I.C.T-750

I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| Efficient Pneumatic Stencil Cleaner

In electronics factories where safety and simplicity matter, the I.C.T-750 pneumatic stencil cleaner stands out as a dependable choice for removing solder paste or red glue from printing stencils. Driven only by compressed air, it requires no electrical connection, making it ideal for areas with power concerns or strict safety rules. The patented 360° rotation spray rods on both sides ensure thorough, uniform cleaning while maintaining stencil tension. One-button operation handles the full clean-and-dry cycle automatically. Liquid recycles through a three-level filter system, cutting waste and costs. Famous pneumatic parts from top makers add reliability, and the modular design keeps maintenance straightforward. This pneumatic stencil cleaner helps maintain high print quality and production efficiency.

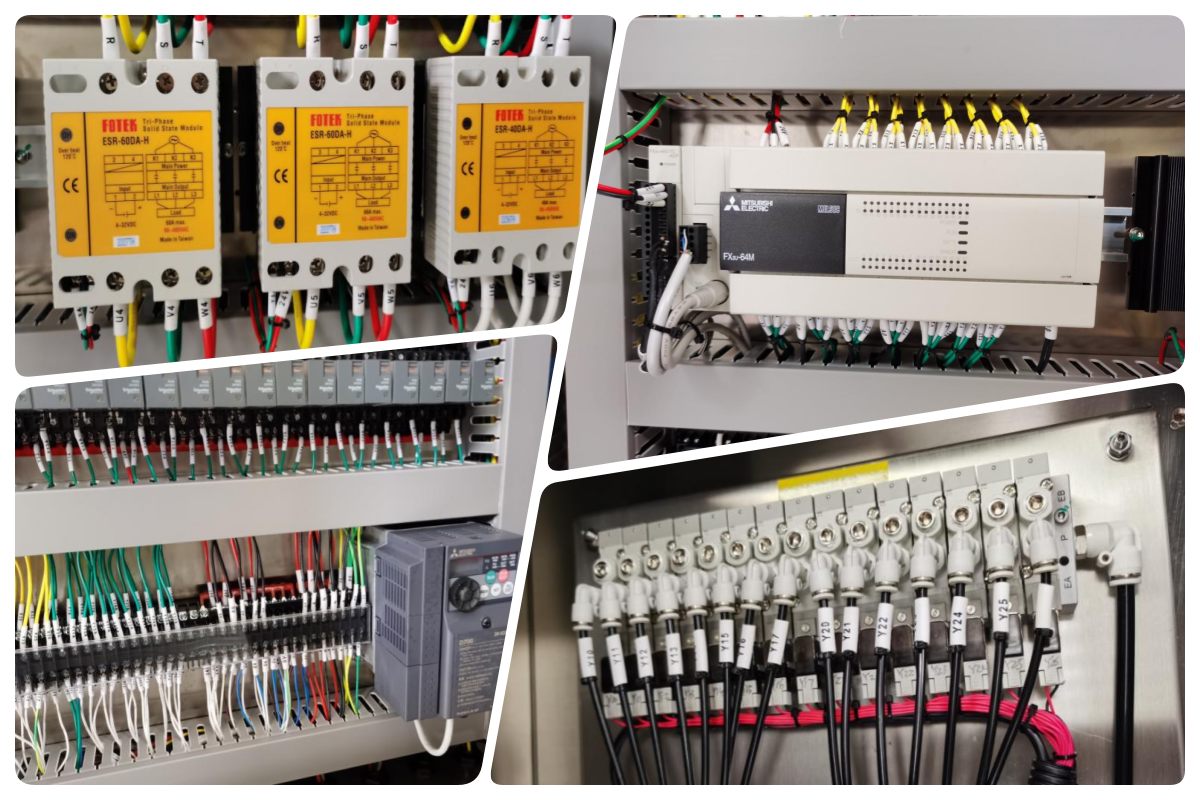

| Feature

Durability forms the foundation of the I.C.T-750 pneumatic stencil cleaner. Constructed from SUS 304 stainless steel, it resists acid, alkali, and corrosion, promising a solid 10-year service life in tough factory conditions. The entire system runs on compressed air alone—no electricity flows through it, reducing risks in certain environments. A high-quality diaphragm pump from USA Ingersoll Rand delivers strong, consistent pressure. Indicator lights come from Japan Koganei, and the timer from Germany Hengstler ensures precise control. These well-known components work together reliably. The machine's modular build allows quick access for checks or part swaps, keeping operations smooth without long interruptions.

The heart of cleaning lies in the patented design of this pneumatic stencil cleaner. 360° rotating spray rods positioned on both sides deliver fluid from every angle, reaching deep into stencil openings for complete removal of residues. As rods spin, they cover the surface evenly without pulling or stressing the stencil frame. Compressed air then blows dry, finishing the job efficiently. One simple button starts the automatic sequence of cleaning and drying. The inner-lock safety door and valve stop everything instantly if opened, protecting operators. This setup guarantees thorough results on solder paste or red glue stencils, matching the cleanliness of more complex systems while staying straightforward and safe.

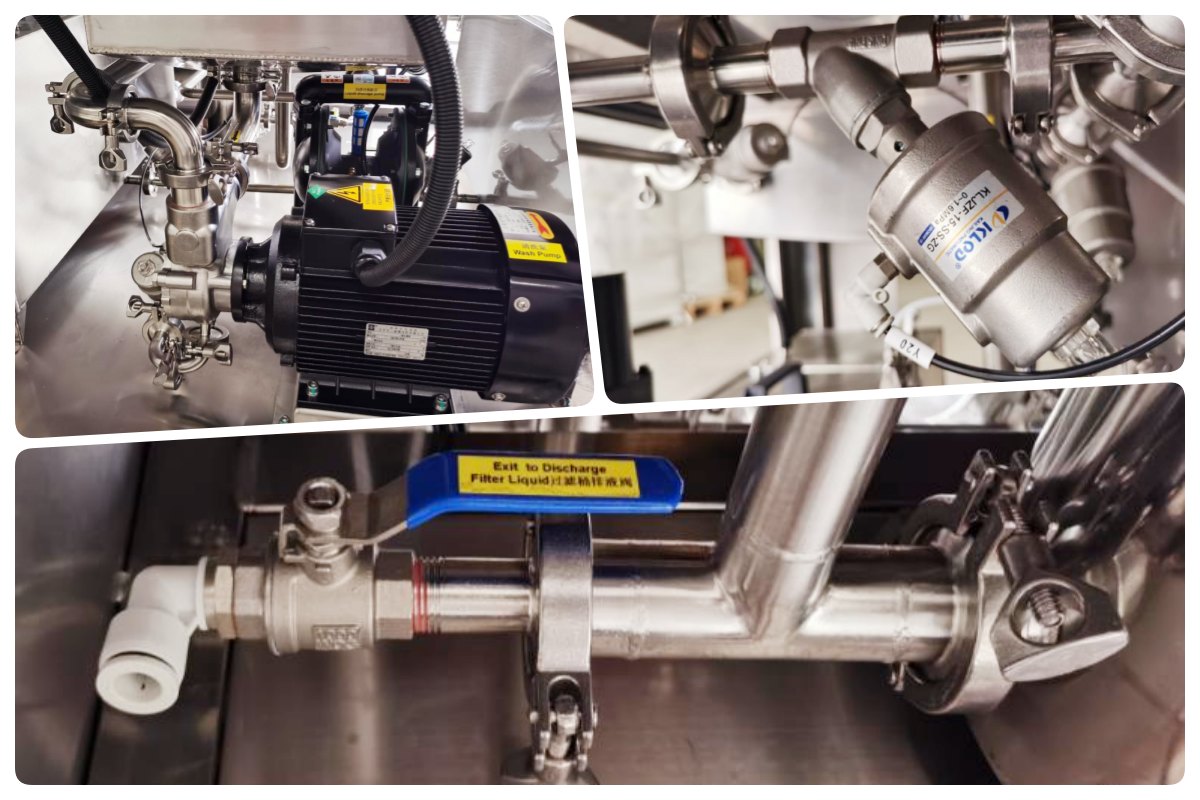

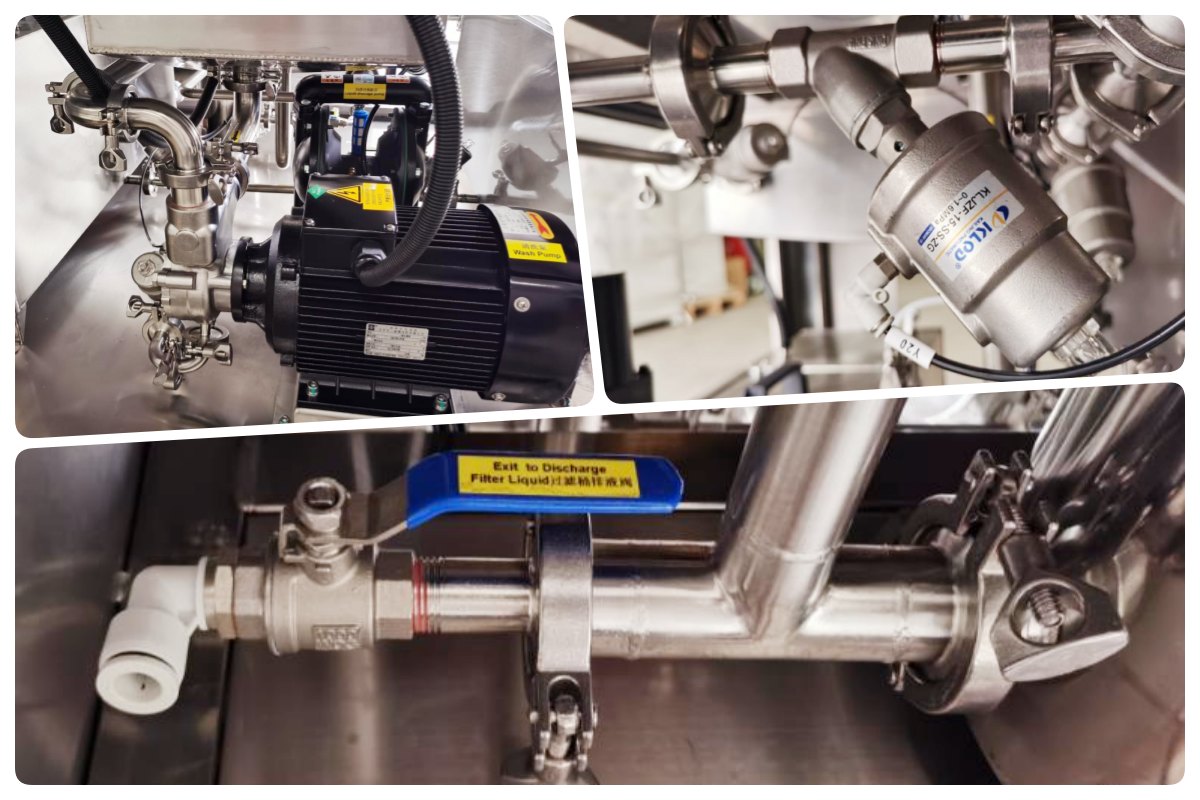

Liquid handling receives careful attention in the I.C.T-750. A 40-liter tank holds cleaning fluid, which recycles through a three-level precise filtering system—20µm, 5µm, and 1µm stages—to remove particles before reuse. This repeated use keeps consumption low and reduces waste. Pipes and valves use stainless steel 304 for strength and clean flow. Large-core filter buckets handle high volume without clogging quickly. The system supports both solvent and aqueous detergents, with the same excellent cleaning outcome. Adjustments to time, pressure, or other settings allow fine-tuning to match specific production needs, ensuring consistent performance over many cycles.

Operation stays simple and secure with the pneumatic stencil cleaner. One button activates the full automatic cycle—cleaning followed by drying—leaving little room for error. Compressed air at 0.5-0.7 MPa powers the process at room temperature, no heating required. The control panel includes clear indicators and a reliable timer for monitoring. Safety features shine through: the inner-lock door prevents access during runs, and the safety valve halts operation immediately if opened. Modular components make any needed maintenance fast and easy. Customers find this balance of ease, safety, and effectiveness makes daily stencil cleaning reliable and worry-free in busy SMT lines.

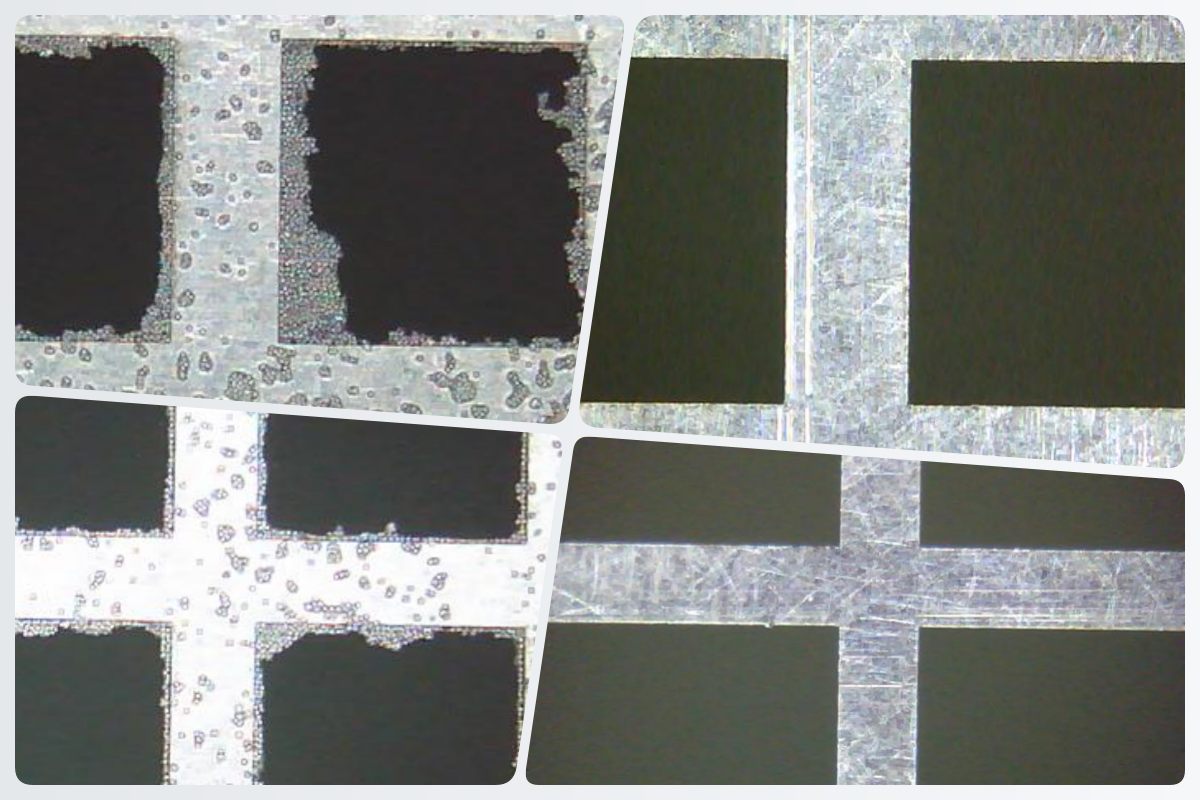

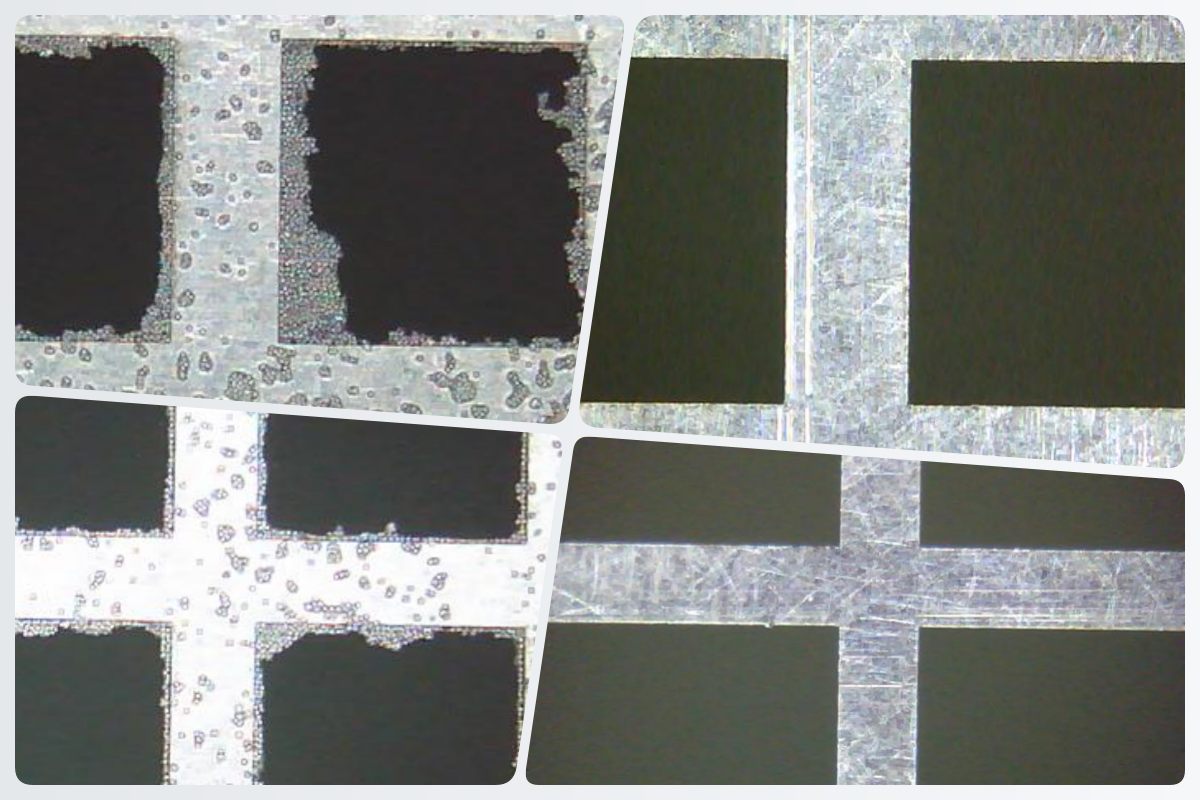

| Comparison Before and After

| Specification

| Parameter | I.C.T-750 (Pneumatic) | I.C.T-800 (Auto Aqueous) |

|---|---|---|

| Power Source | Compressed air only (no electricity) | Electric (AC380V, 3-phase, 33KW total) |

| Max Stencil Size | L750 × W750 × H40 mm | L750 × W750 × H40 mm |

| Cleaning Method | 360° rotation spray + air blow dry | 4 fixed spray rods + 4 air knives, stencil moves back & forth |

| Cleaning Liquid | Solvent or aqueous (both supported) | Aqueous detergent only |

| Liquid Tank Capacity | 40 L | 60 L × 2 (cleaning + rinse) |

| Cleaning Time | 2–4 minutes | 2–5 minutes |

| Drying Time | 2–5 minutes | 3–5 minutes (hot air) |

| Heating Function | No heating (room temperature) | Yes (detergent up to 60°C, hot air up to 90°C) |

| SMT Line Equipment List

For a complete PCB Assembly Line, I.C.T offers key machines like SMT stencil printers, solder paste inspection, high-speed SMT machine, 8 zone reflow oven, 3d AOI inspection, PCB conveyors, and stencil washing machine. These work together to create efficient, high-quality SMT assembly. For DIP assembly lines, we provide selective wave soldering machines and wave soldering equipment to handle through-hole components with precision and reliability. Whether building SMT, DIP, or mixed lines, I.C.T supplies matched equipment and full support for smooth production.

| Customer Success Video

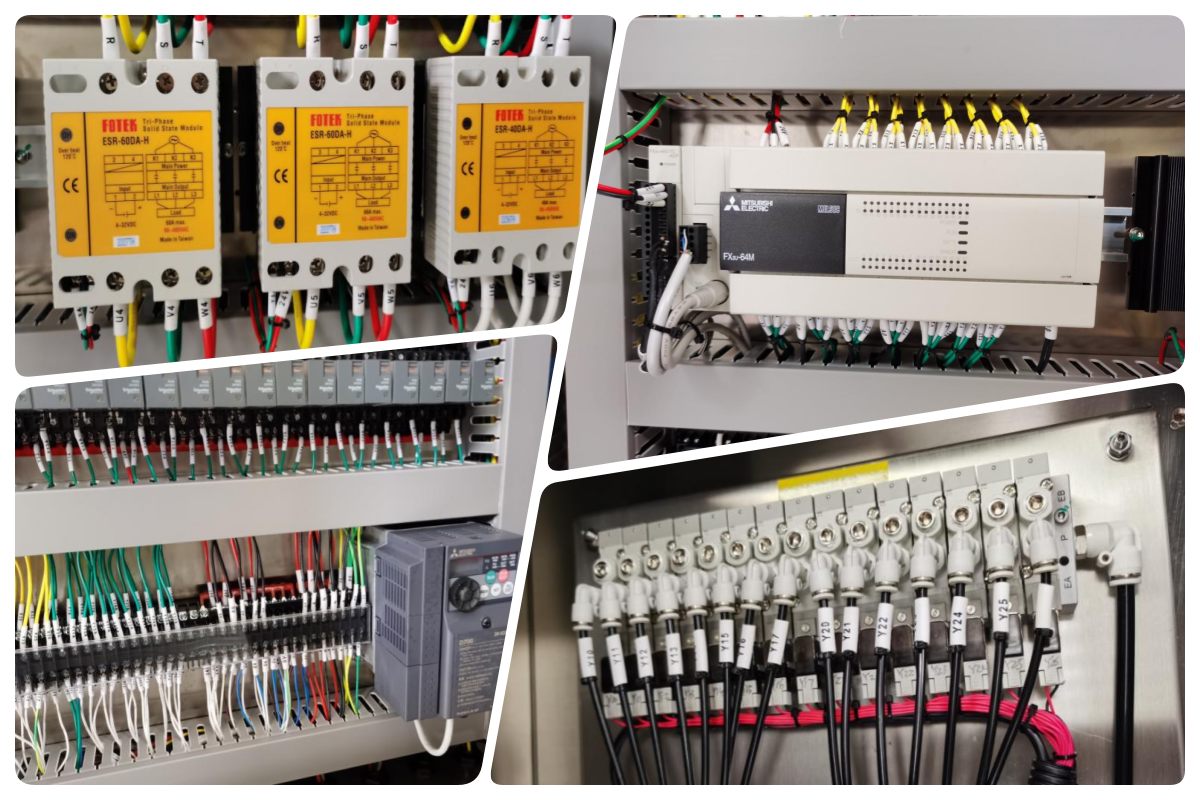

I.C.T successfully supported a North American beauty instrument manufacturer by completing overseas installation and Factory Acceptance Testing on two full SMT production lines. The project passed all production acceptance checks smoothly and on schedule. The delivered equipment included laser marking machines, SMT printers with SPI, Panasonic mounters, Heller reflow ovens, AOI inspection systems, PCB conveyors, PCBA cleaners, and automatic solder paste storage-thawing units. Our engineers provided hands-on setup, detailed training, and debugging support on site until everything operated at full efficiency. This successful collaboration reinforced the customer's trust in I.C.T for delivering complex, high-quality SMT solutions internationally.

| Service and Training

I.C.T provides thorough support to ensure customers gain full benefit from their pneumatic stencil cleaner and complete production setups. Experienced engineers travel globally for on-site installation, commissioning, and practical training sessions. They cover machine operation, routine maintenance, parameter adjustments, and basic troubleshooting steps. Remote technical help responds quickly to questions, often resolving issues promptly. We offer guidance on process improvements to boost yields and cut long-term costs. With more than 25 years of expertise, our team delivers fast, dependable assistance that extends well beyond delivery, allowing factories to maintain smooth output while we handle equipment care and optimization needs.

| Customer Reviews

Customers often speak highly of our engineers' expertise, patience during installation, and swift answers to any concerns that arise. Many praise the pneumatic stencil cleaner for its consistent, thorough cleaning results and noticeable savings on liquid usage. Reviews frequently mention the careful packaging and secure transport that ensured machines arrived in excellent condition after long shipments. Fast response times to questions and clear communication stand out as well. In general, clients view I.C.T as a trustworthy partner that supplies solid equipment alongside attentive, professional service throughout the entire experience.

| Our Certification

The I.C.T-750 pneumatic stencil cleaner meets important global standards for quality and safety. It carries CE certification to confirm compliance with European safety requirements, RoHS approval to limit harmful substances and support environmental standards, and ISO9001 registration for our overall quality management system. We hold several patents on key innovations, such as the 360° rotating spray rod mechanism. These approvals and protections reflect our dedication to safe, eco-conscious, and technically advanced manufacturing. Customers can rely on equipment that adheres to strict international guidelines for performance, durability, and responsible production.

| About Us and Factory

I.C.T develops and produces complete SMT solutions through our own research, design, and manufacturing operations in Dongguan. Founded in 2012, we have expanded rapidly to 89 employees, including 20 skilled engineers, within a 12,000 m² industrial park. Our $30 million registered capital backs eight branch offices around the world. We serve more than 1,600 customers across 72 countries, building strong experience in technical support, local adaptations, and customer relationships. Strict testing procedures and a comprehensive quality management system guide every step of production, guaranteeing consistent high standards. We supply reliable machines and end-to-end assistance to help partners establish or enhance their manufacturing lines globally.

| Efficient Pneumatic Stencil Cleaner

In electronics factories where safety and simplicity matter, the I.C.T-750 pneumatic stencil cleaner stands out as a dependable choice for removing solder paste or red glue from printing stencils. Driven only by compressed air, it requires no electrical connection, making it ideal for areas with power concerns or strict safety rules. The patented 360° rotation spray rods on both sides ensure thorough, uniform cleaning while maintaining stencil tension. One-button operation handles the full clean-and-dry cycle automatically. Liquid recycles through a three-level filter system, cutting waste and costs. Famous pneumatic parts from top makers add reliability, and the modular design keeps maintenance straightforward. This pneumatic stencil cleaner helps maintain high print quality and production efficiency.

| Feature

Durability forms the foundation of the I.C.T-750 pneumatic stencil cleaner. Constructed from SUS 304 stainless steel, it resists acid, alkali, and corrosion, promising a solid 10-year service life in tough factory conditions. The entire system runs on compressed air alone—no electricity flows through it, reducing risks in certain environments. A high-quality diaphragm pump from USA Ingersoll Rand delivers strong, consistent pressure. Indicator lights come from Japan Koganei, and the timer from Germany Hengstler ensures precise control. These well-known components work together reliably. The machine's modular build allows quick access for checks or part swaps, keeping operations smooth without long interruptions.

The heart of cleaning lies in the patented design of this pneumatic stencil cleaner. 360° rotating spray rods positioned on both sides deliver fluid from every angle, reaching deep into stencil openings for complete removal of residues. As rods spin, they cover the surface evenly without pulling or stressing the stencil frame. Compressed air then blows dry, finishing the job efficiently. One simple button starts the automatic sequence of cleaning and drying. The inner-lock safety door and valve stop everything instantly if opened, protecting operators. This setup guarantees thorough results on solder paste or red glue stencils, matching the cleanliness of more complex systems while staying straightforward and safe.

Liquid handling receives careful attention in the I.C.T-750. A 40-liter tank holds cleaning fluid, which recycles through a three-level precise filtering system—20µm, 5µm, and 1µm stages—to remove particles before reuse. This repeated use keeps consumption low and reduces waste. Pipes and valves use stainless steel 304 for strength and clean flow. Large-core filter buckets handle high volume without clogging quickly. The system supports both solvent and aqueous detergents, with the same excellent cleaning outcome. Adjustments to time, pressure, or other settings allow fine-tuning to match specific production needs, ensuring consistent performance over many cycles.

Operation stays simple and secure with the pneumatic stencil cleaner. One button activates the full automatic cycle—cleaning followed by drying—leaving little room for error. Compressed air at 0.5-0.7 MPa powers the process at room temperature, no heating required. The control panel includes clear indicators and a reliable timer for monitoring. Safety features shine through: the inner-lock door prevents access during runs, and the safety valve halts operation immediately if opened. Modular components make any needed maintenance fast and easy. Customers find this balance of ease, safety, and effectiveness makes daily stencil cleaning reliable and worry-free in busy SMT lines.

| Comparison Before and After

| Specification

| Parameter | I.C.T-750 (Pneumatic) | I.C.T-800 (Auto Aqueous) |

|---|---|---|

| Power Source | Compressed air only (no electricity) | Electric (AC380V, 3-phase, 33KW total) |

| Max Stencil Size | L750 × W750 × H40 mm | L750 × W750 × H40 mm |

| Cleaning Method | 360° rotation spray + air blow dry | 4 fixed spray rods + 4 air knives, stencil moves back & forth |

| Cleaning Liquid | Solvent or aqueous (both supported) | Aqueous detergent only |

| Liquid Tank Capacity | 40 L | 60 L × 2 (cleaning + rinse) |

| Cleaning Time | 2–4 minutes | 2–5 minutes |

| Drying Time | 2–5 minutes | 3–5 minutes (hot air) |

| Heating Function | No heating (room temperature) | Yes (detergent up to 60°C, hot air up to 90°C) |

| SMT Line Equipment List

For a complete PCB Assembly Line, I.C.T offers key machines like SMT stencil printers, solder paste inspection, high-speed SMT machine, 8 zone reflow oven, 3d AOI inspection, PCB conveyors, and stencil washing machine. These work together to create efficient, high-quality SMT assembly. For DIP assembly lines, we provide selective wave soldering machines and wave soldering equipment to handle through-hole components with precision and reliability. Whether building SMT, DIP, or mixed lines, I.C.T supplies matched equipment and full support for smooth production.

| Customer Success Video

I.C.T successfully supported a North American beauty instrument manufacturer by completing overseas installation and Factory Acceptance Testing on two full SMT production lines. The project passed all production acceptance checks smoothly and on schedule. The delivered equipment included laser marking machines, SMT printers with SPI, Panasonic mounters, Heller reflow ovens, AOI inspection systems, PCB conveyors, PCBA cleaners, and automatic solder paste storage-thawing units. Our engineers provided hands-on setup, detailed training, and debugging support on site until everything operated at full efficiency. This successful collaboration reinforced the customer's trust in I.C.T for delivering complex, high-quality SMT solutions internationally.

| Service and Training

I.C.T provides thorough support to ensure customers gain full benefit from their pneumatic stencil cleaner and complete production setups. Experienced engineers travel globally for on-site installation, commissioning, and practical training sessions. They cover machine operation, routine maintenance, parameter adjustments, and basic troubleshooting steps. Remote technical help responds quickly to questions, often resolving issues promptly. We offer guidance on process improvements to boost yields and cut long-term costs. With more than 25 years of expertise, our team delivers fast, dependable assistance that extends well beyond delivery, allowing factories to maintain smooth output while we handle equipment care and optimization needs.

| Customer Reviews

Customers often speak highly of our engineers' expertise, patience during installation, and swift answers to any concerns that arise. Many praise the pneumatic stencil cleaner for its consistent, thorough cleaning results and noticeable savings on liquid usage. Reviews frequently mention the careful packaging and secure transport that ensured machines arrived in excellent condition after long shipments. Fast response times to questions and clear communication stand out as well. In general, clients view I.C.T as a trustworthy partner that supplies solid equipment alongside attentive, professional service throughout the entire experience.

| Our Certification

The I.C.T-750 pneumatic stencil cleaner meets important global standards for quality and safety. It carries CE certification to confirm compliance with European safety requirements, RoHS approval to limit harmful substances and support environmental standards, and ISO9001 registration for our overall quality management system. We hold several patents on key innovations, such as the 360° rotating spray rod mechanism. These approvals and protections reflect our dedication to safe, eco-conscious, and technically advanced manufacturing. Customers can rely on equipment that adheres to strict international guidelines for performance, durability, and responsible production.

| About Us and Factory

I.C.T develops and produces complete SMT solutions through our own research, design, and manufacturing operations in Dongguan. Founded in 2012, we have expanded rapidly to 89 employees, including 20 skilled engineers, within a 12,000 m² industrial park. Our $30 million registered capital backs eight branch offices around the world. We serve more than 1,600 customers across 72 countries, building strong experience in technical support, local adaptations, and customer relationships. Strict testing procedures and a comprehensive quality management system guide every step of production, guaranteeing consistent high standards. We supply reliable machines and end-to-end assistance to help partners establish or enhance their manufacturing lines globally.