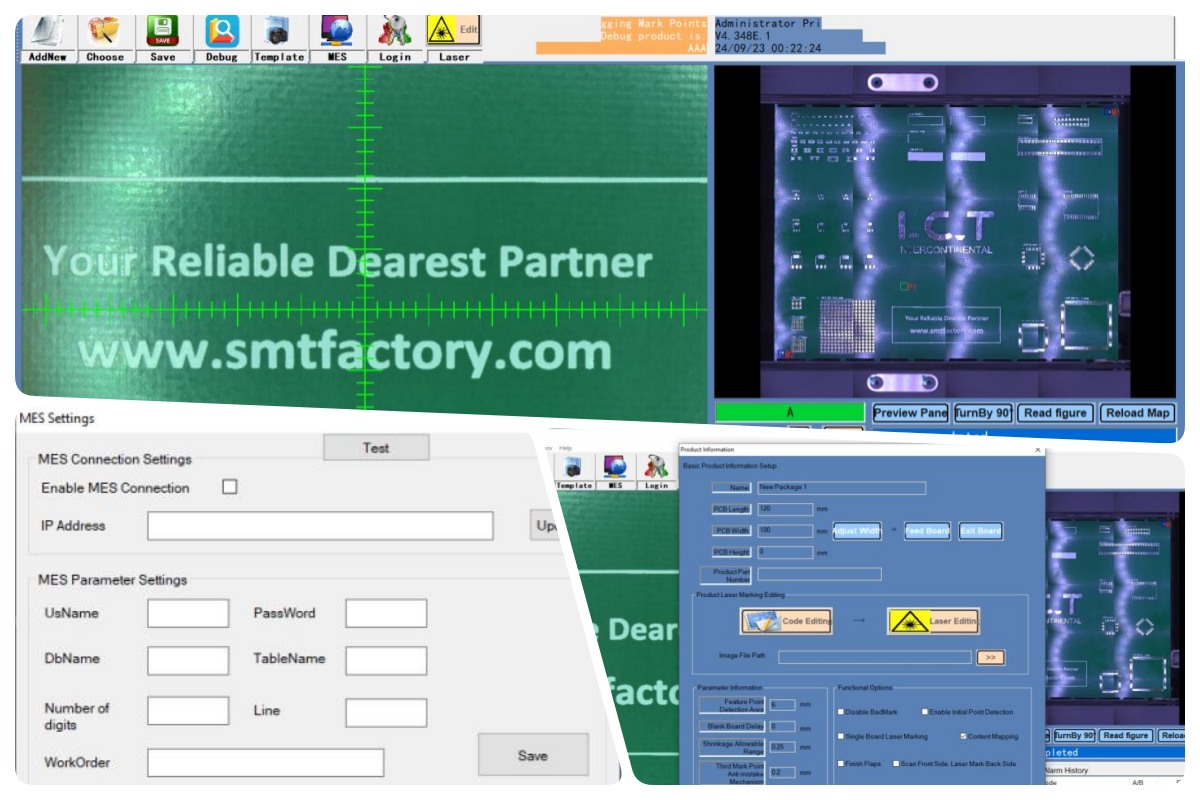

Easy-to-Use Operator System

The software presents a clear, step-by-step interface that new operators learn quickly. It runs on a genuine Windows system and stores multiple job programs for fast product changeover. Full-frame scanning displays layouts directly on screen for simple programming. Coaxial camera setup eliminates extra calibration steps. Standard MES protocol ports allow easy connection to factory systems, with custom options available. This practical design reduces training time and boosts daily efficiency.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Integrated SMT Production Line Solution

I.C.T builds reliable, high-performance PCBA production lines for industries like automotive electronics, medical devices, and consumer products. Every line starts clean with PCB loading, applies precise solder paste using automatic printers and SPI inspection, places components accurately with high-speed mounters, and forms strong joints in multi-zone reflow ovens. Advanced AOI catches defects early, PCB conveyors keep flow smooth and safe, PCBA cleaners remove residues for better reliability, and automatic solder paste storage with warming ensures consistent paste quality. This integrated setup delivers high yield, low defect rates, reduced costs, and stable output. I.C.T provides full support from design to operation, helping factories achieve efficient, traceable SMT production.

| Customer Project Case

I.C.T completed full overseas installation and Factory Acceptance Testing (FAT) for two complete SMT lines at a major North American beauty instrument manufacturer. Both lines passed final production acceptance without issues. Each line featured our fiber laser marking machine for permanent traceability, plus SMT printer with SPI, Panasonic high-speed mounter, Heller multi-zone reflow oven, advanced AOI inspection, reliable PCB conveyors, thorough PCBA cleaning system, and automatic solder paste storage with temperature recovery. Our engineers handled on-site setup, operator training, and process tuning. The customer now operates stable, high-yield lines producing top-quality devices with excellent efficiency and full traceability.

| Global Service and Training Support

I.C.T provides end-to-end technical assistance, starting with professional installation and machine commissioning at your facility. Experienced engineers deliver hands-on operator training, covering programming, daily operation, basic maintenance, and common troubleshooting. We optimize processes to match your specific production goals. Ongoing support includes fast remote diagnostics, on-site visits when needed, and spare parts availability. This complete service package ensures quick startup, maximum machine uptime, and long-term performance you can count on in your SMT operation.

| Customer Experience and Operational Benefits

Customers frequently commend our engineers for their deep knowledge, clear explanations, and fast response to any questions during installation and training. They praise the fiber laser marking machine for consistent mark quality, reliable operation, and seamless line integration. Many highlight the secure, professional packaging that protects equipment perfectly during long-distance shipping. Quick resolution of technical issues builds strong confidence. Overall, clients value the dependable performance and dedicated support that help them maintain high production standards.

| Standards, Control and Production Discipline

I.C.T equipment carries key international certifications that prove safety, reliability, and environmental responsibility. These include CE marking for electrical safety, RoHS compliance for restricted hazardous substances, and ISO9001 certification for our quality management system. We also hold several patents covering innovative laser marking and SMT designs. These credentials confirm that every machine meets global standards and delivers trustworthy, eco-friendly performance in professional manufacturing settings.

| About I.C.T Company and Factory

I.C.T owns its own R&D center and modern production factory in Dongguan, China, covering 12,000 square meters with a dedicated team of 89 staff members, including 20 experienced engineers. Since 2012 the company has grown rapidly and now serves more than 1,600 customers across 72 countries worldwide. Our factory follows strict inspection procedures at every stage, backed by a complete quality management system. We supply full SMT solutions—from initial planning and equipment delivery to training and ongoing optimization—helping factories start, expand, or improve production lines with confidence.

| Reliable Fiber Laser Marking Solution for Modern SMT Lines

In today's fast-moving electronics assembly, the fiber laser marking machine stands out as a smart choice for adding permanent codes, text, and graphics to PCBs. With models sized for PCBs up to 510×460 mm, it achieves ±0.05 mm accuracy and speeds under 7000 mm/s. Customers pick from fiber, CO₂, UV, or green lasers depending on board type—FR4, metals, plastics, or sensitive coatings. Built-in anti-reprint logic prevents duplicate marks, while automatic code verification saves data and flags issues instantly. Seamless MES linkage pulls batch info and pushes results back online. No inks, labels, or solvents needed means less waste and downtime. Factories gain durable traceability that holds up through reflow, cleaning, and testing. This Co2 UV Laser Marking Machine variant fits perfectly into high-volume lines, boosting quality control and compliance without slowing production.

| Feature

Advanced Driving System

The driving system uses an arch bridge suspension with heavy-duty ball screws and linear guides from trusted brands like TBI and HIWIN. Two separate high-precision servo motors control the X and Y axes independently for smooth, accurate motion. Flexible closed tank chains and protective profiles keep everything running without interruption. A special dust cover design cuts down on cleaning time and repair frequency. This solid structure handles heavy use in busy SMT factories while keeping positioning exact and maintenance simple over many years of operation.

Reliable Marking System

Select the best laser—UV, green, fiber, or CO₂—to match your exact PCB material and requirements. All lasers deliver stable wavelength output, long working life, and tight focus. The focal length comes pre-calibrated from the factory, so no manual adjustment is needed; the Z axis moves automatically. Proper cooling systems keep each laser type running at peak performance. Different beam shapes and options handle complex surfaces and tight tolerances. This setup ensures consistent, high-quality marks on every board, even in high-volume production.

Efficient Transport System

A built-in flip mechanism handles double-sided PCBs in one pass when required. Segmented guide rails use ESD-safe belts to prevent static damage during movement. High-strength synchronous belts allow adjustable speed for perfect line balance. Special tension devices keep belts tight and aligned at all times. Ball screws and rigid shafts adjust rail width evenly, maintaining front-to-back parallelism. Cylinder stops with fine-tuning provide accurate board positioning. This transport design moves PCBs safely and reliably through the marking process.

Stable Control System

The control layout follows clean, standardized wiring for fast inspection and easy repairs. High-precision servo motors and drives deliver stable, repeatable performance. Smart air convection cooling prevents overheating during long runs. Our in-house integrated control board runs reliably with minimal troubleshooting. A separate leakage protection switch adds extra safety and meets international CE and UL standards. This thoughtful engineering keeps the machine dependable in demanding 24/7 SMT environments.

Easy-to-Use Operator System

The software presents a clear, step-by-step interface that new operators learn quickly. It runs on a genuine Windows system and stores multiple job programs for fast product changeover. Full-frame scanning displays layouts directly on screen for simple programming. Coaxial camera setup eliminates extra calibration steps. Standard MES protocol ports allow easy connection to factory systems, with custom options available. This practical design reduces training time and boosts daily efficiency.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Integrated SMT Production Line Solution

I.C.T builds reliable, high-performance PCBA production lines for industries like automotive electronics, medical devices, and consumer products. Every line starts clean with PCB loading, applies precise solder paste using automatic printers and SPI inspection, places components accurately with high-speed mounters, and forms strong joints in multi-zone reflow ovens. Advanced AOI catches defects early, PCB conveyors keep flow smooth and safe, PCBA cleaners remove residues for better reliability, and automatic solder paste storage with warming ensures consistent paste quality. This integrated setup delivers high yield, low defect rates, reduced costs, and stable output. I.C.T provides full support from design to operation, helping factories achieve efficient, traceable SMT production.

| Customer Project Case

I.C.T completed full overseas installation and Factory Acceptance Testing (FAT) for two complete SMT lines at a major North American beauty instrument manufacturer. Both lines passed final production acceptance without issues. Each line featured our fiber laser marking machine for permanent traceability, plus SMT printer with SPI, Panasonic high-speed mounter, Heller multi-zone reflow oven, advanced AOI inspection, reliable PCB conveyors, thorough PCBA cleaning system, and automatic solder paste storage with temperature recovery. Our engineers handled on-site setup, operator training, and process tuning. The customer now operates stable, high-yield lines producing top-quality devices with excellent efficiency and full traceability.

| Global Service and Training Support

I.C.T provides end-to-end technical assistance, starting with professional installation and machine commissioning at your facility. Experienced engineers deliver hands-on operator training, covering programming, daily operation, basic maintenance, and common troubleshooting. We optimize processes to match your specific production goals. Ongoing support includes fast remote diagnostics, on-site visits when needed, and spare parts availability. This complete service package ensures quick startup, maximum machine uptime, and long-term performance you can count on in your SMT operation.

| Customer Experience and Operational Benefits

Customers frequently commend our engineers for their deep knowledge, clear explanations, and fast response to any questions during installation and training. They praise the fiber laser marking machine for consistent mark quality, reliable operation, and seamless line integration. Many highlight the secure, professional packaging that protects equipment perfectly during long-distance shipping. Quick resolution of technical issues builds strong confidence. Overall, clients value the dependable performance and dedicated support that help them maintain high production standards.

| Standards, Control and Production Discipline

I.C.T equipment carries key international certifications that prove safety, reliability, and environmental responsibility. These include CE marking for electrical safety, RoHS compliance for restricted hazardous substances, and ISO9001 certification for our quality management system. We also hold several patents covering innovative laser marking and SMT designs. These credentials confirm that every machine meets global standards and delivers trustworthy, eco-friendly performance in professional manufacturing settings.

| About I.C.T Company and Factory

I.C.T owns its own R&D center and modern production factory in Dongguan, China, covering 12,000 square meters with a dedicated team of 89 staff members, including 20 experienced engineers. Since 2012 the company has grown rapidly and now serves more than 1,600 customers across 72 countries worldwide. Our factory follows strict inspection procedures at every stage, backed by a complete quality management system. We supply full SMT solutions—from initial planning and equipment delivery to training and ongoing optimization—helping factories start, expand, or improve production lines with confidence.