I.C.T-5146CW

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT AOI Coating Inspector

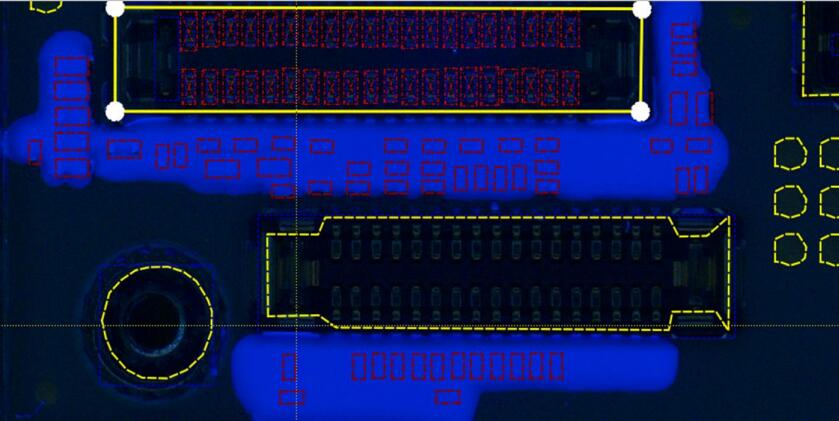

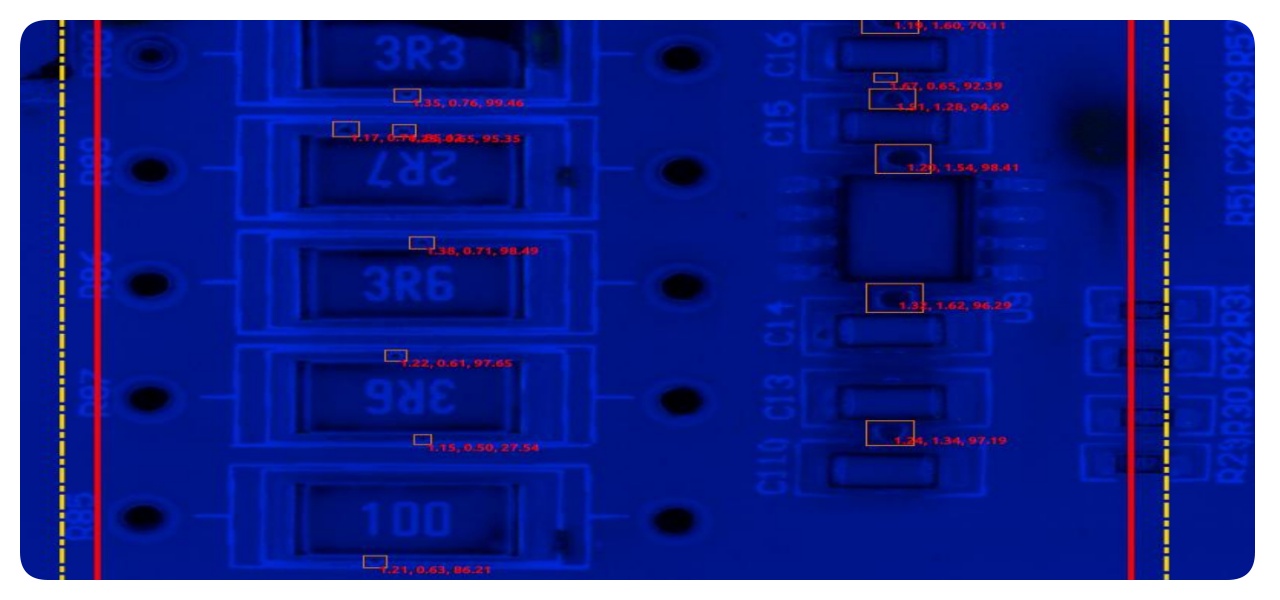

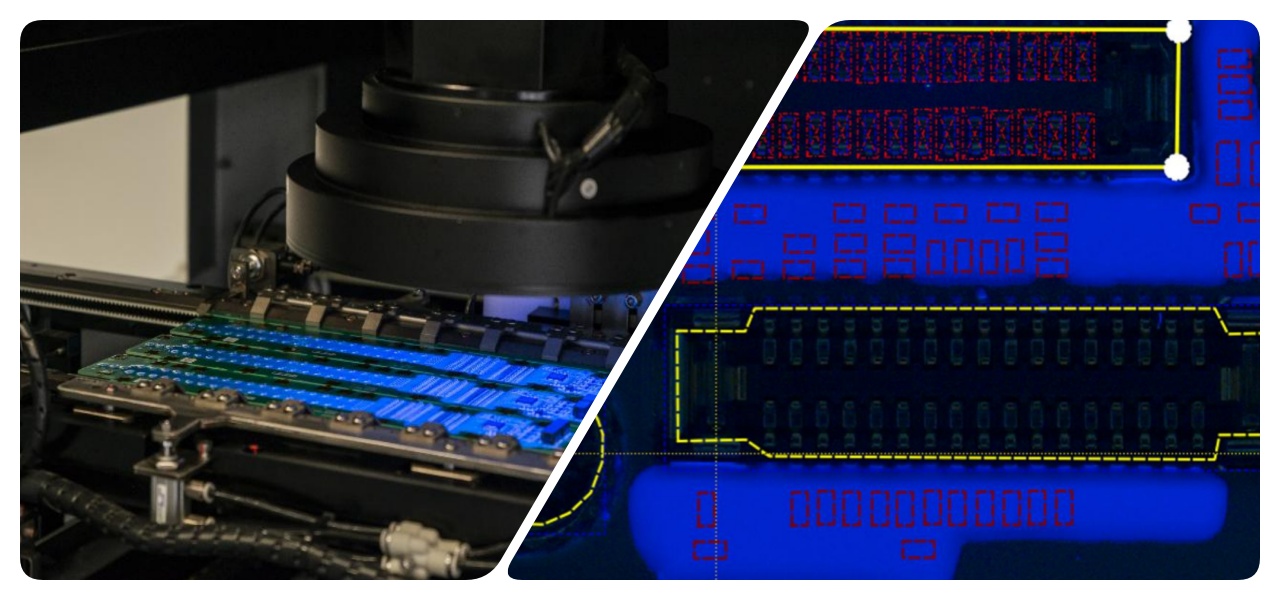

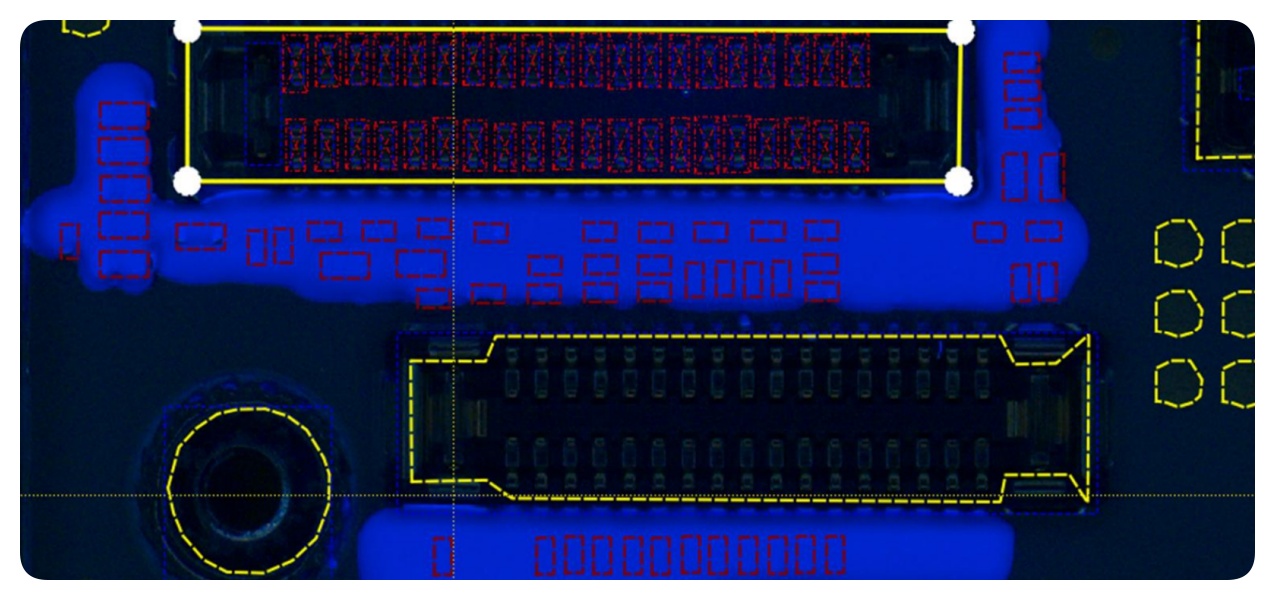

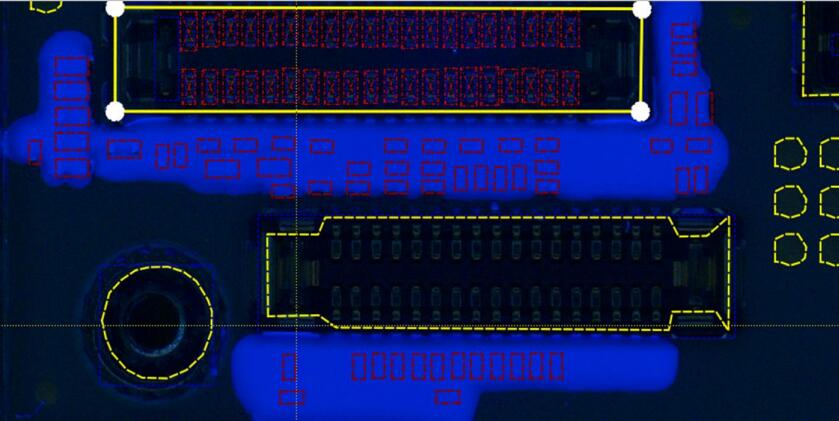

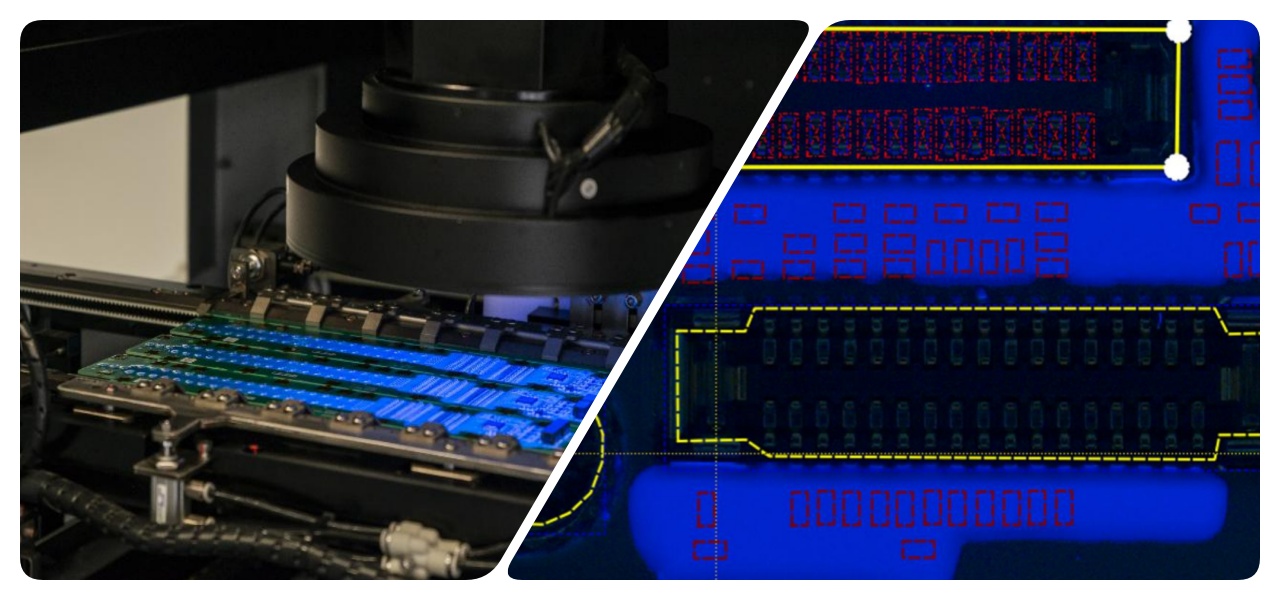

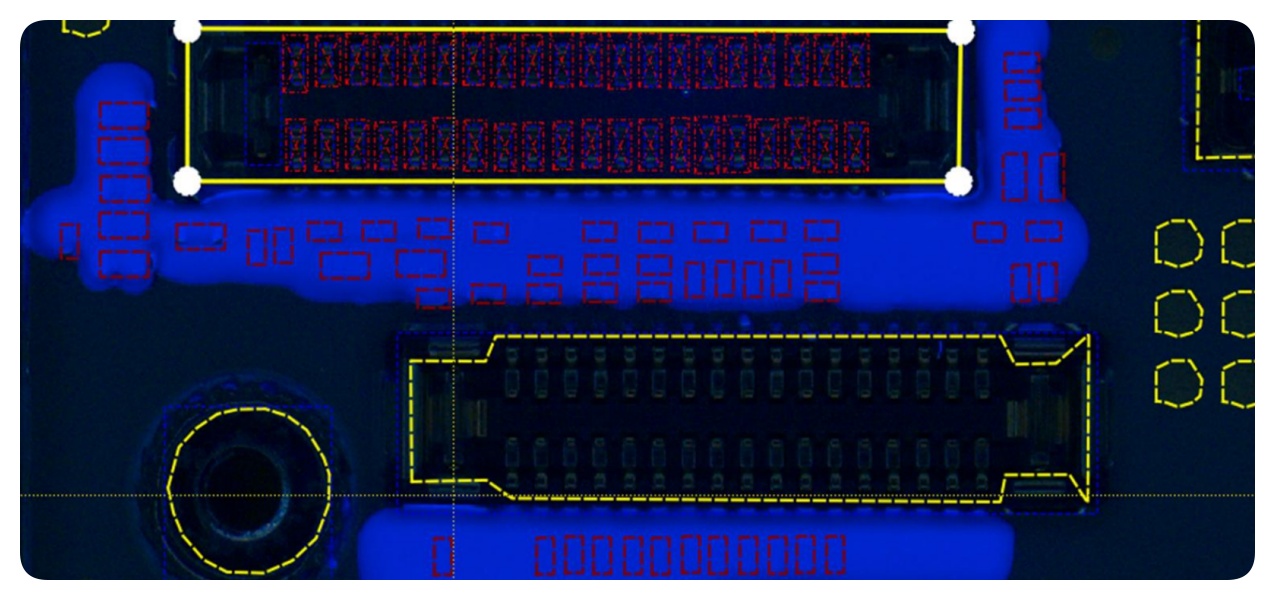

The pcb test machine aoi machine, model AI-5146C, excels in online inspection for conformal coatings on PCBs. It uses a high-precision color camera to capture images in real time and applies CNN algorithms to judge defects intelligently. This automatic pcb aoi machine locks coating borders automatically and identifies areas without halting production. It handles various issues like excessive or insufficient coating, air bubbles, and foreign objects. UV light sources make phosphorus-containing glues stand out clearly. Configurations support whole-board or double-side inspections, fitting SMT and DIP applications. Data traceability includes SPC alarms, log storage, and NG warnings for better quality control. Remote programming and centralized management boost operational efficiency. Overall, this pcb test machine aoi machine ensures reliable results in high-volume manufacturing environments, reducing false alarms and setup times significantly.

| Feature

Our pcb test machine aoi machine leverages deep learning to optimize data and simplify programming tasks. It identifies components and solder joints with one click, cutting down on time and errors compared to traditional methods. The system auto-detects coating zones and creates matching shapes intelligently. Users can switch light sources to check SMT, DIP, or soldering defects easily. As an automatic pcb aoi machine, it accommodates multi-panel and mixed boards up to 510x460mm in size.

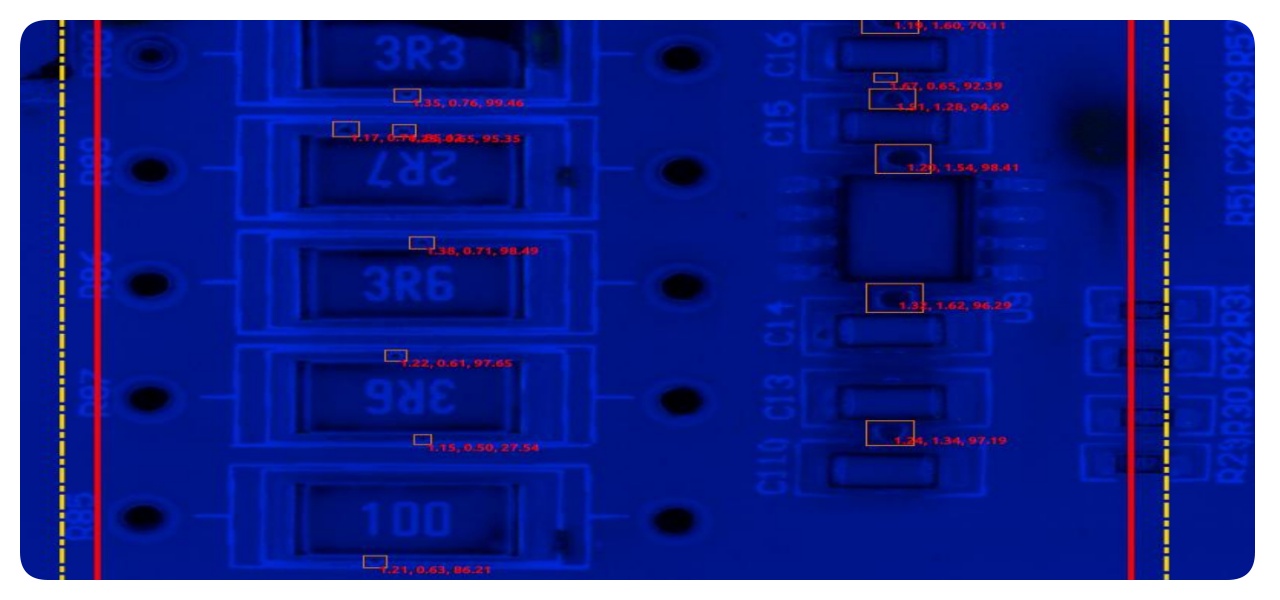

The pcb test machine aoi machine employs specialized algorithms to spot bubbles as tiny as 0.05mm and foreign items like hair strands without manual input. It visualizes bubble values and provides glue width metrics, including averages, minima, and maxima, for standardized evaluations. Non-coated spots can be shielded with custom frames to prevent false positives and minimize rejudgments.

Setup on the pcb test machine aoi machine is quick, needing just 10-15 minutes with flexible offline or online choices. Areas can be selected in any shape, with automatic ion checkboxes for coating decisions. Files from existing formats load directly, skipping repeated tweaks. Bad mark skipping and rotation identification at various angles add versatility.

Operating at 0.23 seconds per FOV, the pcb test machine aoi machine conducts checks without stopping board flow. UV and white lights offer clear defect views, handling large boards up to 690x460mm and weights to 3kg. Precision motion via AC servo drivers achieves 0.01mm accuracy.

| Specification

| Model | I.C.T Coating Online AOI AI-5146C | I.C.T Coating Online AOI AI-5146CW |

| FOV | 15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm | 21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution | 15um(Standard), 10um | 21.5um(standard) /15um /10um |

| Camera | Single side camera12M | Dual side camera 5M |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:25mm, Bottom:80mm | Top:75mm,Bottom:70mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | 570W |

| Communication | SMEMA | |

| Weight | 750Kg | 890Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

In a recent electronics manufacturing project, we installed a double-sided coating line with return conveyor for a client. The video demonstrates the entire workflow from elevator to unloader, featuring machines such as coating loader, coater, elevator, coating AOI, IR curing oven, selector conveyor, flipper, and unloader. The line includes bottom fixture return for efficient operations and barcode scanning across all stages. It automatically detects PCB top and bottom sides, loading the appropriate programs for production.

| Service and Training Support

I.C.T delivers comprehensive services for the pcb test machine aoi machine, covering installation, maintenance, and ongoing support. Our team provides on-site setups and remote debugging to minimize downtime. Training sessions teach operation, programming, and troubleshooting in clear, practical ways. Global centers ensure fast responses to issues, with spare parts readily available.

| Customer Reviews

Customers often praise our engineers for their knowledge and rapid problem-solving during installations. They highlight the pcb test machine aoi machine for its accuracy and user-friendly design. Secure packaging and timely shipping prevent any damage in transit. Quick responses to queries strengthen partnerships and efficiency. Many note the robust build quality that withstands daily use. Service teams earn compliments for thorough training sessions.

| Certifications and Standards

I.C.T holds essential certifications like CE, RoHS, ISO9001, and various patents for the pcb test machine aoi machine. These ensure compliance with global standards for safety and environmental protection. Rigorous testing processes verify performance and reliability. Patents cover innovative features in inspection technology.

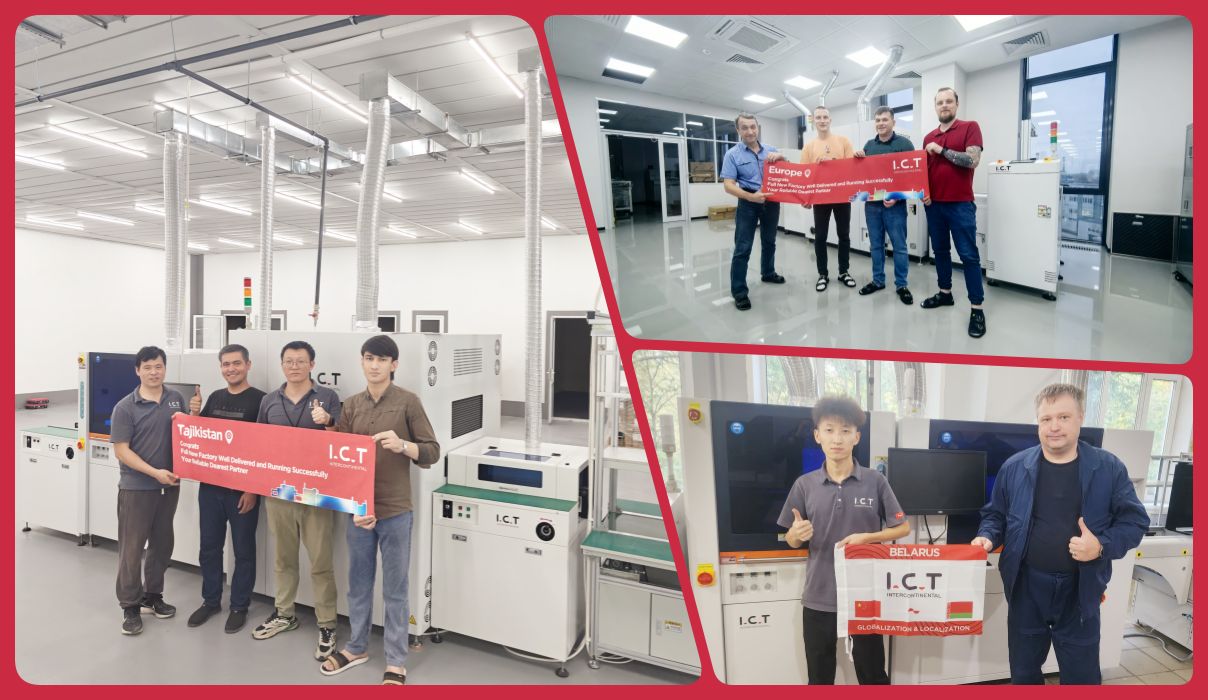

| About I.C.T Company and Our SMT Factory

I.C.T leads in SMT solutions with in-house R&D and manufacturing capabilities. Our team exceeds 89 members, driving rapid growth in recent years. We serve over 1600 customers across 72 countries worldwide.Factories implement strict inspection flows and robust quality management systems. This ensures consistent high standards in all products. Our vision as a cross-value platform emphasizes integrity, openness, and sharing.

| I.C.T SMT AOI Coating Inspector

The pcb test machine aoi machine, model AI-5146C, excels in online inspection for conformal coatings on PCBs. It uses a high-precision color camera to capture images in real time and applies CNN algorithms to judge defects intelligently. This automatic pcb aoi machine locks coating borders automatically and identifies areas without halting production. It handles various issues like excessive or insufficient coating, air bubbles, and foreign objects. UV light sources make phosphorus-containing glues stand out clearly. Configurations support whole-board or double-side inspections, fitting SMT and DIP applications. Data traceability includes SPC alarms, log storage, and NG warnings for better quality control. Remote programming and centralized management boost operational efficiency. Overall, this pcb test machine aoi machine ensures reliable results in high-volume manufacturing environments, reducing false alarms and setup times significantly.

| Feature

Our pcb test machine aoi machine leverages deep learning to optimize data and simplify programming tasks. It identifies components and solder joints with one click, cutting down on time and errors compared to traditional methods. The system auto-detects coating zones and creates matching shapes intelligently. Users can switch light sources to check SMT, DIP, or soldering defects easily. As an automatic pcb aoi machine, it accommodates multi-panel and mixed boards up to 510x460mm in size.

The pcb test machine aoi machine employs specialized algorithms to spot bubbles as tiny as 0.05mm and foreign items like hair strands without manual input. It visualizes bubble values and provides glue width metrics, including averages, minima, and maxima, for standardized evaluations. Non-coated spots can be shielded with custom frames to prevent false positives and minimize rejudgments.

Setup on the pcb test machine aoi machine is quick, needing just 10-15 minutes with flexible offline or online choices. Areas can be selected in any shape, with automatic ion checkboxes for coating decisions. Files from existing formats load directly, skipping repeated tweaks. Bad mark skipping and rotation identification at various angles add versatility.

Operating at 0.23 seconds per FOV, the pcb test machine aoi machine conducts checks without stopping board flow. UV and white lights offer clear defect views, handling large boards up to 690x460mm and weights to 3kg. Precision motion via AC servo drivers achieves 0.01mm accuracy.

| Specification

| Model | I.C.T Coating Online AOI AI-5146C | I.C.T Coating Online AOI AI-5146CW |

| FOV | 15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm | 21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution | 15um(Standard), 10um | 21.5um(standard) /15um /10um |

| Camera | Single side camera12M | Dual side camera 5M |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:25mm, Bottom:80mm | Top:75mm,Bottom:70mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | 570W |

| Communication | SMEMA | |

| Weight | 750Kg | 890Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

In a recent electronics manufacturing project, we installed a double-sided coating line with return conveyor for a client. The video demonstrates the entire workflow from elevator to unloader, featuring machines such as coating loader, coater, elevator, coating AOI, IR curing oven, selector conveyor, flipper, and unloader. The line includes bottom fixture return for efficient operations and barcode scanning across all stages. It automatically detects PCB top and bottom sides, loading the appropriate programs for production.

| Service and Training Support

I.C.T delivers comprehensive services for the pcb test machine aoi machine, covering installation, maintenance, and ongoing support. Our team provides on-site setups and remote debugging to minimize downtime. Training sessions teach operation, programming, and troubleshooting in clear, practical ways. Global centers ensure fast responses to issues, with spare parts readily available.

| Customer Reviews

Customers often praise our engineers for their knowledge and rapid problem-solving during installations. They highlight the pcb test machine aoi machine for its accuracy and user-friendly design. Secure packaging and timely shipping prevent any damage in transit. Quick responses to queries strengthen partnerships and efficiency. Many note the robust build quality that withstands daily use. Service teams earn compliments for thorough training sessions.

| Certifications and Standards

I.C.T holds essential certifications like CE, RoHS, ISO9001, and various patents for the pcb test machine aoi machine. These ensure compliance with global standards for safety and environmental protection. Rigorous testing processes verify performance and reliability. Patents cover innovative features in inspection technology.

| About I.C.T Company and Our SMT Factory

I.C.T leads in SMT solutions with in-house R&D and manufacturing capabilities. Our team exceeds 89 members, driving rapid growth in recent years. We serve over 1600 customers across 72 countries worldwide.Factories implement strict inspection flows and robust quality management systems. This ensures consistent high standards in all products. Our vision as a cross-value platform emphasizes integrity, openness, and sharing.