I.C.T-SS330 / SS430 / SS540 / SS550

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Selective Soldering Nozzle Part for SS330

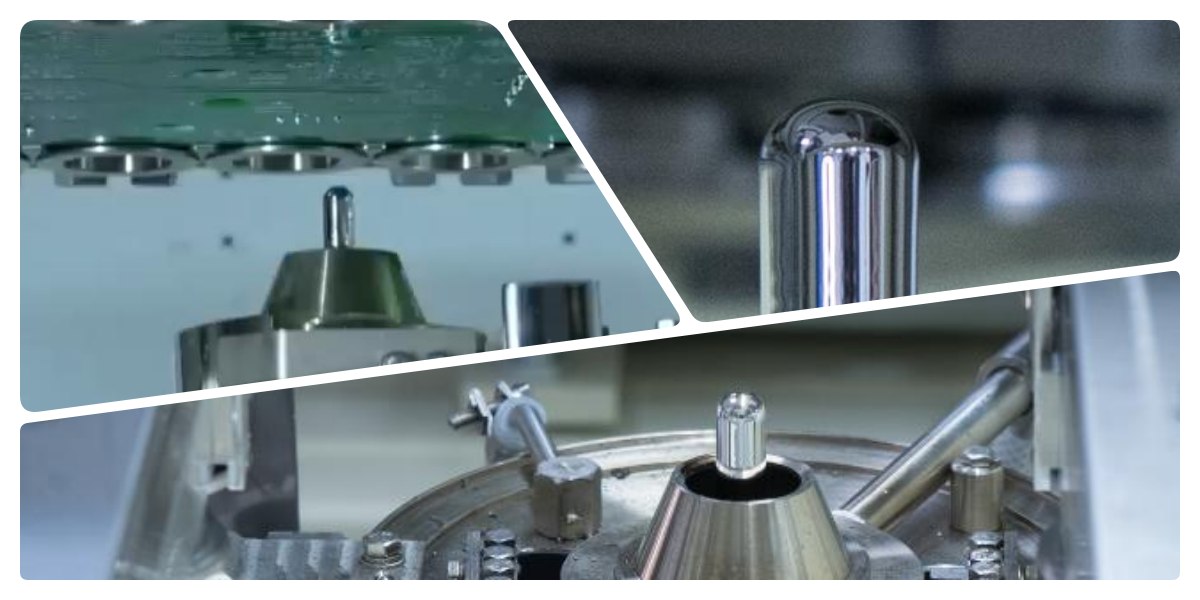

The selective soldering nozzle part, crafted by I.C.T in China, is a key component for the SS550 series, elevating PCB soldering precision. Perfect for the Select Offline Wave Soldering Machine, it ensures accurate flux and solder delivery on through-hole components, ideal for automotive and power supply needs. Paired with PC control, it saves settings like temperature and paths for repeatable quality. Its design fits modular offline setups, with auto-calibration and CCD alignment maintaining high standards. Backed by I.C.T’s 26 years of expertise, it serves 1600+ clients in 72 countries with reliable performance.

| DIP Line Equipment List

The selective soldering nozzle part excels in the Select Offline Wave Soldering Machine with accurate flux application. This German-engineered high-frequency pulse valve sprays tiny dots with solid content under 10%, minimizing waste. Mounted on an XY platform with 0.02mm precision, it includes a tray for easy residue cleanup. Pressure tanks and Japanese SMC parts ensure steady flow, with visible gauges for quick checks, making it perfect for detailed offline soldering.

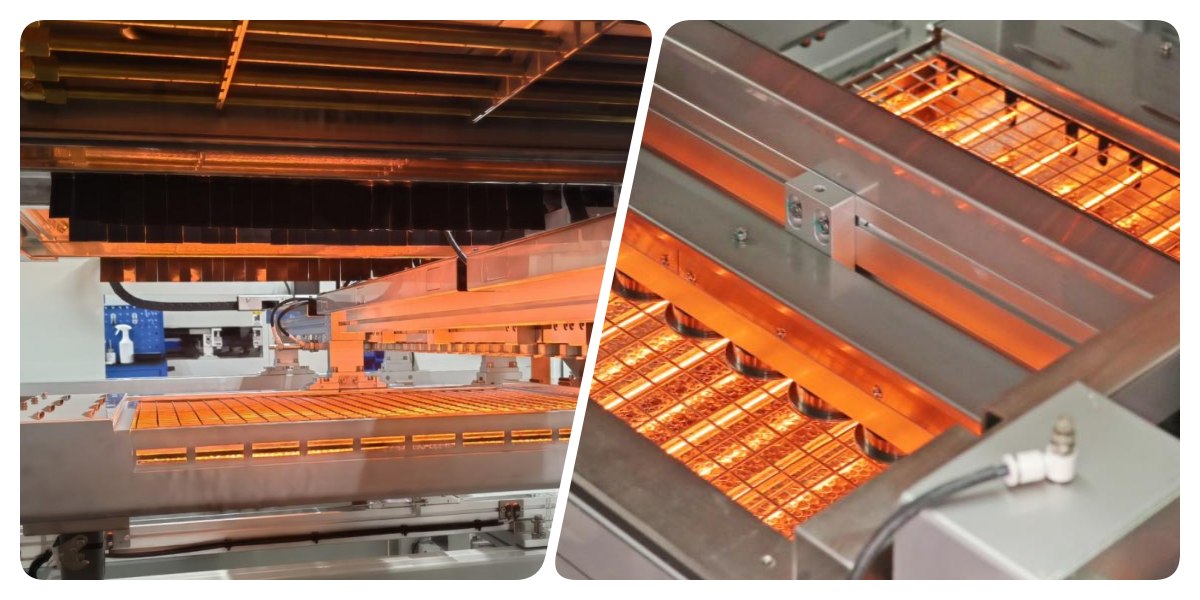

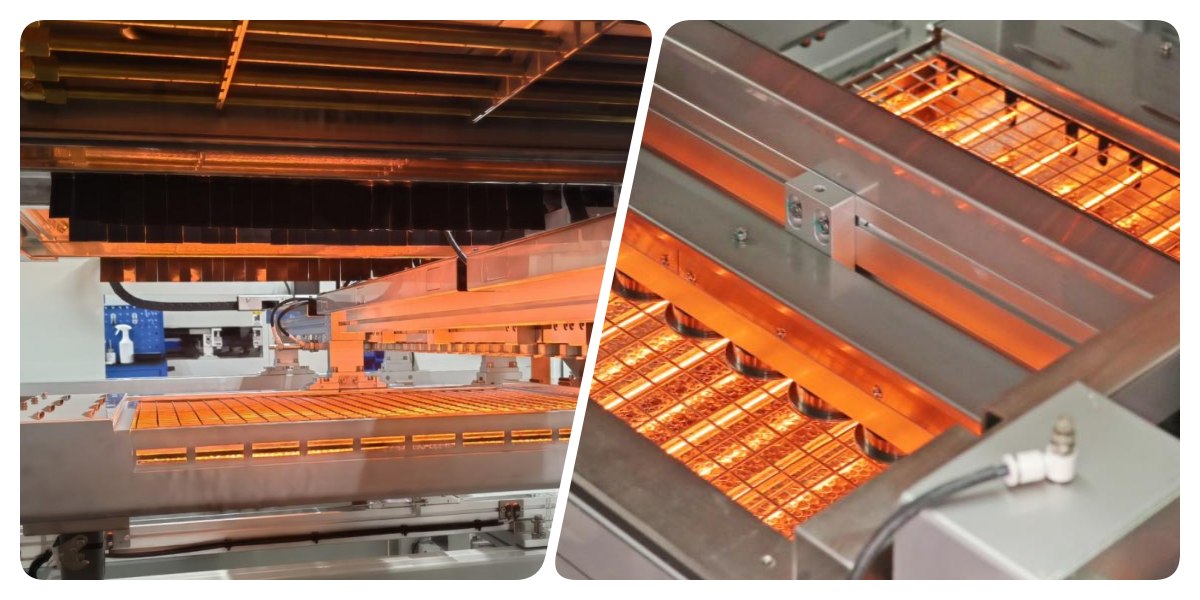

The nozzle part works with a preheat system that preps boards effectively for the selective soldering nozzle part. Adjustable bottom IR and top hot air heat reach 150°C in 15 minutes, using high-temp cotton for stability with top-brand parts. The tool-free plug-in design reduces maintenance time. This setup ensures strong welds, enhancing the nozzle’s performance in offline tasks.

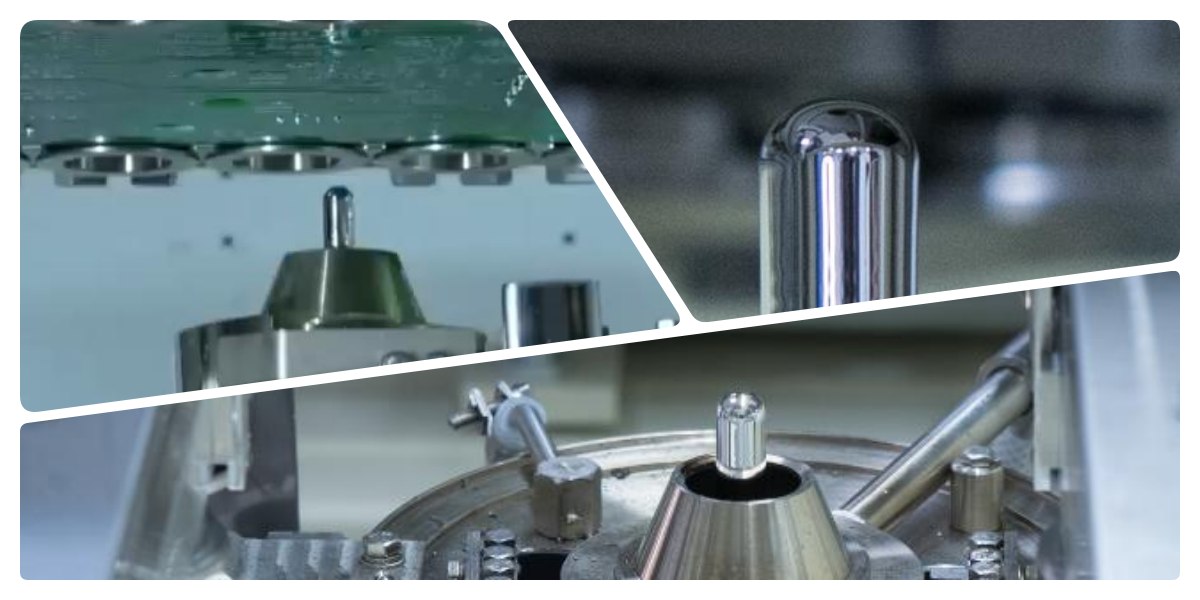

The selective soldering nozzle part shines with the Select Offline Wave Soldering Machine’s soldering system. Paired with a Swedish PRECIMETER pump, it maintains a stable solder wave, with software controlling temps and N2 flow. The stainless steel pot with anti-corrosion coating heats fast, while N2 reduces dross for clean joints. It handles complex components, boosting the nozzle’s reliability.

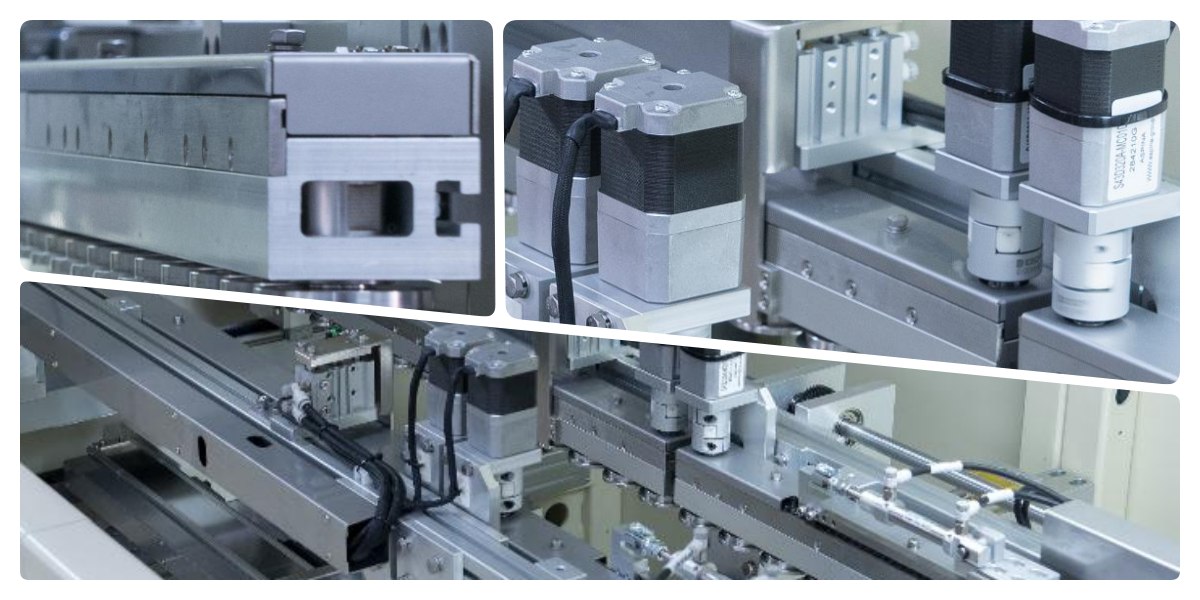

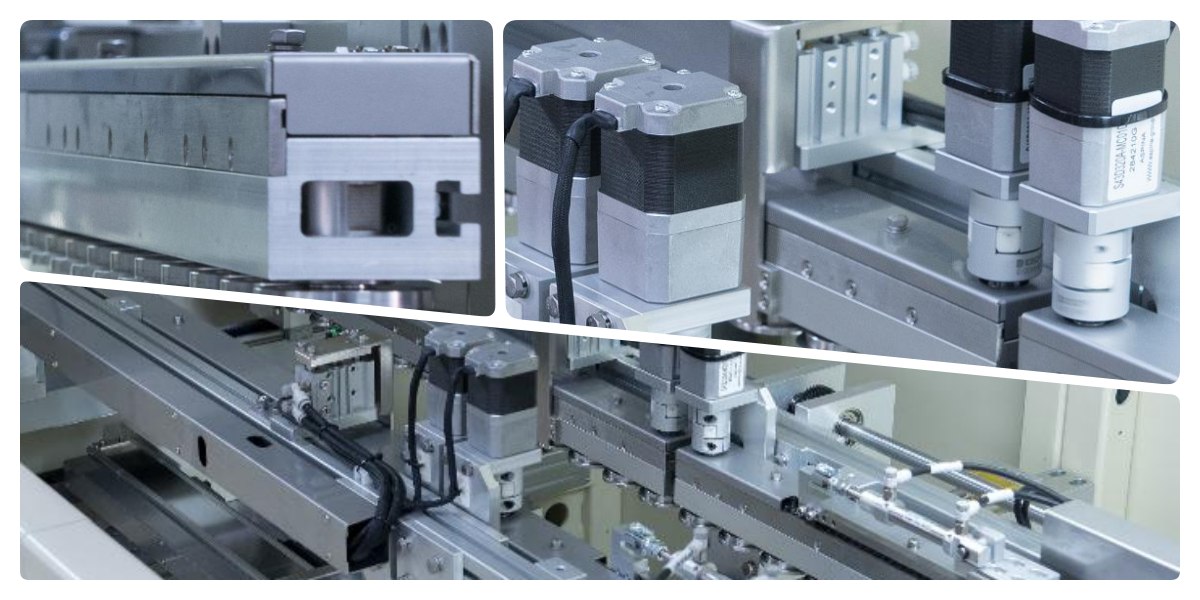

The nozzle part supports a durable transmission system for smooth PCB handling. Built with sturdy profiles and rollers, it handles 20kg loads with side and top clamps. Japanese motors ensure reliable movement, fitting modular offline setups. This design keeps production flowing, complementing the nozzle’s precision.

The selective soldering nozzle part integrates with a reliable Keyence PLC control system meeting CE standards. Global parts and Cat-6 cables ensure fast, stable operation, with data tracking for quality checks. It adapts to offline needs, enhancing the nozzle’s performance in small setups.

The operating system makes the selective soldering nozzle part easy to use with guided CCD programming. Picture mode verifies coordinates, with real-time monitoring in one click. Choose English or Chinese, with WiFi updates via MES. Data traces each solder point, simplifying use with the Select Offline Wave Soldering Machine.

| Specification

| Category | Item | Specification |

|---|---|---|

| Flux System | Flux Storage Tank | 1L |

| Spray Nozzle Size | 130um (180, 210um Option) | |

| Spray Range | 3~8mm | |

| Spray Speed | 0~20mm/s | |

| Spray Nozzle Move Speed | 0~400mm/s | |

| Spray Pressure | 0.05~0.1MPa | |

| Soldering System | Nozzle Inner Diameter | Φ 2.5-30mm (Customization) |

| Wave Height | 3~5mm | |

| Solder Pot Z Axis Area | 50 mm | |

| Soldering Precision | ±0.25 mm | |

| Solder Pot Power | 1.2kw | |

| Solder Capacity | 7Kg | |

| Max. Temperature | 350℃ | |

| Warm-up Time | <60min (setting 300℃) | |

| Transport System | Max Fixture Size | 6060mm-330330mm |

| Max PCB Size | 6060mm-330330mm | |

| PCB Top Clearance | 300mm | |

| PCB Bottom Clearance | 60mm | |

| PCB Weight | <15Kg | |

| PCB Thickness | 0.5-6.0mm | |

| Facility | N2 Purity | Purity of N2: 99.999%, 25 L/min, Φ6mm |

| N2 Pressure | 0.5~1.0 MPa | |

| Air Pressure | 4~6Kg/cm² | |

| Power Supply | 1P3W, 220VAC±10%, 50/60HZ | |

| Power | 16A, 3Kw | |

| Dimension | L1000W1180H1600mm | |

| Weight | 480kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Case Study

In October 2025, I.C.T engineers visited a European client to optimize a Select Offline Wave Soldering Machine line with the selective soldering nozzle part. The video showed the nozzle delivering precise flux and solder on PCBs, with auto-calibration ensuring consistency. Engineers trained staff and adjusted settings, enabling smooth offline production. The client praised the nozzle’s accuracy and I.C.T’s support, improving their output of high-quality boards.

| Service and Training Support

I.C.T offers full support for the selective soldering nozzle part with on-site setup and 24/7 help. Engineers provide training on operation and maintenance, plus remote assistance tailored to your needs. With 26 years in SMT, we optimize your offline line. Long-term plans include check-ups, keeping your production reliable.

| Client Appreciation

Clients commend I.C.T engineers for their expertise with the selective soldering nozzle part, offering quick fixes. The nozzle’s precise soldering impresses, with secure packaging ensuring safe delivery. Fast issue resolution keeps production on track, with feedback like, "I.C.T’s support is excellent," building trust.

| Recognized Standards

The selective soldering nozzle part meets CE, RoHS, and ISO9001 certifications for global safety and quality. I.C.T’s patents on nozzle and wave tech showcase innovation. These credentials ensure reliable, eco-friendly performance with the Select Offline Wave Soldering Machine.

| I.C.T Company and Factory Insights

I.C.T leads SMT with in-house R&D and three factories, growing to 89 staff over 26 years. We serve 1600+ clients in 72 countries, offering selective soldering nozzle parts with strict testing and quality systems. Our compact designs support offline setups globally. We innovate daily, fostering partnerships for your success.

| Selective Soldering Nozzle Part for SS330

The selective soldering nozzle part, crafted by I.C.T in China, is a key component for the SS550 series, elevating PCB soldering precision. Perfect for the Select Offline Wave Soldering Machine, it ensures accurate flux and solder delivery on through-hole components, ideal for automotive and power supply needs. Paired with PC control, it saves settings like temperature and paths for repeatable quality. Its design fits modular offline setups, with auto-calibration and CCD alignment maintaining high standards. Backed by I.C.T’s 26 years of expertise, it serves 1600+ clients in 72 countries with reliable performance.

| DIP Line Equipment List

The selective soldering nozzle part excels in the Select Offline Wave Soldering Machine with accurate flux application. This German-engineered high-frequency pulse valve sprays tiny dots with solid content under 10%, minimizing waste. Mounted on an XY platform with 0.02mm precision, it includes a tray for easy residue cleanup. Pressure tanks and Japanese SMC parts ensure steady flow, with visible gauges for quick checks, making it perfect for detailed offline soldering.

The nozzle part works with a preheat system that preps boards effectively for the selective soldering nozzle part. Adjustable bottom IR and top hot air heat reach 150°C in 15 minutes, using high-temp cotton for stability with top-brand parts. The tool-free plug-in design reduces maintenance time. This setup ensures strong welds, enhancing the nozzle’s performance in offline tasks.

The selective soldering nozzle part shines with the Select Offline Wave Soldering Machine’s soldering system. Paired with a Swedish PRECIMETER pump, it maintains a stable solder wave, with software controlling temps and N2 flow. The stainless steel pot with anti-corrosion coating heats fast, while N2 reduces dross for clean joints. It handles complex components, boosting the nozzle’s reliability.

The nozzle part supports a durable transmission system for smooth PCB handling. Built with sturdy profiles and rollers, it handles 20kg loads with side and top clamps. Japanese motors ensure reliable movement, fitting modular offline setups. This design keeps production flowing, complementing the nozzle’s precision.

The selective soldering nozzle part integrates with a reliable Keyence PLC control system meeting CE standards. Global parts and Cat-6 cables ensure fast, stable operation, with data tracking for quality checks. It adapts to offline needs, enhancing the nozzle’s performance in small setups.

The operating system makes the selective soldering nozzle part easy to use with guided CCD programming. Picture mode verifies coordinates, with real-time monitoring in one click. Choose English or Chinese, with WiFi updates via MES. Data traces each solder point, simplifying use with the Select Offline Wave Soldering Machine.

| Specification

| Category | Item | Specification |

|---|---|---|

| Flux System | Flux Storage Tank | 1L |

| Spray Nozzle Size | 130um (180, 210um Option) | |

| Spray Range | 3~8mm | |

| Spray Speed | 0~20mm/s | |

| Spray Nozzle Move Speed | 0~400mm/s | |

| Spray Pressure | 0.05~0.1MPa | |

| Soldering System | Nozzle Inner Diameter | Φ 2.5-30mm (Customization) |

| Wave Height | 3~5mm | |

| Solder Pot Z Axis Area | 50 mm | |

| Soldering Precision | ±0.25 mm | |

| Solder Pot Power | 1.2kw | |

| Solder Capacity | 7Kg | |

| Max. Temperature | 350℃ | |

| Warm-up Time | <60min (setting 300℃) | |

| Transport System | Max Fixture Size | 6060mm-330330mm |

| Max PCB Size | 6060mm-330330mm | |

| PCB Top Clearance | 300mm | |

| PCB Bottom Clearance | 60mm | |

| PCB Weight | <15Kg | |

| PCB Thickness | 0.5-6.0mm | |

| Facility | N2 Purity | Purity of N2: 99.999%, 25 L/min, Φ6mm |

| N2 Pressure | 0.5~1.0 MPa | |

| Air Pressure | 4~6Kg/cm² | |

| Power Supply | 1P3W, 220VAC±10%, 50/60HZ | |

| Power | 16A, 3Kw | |

| Dimension | L1000W1180H1600mm | |

| Weight | 480kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Case Study

In October 2025, I.C.T engineers visited a European client to optimize a Select Offline Wave Soldering Machine line with the selective soldering nozzle part. The video showed the nozzle delivering precise flux and solder on PCBs, with auto-calibration ensuring consistency. Engineers trained staff and adjusted settings, enabling smooth offline production. The client praised the nozzle’s accuracy and I.C.T’s support, improving their output of high-quality boards.

| Service and Training Support

I.C.T offers full support for the selective soldering nozzle part with on-site setup and 24/7 help. Engineers provide training on operation and maintenance, plus remote assistance tailored to your needs. With 26 years in SMT, we optimize your offline line. Long-term plans include check-ups, keeping your production reliable.

| Client Appreciation

Clients commend I.C.T engineers for their expertise with the selective soldering nozzle part, offering quick fixes. The nozzle’s precise soldering impresses, with secure packaging ensuring safe delivery. Fast issue resolution keeps production on track, with feedback like, "I.C.T’s support is excellent," building trust.

| Recognized Standards

The selective soldering nozzle part meets CE, RoHS, and ISO9001 certifications for global safety and quality. I.C.T’s patents on nozzle and wave tech showcase innovation. These credentials ensure reliable, eco-friendly performance with the Select Offline Wave Soldering Machine.

| I.C.T Company and Factory Insights

I.C.T leads SMT with in-house R&D and three factories, growing to 89 staff over 26 years. We serve 1600+ clients in 72 countries, offering selective soldering nozzle parts with strict testing and quality systems. Our compact designs support offline setups globally. We innovate daily, fostering partnerships for your success.