I.C.T- AI-4026

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced DIP AOI Inspection System

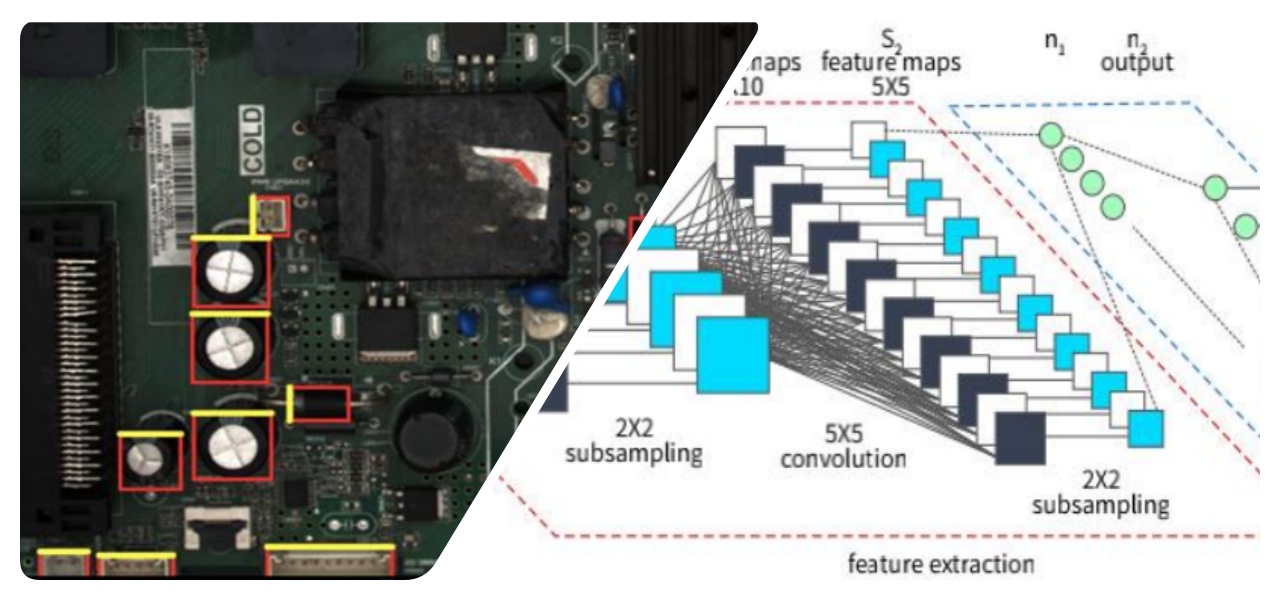

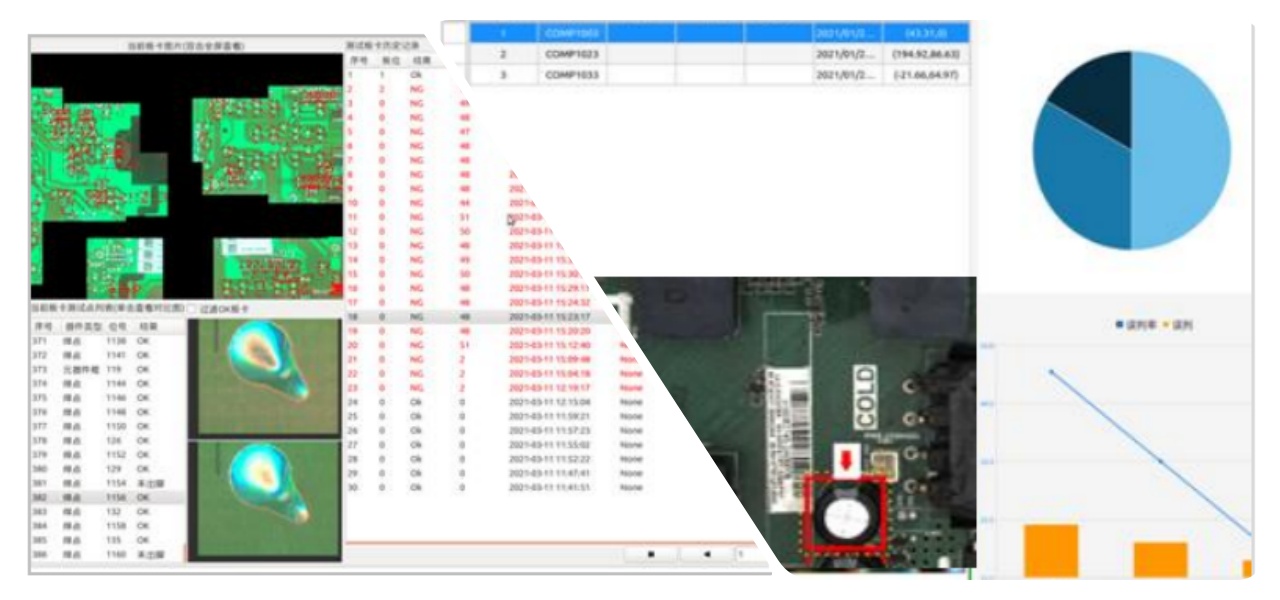

The DIP AOI AI4026 is a cutting-edge inspection system designed to check printed circuit boards (PCBs) with high accuracy. This machine uses advanced optical technology to find defects fast, making it perfect for surface-mount technology (SMT) production lines. Built by I.C.T, a leader in manufacturing and service, this system helps factories improve quality and save time. It works well for both small and large businesses, offering a simple interface that anyone can learn. With I.C.T’s global support, you get fast delivery and expert help. Choose this reliable tool to meet your production needs and grow your business with confidence.

| Feature

The DIP AOI AI4026 uses top optical inspection technology to spot even tiny defects on PCBs. This machine scans boards quickly and shows clear results, helping workers fix problems fast. It reduces errors and improves product quality, which is key for SMT lines. With its easy setup, any operator can use it without special training. This feature saves time and ensures your production stays on track every day.

This inspection system fits perfectly into DIP production lines, boosting efficiency. It works fast to check boards without slowing down your process. The machine’s design allows smooth operation, making it a great choice for busy factories. I.C.T’s team ensures it meets your specific needs with expert setup support. This helps you produce more in less time, keeping your business competitive.

The DIP AOI AI4026 comes with a simple interface that anyone can use. Operators can start checking PCBs with basic training, saving time on learning. The clear display shows results easily, making it simple to spot issues. This design helps small teams work effectively and reduces mistakes. With I.C.T’s support, you get ongoing help to keep the system running smoothly.

| Specification

| Model | I.C.T DIP Online AOI AI-4026(Before THT Soldering) | I.C.T DIP Online AOI AI-4026L(Before THT Soldering) |

| FOV | 400*300mm | 520*380mm |

| Resolution | 90um | 80um |

| Camera | 12M | 31M |

| Mixing PCB inspection | Support calling program automatically | |

| PCB Size | 50*50mm ~ 400*300mm | 50*50mm ~ 520*380mm |

| Display | 23.8 inch FHD display | |

| Data output | Autogenerated statistic analysis SPC | |

| Special function | Automatic search of elements and quick programming | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 200W | |

| Compressed Air | 0.4 ~ 0.6Mpa | |

| Communication | SMEMA | |

| Weight | 120Kg | |

| Dimension | L715*W760~1210*H1315~1700mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Service & Training

I.C.T offers top-notch service and training for the DIP AOI AI4026. Our skilled engineers provide on-site setup and teach your team how to use the machine effectively. We offer regular updates and maintenance to keep it running well. With our global network, help is always nearby, no matter where you are. This support ensures your investment lasts long and performs at its best. Choose I.C.T for reliable service that grows with your business.

| Customer Reviews

Customers love our engineers for their knowledge and friendly help. They admire the DIP AOI AI4026 for its accuracy and durability. Our careful packing and fast shipping also get high marks. Clients appreciate how quickly we solve their issues, keeping their production smooth. This feedback shows I.C.T’s commitment to quality and customer satisfaction.

| Our Certification

I.C.T is proud to hold certifications like CE, RoHS, ISO9001, and patents. These awards prove our commitment to safety, quality, and innovation. Our products meet global standards, giving you confidence in every purchase. With these credentials, you know I.C.T delivers reliable and trusted solutions.

| About I.C.T & Our Factory

I.C.T is a growing company with its own research, development, and production teams. We have a large staff and serve thousands of clients across many countries worldwide. Our factory uses strict testing processes and a strong quality management system to ensure top products. Over the years, we’ve expanded rapidly, offering reliable solutions globally. Trust I.C.T for innovative technology and high-quality manufacturing.

| Advanced DIP AOI Inspection System

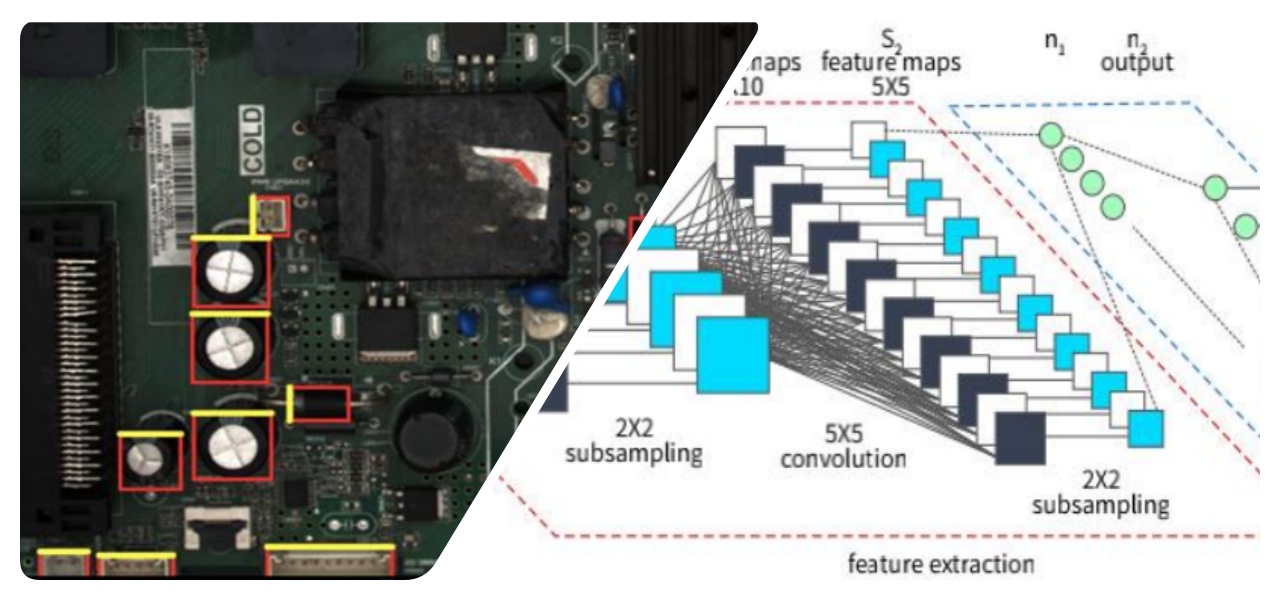

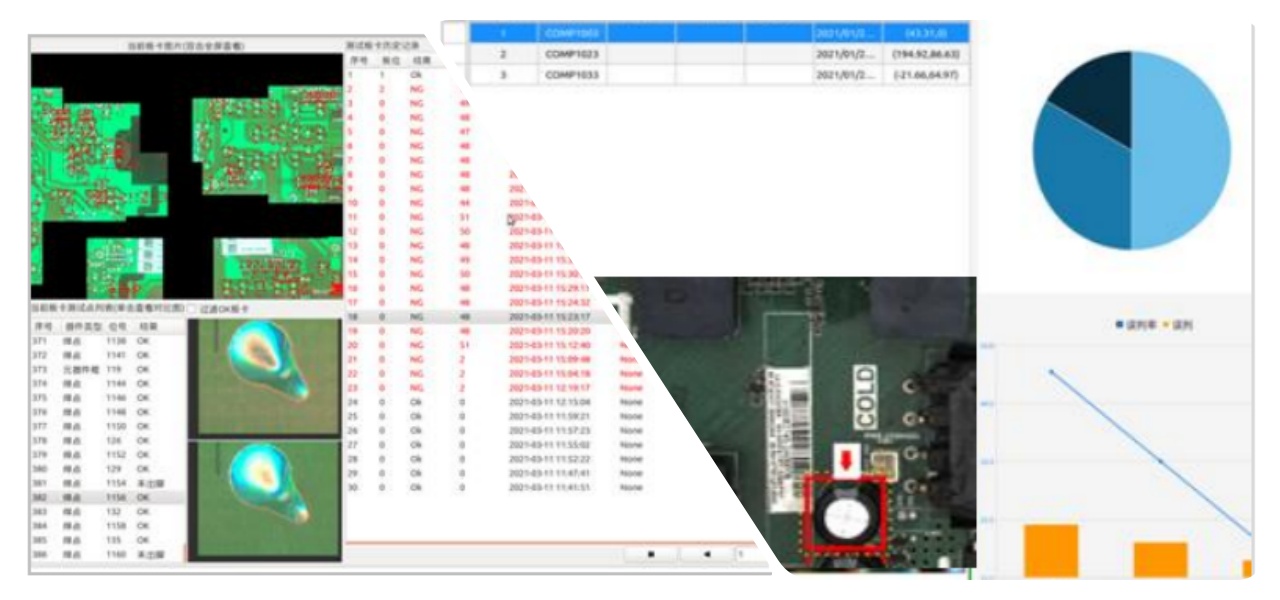

The DIP AOI AI4026 is a cutting-edge inspection system designed to check printed circuit boards (PCBs) with high accuracy. This machine uses advanced optical technology to find defects fast, making it perfect for surface-mount technology (SMT) production lines. Built by I.C.T, a leader in manufacturing and service, this system helps factories improve quality and save time. It works well for both small and large businesses, offering a simple interface that anyone can learn. With I.C.T’s global support, you get fast delivery and expert help. Choose this reliable tool to meet your production needs and grow your business with confidence.

| Feature

The DIP AOI AI4026 uses top optical inspection technology to spot even tiny defects on PCBs. This machine scans boards quickly and shows clear results, helping workers fix problems fast. It reduces errors and improves product quality, which is key for SMT lines. With its easy setup, any operator can use it without special training. This feature saves time and ensures your production stays on track every day.

This inspection system fits perfectly into DIP production lines, boosting efficiency. It works fast to check boards without slowing down your process. The machine’s design allows smooth operation, making it a great choice for busy factories. I.C.T’s team ensures it meets your specific needs with expert setup support. This helps you produce more in less time, keeping your business competitive.

The DIP AOI AI4026 comes with a simple interface that anyone can use. Operators can start checking PCBs with basic training, saving time on learning. The clear display shows results easily, making it simple to spot issues. This design helps small teams work effectively and reduces mistakes. With I.C.T’s support, you get ongoing help to keep the system running smoothly.

| Specification

| Model | I.C.T DIP Online AOI AI-4026(Before THT Soldering) | I.C.T DIP Online AOI AI-4026L(Before THT Soldering) |

| FOV | 400*300mm | 520*380mm |

| Resolution | 90um | 80um |

| Camera | 12M | 31M |

| Mixing PCB inspection | Support calling program automatically | |

| PCB Size | 50*50mm ~ 400*300mm | 50*50mm ~ 520*380mm |

| Display | 23.8 inch FHD display | |

| Data output | Autogenerated statistic analysis SPC | |

| Special function | Automatic search of elements and quick programming | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 200W | |

| Compressed Air | 0.4 ~ 0.6Mpa | |

| Communication | SMEMA | |

| Weight | 120Kg | |

| Dimension | L715*W760~1210*H1315~1700mm | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Service & Training

I.C.T offers top-notch service and training for the DIP AOI AI4026. Our skilled engineers provide on-site setup and teach your team how to use the machine effectively. We offer regular updates and maintenance to keep it running well. With our global network, help is always nearby, no matter where you are. This support ensures your investment lasts long and performs at its best. Choose I.C.T for reliable service that grows with your business.

| Customer Reviews

Customers love our engineers for their knowledge and friendly help. They admire the DIP AOI AI4026 for its accuracy and durability. Our careful packing and fast shipping also get high marks. Clients appreciate how quickly we solve their issues, keeping their production smooth. This feedback shows I.C.T’s commitment to quality and customer satisfaction.

| Our Certification

I.C.T is proud to hold certifications like CE, RoHS, ISO9001, and patents. These awards prove our commitment to safety, quality, and innovation. Our products meet global standards, giving you confidence in every purchase. With these credentials, you know I.C.T delivers reliable and trusted solutions.

| About I.C.T & Our Factory

I.C.T is a growing company with its own research, development, and production teams. We have a large staff and serve thousands of clients across many countries worldwide. Our factory uses strict testing processes and a strong quality management system to ensure top products. Over the years, we’ve expanded rapidly, offering reliable solutions globally. Trust I.C.T for innovative technology and high-quality manufacturing.