I.C.T-SS550P2

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| 3 Solder Pot Selective Wave Soldering Machine

Hey, check this out – inside our huge Dongguan factory we built you the ultimate 3 Solder Pot Selective Wave Soldering Machine so you can run three different alloys at the same time without ever draining a pot. Your board sits totally still while a feather-light aluminum gantry on Panasonic motors zips around hitting every pin in only 0.8 seconds. Nitrogen keeps everything shiny and waste almost zero. You control every single thing – paths, temps, spray amount, wave height – on a giant touchscreen and save as many programs as you want for instant changeovers. Auto-calibration, live camera, German spray valve, and three titanium pots make your 3 Solder Pot Selective Wave Soldering Machine run like a beast 24/7.

| DIP Line Equipment List

A German high-speed valve shoots tiny flux dots (less than 10 % solids) perfect to 0.02 mm every time. The tank is pressurized and has a digital meter so pressure never drops. Leftover flux falls into a slide-out tray – two seconds and it’s clean. Japanese SMC air parts and big gauges make checking it super easy. An auto pump keeps the flux flowing non-stop. This setup nails every single pad on your 3 Solder Pot Selective Wave Soldering Machine.

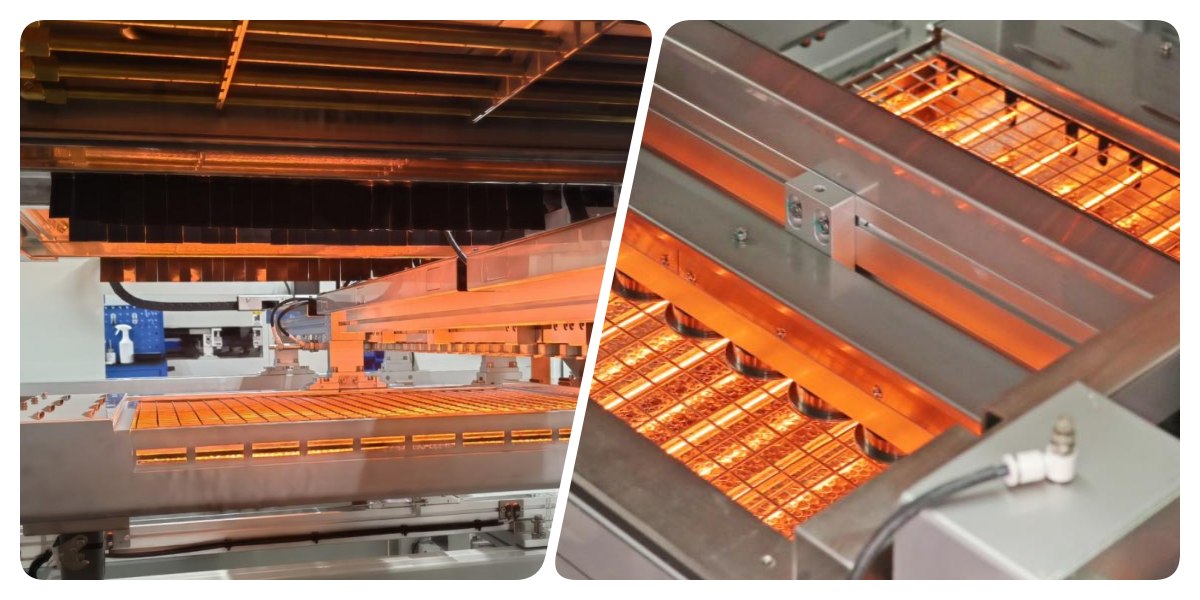

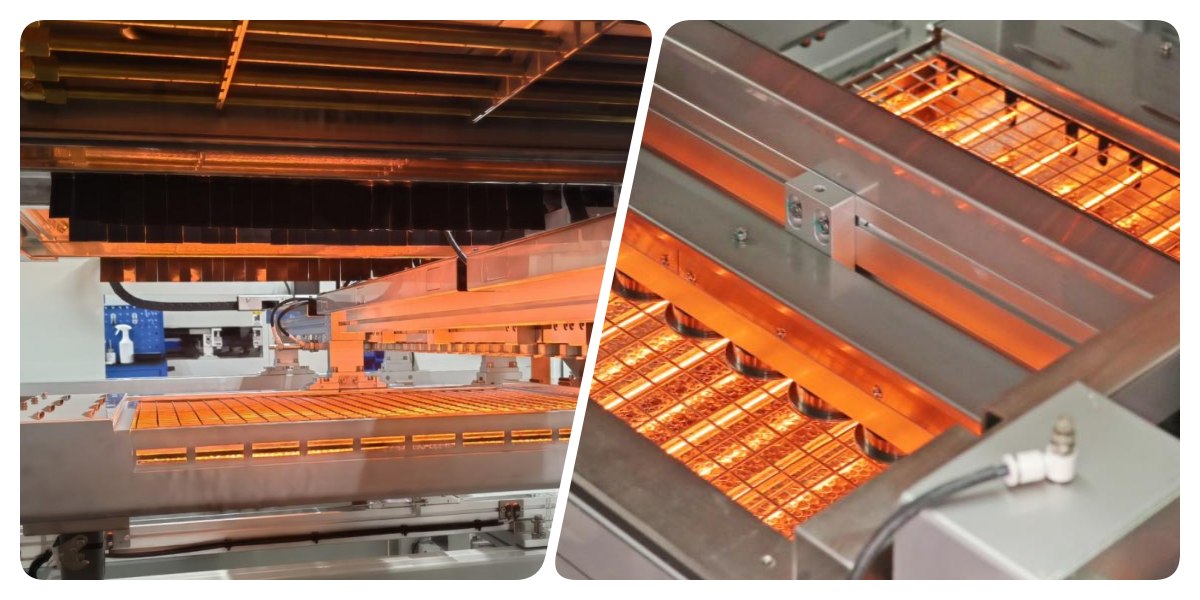

Bottom infrared heaters come standard and you can move them up or down; top hot-air or extra IR is optional. Thick insulation and an open-grid design spread heat perfectly across your whole board. The heaters and motors are top-brand, super quiet, and you can swap them without tools. Your boards come out perfectly warmed up and never warped, ready for killer joints at 0.8-second speed.

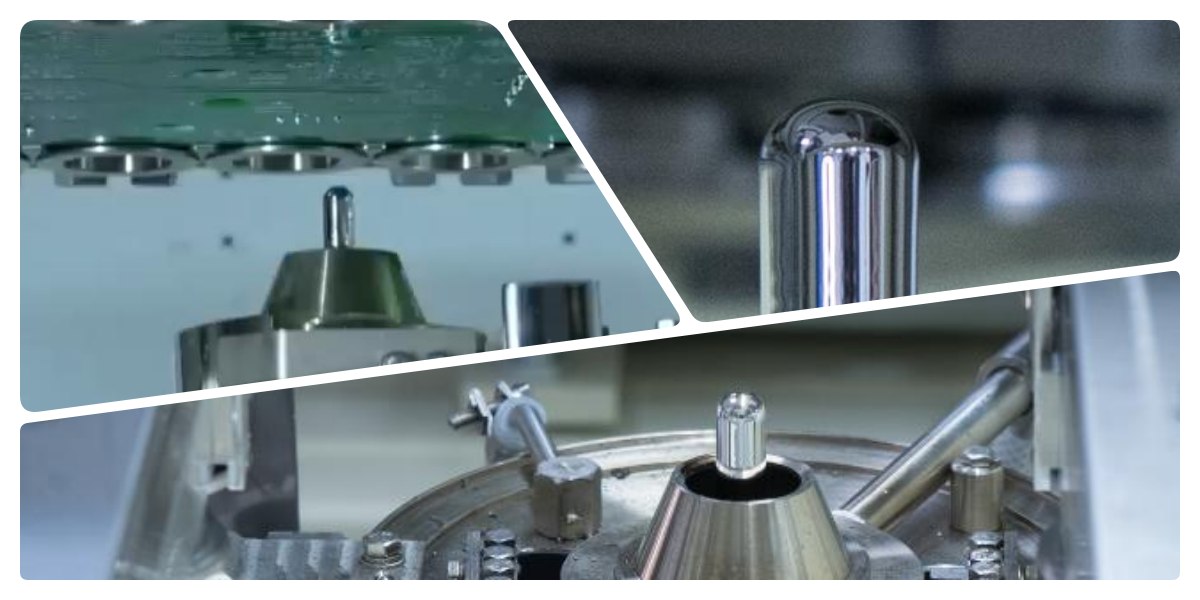

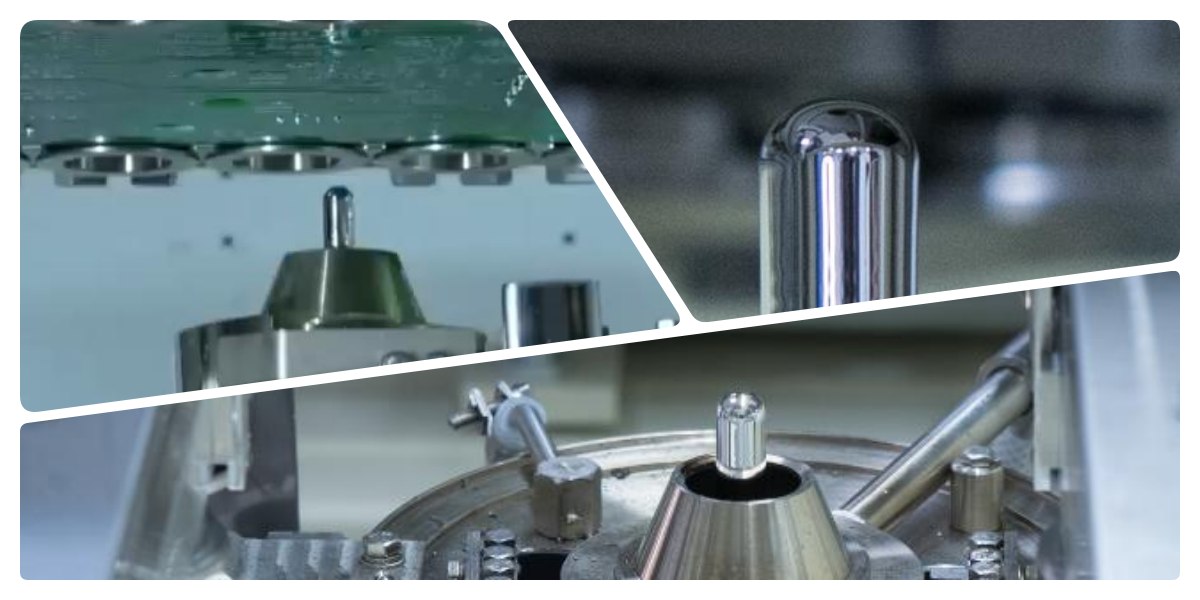

Three German electromagnetic pumps plus three titanium pots give you rock-solid mini waves that never leak or drift. You set nitrogen flow, solder temp, wave height, and auto-calibration right on the touchscreen. Nitrogen makes the joints look like mirrors and there’s almost no dross. A laser watches the height, nozzles clean themselves, and 900 hours of video are saved. This is the unbeatable heart of your 3 Solder Pot Selective Wave Soldering Machine.

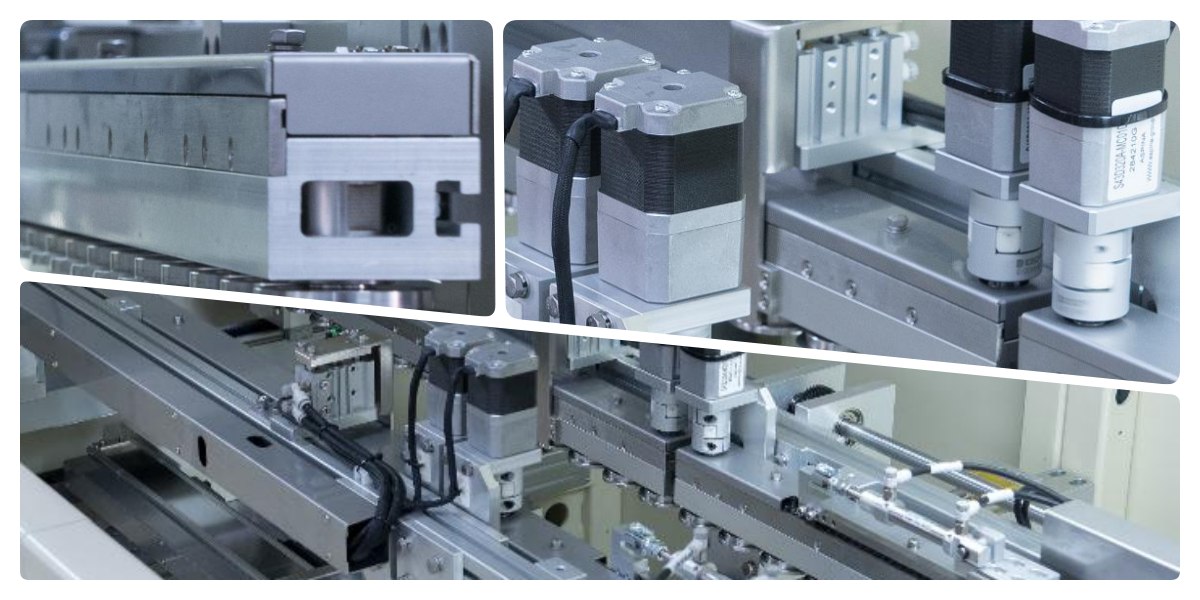

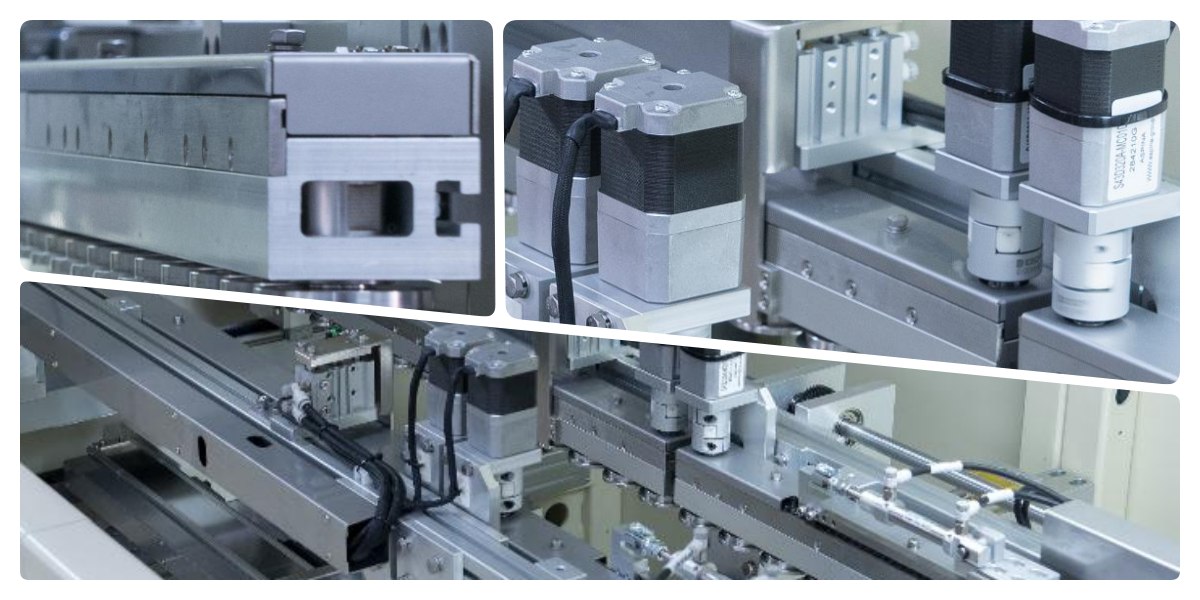

A three-section roller line plus air clamps on the sides and top hold boards up to 20 kg dead still. Beefy rails and fast servos move everything smooth as butter. Thick or double-sided boards? No problem. It’s built to run non-stop on any 3 Solder Pot Selective Wave Soldering Machine setup.

The brain is a CE-certified PLC with Cat-6 wiring and full factory-network hookup. Step-by-step wizards, picture editing, auto nozzle detection, and four languages make learning crazy fast. Remote tech support keeps your 3 Solder Pot Selective Wave Soldering Machine making money all day, every day.

Big bright screen, simple guides, one-tap live camera view, and voice alerts make running it feel like a video game. Flip between English, Chinese, Japanese, or Russian in seconds. Custom lights and Wi-Fi keep you posted without walking over.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Hook your 3 Solder Pot Selective Wave Soldering Machine up to our Electronics Assembly Line and you’ve got the perfect high-mix THT dream team. You get a lightning-fast inserter that places parts dead-on, a smart loader that feeds boards smoothly into the machine, a gentle unloader that catches finished boards without stress, and a long conveyor for final checks. Everything is built in-house, CE-certified, and switches jobs in seconds at 0.8-second cycles. With parts warehouses and techs in 72 countries, we keep your whole through-hole line running fast and cheap from start to finish.

| Product Name | Purpose in DIP Line |

|---|---|

Automatically places components onto PCBs with precision for DIP production line. | |

Melts solder to form solid joints on PCBs during THT plug-in process. | |

Robotic selective soldering machine | Applies solder selectively to specific areas for accurate THT assembly |

| PTH Post Wave and Selective Solder AOI | Inspects solder joints and placement defects on DIP assembled PCB. |

| Customer Success Video

Early 2025 a big Vietnamese camera company flew in to test their new 3 Solder Pot Selective Wave Soldering Machine. Our engineers loaded their real boards, ran full 0.8-second cycles while the customer watched perfect joints appear live on the camera, then trained their crew for two whole days on programming, cleaning, and fixing anything. They left totally confident and ready to rock volume the minute the crate landed – that’s how I.C.T rolls worldwide.

| Professional Service and Training

From the day we crate it to years later, we’ve got your back. Twenty senior engineers plus local teams in 72 countries will train you on-site or online whenever you need. Spare-parts warehouses on three continents and real 24/7 hotline keep your 3 Solder Pot Selective Wave Soldering Machine running like new forever.

| Customer Praise

Customer at factories keep telling us our engineers are super patient and actually care. They go nuts over the pinpoint flux, rock-solid three waves, and how fast the 3 Solder Pot Selective Wave Soldering Machine pays for itself with almost no rework at 0.8-second speed. Crates show up perfect and same-day remote fixes turn new customers into friends for life.

| Industry Certifications

Your 3 Solder Pot Selective Wave Soldering Machine comes with CE safety, RoHS green mark, ISO9001 quality badge, and a bunch of our own patents on valves, pumps, and laser tech. These stamps mean you’re getting safe, clean, battle-tested gear you can trust anywhere on the planet.

| About I.C.T Company and Factory

Since 2012 we’ve grown into a giant 12,000 m² campus with 89 teammates, 20 engineers, and 8 offices around the world. We design, cut, weld, assemble, and test everything under one roof. We already help over 1,600 factories in 72 countries with full SMT and THT lines, and every 3 Solder Pot Selective Wave Soldering Machine leaves after super-strict checks and real quality control.

| 3 Solder Pot Selective Wave Soldering Machine

Hey, check this out – inside our huge Dongguan factory we built you the ultimate 3 Solder Pot Selective Wave Soldering Machine so you can run three different alloys at the same time without ever draining a pot. Your board sits totally still while a feather-light aluminum gantry on Panasonic motors zips around hitting every pin in only 0.8 seconds. Nitrogen keeps everything shiny and waste almost zero. You control every single thing – paths, temps, spray amount, wave height – on a giant touchscreen and save as many programs as you want for instant changeovers. Auto-calibration, live camera, German spray valve, and three titanium pots make your 3 Solder Pot Selective Wave Soldering Machine run like a beast 24/7.

| DIP Line Equipment List

A German high-speed valve shoots tiny flux dots (less than 10 % solids) perfect to 0.02 mm every time. The tank is pressurized and has a digital meter so pressure never drops. Leftover flux falls into a slide-out tray – two seconds and it’s clean. Japanese SMC air parts and big gauges make checking it super easy. An auto pump keeps the flux flowing non-stop. This setup nails every single pad on your 3 Solder Pot Selective Wave Soldering Machine.

Bottom infrared heaters come standard and you can move them up or down; top hot-air or extra IR is optional. Thick insulation and an open-grid design spread heat perfectly across your whole board. The heaters and motors are top-brand, super quiet, and you can swap them without tools. Your boards come out perfectly warmed up and never warped, ready for killer joints at 0.8-second speed.

Three German electromagnetic pumps plus three titanium pots give you rock-solid mini waves that never leak or drift. You set nitrogen flow, solder temp, wave height, and auto-calibration right on the touchscreen. Nitrogen makes the joints look like mirrors and there’s almost no dross. A laser watches the height, nozzles clean themselves, and 900 hours of video are saved. This is the unbeatable heart of your 3 Solder Pot Selective Wave Soldering Machine.

A three-section roller line plus air clamps on the sides and top hold boards up to 20 kg dead still. Beefy rails and fast servos move everything smooth as butter. Thick or double-sided boards? No problem. It’s built to run non-stop on any 3 Solder Pot Selective Wave Soldering Machine setup.

The brain is a CE-certified PLC with Cat-6 wiring and full factory-network hookup. Step-by-step wizards, picture editing, auto nozzle detection, and four languages make learning crazy fast. Remote tech support keeps your 3 Solder Pot Selective Wave Soldering Machine making money all day, every day.

Big bright screen, simple guides, one-tap live camera view, and voice alerts make running it feel like a video game. Flip between English, Chinese, Japanese, or Russian in seconds. Custom lights and Wi-Fi keep you posted without walking over.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Hook your 3 Solder Pot Selective Wave Soldering Machine up to our Electronics Assembly Line and you’ve got the perfect high-mix THT dream team. You get a lightning-fast inserter that places parts dead-on, a smart loader that feeds boards smoothly into the machine, a gentle unloader that catches finished boards without stress, and a long conveyor for final checks. Everything is built in-house, CE-certified, and switches jobs in seconds at 0.8-second cycles. With parts warehouses and techs in 72 countries, we keep your whole through-hole line running fast and cheap from start to finish.

| Product Name | Purpose in DIP Line |

|---|---|

Automatically places components onto PCBs with precision for DIP production line. | |

Melts solder to form solid joints on PCBs during THT plug-in process. | |

Robotic selective soldering machine | Applies solder selectively to specific areas for accurate THT assembly |

| PTH Post Wave and Selective Solder AOI | Inspects solder joints and placement defects on DIP assembled PCB. |

| Customer Success Video

Early 2025 a big Vietnamese camera company flew in to test their new 3 Solder Pot Selective Wave Soldering Machine. Our engineers loaded their real boards, ran full 0.8-second cycles while the customer watched perfect joints appear live on the camera, then trained their crew for two whole days on programming, cleaning, and fixing anything. They left totally confident and ready to rock volume the minute the crate landed – that’s how I.C.T rolls worldwide.

| Professional Service and Training

From the day we crate it to years later, we’ve got your back. Twenty senior engineers plus local teams in 72 countries will train you on-site or online whenever you need. Spare-parts warehouses on three continents and real 24/7 hotline keep your 3 Solder Pot Selective Wave Soldering Machine running like new forever.

| Customer Praise

Customer at factories keep telling us our engineers are super patient and actually care. They go nuts over the pinpoint flux, rock-solid three waves, and how fast the 3 Solder Pot Selective Wave Soldering Machine pays for itself with almost no rework at 0.8-second speed. Crates show up perfect and same-day remote fixes turn new customers into friends for life.

| Industry Certifications

Your 3 Solder Pot Selective Wave Soldering Machine comes with CE safety, RoHS green mark, ISO9001 quality badge, and a bunch of our own patents on valves, pumps, and laser tech. These stamps mean you’re getting safe, clean, battle-tested gear you can trust anywhere on the planet.

| About I.C.T Company and Factory

Since 2012 we’ve grown into a giant 12,000 m² campus with 89 teammates, 20 engineers, and 8 offices around the world. We design, cut, weld, assemble, and test everything under one roof. We already help over 1,600 factories in 72 countries with full SMT and THT lines, and every 3 Solder Pot Selective Wave Soldering Machine leaves after super-strict checks and real quality control.