I.C.T Simple DIP Assembly Line

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

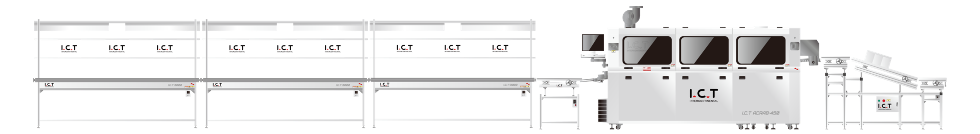

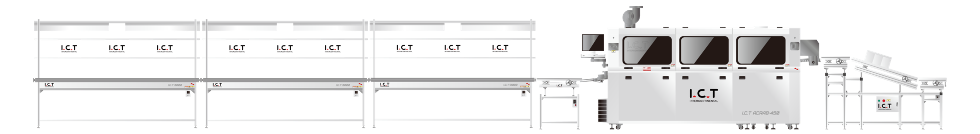

| Simple DIP Assembly Line Overview

The simple DIP assembly line is developed to meet the practical needs of manufacturers seeking reliable and cost-effective through-hole production. It is widely applied in electronics assembly line environments where product stability, mechanical strength, and process flexibility are essential. This solution supports manual insertion and assisted automation, making it suitable for factories producing power boards, control modules, and mixed-technology PCBA products. By organizing insertion, soldering, inspection, and handling processes into a coordinated workflow, the assembly line reduces unnecessary handling and improves overall efficiency. The system is especially effective for manufacturers who require consistent quality while maintaining flexibility for product variation and changing production volumes.

| DIP Line Equipment List

A standard simple DIP assembly line is composed of multiple functional stations arranged to support smooth and continuous production. Manual or semi-automatic DIP insertion stations allow operators to place components efficiently while maintaining accuracy. Conveyor systems link each process step, ensuring stable PCB transfer throughout the assembly line. The wave soldering unit provides controlled soldering for through-hole components, followed by cooling and visual inspection stations. Optional rework, repair, or testing areas can be added based on product requirements. For DIP Insertion Line applications, the equipment layout emphasizes ergonomic operation, process consistency, and easy adjustment to support different board sizes and production needs.

| Customer Success Video

In a recent international project, I.C.T supported KDC with the deployment of a simple DIP assembly line at their manufacturing site in Mexico. The solution integrated an I.C.T full-automatic insertion machine, a JUKI JM100 auto plug-in system, and an Acrab350 wave soldering unit to form a complete and efficient DIP Insertion Line. During installation, the engineering team resolved local power configuration differences and carefully adjusted process parameters to ensure smooth PCB flow across the assembly line. After commissioning, the line passed all acceptance criteria, reaching stable production speeds above 5 meters per minute with zero defects on THT boards. The customer reported a noticeable improvement in output efficiency and operational stability.

| Comprehensive Service Support

I.C.T provides comprehensive service support for every simple DIP assembly line, covering the full project lifecycle. Services include process evaluation, layout planning, equipment integration, installation, and operator training. Beyond commissioning, I.C.T offers ongoing technical assistance to support stable operation of the assembly line under real production conditions. With a global service network and experienced engineering teams, support can be delivered both remotely and on site when required. This service approach helps customers reduce production risks, shorten ramp-up cycles, and maintain consistent performance across different Electronics Assembly Line environments, even when operating in overseas or emerging markets.

| Customer Feedback

Customers operating the simple DIP assembly line consistently highlight its stability and ease of operation. Many value the balanced combination of manual flexibility and structured process control within the assembly line. Feedback often emphasizes smooth production flow, reduced rework, and practical equipment layout that supports daily operation. Customers also recognize the professionalism of I.C.T’s technical team and the reliability of support during setup and production startup. The availability of responsive assistance gives manufacturers confidence when expanding capacity or adapting the DIP Insertion Line to new products and changing production requirements.

| Certifications and Standards

The simple DIP assembly line is designed and manufactured in accordance with internationally recognized quality and safety standards. Equipment supplied by I.C.T complies with CE requirements and follows standardized electrical and mechanical safety guidelines. Quality management systems are aligned with ISO-based processes to ensure consistent manufacturing quality and traceability. Where applicable, materials and processes meet RoHS and environmental compliance standards. These certifications and standards help customers deploy the assembly line globally, reduce regulatory risks, and maintain reliable operation across different regional markets and application environments.

| About I.C.T Company and Factory

I.C.T is an experienced provider of integrated electronics manufacturing solutions, offering complete systems for SMT, DIP, assembly, and smart factory applications. The company operates dedicated manufacturing facilities and maintains a strong global service network to support customers worldwide. With extensive project experience across different Electronics Assembly Line environments, I.C.T focuses on practical system design, reliable equipment integration, and long-term operational support. By combining in-house manufacturing capabilities with global engineering expertise, I.C.T helps customers build scalable, efficient, and competitive production lines tailored to real manufacturing needs.

| Simple DIP Assembly Line Overview

The simple DIP assembly line is developed to meet the practical needs of manufacturers seeking reliable and cost-effective through-hole production. It is widely applied in electronics assembly line environments where product stability, mechanical strength, and process flexibility are essential. This solution supports manual insertion and assisted automation, making it suitable for factories producing power boards, control modules, and mixed-technology PCBA products. By organizing insertion, soldering, inspection, and handling processes into a coordinated workflow, the assembly line reduces unnecessary handling and improves overall efficiency. The system is especially effective for manufacturers who require consistent quality while maintaining flexibility for product variation and changing production volumes.

| DIP Line Equipment List

A standard simple DIP assembly line is composed of multiple functional stations arranged to support smooth and continuous production. Manual or semi-automatic DIP insertion stations allow operators to place components efficiently while maintaining accuracy. Conveyor systems link each process step, ensuring stable PCB transfer throughout the assembly line. The wave soldering unit provides controlled soldering for through-hole components, followed by cooling and visual inspection stations. Optional rework, repair, or testing areas can be added based on product requirements. For DIP Insertion Line applications, the equipment layout emphasizes ergonomic operation, process consistency, and easy adjustment to support different board sizes and production needs.

| Customer Success Video

In a recent international project, I.C.T supported KDC with the deployment of a simple DIP assembly line at their manufacturing site in Mexico. The solution integrated an I.C.T full-automatic insertion machine, a JUKI JM100 auto plug-in system, and an Acrab350 wave soldering unit to form a complete and efficient DIP Insertion Line. During installation, the engineering team resolved local power configuration differences and carefully adjusted process parameters to ensure smooth PCB flow across the assembly line. After commissioning, the line passed all acceptance criteria, reaching stable production speeds above 5 meters per minute with zero defects on THT boards. The customer reported a noticeable improvement in output efficiency and operational stability.

| Comprehensive Service Support

I.C.T provides comprehensive service support for every simple DIP assembly line, covering the full project lifecycle. Services include process evaluation, layout planning, equipment integration, installation, and operator training. Beyond commissioning, I.C.T offers ongoing technical assistance to support stable operation of the assembly line under real production conditions. With a global service network and experienced engineering teams, support can be delivered both remotely and on site when required. This service approach helps customers reduce production risks, shorten ramp-up cycles, and maintain consistent performance across different Electronics Assembly Line environments, even when operating in overseas or emerging markets.

| Customer Feedback

Customers operating the simple DIP assembly line consistently highlight its stability and ease of operation. Many value the balanced combination of manual flexibility and structured process control within the assembly line. Feedback often emphasizes smooth production flow, reduced rework, and practical equipment layout that supports daily operation. Customers also recognize the professionalism of I.C.T’s technical team and the reliability of support during setup and production startup. The availability of responsive assistance gives manufacturers confidence when expanding capacity or adapting the DIP Insertion Line to new products and changing production requirements.

| Certifications and Standards

The simple DIP assembly line is designed and manufactured in accordance with internationally recognized quality and safety standards. Equipment supplied by I.C.T complies with CE requirements and follows standardized electrical and mechanical safety guidelines. Quality management systems are aligned with ISO-based processes to ensure consistent manufacturing quality and traceability. Where applicable, materials and processes meet RoHS and environmental compliance standards. These certifications and standards help customers deploy the assembly line globally, reduce regulatory risks, and maintain reliable operation across different regional markets and application environments.

| About I.C.T Company and Factory

I.C.T is an experienced provider of integrated electronics manufacturing solutions, offering complete systems for SMT, DIP, assembly, and smart factory applications. The company operates dedicated manufacturing facilities and maintains a strong global service network to support customers worldwide. With extensive project experience across different Electronics Assembly Line environments, I.C.T focuses on practical system design, reliable equipment integration, and long-term operational support. By combining in-house manufacturing capabilities with global engineering expertise, I.C.T helps customers build scalable, efficient, and competitive production lines tailored to real manufacturing needs.