I.C.T-SS430

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Off-line Selective Soldering Machine

The I.C.T off-line selective soldering machine is built in China for flexible, high-volume PCB soldering. It fixes the PCB while the spray and soldering platform move, ensuring top quality. With N2 online heating, it wets solder well and reduces dross. Full PC control lets you set paths, temperatures, flux, and more, saving menus for repeat jobs. Auto wave height check and CCD mark positioning keep everything stable.

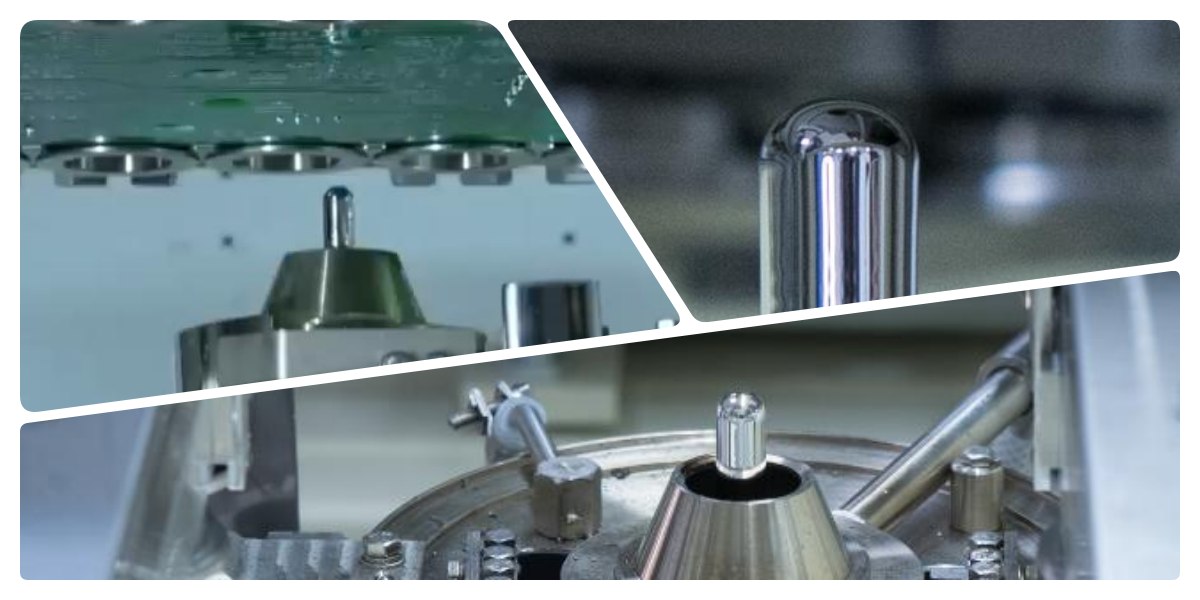

Panasonic servo motors drive smooth, quiet motion on linear rails. A German jet valve sprays tiny flux dots precisely. The pressure tank holds flux steady. An electromagnetic pump from Germany ensures reliable peaks. The Ti solder pot heats fast without leaks. This selective soldering machine suits multi-wave needs in electronics factories.

| DIP Line Equipment List

The flux system uses a high-frequency pulse injection valve from Germany for small, accurate dots. Flux solid content stays under 10%. A tray catches residue for easy cleaning. The nozzle on XY platform repeats positions to 0.02mm. Pressure tank keeps flow stable regardless of flux level. High-precision flow meter controls output with corrosion-resistant parts. Japanese SMC pneumatics ensure reliability. Meters and flows show on the machine surface for quick checks. External design aids operation. An SMC auto pump supplies flux steadily. This setup in the selective soldering machine gives clean, consistent fluxing.

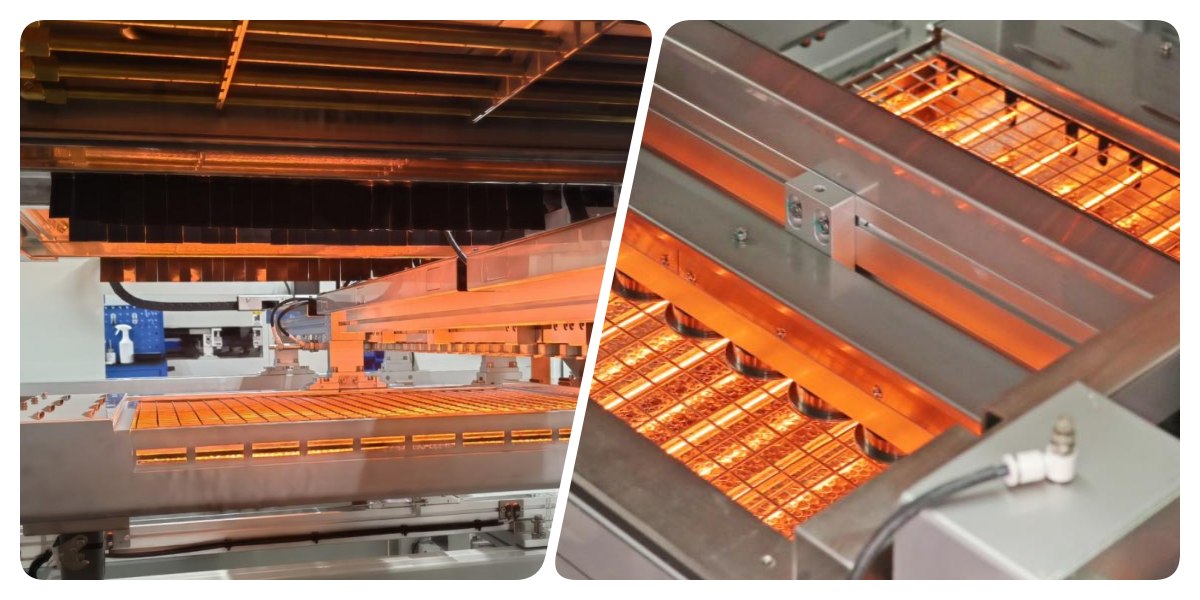

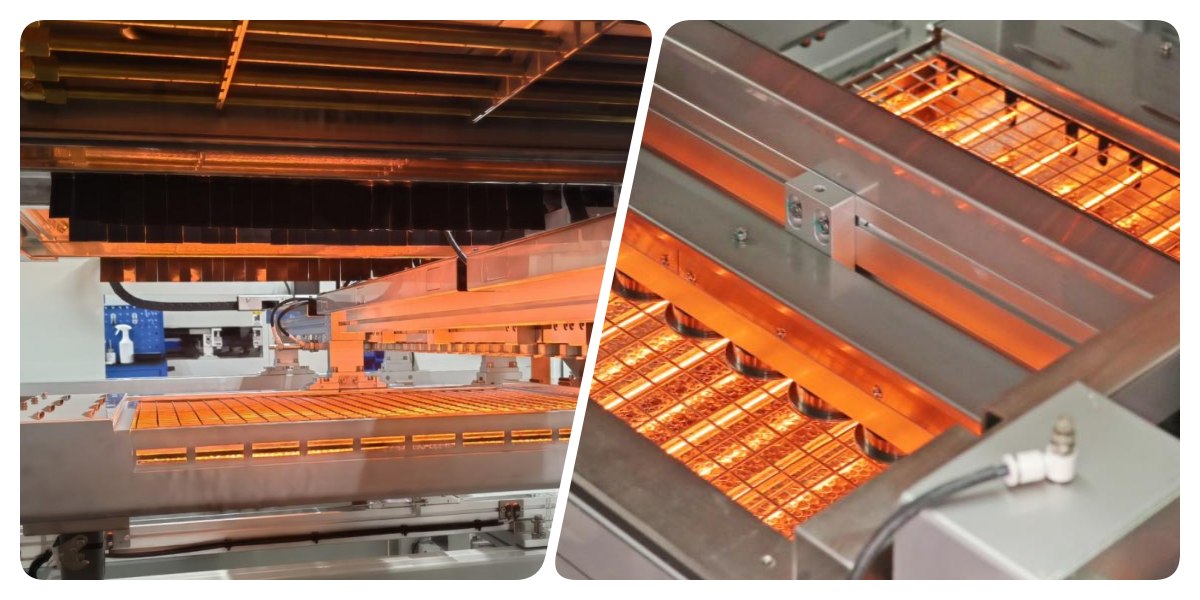

Bottom IR preheating comes standard and adjusts position. Top IR or hot air is optional. Structure maximizes heat area. High-temperature cotton holds steady temps. Top-brand parts generate and conduct heat well. Plug-in design allows tool-free fixes. This preheats PCBs evenly before soldering in the selective soldering machine.

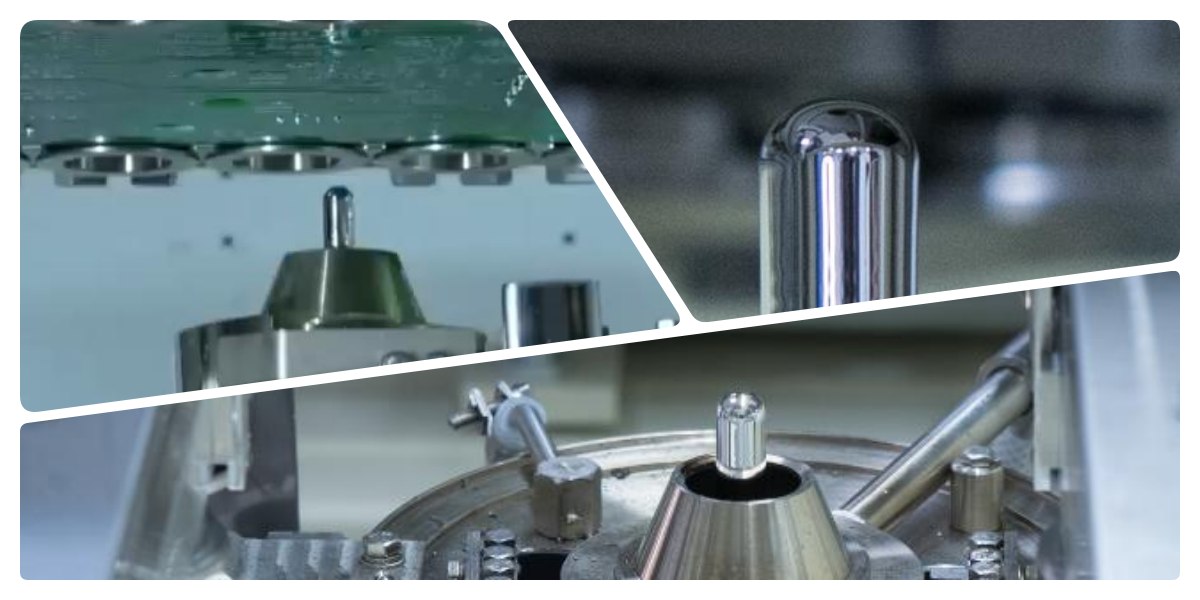

Electromagnetic pump stabilizes peaks. Set solder temp, N2, wave height in software. Ti pot avoids leaks, heats quickly with cast iron outside. N2 heats online to wet solder and cut dross. Industry-best tin spray stability. Real-time CCD monitoring saves video for 900 hours. XYZ platform uses lightweight modules and high-speed servos with reducers. Sealed parts fight pollution. Omron sensors ensure accuracy. Auto nozzle cleaning uses powder, adjustable frequency. Laser detects wave height without contact or error. This core of the selective soldering machine delivers consistent joints.

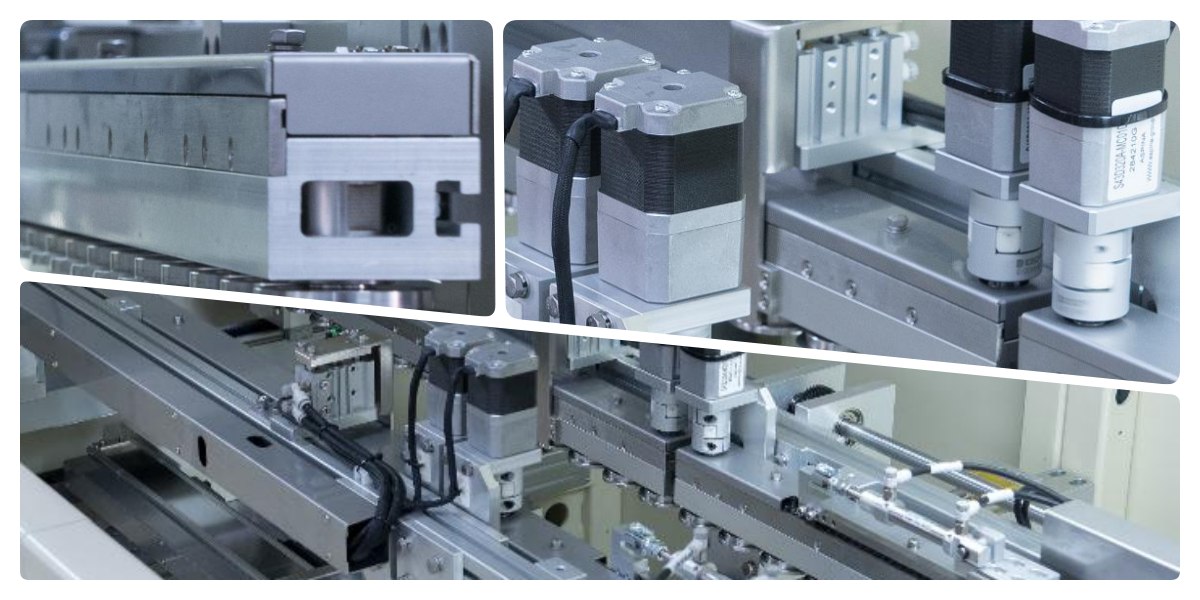

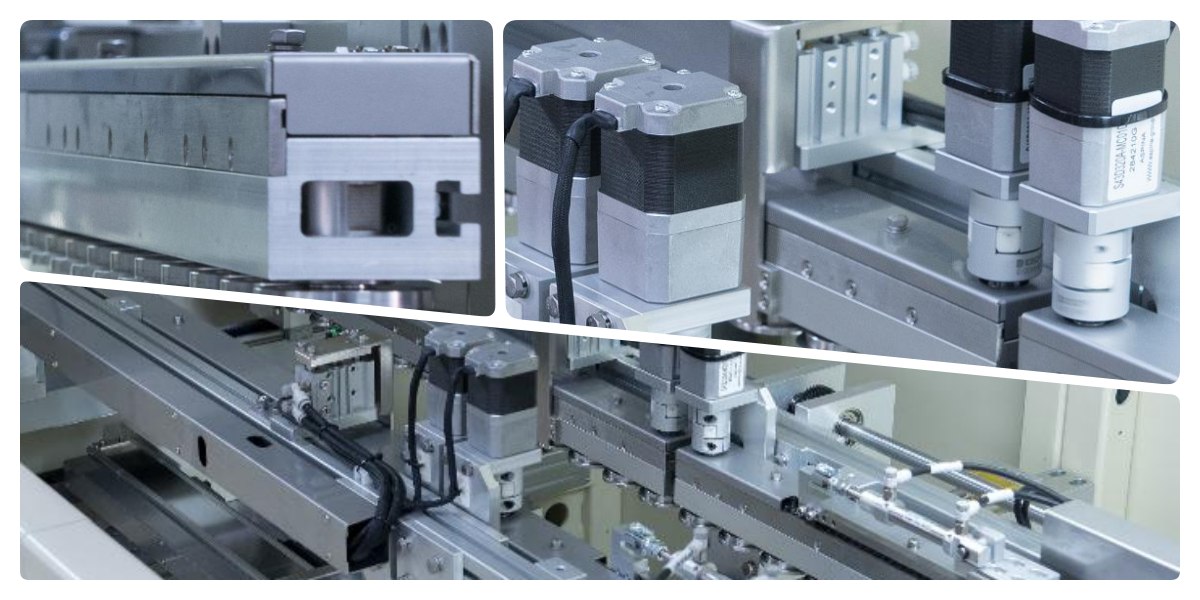

Special profiles ensure stable, rational design for convenience. The transmission module consists of three roller parts. PCBA side clamp and top clamp system secure the board during process. Thickened customized rail supports up to 20KG load. This setup in the 2 axis selective PCB THT soldering machine handles various board sizes smoothly from front to rear. Width adjusts easily, though not needed for fixed sizes. High-precision module drives precise transport. It integrates with flux, preheat, and soldering steps for efficient flow.

PLC plus module high-end bus control system ensures stability and scalability. It conforms to CE and other standards with underfloor Industry 4.0 design. Adding soldering module control boosts capacity while keeping stable. Application of global high-quality stable electrical parts. Cat-6 network cable enables faster communication and sensitive response. Operators guide programming easily. CCD fast programming identifies nozzle types auto. Picture programming corrects coordinates intelligently. Real-time data visualization switches to CCD monitoring with one button. Multi-language support includes Chinese, English, Japanese, Russian. This control in the selective soldering machine traces every parameter for quality.

The operating system uses guided programming for easy steps. CCD fast programming identifies nozzle types automatically. Picture programming corrects coordinates and verifies them smartly. Real-time data shows on the interface clearly. One button switches to CCD soldering monitoring. Languages include Chinese, English, Japanese, and Russian. MES standards support WIFI, online upgrades, and remote control. Voice alarms and custom lights alert issues. Soldering data traces every point for confirmation. This setup in the selective soldering machine makes operation simple and efficient for all users.

| Specification

Off-line Selective Wave Soldering Machine | |

Model | I.C.T SS430 |

Flux Storage Tank | 1L |

Flux Support | Flux Alarm, Automatic |

Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1set |

Spray Nozzle Size | 130um (180, 210um Option) |

Spray Range | 3~8mm |

Spray speed | 0~20mm/s |

Spray Nozzle move speed | 0~400mm/s |

Spray Precision | 0.1mm |

Spray Pressure | 0.05~0.1 MPa |

Preheating Mode | IR Heating |

Preheating Area | L500mm*W500mm |

Soldering Precision | ±0.25 mm |

Soldering monitoring | CCD |

Solder Capacity | 12Kg |

Max PCB Size | 500*500mm |

Max PCB Size | 60mm |

PCB Thickness | 0.5-6.0mm |

PCB Weight | <20Kg |

Operating System | Windows10 |

Power Supply | 220VAC±10%, 50/60HZ |

Dimension | L1400*W2580*H1722mm |

Weight | Approx:700kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2025, a Vietnam client visited I.C.T factory to inspect the selective soldering machine for their needs. They provide equipment to a world-famous camera brand. Our engineers demonstrated the machine, running tests on sample PCBs. They trained the team on flux setup, programming paths, and wave calibration.

The client checked precise spraying and stable soldering live. Training covered PC controls, maintenance, and troubleshooting. This hands-on support ensured smooth integration at their site. The visit built trust, leading to successful deployment. It shows I.C.T's commitment to global clients with on-site expertise.

| Professional Service and Training

I.C.T provides full installation, maintenance, and support. Engineers train on operation, programming, and fixes. We optimize processes and adjust for changes. Remote help and upgrades keep machines running. Global centers offer quick response. This ensures worry-free use of the selective soldering machine.

| Customer Praise

Clients love our skilled engineers for quick, expert training and fixes. They praise the selective soldering machine for reliable, high-pass-rate joints. Safe, damage-free packing ensures safe arrival. Fast responses solve problems in hours. This builds lasting trust.

| Industry Certifications

I.C.T products carry CE for safety compliance, RoHS for eco-friendly materials, and ISO9001 for quality management. Our patents cover key tech like flux systems and wave control. These certifications prove reliable, green manufacturing. Strict tests back every selective soldering machine.

| About I.C.T Company and Factory

I.C.T develops and manufactures equipment internally in a 12000m² facility. With 89 employees including 20 engineers and 8 branches, we expand rapidly since 2012. We support over 1600 customers across 72 nations in electronics manufacturing. Our factories enforce rigorous testing flows and full quality management. This covers SMT, DIP, and more for complete solutions. From 0 to 1, we help build and optimize lines with training and adjustments.

| Off-line Selective Soldering Machine

The I.C.T off-line selective soldering machine is built in China for flexible, high-volume PCB soldering. It fixes the PCB while the spray and soldering platform move, ensuring top quality. With N2 online heating, it wets solder well and reduces dross. Full PC control lets you set paths, temperatures, flux, and more, saving menus for repeat jobs. Auto wave height check and CCD mark positioning keep everything stable.

Panasonic servo motors drive smooth, quiet motion on linear rails. A German jet valve sprays tiny flux dots precisely. The pressure tank holds flux steady. An electromagnetic pump from Germany ensures reliable peaks. The Ti solder pot heats fast without leaks. This selective soldering machine suits multi-wave needs in electronics factories.

| DIP Line Equipment List

The flux system uses a high-frequency pulse injection valve from Germany for small, accurate dots. Flux solid content stays under 10%. A tray catches residue for easy cleaning. The nozzle on XY platform repeats positions to 0.02mm. Pressure tank keeps flow stable regardless of flux level. High-precision flow meter controls output with corrosion-resistant parts. Japanese SMC pneumatics ensure reliability. Meters and flows show on the machine surface for quick checks. External design aids operation. An SMC auto pump supplies flux steadily. This setup in the selective soldering machine gives clean, consistent fluxing.

Bottom IR preheating comes standard and adjusts position. Top IR or hot air is optional. Structure maximizes heat area. High-temperature cotton holds steady temps. Top-brand parts generate and conduct heat well. Plug-in design allows tool-free fixes. This preheats PCBs evenly before soldering in the selective soldering machine.

Electromagnetic pump stabilizes peaks. Set solder temp, N2, wave height in software. Ti pot avoids leaks, heats quickly with cast iron outside. N2 heats online to wet solder and cut dross. Industry-best tin spray stability. Real-time CCD monitoring saves video for 900 hours. XYZ platform uses lightweight modules and high-speed servos with reducers. Sealed parts fight pollution. Omron sensors ensure accuracy. Auto nozzle cleaning uses powder, adjustable frequency. Laser detects wave height without contact or error. This core of the selective soldering machine delivers consistent joints.

Special profiles ensure stable, rational design for convenience. The transmission module consists of three roller parts. PCBA side clamp and top clamp system secure the board during process. Thickened customized rail supports up to 20KG load. This setup in the 2 axis selective PCB THT soldering machine handles various board sizes smoothly from front to rear. Width adjusts easily, though not needed for fixed sizes. High-precision module drives precise transport. It integrates with flux, preheat, and soldering steps for efficient flow.

PLC plus module high-end bus control system ensures stability and scalability. It conforms to CE and other standards with underfloor Industry 4.0 design. Adding soldering module control boosts capacity while keeping stable. Application of global high-quality stable electrical parts. Cat-6 network cable enables faster communication and sensitive response. Operators guide programming easily. CCD fast programming identifies nozzle types auto. Picture programming corrects coordinates intelligently. Real-time data visualization switches to CCD monitoring with one button. Multi-language support includes Chinese, English, Japanese, Russian. This control in the selective soldering machine traces every parameter for quality.

The operating system uses guided programming for easy steps. CCD fast programming identifies nozzle types automatically. Picture programming corrects coordinates and verifies them smartly. Real-time data shows on the interface clearly. One button switches to CCD soldering monitoring. Languages include Chinese, English, Japanese, and Russian. MES standards support WIFI, online upgrades, and remote control. Voice alarms and custom lights alert issues. Soldering data traces every point for confirmation. This setup in the selective soldering machine makes operation simple and efficient for all users.

| Specification

Off-line Selective Wave Soldering Machine | |

Model | I.C.T SS430 |

Flux Storage Tank | 1L |

Flux Support | Flux Alarm, Automatic |

Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1set |

Spray Nozzle Size | 130um (180, 210um Option) |

Spray Range | 3~8mm |

Spray speed | 0~20mm/s |

Spray Nozzle move speed | 0~400mm/s |

Spray Precision | 0.1mm |

Spray Pressure | 0.05~0.1 MPa |

Preheating Mode | IR Heating |

Preheating Area | L500mm*W500mm |

Soldering Precision | ±0.25 mm |

Soldering monitoring | CCD |

Solder Capacity | 12Kg |

Max PCB Size | 500*500mm |

Max PCB Size | 60mm |

PCB Thickness | 0.5-6.0mm |

PCB Weight | <20Kg |

Operating System | Windows10 |

Power Supply | 220VAC±10%, 50/60HZ |

Dimension | L1400*W2580*H1722mm |

Weight | Approx:700kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2025, a Vietnam client visited I.C.T factory to inspect the selective soldering machine for their needs. They provide equipment to a world-famous camera brand. Our engineers demonstrated the machine, running tests on sample PCBs. They trained the team on flux setup, programming paths, and wave calibration.

The client checked precise spraying and stable soldering live. Training covered PC controls, maintenance, and troubleshooting. This hands-on support ensured smooth integration at their site. The visit built trust, leading to successful deployment. It shows I.C.T's commitment to global clients with on-site expertise.

| Professional Service and Training

I.C.T provides full installation, maintenance, and support. Engineers train on operation, programming, and fixes. We optimize processes and adjust for changes. Remote help and upgrades keep machines running. Global centers offer quick response. This ensures worry-free use of the selective soldering machine.

| Customer Praise

Clients love our skilled engineers for quick, expert training and fixes. They praise the selective soldering machine for reliable, high-pass-rate joints. Safe, damage-free packing ensures safe arrival. Fast responses solve problems in hours. This builds lasting trust.

| Industry Certifications

I.C.T products carry CE for safety compliance, RoHS for eco-friendly materials, and ISO9001 for quality management. Our patents cover key tech like flux systems and wave control. These certifications prove reliable, green manufacturing. Strict tests back every selective soldering machine.

| About I.C.T Company and Factory

I.C.T develops and manufactures equipment internally in a 12000m² facility. With 89 employees including 20 engineers and 8 branches, we expand rapidly since 2012. We support over 1600 customers across 72 nations in electronics manufacturing. Our factories enforce rigorous testing flows and full quality management. This covers SMT, DIP, and more for complete solutions. From 0 to 1, we help build and optimize lines with training and adjustments.