I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| Reliable PCB Industrial Ultrasonic Cleaner

Manufacturers in electronics turn to the I.C.T-800 PCB industrial ultrasonic cleaner when they need dependable removal of solder paste from stencils, red glue from masks, flux from misprinted boards, and residues from large PCBAs. Everything happens inside one chamber: aqueous detergent wash, DI water rinse, and powerful hot air drying. Four fixed spray rods and air knives stay put while the stencil moves back and forth, delivering steady, thorough cleaning without stressing the stencil frame. Heating keeps the detergent at the right temperature, stirring ensures even mixing, filters catch particles, and resistivity checks confirm rinse quality. This machine boosts print accuracy, lowers defects, and saves money in high-output SMT setups.

| Feature

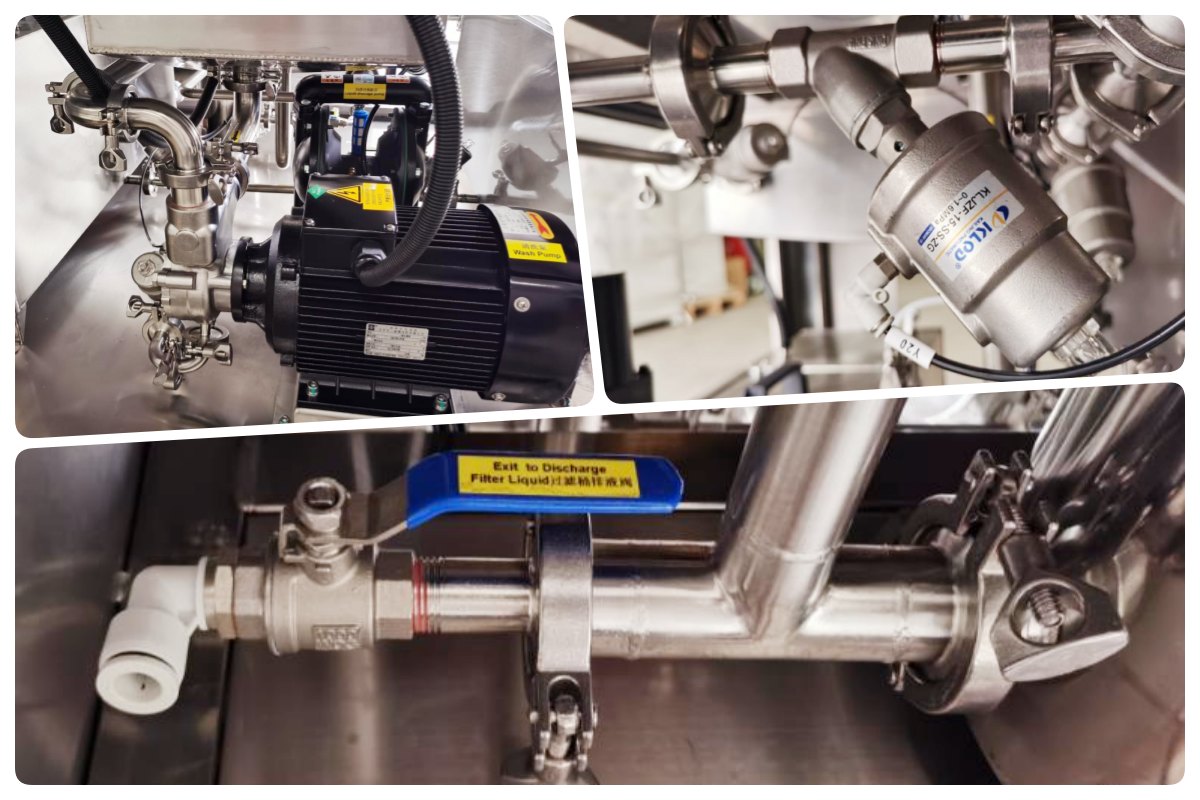

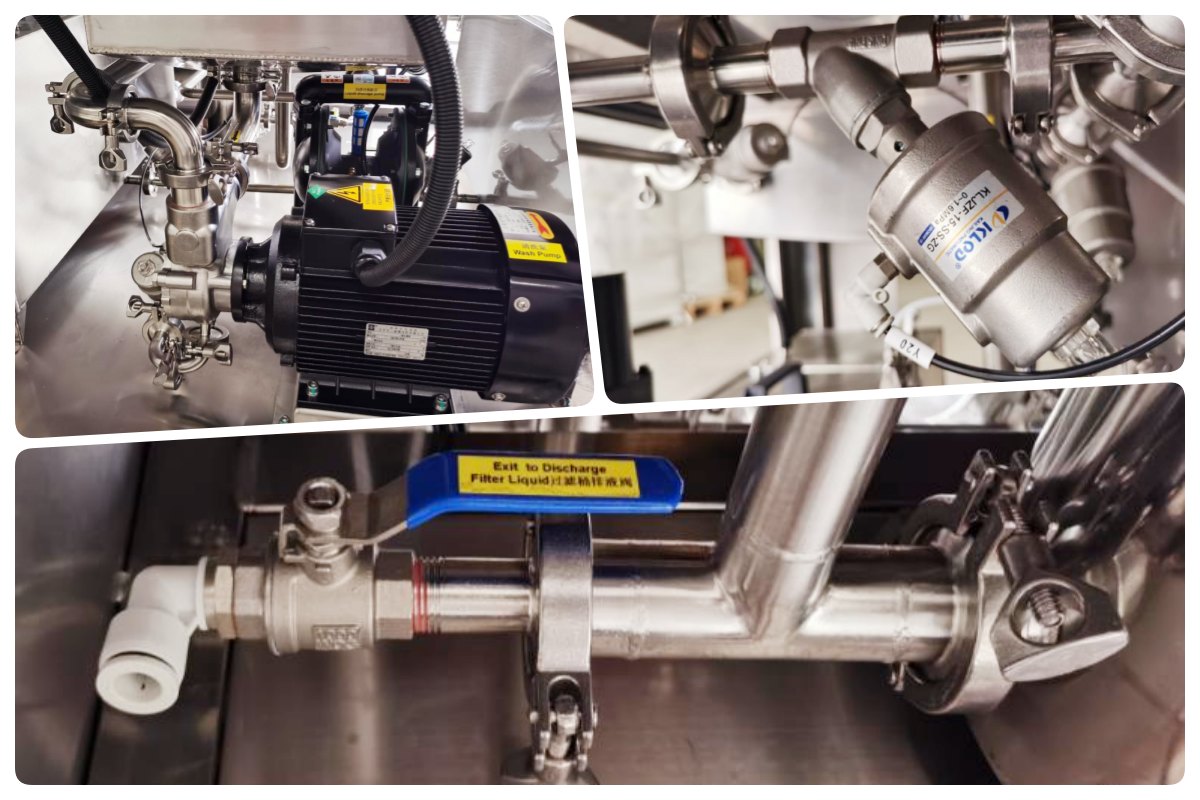

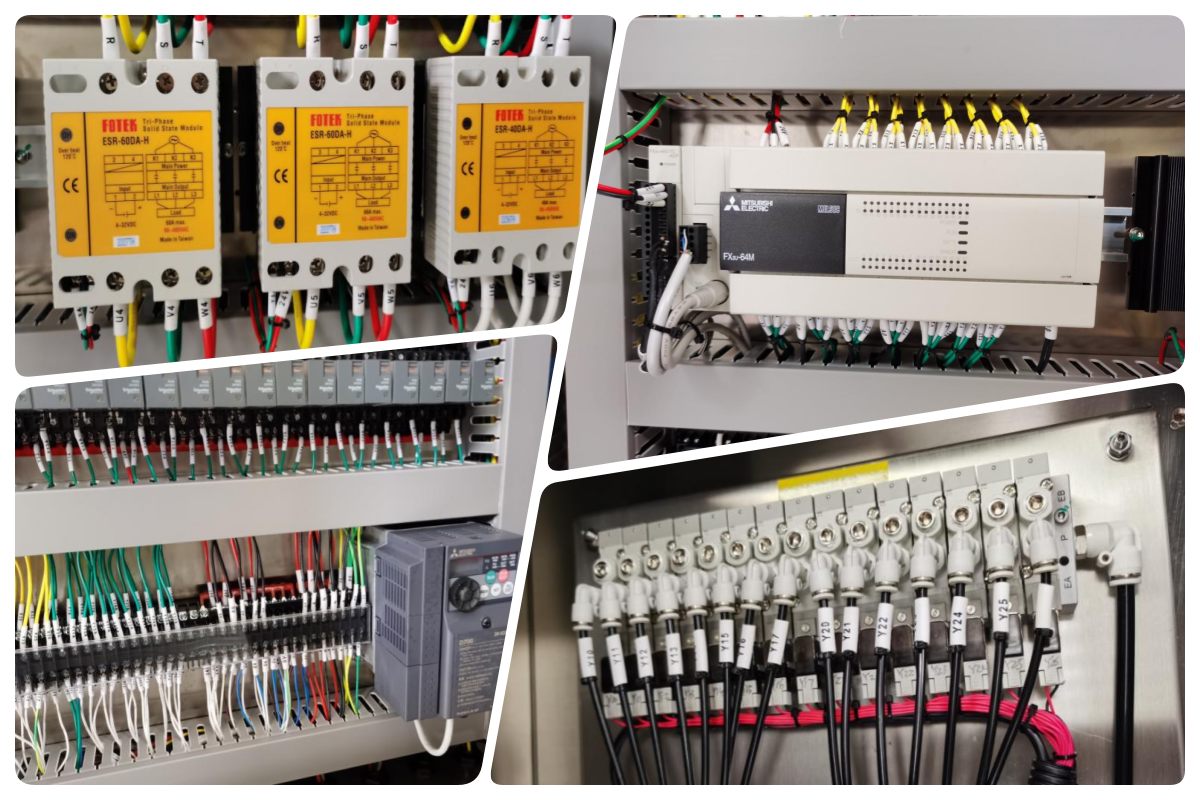

Strong power comes first in the I.C.T-800 PCB industrial ultra sonic cleaner PCB. A high-power motor pairs with a diaphragm pump to push cleaning fluid out fast and pull it back efficiently for reuse. Quick-connect fittings on all pneumatic lines make maintenance straightforward and speedy. Every pipeline joint uses quick-release design so parts swap out without delay. Angle seat valves appear at several points, letting the same circuit handle both forward filling and reverse recovery of liquid. Pipeline markings show clear flow directions to prevent mix-ups. Operators find this setup dependable day after day, keeping downtime low and service simple in demanding factory environments.

Cleaning happens reliably thanks to the smart design in this PCB industrial ultrasonic cleaner. Four fixed spray bars and four air knives stay stationary while the stencil rack moves steadily back and forth, covering every spot evenly and quickly. The adjustable clamp holds stencils of different sizes securely and lets users change them without hassle. Bottom guide channels include pulleys so no water pools up, making it easy to slide boards in and out. Double-sealed doors trap any leftover liquid in the recovery area near the entrance. A stepper motor drives precise reciprocating action for complete coverage. Beyond stencils, it tackles residues on copper masks, resin plates, misprints, and full PCBA.

Large tanks reduce refill interruptions on the I.C.T-800. Two 60-liter vessels—one for cleaning detergent, one for rinse—support longer runs before topping up. Built-in heaters raise aqueous fluid temperature to as high as 60°C for stronger action against stubborn residues. Probes let operators set exact temperatures, while four curved stirring blades keep everything uniformly blended. Liquid level sensors trigger audible and visual alerts when supplies run low. Precision filters work both before spraying and during return flow, blocking contaminants from reaching parts or re-entering the system. This thoughtful tank arrangement delivers steady performance over extended shifts in production settings.

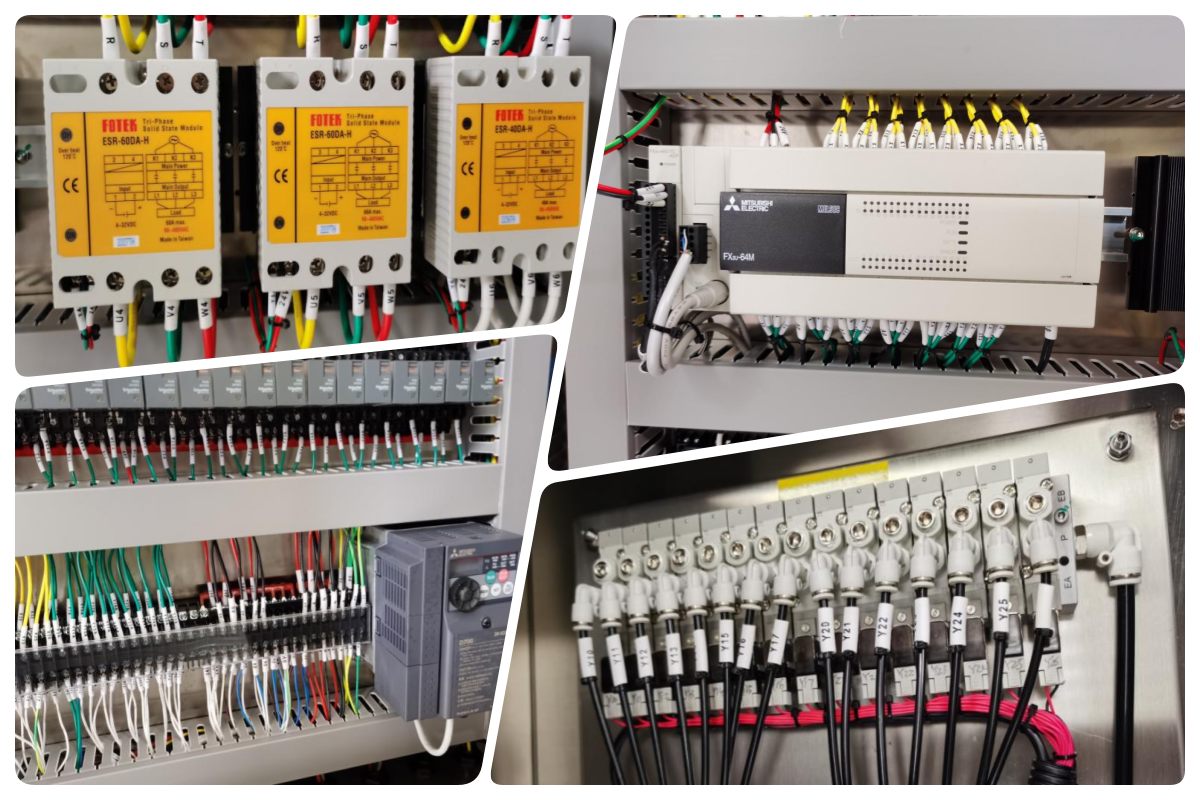

Easy control defines the I.C.T-800 experience. An English-language color touch screen connects to PLC logic, letting users adjust and watch every parameter closely. Set cleaning temperature, wash duration, rinse cycles and times, rinse heat, hot air dry length and temperature, plus resistivity levels—all monitored live. Imported brand components ensure long-term dependability. Separate boxes for electrical and pneumatic controls prevent any crossover issues. The whole layout follows CE and UL guidelines, so routine checks and repairs stay simple and safe. Precise settings like these help maintain repeatable quality, giving operators confidence in every cycle.

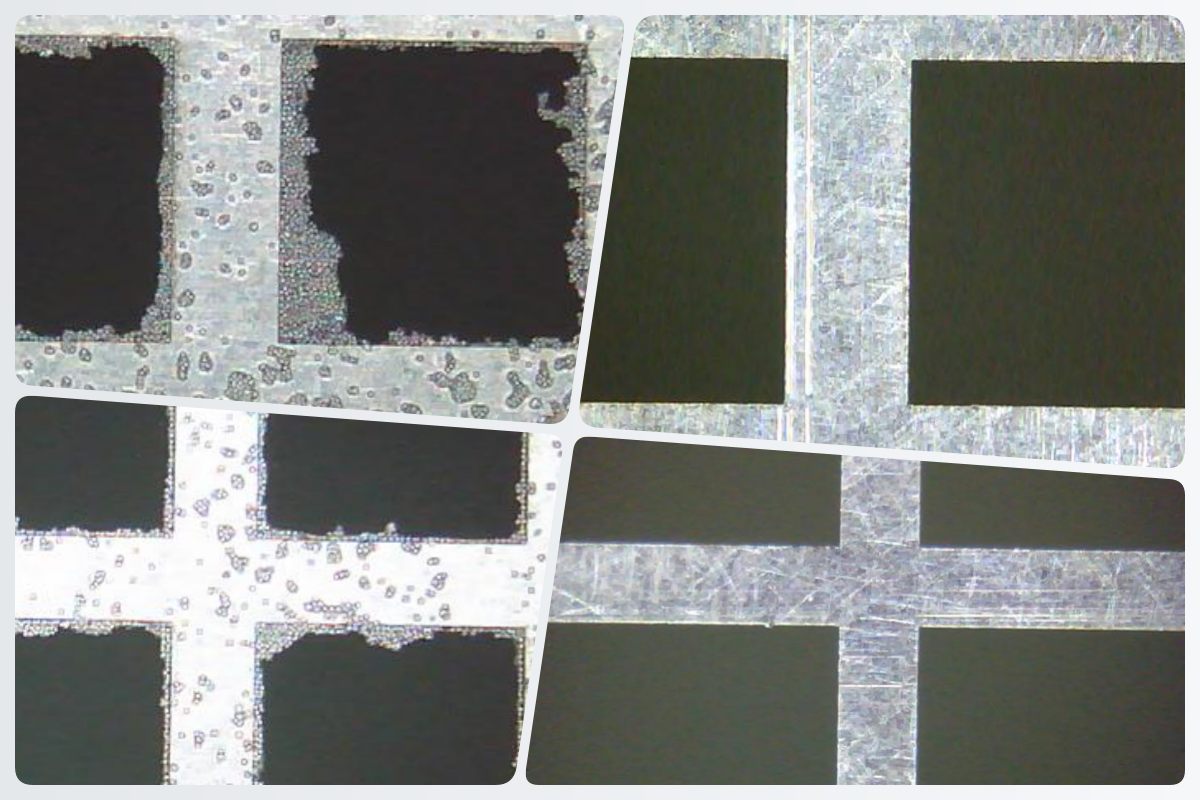

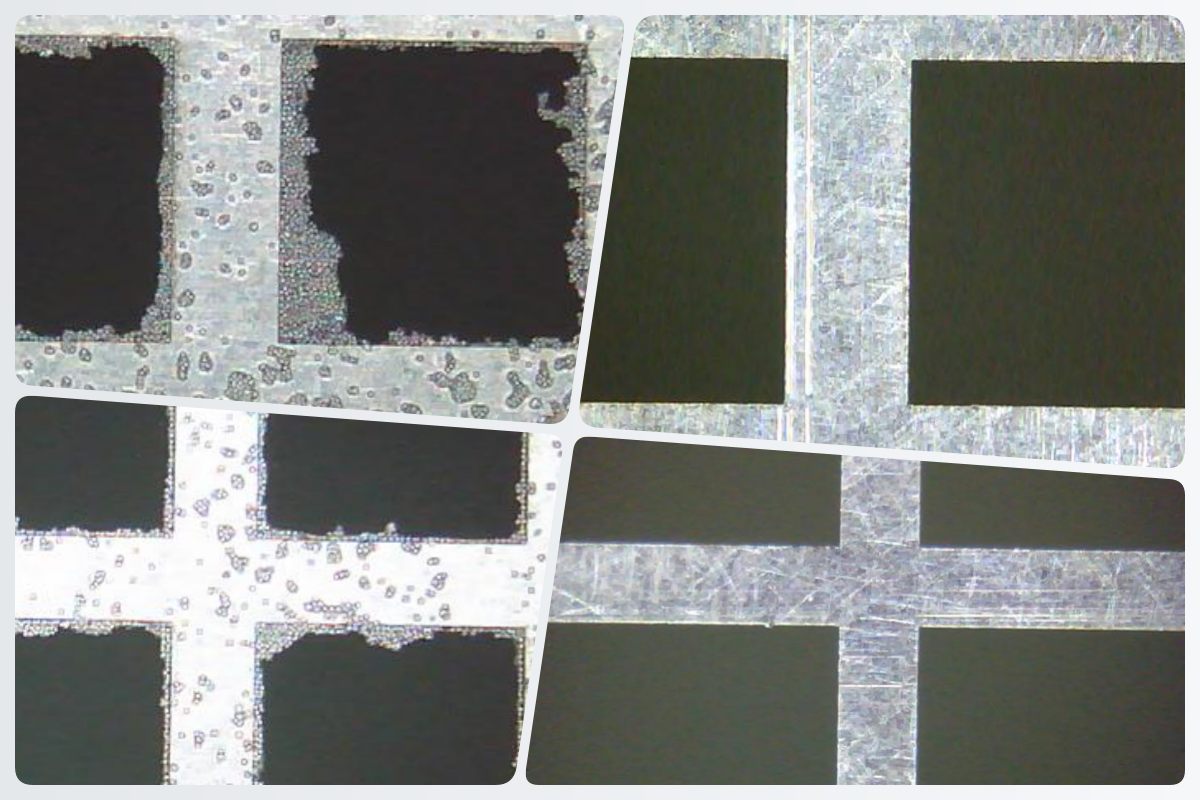

| Comparison Before and After

| Specification

| Parameter | I.C.T-750 (Pneumatic) | I.C.T-800 (Auto Aqueous) |

|---|---|---|

| Power Source | Compressed air only (no electricity) | Electric (AC380V, 3-phase, 33KW total) |

| Max Stencil Size | L750 × W750 × H40 mm | L750 × W750 × H40 mm |

| Cleaning Method | 360° rotation spray + air blow dry | 4 fixed spray rods + 4 air knives, stencil moves back & forth |

| Cleaning Liquid | Solvent or aqueous (both supported) | Aqueous detergent only |

| Liquid Tank Capacity | 40 L | 60 L × 2 (cleaning + rinse) |

| Cleaning Time | 2–4 minutes | 2–5 minutes |

| Drying Time | 2–5 minutes | 3–5 minutes (hot air) |

| Heating Function | No heating (room temperature) | Yes (detergent up to 60°C, hot air up to 90°C) |

| SMT Line Equipment List

Complete SMT whole line from I.C.T include essential units like stencil printers, SPI inspection, fast SMD PCB Pick Place Machine, reflow soldering ovens, Online AOI machine, and conveyor links, all matched for smooth high-yield assembly. For through-hole work, DIP lines feature plug-in stations, auto insertion machines, selective soldering, wave soldering, AOI checks, and tinning equipment to handle components precisely. Whether setting up pure SMT, DIP, or hybrid setups, I.C.T supplies coordinated machines backed by full planning, installation, and ongoing support to keep production efficient and reliable from day one.

| Customer Success Video

I.C.T delivered strong results for a North American beauty instrument producer by handling full overseas installation and Factory Acceptance Testing on two complete SMT lines. The project wrapped up smoothly, passing all production checks without delay. Equipment covered everything needed: laser marking units, SMT printers paired with SPI, Panasonic chip placers, Heller reflow ovens, AOI inspection tools, PCB transfer conveyors, PCBA cleaners, and automatic solder paste storage-thawing systems. Our engineers stayed on site for setup, hands-on training, and fine-tuning until lines ran at peak efficiency. This smooth execution built lasting trust and proved I.C.T's ability to support complex, high-standard projects far from home.

| Service and Training

I.C.T stands ready with complete backup so customers get maximum value from their PCB industrial ultrasonic cleaner and full lines. Skilled engineers travel worldwide for installation, startup commissioning, and detailed operator training. Sessions cover daily use, routine upkeep, setting adjustments, and quick fixes for common issues. Remote assistance handles urgent questions fast, often the same day. We share process tips to raise yields and drop expenses over time. Drawing on more than 25 years in the field, our team responds promptly and stays committed long after delivery, letting factories concentrate on output while we manage equipment reliability and support needs.

| Customer Reviews

Clients frequently commend our engineers for their deep knowledge, clear explanations, and rapid handling of any concerns during setup and follow-up visits. Many point out the PCB industrial ultrasonic cleaner's solid build, spotless cleaning performance, and impressive savings on consumables. Several reviews highlight careful packing and secure shipping that kept machines arriving undamaged after international transit. Quick email and phone responses earn special thanks, showing real dedication to customer success. Overall, people describe I.C.T as a dependable supplier that combines quality gear with attentive, professional service from start to finish.

| Our Certification

Every I.C.T-800 PCB industrial ultrasonic cleaner carries key international approvals that assure safety and quality. CE marking confirms it meets strict European safety rules, RoHS compliance guarantees low hazardous substances for eco-friendly use, and ISO9001 certification backs our full quality management system. Multiple patents protect unique features like the fixed spray and moving stencil approach. These credentials demonstrate our focus on secure operation, environmental responsibility, and innovative engineering. Buyers know they receive equipment built to global benchmarks for performance, durability, and responsible manufacturing practices.

| About Us and Factory

I.C.T builds full SMT solutions with in-house research, design, and manufacturing at our Dongguan facility. Since 2012 we have grown quickly to 89 team members, including 20 dedicated engineers, across 12,000 square meters of space. Our $30 million registered capital supports eight global branch offices. We now serve over 1,600 customers in 72 countries, gaining deep insight into technical needs, local conditions, and trust-building. Strict inspection steps and a robust quality system run through every production stage, ensuring consistent high standards. We deliver dependable machines and comprehensive guidance to help partners establish, expand, or refine their manufacturing operations worldwide.

| Reliable PCB Industrial Ultrasonic Cleaner

Manufacturers in electronics turn to the I.C.T-800 PCB industrial ultrasonic cleaner when they need dependable removal of solder paste from stencils, red glue from masks, flux from misprinted boards, and residues from large PCBAs. Everything happens inside one chamber: aqueous detergent wash, DI water rinse, and powerful hot air drying. Four fixed spray rods and air knives stay put while the stencil moves back and forth, delivering steady, thorough cleaning without stressing the stencil frame. Heating keeps the detergent at the right temperature, stirring ensures even mixing, filters catch particles, and resistivity checks confirm rinse quality. This machine boosts print accuracy, lowers defects, and saves money in high-output SMT setups.

| Feature

Strong power comes first in the I.C.T-800 PCB industrial ultra sonic cleaner PCB. A high-power motor pairs with a diaphragm pump to push cleaning fluid out fast and pull it back efficiently for reuse. Quick-connect fittings on all pneumatic lines make maintenance straightforward and speedy. Every pipeline joint uses quick-release design so parts swap out without delay. Angle seat valves appear at several points, letting the same circuit handle both forward filling and reverse recovery of liquid. Pipeline markings show clear flow directions to prevent mix-ups. Operators find this setup dependable day after day, keeping downtime low and service simple in demanding factory environments.

Cleaning happens reliably thanks to the smart design in this PCB industrial ultrasonic cleaner. Four fixed spray bars and four air knives stay stationary while the stencil rack moves steadily back and forth, covering every spot evenly and quickly. The adjustable clamp holds stencils of different sizes securely and lets users change them without hassle. Bottom guide channels include pulleys so no water pools up, making it easy to slide boards in and out. Double-sealed doors trap any leftover liquid in the recovery area near the entrance. A stepper motor drives precise reciprocating action for complete coverage. Beyond stencils, it tackles residues on copper masks, resin plates, misprints, and full PCBA.

Large tanks reduce refill interruptions on the I.C.T-800. Two 60-liter vessels—one for cleaning detergent, one for rinse—support longer runs before topping up. Built-in heaters raise aqueous fluid temperature to as high as 60°C for stronger action against stubborn residues. Probes let operators set exact temperatures, while four curved stirring blades keep everything uniformly blended. Liquid level sensors trigger audible and visual alerts when supplies run low. Precision filters work both before spraying and during return flow, blocking contaminants from reaching parts or re-entering the system. This thoughtful tank arrangement delivers steady performance over extended shifts in production settings.

Easy control defines the I.C.T-800 experience. An English-language color touch screen connects to PLC logic, letting users adjust and watch every parameter closely. Set cleaning temperature, wash duration, rinse cycles and times, rinse heat, hot air dry length and temperature, plus resistivity levels—all monitored live. Imported brand components ensure long-term dependability. Separate boxes for electrical and pneumatic controls prevent any crossover issues. The whole layout follows CE and UL guidelines, so routine checks and repairs stay simple and safe. Precise settings like these help maintain repeatable quality, giving operators confidence in every cycle.

| Comparison Before and After

| Specification

| Parameter | I.C.T-750 (Pneumatic) | I.C.T-800 (Auto Aqueous) |

|---|---|---|

| Power Source | Compressed air only (no electricity) | Electric (AC380V, 3-phase, 33KW total) |

| Max Stencil Size | L750 × W750 × H40 mm | L750 × W750 × H40 mm |

| Cleaning Method | 360° rotation spray + air blow dry | 4 fixed spray rods + 4 air knives, stencil moves back & forth |

| Cleaning Liquid | Solvent or aqueous (both supported) | Aqueous detergent only |

| Liquid Tank Capacity | 40 L | 60 L × 2 (cleaning + rinse) |

| Cleaning Time | 2–4 minutes | 2–5 minutes |

| Drying Time | 2–5 minutes | 3–5 minutes (hot air) |

| Heating Function | No heating (room temperature) | Yes (detergent up to 60°C, hot air up to 90°C) |

| SMT Line Equipment List

Complete SMT whole line from I.C.T include essential units like stencil printers, SPI inspection, fast SMD PCB Pick Place Machine, reflow soldering ovens, Online AOI machine, and conveyor links, all matched for smooth high-yield assembly. For through-hole work, DIP lines feature plug-in stations, auto insertion machines, selective soldering, wave soldering, AOI checks, and tinning equipment to handle components precisely. Whether setting up pure SMT, DIP, or hybrid setups, I.C.T supplies coordinated machines backed by full planning, installation, and ongoing support to keep production efficient and reliable from day one.

| Customer Success Video

I.C.T delivered strong results for a North American beauty instrument producer by handling full overseas installation and Factory Acceptance Testing on two complete SMT lines. The project wrapped up smoothly, passing all production checks without delay. Equipment covered everything needed: laser marking units, SMT printers paired with SPI, Panasonic chip placers, Heller reflow ovens, AOI inspection tools, PCB transfer conveyors, PCBA cleaners, and automatic solder paste storage-thawing systems. Our engineers stayed on site for setup, hands-on training, and fine-tuning until lines ran at peak efficiency. This smooth execution built lasting trust and proved I.C.T's ability to support complex, high-standard projects far from home.

| Service and Training

I.C.T stands ready with complete backup so customers get maximum value from their PCB industrial ultrasonic cleaner and full lines. Skilled engineers travel worldwide for installation, startup commissioning, and detailed operator training. Sessions cover daily use, routine upkeep, setting adjustments, and quick fixes for common issues. Remote assistance handles urgent questions fast, often the same day. We share process tips to raise yields and drop expenses over time. Drawing on more than 25 years in the field, our team responds promptly and stays committed long after delivery, letting factories concentrate on output while we manage equipment reliability and support needs.

| Customer Reviews

Clients frequently commend our engineers for their deep knowledge, clear explanations, and rapid handling of any concerns during setup and follow-up visits. Many point out the PCB industrial ultrasonic cleaner's solid build, spotless cleaning performance, and impressive savings on consumables. Several reviews highlight careful packing and secure shipping that kept machines arriving undamaged after international transit. Quick email and phone responses earn special thanks, showing real dedication to customer success. Overall, people describe I.C.T as a dependable supplier that combines quality gear with attentive, professional service from start to finish.

| Our Certification

Every I.C.T-800 PCB industrial ultrasonic cleaner carries key international approvals that assure safety and quality. CE marking confirms it meets strict European safety rules, RoHS compliance guarantees low hazardous substances for eco-friendly use, and ISO9001 certification backs our full quality management system. Multiple patents protect unique features like the fixed spray and moving stencil approach. These credentials demonstrate our focus on secure operation, environmental responsibility, and innovative engineering. Buyers know they receive equipment built to global benchmarks for performance, durability, and responsible manufacturing practices.

| About Us and Factory

I.C.T builds full SMT solutions with in-house research, design, and manufacturing at our Dongguan facility. Since 2012 we have grown quickly to 89 team members, including 20 dedicated engineers, across 12,000 square meters of space. Our $30 million registered capital supports eight global branch offices. We now serve over 1,600 customers in 72 countries, gaining deep insight into technical needs, local conditions, and trust-building. Strict inspection steps and a robust quality system run through every production stage, ensuring consistent high standards. We deliver dependable machines and comprehensive guidance to help partners establish, expand, or refine their manufacturing operations worldwide.