I.C.T-SS540

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Pcba Automatic Selective Wave Soldering Machine SS550

The Pcba Automatic Selective Wave Soldering Machine SS550, built by I.C.T in China, is a game-changer for automated PCB soldering. Perfect for high-volume production, it keeps PCBs steady while the spray and solder platform moves, ensuring accuracy for complex boards.

Full PC control lets you save paths, temperatures, and flux details, offering consistent results every time. Its modular design fits any setup, with auto wave calibration and CCD alignment enhancing quality. As a quick Selective Wave Soldering Machine, it cuts setup time and boosts efficiency. Backed by I.C.T’s 26 years of expertise, it serves 1600+ clients across 72 countries with reliable global support.

| DIP Line Equipment List

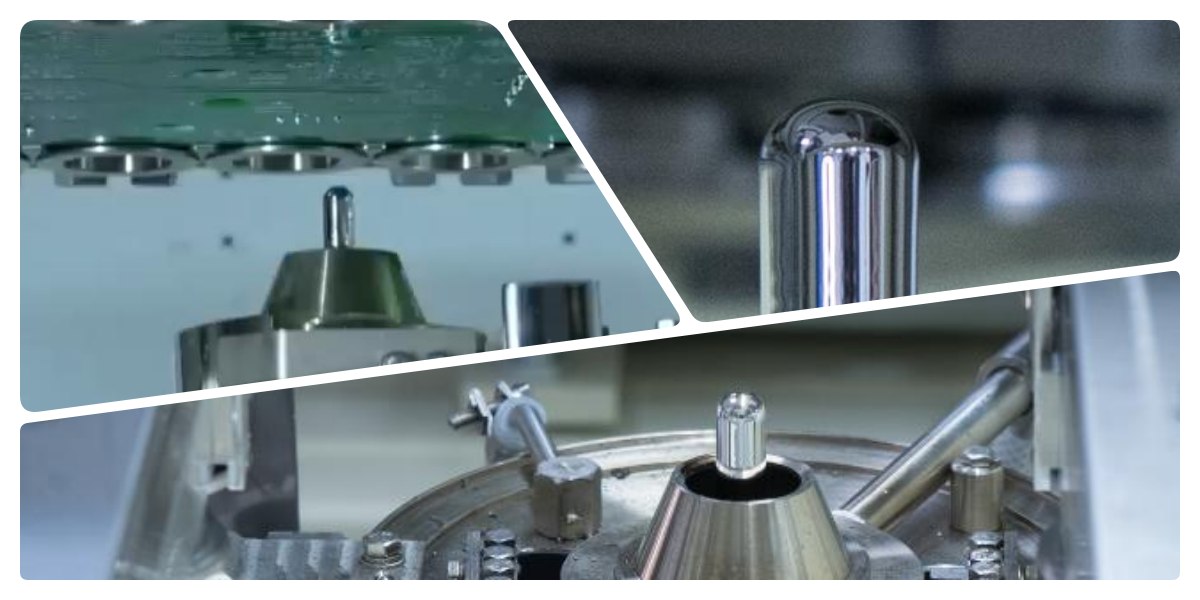

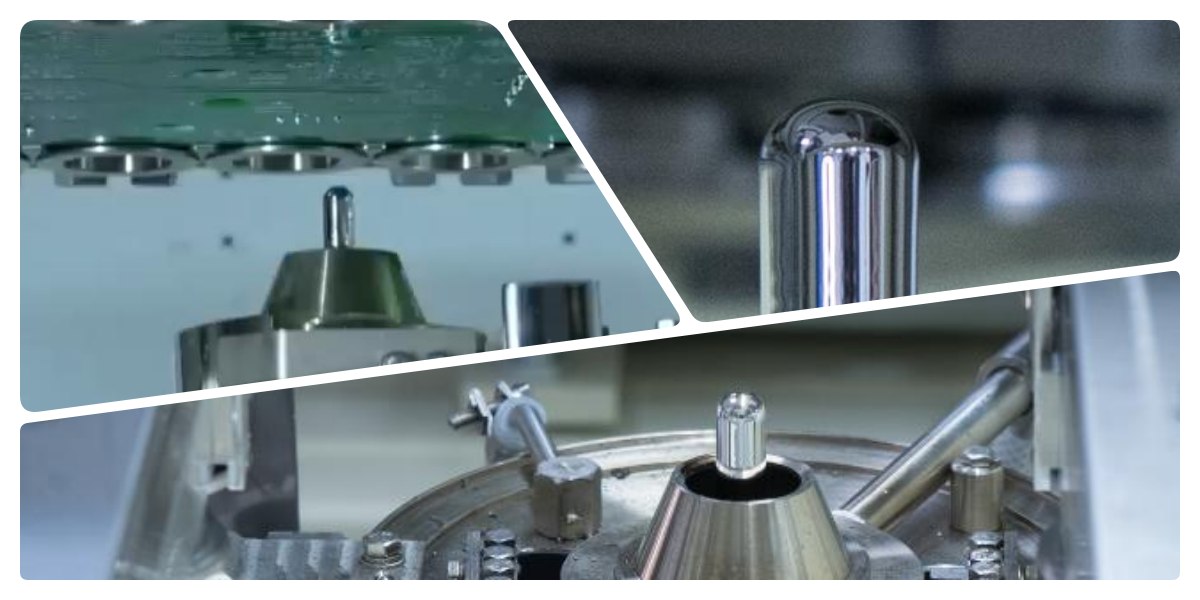

The Pcba Automatic Selective Wave Soldering Machine features a smart flux system for perfect coverage. A German high-frequency pulse valve sprays tiny flux dots with solid content under 10%, reducing waste. A tray catches residue for easy cleanup, and the nozzle on an XY platform hits 0.02mm accuracy. Pressure tanks keep flow steady with Japanese SMC parts, while visible gauges simplify checks. This setup ensures clean, efficient soldering, ideal for quick production runs.

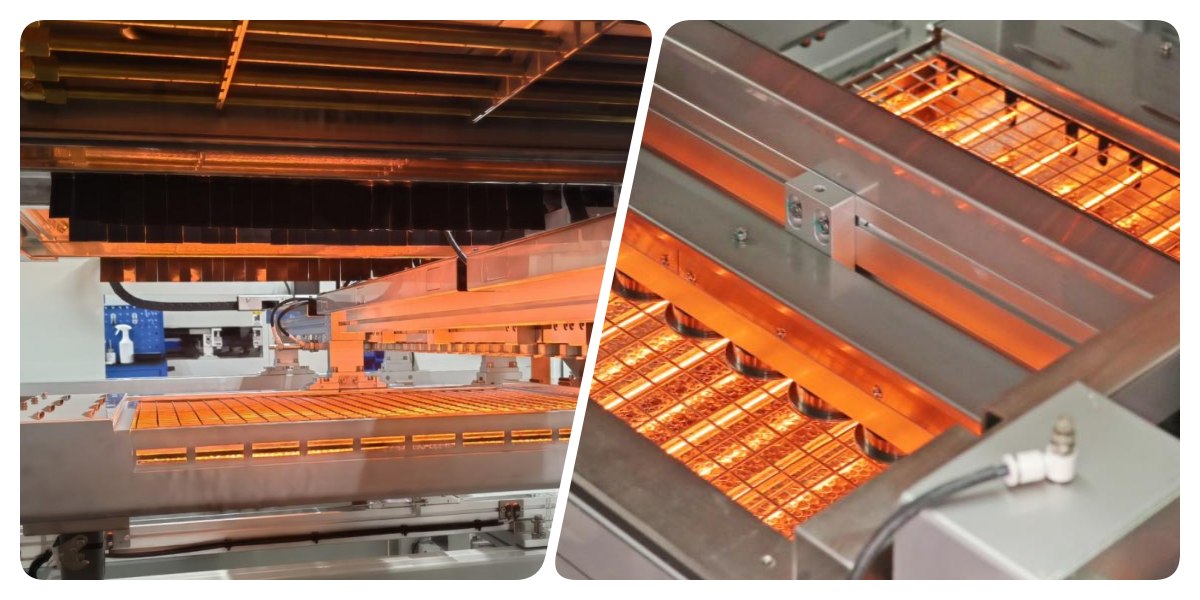

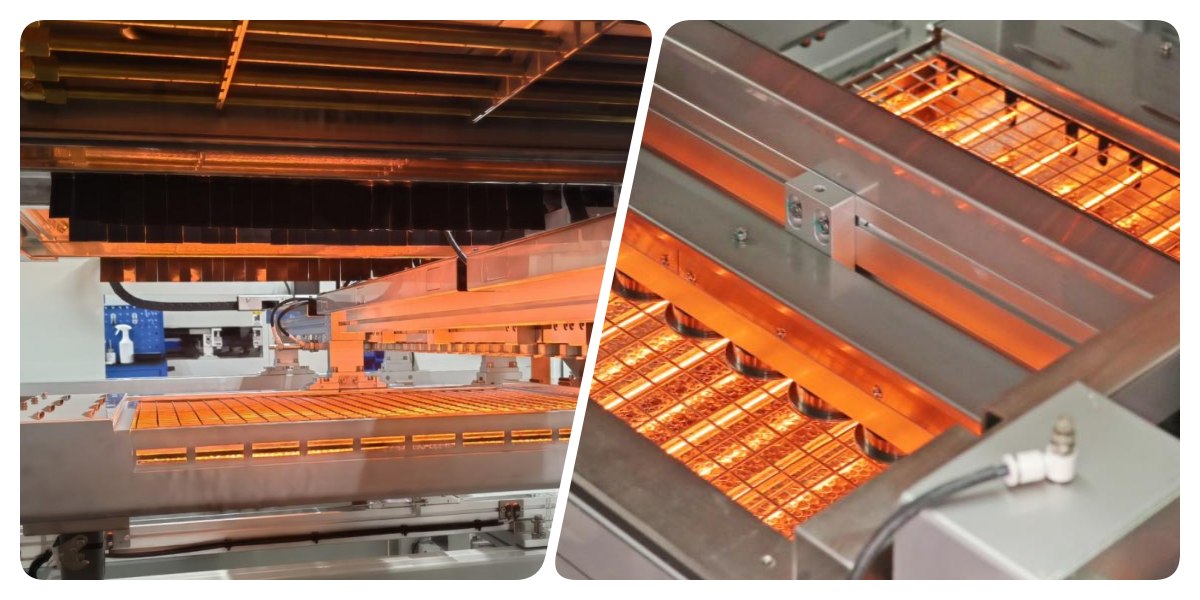

The preheat system in this quick Selective Wave Soldering Machine preps boards fast and evenly. It offers adjustable bottom IR heating and top hot air, reaching 150°C in about 15 minutes. High-temp cotton locks in heat, using top-brand parts for stability. The tool-free plug-in design cuts maintenance time. This setup ensures strong welds and minimizes errors, perfect for speeding up your line.

The soldering system stands out with advanced tech in the Pcba Automatic Selective Wave Soldering Machine. A Swedish PRECIMETER pump keeps the solder wave stable, with software controlling temps and N2 flow. The stainless steel pot with anti-corrosion coating heats fast with cast iron, while N2 reduces dross for clean joints. It handles tough components, delivering high-quality results quickly.

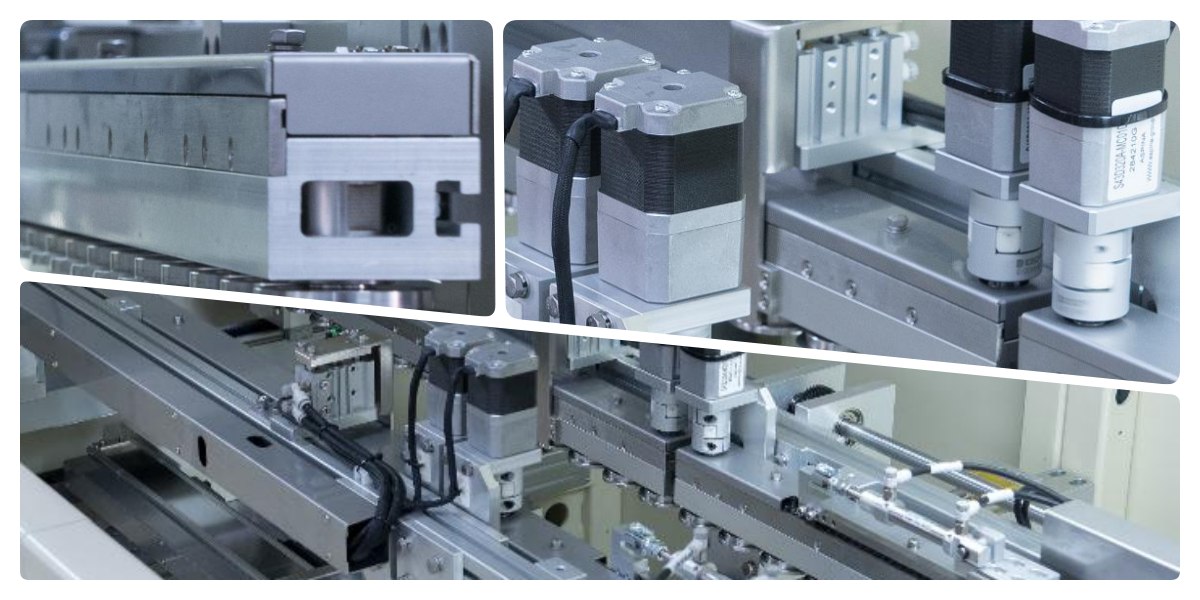

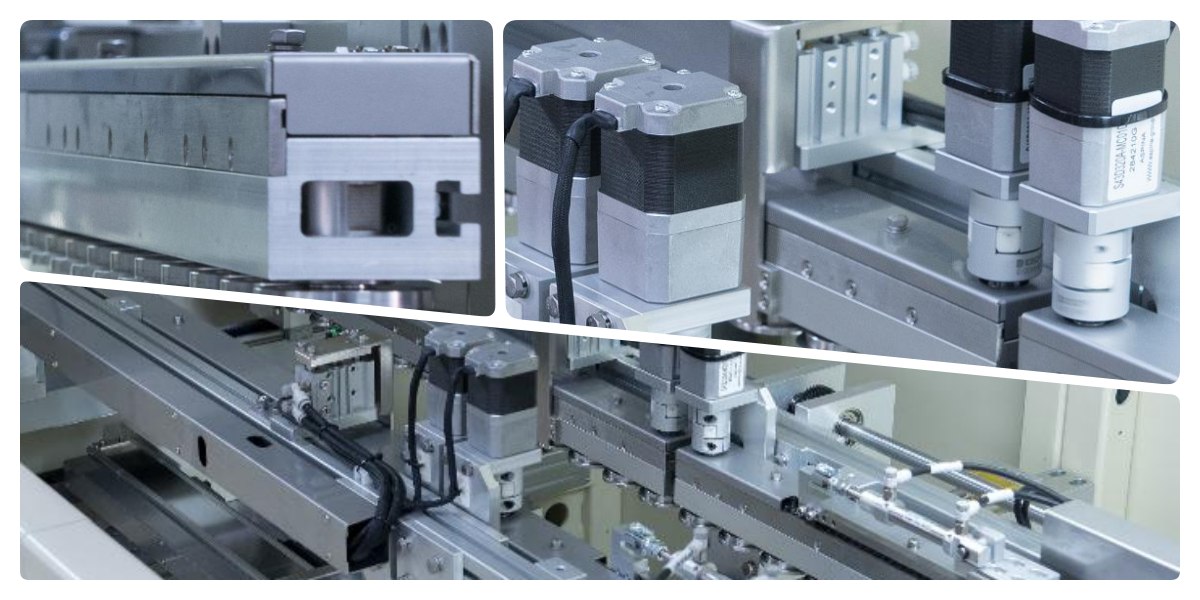

The transmission system ensures smooth PCB flow in this quick Selective Wave Soldering Machine. Built with sturdy profiles and rollers, it supports up to 20kg loads with side and top clamps. Japanese motors drive it reliably, fitting modular setups. Online swaps keep production moving, making it a flexible choice for fast-paced shops.

Control is solid in the Pcba Automatic Selective Wave Soldering Machine with a Keyence PLC system meeting CE standards. Global parts and Cat-6 cables ensure fast, stable operation, with data tracking for quality checks. It adapts to growing needs, supporting quick adjustments in production.

The operating system makes this quick Selective Wave Soldering Machine easy to use. Guided CCD programming speeds setup, with picture mode for coordinate checks and real-time monitoring. Choose English or Chinese, with WiFi updates via MES. Data traces each solder point, cutting training time for fast starts.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In October 2025, I.C.T engineers visited a European client to support a new PCBA Automatic Selective Wave Soldering Machine SS550 setup. The video highlighted its quick setup, with precise flux spray and steady soldering on complex PCBs. Engineers trained the team and fine-tuned settings, ensuring smooth production within hours. The client praised the machine’s speed and I.C.T’s on-site expertise, boosting their output of high-quality boards for automotive use.

| Professional Service and Training

I.C.T provides full support for the Pcba Automatic Selective Wave Soldering Machine with on-site installs and 24/7 help. Our engineers offer training on operation and maintenance, plus remote assistance to match your needs. With 26 years in SMT, we optimize your line for speed. Long-term plans include regular checks, keeping your production worry-free and fast.

| Customer Praise

Clients rave about I.C.T engineers’ quick setup skills on the Pcba Automatic Selective Wave Soldering Machine. The machine’s fast, clean soldering wins praise, with secure packaging ensuring safe delivery. Rapid issue fixes keep lines running, with one user noting, "I.C.T’s speed saved us days!" This builds strong trust.

| Industry Certifications

The PCBA Automatic Selective Wave Soldering Machine holds CE, RoHS, and ISO9001 certifications, meeting global standards. I.C.T’s patents on wave and flux tech show innovation. These credentials guarantee safe, reliable equipment for quick production worldwide.

| About I.C.T Company and Factory

I.C.T leads SMT with in-house R&D and three factories, growing to 89 staff over 26 years. We serve 1600+ clients in 72 countries, offering quick Selective Wave Soldering solutions with strict testing and quality systems. Our global network and compact designs support fast setups. We innovate daily, building partnerships for your factory’s success.

| Pcba Automatic Selective Wave Soldering Machine SS550

The Pcba Automatic Selective Wave Soldering Machine SS550, built by I.C.T in China, is a game-changer for automated PCB soldering. Perfect for high-volume production, it keeps PCBs steady while the spray and solder platform moves, ensuring accuracy for complex boards.

Full PC control lets you save paths, temperatures, and flux details, offering consistent results every time. Its modular design fits any setup, with auto wave calibration and CCD alignment enhancing quality. As a quick Selective Wave Soldering Machine, it cuts setup time and boosts efficiency. Backed by I.C.T’s 26 years of expertise, it serves 1600+ clients across 72 countries with reliable global support.

| DIP Line Equipment List

The Pcba Automatic Selective Wave Soldering Machine features a smart flux system for perfect coverage. A German high-frequency pulse valve sprays tiny flux dots with solid content under 10%, reducing waste. A tray catches residue for easy cleanup, and the nozzle on an XY platform hits 0.02mm accuracy. Pressure tanks keep flow steady with Japanese SMC parts, while visible gauges simplify checks. This setup ensures clean, efficient soldering, ideal for quick production runs.

The preheat system in this quick Selective Wave Soldering Machine preps boards fast and evenly. It offers adjustable bottom IR heating and top hot air, reaching 150°C in about 15 minutes. High-temp cotton locks in heat, using top-brand parts for stability. The tool-free plug-in design cuts maintenance time. This setup ensures strong welds and minimizes errors, perfect for speeding up your line.

The soldering system stands out with advanced tech in the Pcba Automatic Selective Wave Soldering Machine. A Swedish PRECIMETER pump keeps the solder wave stable, with software controlling temps and N2 flow. The stainless steel pot with anti-corrosion coating heats fast with cast iron, while N2 reduces dross for clean joints. It handles tough components, delivering high-quality results quickly.

The transmission system ensures smooth PCB flow in this quick Selective Wave Soldering Machine. Built with sturdy profiles and rollers, it supports up to 20kg loads with side and top clamps. Japanese motors drive it reliably, fitting modular setups. Online swaps keep production moving, making it a flexible choice for fast-paced shops.

Control is solid in the Pcba Automatic Selective Wave Soldering Machine with a Keyence PLC system meeting CE standards. Global parts and Cat-6 cables ensure fast, stable operation, with data tracking for quality checks. It adapts to growing needs, supporting quick adjustments in production.

The operating system makes this quick Selective Wave Soldering Machine easy to use. Guided CCD programming speeds setup, with picture mode for coordinate checks and real-time monitoring. Choose English or Chinese, with WiFi updates via MES. Data traces each solder point, cutting training time for fast starts.

| Specification

| On-line Selective Wave Soldering Machine | ||||

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1 | I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System | ||||

| Nozzle Quantity | 1 | 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System | ||||

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic | |||

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set | |||

| Spray Nozzle Size | 130um (180um, 210um Option) | |||

| Spray Speed | 0~20mm/s | |||

| Spray Nozzle Move Speed | 0~400mm/s | |||

| Preheating System | ||||

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 | |||

| Bottom Preheating Power | Max.12kw | |||

| Top Preheating Power | Max.6kw | |||

| Warm-up Time | Approx.15min (setting 150℃) | |||

| Control Mode | PC+PLC | |||

| Transport System | ||||

| PCB Size (with fixture) | 120*60~500*500mm | |||

| PCB Replacement | Online | |||

| PCB Top Clearance | 120mm | |||

| Transport Height | 900±20mm | |||

| Transport Width | 60~500mm | |||

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In October 2025, I.C.T engineers visited a European client to support a new PCBA Automatic Selective Wave Soldering Machine SS550 setup. The video highlighted its quick setup, with precise flux spray and steady soldering on complex PCBs. Engineers trained the team and fine-tuned settings, ensuring smooth production within hours. The client praised the machine’s speed and I.C.T’s on-site expertise, boosting their output of high-quality boards for automotive use.

| Professional Service and Training

I.C.T provides full support for the Pcba Automatic Selective Wave Soldering Machine with on-site installs and 24/7 help. Our engineers offer training on operation and maintenance, plus remote assistance to match your needs. With 26 years in SMT, we optimize your line for speed. Long-term plans include regular checks, keeping your production worry-free and fast.

| Customer Praise

Clients rave about I.C.T engineers’ quick setup skills on the Pcba Automatic Selective Wave Soldering Machine. The machine’s fast, clean soldering wins praise, with secure packaging ensuring safe delivery. Rapid issue fixes keep lines running, with one user noting, "I.C.T’s speed saved us days!" This builds strong trust.

| Industry Certifications

The PCBA Automatic Selective Wave Soldering Machine holds CE, RoHS, and ISO9001 certifications, meeting global standards. I.C.T’s patents on wave and flux tech show innovation. These credentials guarantee safe, reliable equipment for quick production worldwide.

| About I.C.T Company and Factory

I.C.T leads SMT with in-house R&D and three factories, growing to 89 staff over 26 years. We serve 1600+ clients in 72 countries, offering quick Selective Wave Soldering solutions with strict testing and quality systems. Our global network and compact designs support fast setups. We innovate daily, building partnerships for your factory’s success.