I.C.T-510

I.C.T

PCB Laser Marking

| Availability: | |

|---|---|

| Quantity: | |

| Versatile Laser Marking Machines for PCB Traceability

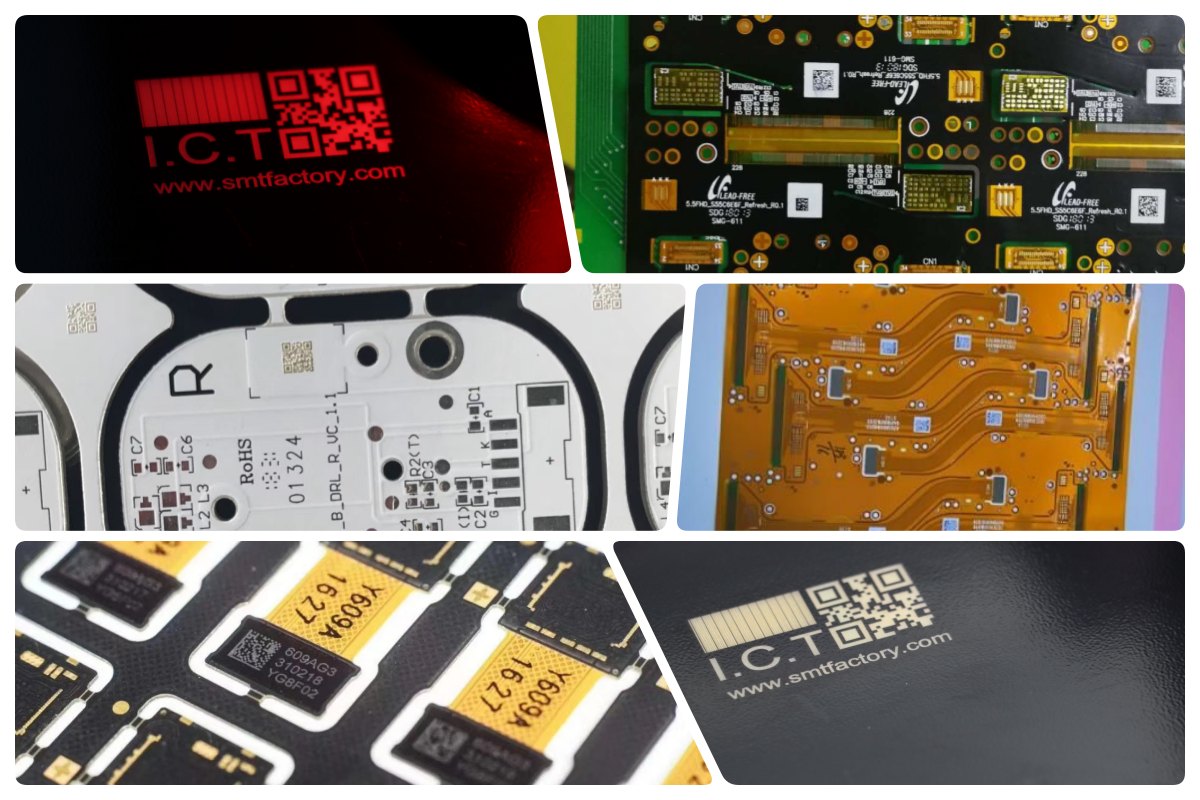

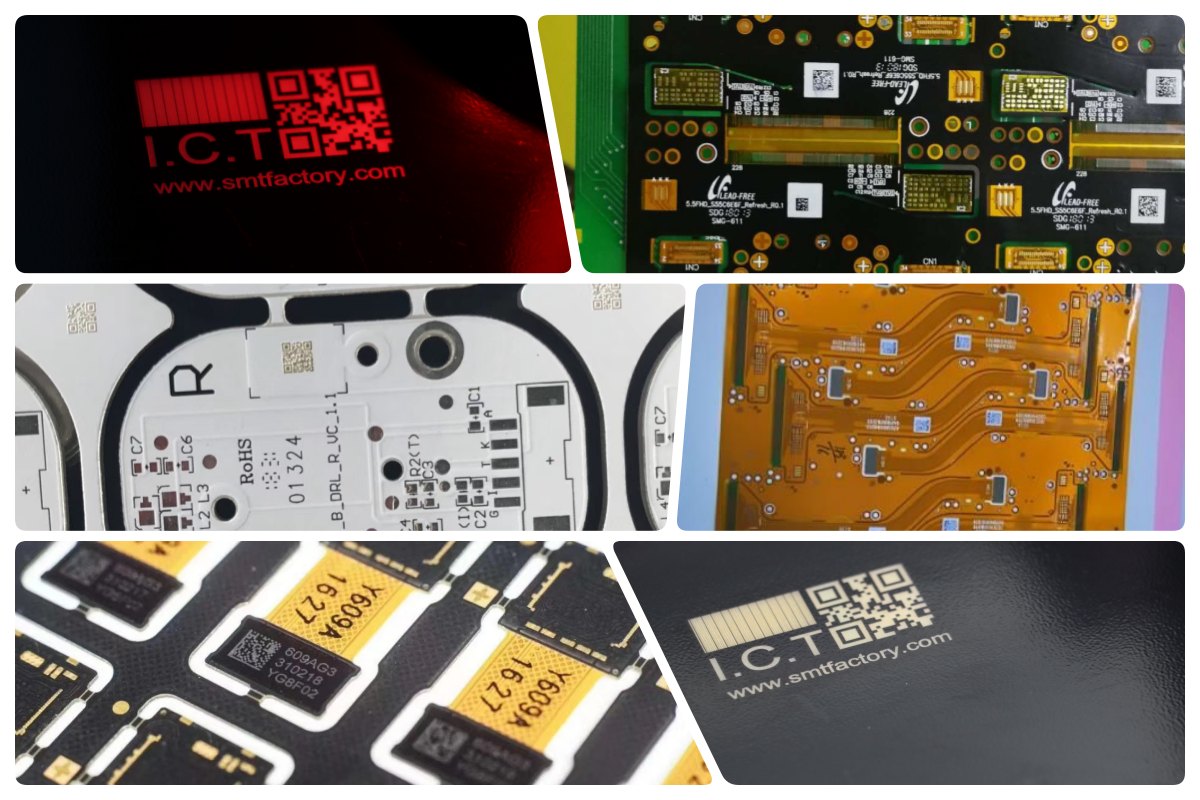

The laser marking machines provide a non-contact, high-precision way to mark text, barcodes, QR codes, and graphics directly on PCBs in SMT lines. They deliver ±0.05 mm accuracy and handle board sizes up to 510×460 mm across four models: I.C.T-400, 460, 510, and 510L. Laser options include UV for delicate surfaces, Green for plastics, Fiber for metals, and CO₂ for FR4, with the 50W fiber laser marking machine variant excelling on conductive traces and metal areas. The system links smoothly to assembly lines for real-time MES data exchange and offers both online and offline modes. Without inks, labels, or solvents, it eliminates consumable costs, prevents pollution, and avoids duplicate marking issues. Capable of speeds up to 7000 mm/s with stable output, these machines ensure clear, lasting marks that support efficient traceability and meet strict quality demands in electronics manufacturing.

| Feature

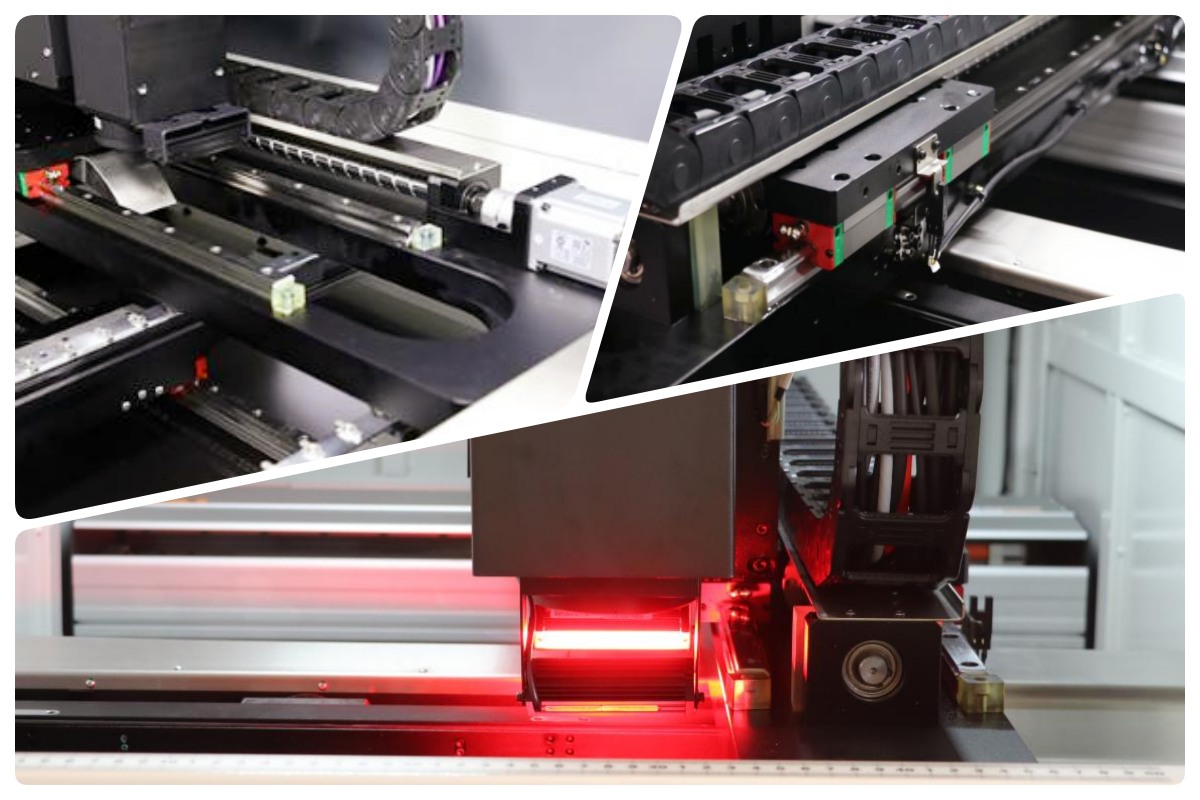

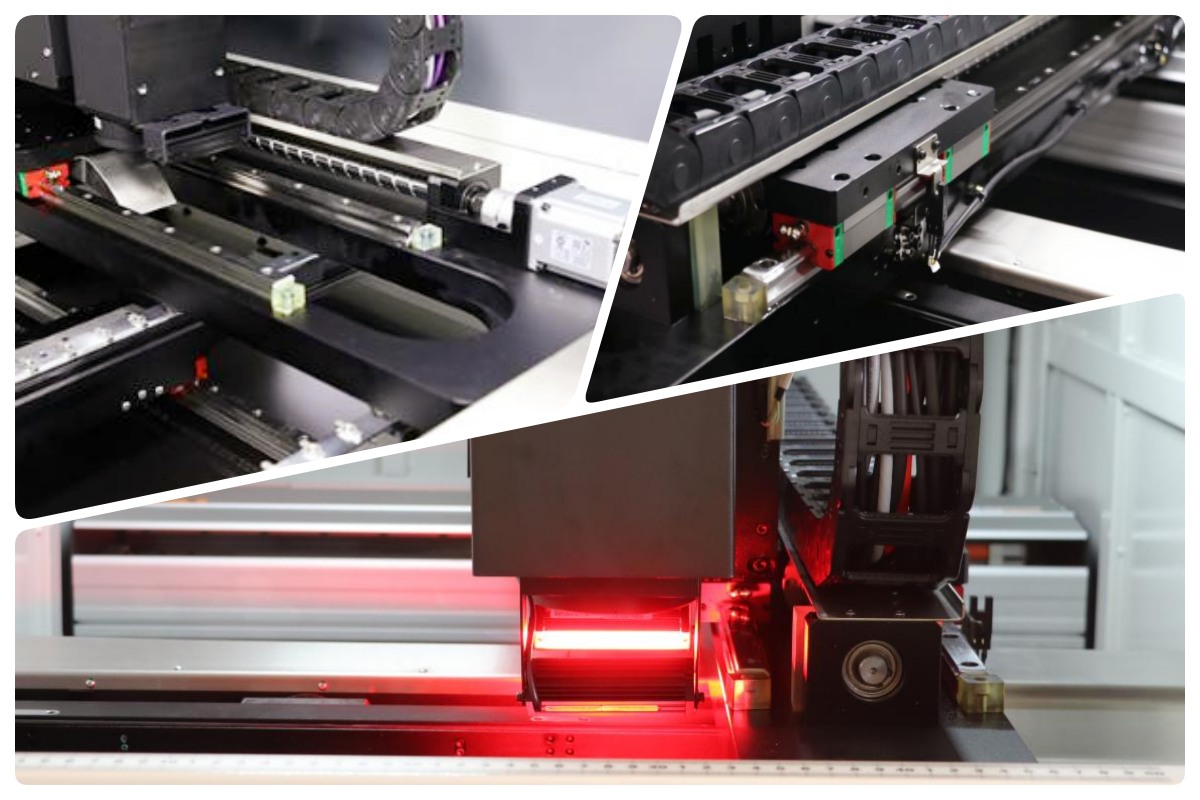

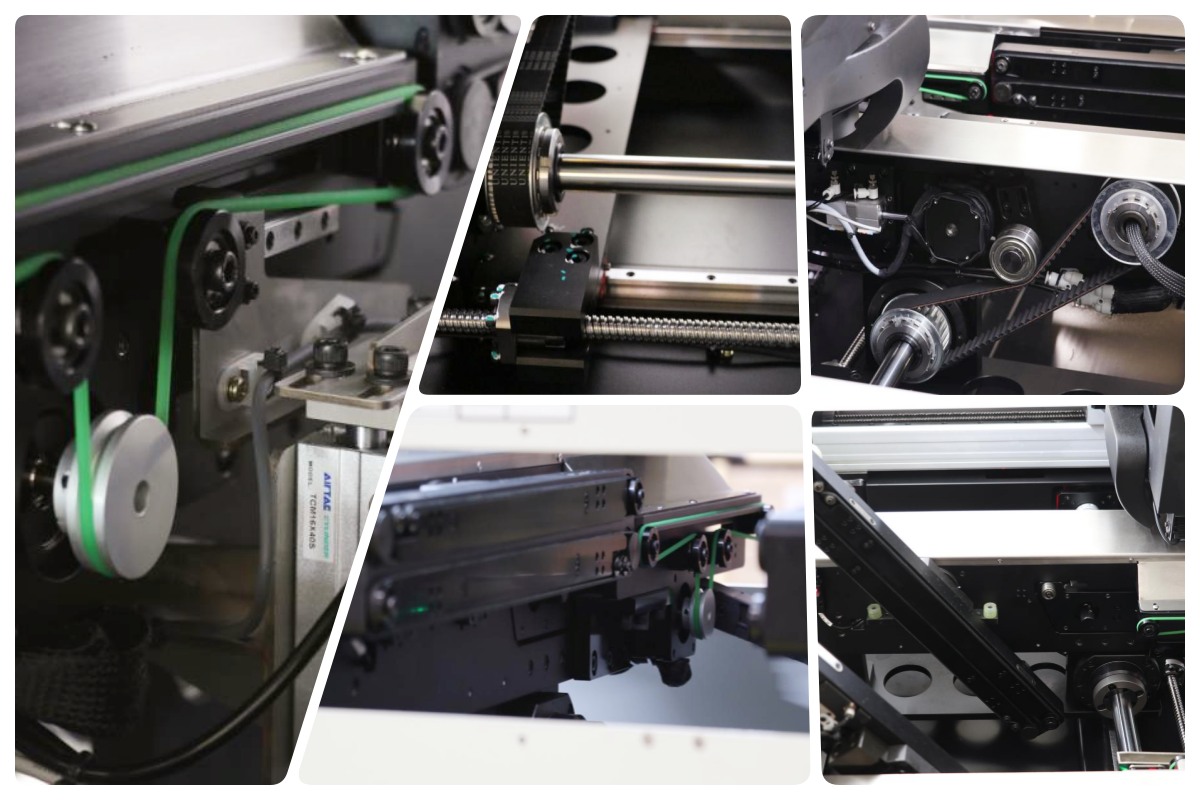

Robust Driving System for Smooth Movement

The driving system features an arch bridge suspension design paired with high-quality ball screws and linear guides from trusted suppliers TBI and HIWIN/PMI. Two separate high-precision servo motors independently control the X and Y axes, maintaining exact positioning under varying board weights. Flexible closed tank chains, supported by auxiliary profiles, deliver steady, low-vibration travel during extended operation. A practical dust cover protects key components from contaminants, which lowers cleaning frequency and overall maintenance expenses. This solid engineering keeps the laser marking machines performing consistently in fast-paced SMT environments, directly contributing to reliable mark placement and reduced line downtime.

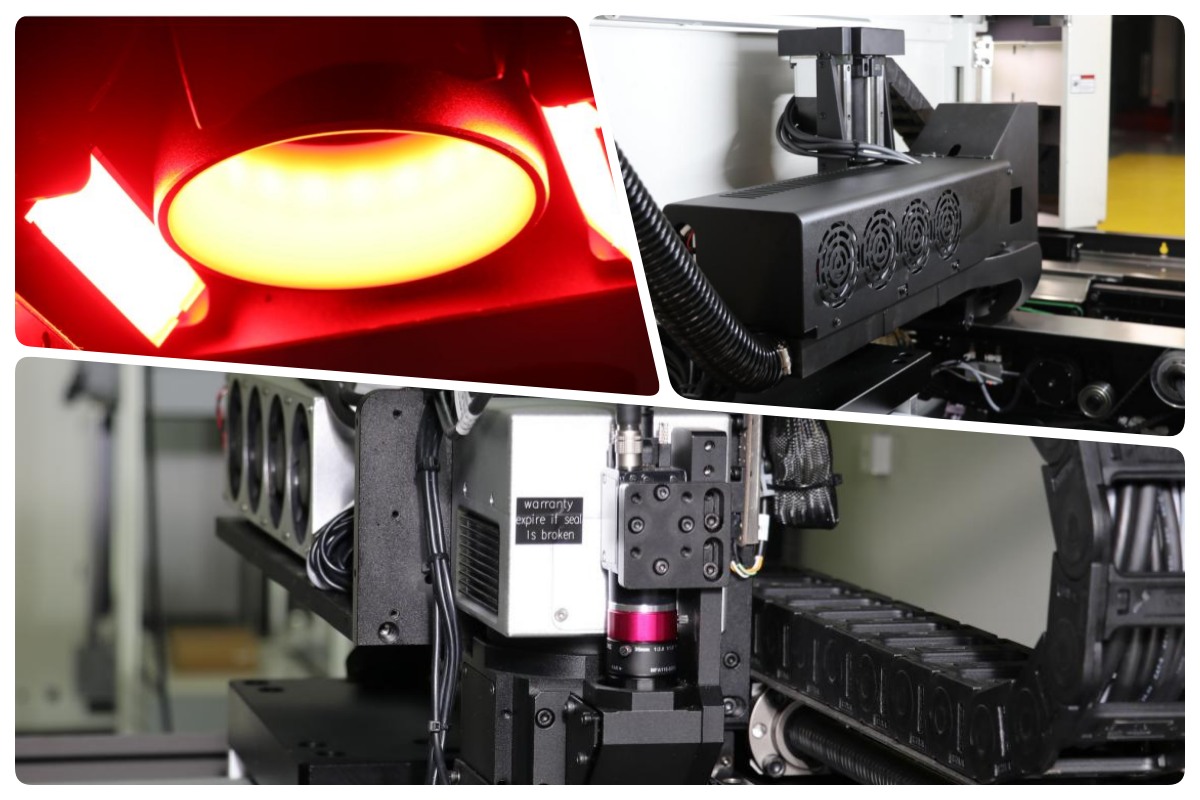

Flexible Marking System for Broad Applications

Operators select from UV, Green, Fiber, or CO₂ lasers based on material type and production needs. Each laser maintains stable wavelength, high precision, and long service life for dependable daily use. Factory calibration sets the focal length accurately, eliminating manual adjustments, while the Z-axis automatically matches board height. Cooling methods are chosen specifically for each laser to prevent thermal problems in continuous runs. Multiple beam configurations handle complex layouts and challenging surfaces effectively. This adaptable system allows the laser marking machines to produce sharp, uniform marks that meet traceability requirements across various electronics assembly processes.

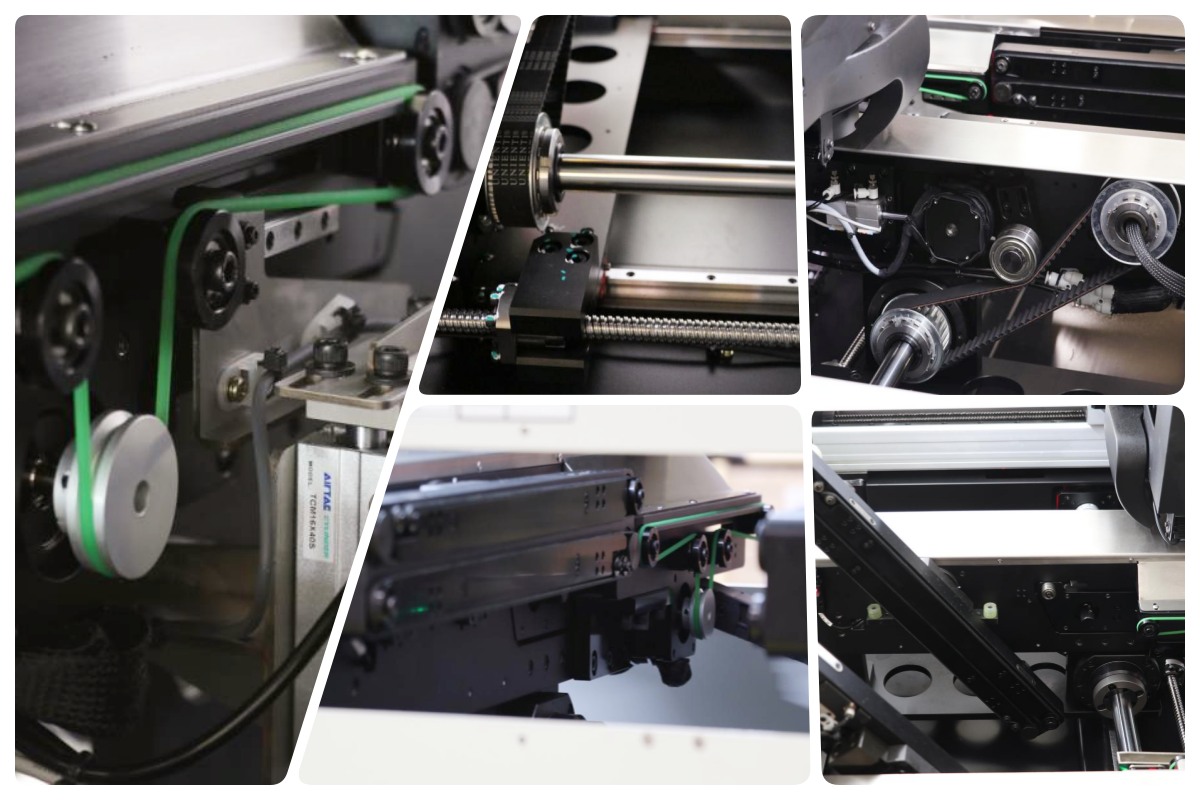

Protective Transport System for Safe Handling

Models with integrated flip function process double-sided PCBs in a single cycle, addressing complex marking needs efficiently. Segmented guide rails use ESD anti-static belts to shield sensitive components from static discharge. High-strength synchronous belts offer adjustable speed to align with line flow, while dedicated tensioning devices keep belts in optimal condition. Ball screws and rigid shafts enable synchronous width adjustment, ensuring perfect front-to-rear rail parallelism and preventing board misalignment. Cylinder baffles provide fine stopping accuracy. These elements combine to move PCBs gently and precisely, supporting uninterrupted production and high first-pass yield.

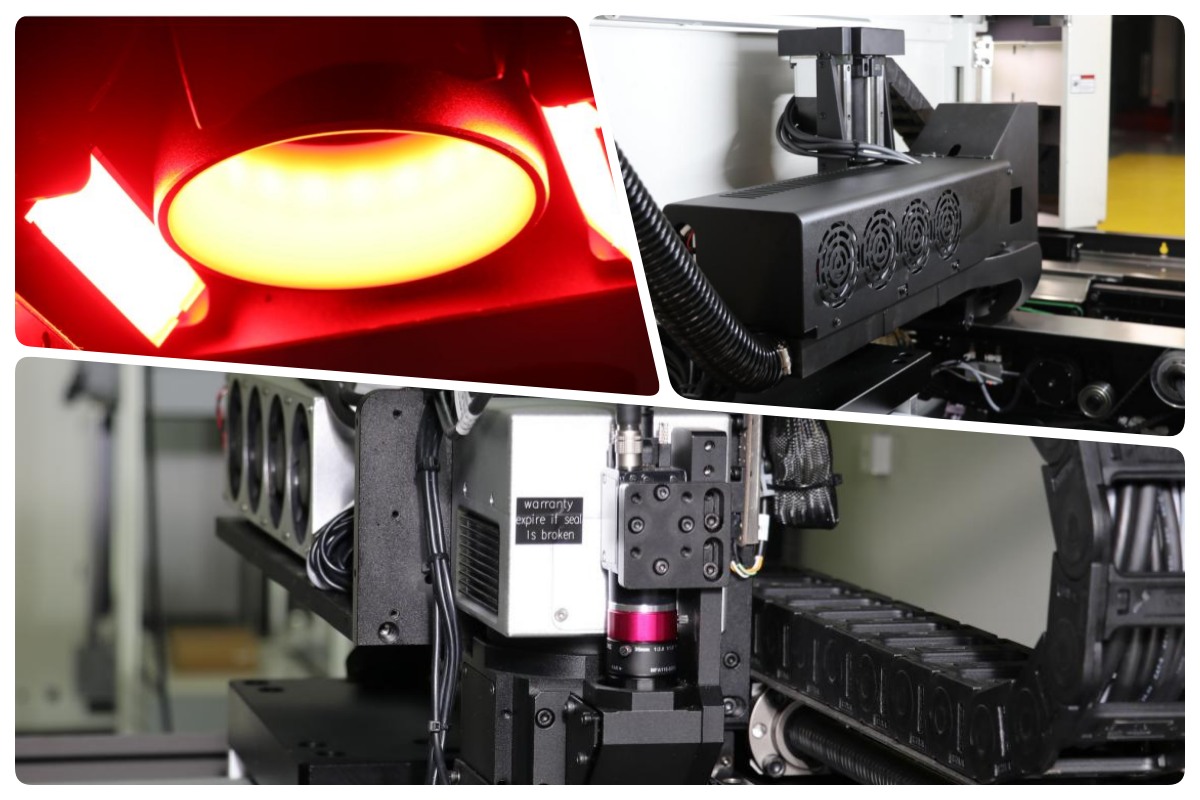

Dependable Control System for Safe Operation

The control layout uses organized wiring and clear labeling, making routine checks and repairs straightforward. High-precision servo drives and motors ensure smooth, vibration-free motion across the working area. Air convection cooling effectively manages heat buildup in production settings. I.C.T’s integrated control board operates reliably with simple maintenance needs. An independent leakage protection switch adds electrical safety, and full compliance with CE and UL standards meets global requirements. This practical design keeps the laser marking machines running safely and predictably, allowing focus on output rather than troubleshooting.

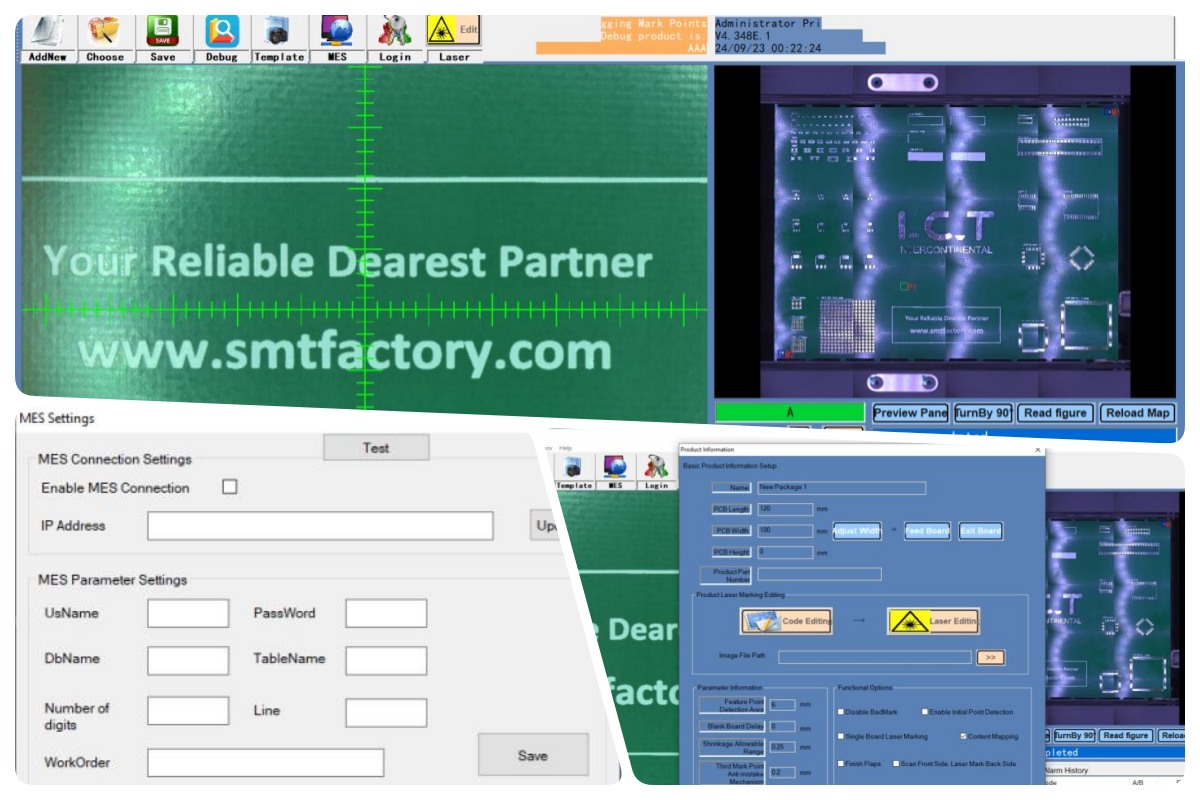

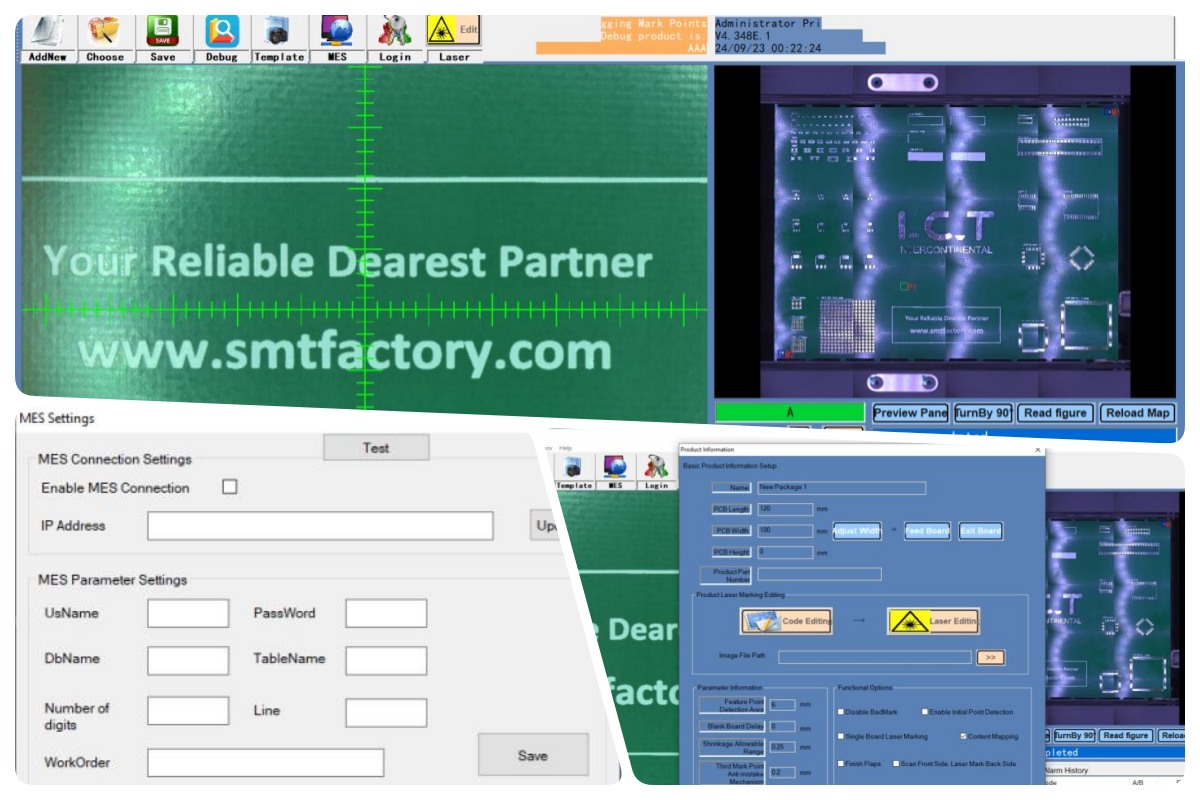

Easy-to-Use Operator Interface

The interface offers a guided, intuitive layout that reduces training time for operators. Built on a genuine Windows platform, it stores multiple programs for fast product changeovers. Full-frame scanning displays alignment patterns directly on screen, accelerating programming. Coaxial camera placement eliminates extra calibration steps. Standard MES ports support seamless factory system connections, with custom protocols available. These features minimize errors, shorten setup time, and help integrate the laser marking machines smoothly into existing SMT workflows.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Integrated SMT Production Line Solution

I.C.T provides complete high-quality SMT lines designed for demanding sectors like automotive electronics, medical devices, and LED lighting. The line starts with a PCB vacuum loader that feeds clean PCB into the process. Next, an automatic solder paste printer deposits paste with high precision. High-speed PCB placement machine place components accurately and efficiently. Multi-zone Lyra reflow ovens create strong, reliable solder joints. Advanced AOI machine detect defects early to maximize yield. Robust PCB conveyors ensure smooth, synchronized movement across stations. PCBA cleaning machines remove flux residues for enhanced reliability. A fully automatic solder paste storage and tempering cabinet maintains paste quality at all times. This integrated solution delivers high yield, lower costs, and consistent performance, supported by I.C.T's full-service commitment from installation to ongoing technical support.

| Customer Project Case

I.C.T completed overseas installation and Factory Acceptance Testing (FAT) for two full SMT production lines at a North American beauty instrument manufacturer. Both lines passed production acceptance smoothly. Each line featured our laser marking machines for reliable traceability, SMT printer with SPI, Panasonic mounter, Heller reflow oven, AOI inspection, PCB conveyors, PCBA cleaning machine, and automatic solder paste storage and warming cabinet. Engineers handled on-site setup, provided thorough training, and optimized processes to match exact needs. The customer now runs stable, high-efficiency lines capable of supporting expanded production of quality beauty and personal-care products.

| Global Service and Training Support

I.C.T delivers complete technical assistance, starting with professional on-site installation and commissioning for quick startup. Training covers machine operation, software use, programming, maintenance, and basic troubleshooting. Engineers share optimization tips to enhance marking quality and line throughput. Post-installation support includes rapid remote diagnostics, fast spare parts delivery, and scheduled follow-ups. This ongoing commitment minimizes downtime, extends equipment life, and keeps performance high. Customers gain confidence knowing the laser marking machines receive dedicated, responsive service throughout their lifecycle.

| Customer Experience and Operational Benefits

Customers often commend our engineers for their expertise, clear explanations, and prompt resolution of setup issues. Many appreciate the laser marking machines for stable performance, sharp marks, and easy integration. Positive comments highlight secure packaging and safe global shipping that protect equipment in transit. Fast responses to technical questions strengthen trust. Overall, clients value the reliable machines paired with attentive service that supports consistent, high-quality production.

| Standards, Control and Production Discipline

I.C.T machines hold key certifications that verify safety, environmental compliance, and quality standards. These include CE for electrical safety, RoHS to restrict hazardous substances, and ISO9001 for structured quality management. Multiple patents protect innovative features in laser control, motion systems, and integration. These credentials confirm the laser marking machines meet global requirements, operate responsibly, and earn trust from manufacturers worldwide.

| About I.C.T Company and Factory

I.C.T operates its own R&D team and manufacturing facility in Dongguan, China, spanning 12,000 m² with 89 employees including 20 engineers. Since 2012, the company has expanded rapidly and now serves over 1,600 customers in 72 countries. The factory applies rigorous testing at every production stage, backed by a comprehensive quality management system for consistent performance. We offer end-to-end SMT solutions—from planning and equipment supply to installation, training, and process improvement—helping clients build efficient, reliable manufacturing systems globally.

| Versatile Laser Marking Machines for PCB Traceability

The laser marking machines provide a non-contact, high-precision way to mark text, barcodes, QR codes, and graphics directly on PCBs in SMT lines. They deliver ±0.05 mm accuracy and handle board sizes up to 510×460 mm across four models: I.C.T-400, 460, 510, and 510L. Laser options include UV for delicate surfaces, Green for plastics, Fiber for metals, and CO₂ for FR4, with the 50W fiber laser marking machine variant excelling on conductive traces and metal areas. The system links smoothly to assembly lines for real-time MES data exchange and offers both online and offline modes. Without inks, labels, or solvents, it eliminates consumable costs, prevents pollution, and avoids duplicate marking issues. Capable of speeds up to 7000 mm/s with stable output, these machines ensure clear, lasting marks that support efficient traceability and meet strict quality demands in electronics manufacturing.

| Feature

Robust Driving System for Smooth Movement

The driving system features an arch bridge suspension design paired with high-quality ball screws and linear guides from trusted suppliers TBI and HIWIN/PMI. Two separate high-precision servo motors independently control the X and Y axes, maintaining exact positioning under varying board weights. Flexible closed tank chains, supported by auxiliary profiles, deliver steady, low-vibration travel during extended operation. A practical dust cover protects key components from contaminants, which lowers cleaning frequency and overall maintenance expenses. This solid engineering keeps the laser marking machines performing consistently in fast-paced SMT environments, directly contributing to reliable mark placement and reduced line downtime.

Flexible Marking System for Broad Applications

Operators select from UV, Green, Fiber, or CO₂ lasers based on material type and production needs. Each laser maintains stable wavelength, high precision, and long service life for dependable daily use. Factory calibration sets the focal length accurately, eliminating manual adjustments, while the Z-axis automatically matches board height. Cooling methods are chosen specifically for each laser to prevent thermal problems in continuous runs. Multiple beam configurations handle complex layouts and challenging surfaces effectively. This adaptable system allows the laser marking machines to produce sharp, uniform marks that meet traceability requirements across various electronics assembly processes.

Protective Transport System for Safe Handling

Models with integrated flip function process double-sided PCBs in a single cycle, addressing complex marking needs efficiently. Segmented guide rails use ESD anti-static belts to shield sensitive components from static discharge. High-strength synchronous belts offer adjustable speed to align with line flow, while dedicated tensioning devices keep belts in optimal condition. Ball screws and rigid shafts enable synchronous width adjustment, ensuring perfect front-to-rear rail parallelism and preventing board misalignment. Cylinder baffles provide fine stopping accuracy. These elements combine to move PCBs gently and precisely, supporting uninterrupted production and high first-pass yield.

Dependable Control System for Safe Operation

The control layout uses organized wiring and clear labeling, making routine checks and repairs straightforward. High-precision servo drives and motors ensure smooth, vibration-free motion across the working area. Air convection cooling effectively manages heat buildup in production settings. I.C.T’s integrated control board operates reliably with simple maintenance needs. An independent leakage protection switch adds electrical safety, and full compliance with CE and UL standards meets global requirements. This practical design keeps the laser marking machines running safely and predictably, allowing focus on output rather than troubleshooting.

Easy-to-Use Operator Interface

The interface offers a guided, intuitive layout that reduces training time for operators. Built on a genuine Windows platform, it stores multiple programs for fast product changeovers. Full-frame scanning displays alignment patterns directly on screen, accelerating programming. Coaxial camera placement eliminates extra calibration steps. Standard MES ports support seamless factory system connections, with custom protocols available. These features minimize errors, shorten setup time, and help integrate the laser marking machines smoothly into existing SMT workflows.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Integrated SMT Production Line Solution

I.C.T provides complete high-quality SMT lines designed for demanding sectors like automotive electronics, medical devices, and LED lighting. The line starts with a PCB vacuum loader that feeds clean PCB into the process. Next, an automatic solder paste printer deposits paste with high precision. High-speed PCB placement machine place components accurately and efficiently. Multi-zone Lyra reflow ovens create strong, reliable solder joints. Advanced AOI machine detect defects early to maximize yield. Robust PCB conveyors ensure smooth, synchronized movement across stations. PCBA cleaning machines remove flux residues for enhanced reliability. A fully automatic solder paste storage and tempering cabinet maintains paste quality at all times. This integrated solution delivers high yield, lower costs, and consistent performance, supported by I.C.T's full-service commitment from installation to ongoing technical support.

| Customer Project Case

I.C.T completed overseas installation and Factory Acceptance Testing (FAT) for two full SMT production lines at a North American beauty instrument manufacturer. Both lines passed production acceptance smoothly. Each line featured our laser marking machines for reliable traceability, SMT printer with SPI, Panasonic mounter, Heller reflow oven, AOI inspection, PCB conveyors, PCBA cleaning machine, and automatic solder paste storage and warming cabinet. Engineers handled on-site setup, provided thorough training, and optimized processes to match exact needs. The customer now runs stable, high-efficiency lines capable of supporting expanded production of quality beauty and personal-care products.

| Global Service and Training Support

I.C.T delivers complete technical assistance, starting with professional on-site installation and commissioning for quick startup. Training covers machine operation, software use, programming, maintenance, and basic troubleshooting. Engineers share optimization tips to enhance marking quality and line throughput. Post-installation support includes rapid remote diagnostics, fast spare parts delivery, and scheduled follow-ups. This ongoing commitment minimizes downtime, extends equipment life, and keeps performance high. Customers gain confidence knowing the laser marking machines receive dedicated, responsive service throughout their lifecycle.

| Customer Experience and Operational Benefits

Customers often commend our engineers for their expertise, clear explanations, and prompt resolution of setup issues. Many appreciate the laser marking machines for stable performance, sharp marks, and easy integration. Positive comments highlight secure packaging and safe global shipping that protect equipment in transit. Fast responses to technical questions strengthen trust. Overall, clients value the reliable machines paired with attentive service that supports consistent, high-quality production.

| Standards, Control and Production Discipline

I.C.T machines hold key certifications that verify safety, environmental compliance, and quality standards. These include CE for electrical safety, RoHS to restrict hazardous substances, and ISO9001 for structured quality management. Multiple patents protect innovative features in laser control, motion systems, and integration. These credentials confirm the laser marking machines meet global requirements, operate responsibly, and earn trust from manufacturers worldwide.

| About I.C.T Company and Factory

I.C.T operates its own R&D team and manufacturing facility in Dongguan, China, spanning 12,000 m² with 89 employees including 20 engineers. Since 2012, the company has expanded rapidly and now serves over 1,600 customers in 72 countries. The factory applies rigorous testing at every production stage, backed by a comprehensive quality management system for consistent performance. We offer end-to-end SMT solutions—from planning and equipment supply to installation, training, and process improvement—helping clients build efficient, reliable manufacturing systems globally.