I.C.T-W2

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| W-Series Lead-Free PCB Wave Soldering Equipment

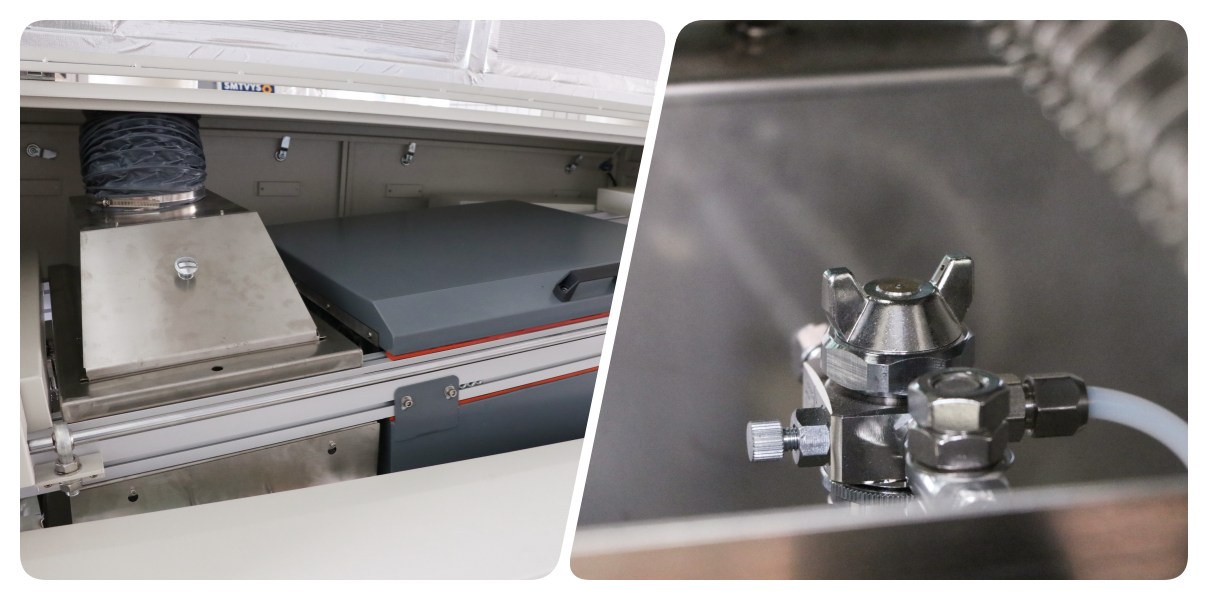

The W-Series Lead-Free PCB Wave Soldering Equipment is a mature product from I.C.T, proven through years of market testing and receiving long-term positive feedback from customers. It features unmatched heating performance and a precise temperature control system, meeting the needs of various welding processes, especially with its energy-saving design that significantly reduces operating costs.

Supporting a maximum PCB size of 400mm, a solder pot capacity of 180kg, and a transmission height of 750±20mm, this automatic wave soldering machine is ideal for automotive electronics, communications, and consumer products. Equipped with Japan Kuroda nozzles and PLC control, it ensures safety and efficiency. I.C.T provides global installation, maintenance, and training services, helping customers optimize production and enhance efficiency.

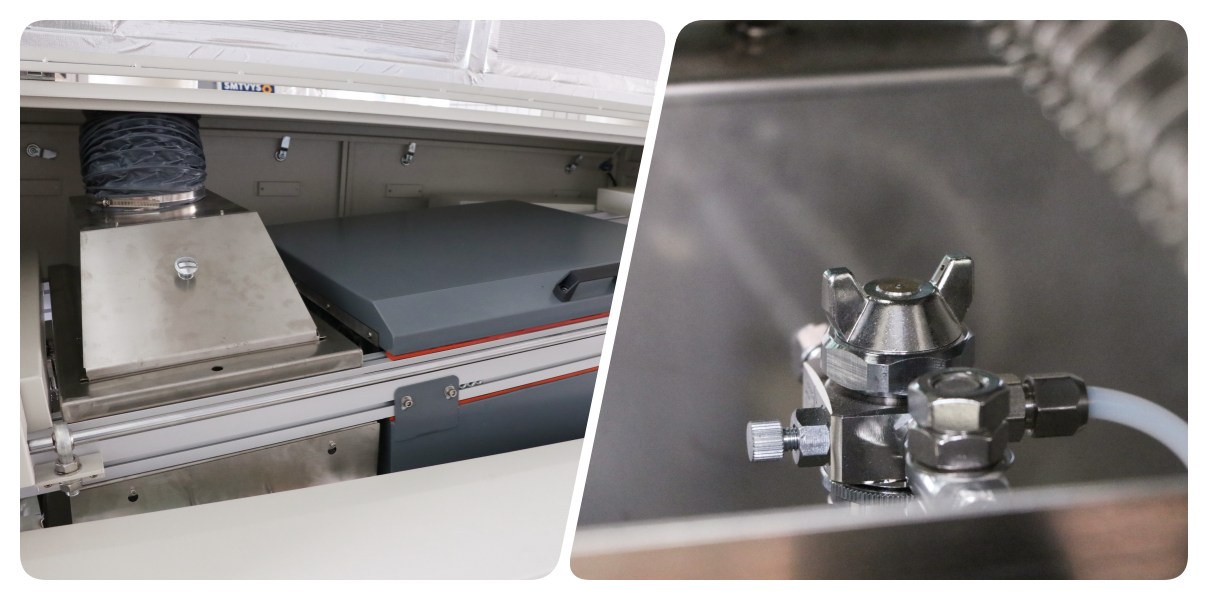

| Feature

The W-Series features a precise spray system with adjustable Japan Kuroda nozzles, ensuring long-term spray uniformity and reliability. PLC or manual switch control allows accurate adjustment of spray time, speed, and FLUX flow, with digital settings for flow, angle, density, and width that can be recorded. This system promotes economy and environmental protection while reducing FLUX waste with a pyramid-shaped mask and filter screen, making it a cost-effective choice for high-volume PCB production.

Safety is prioritized with third-party over-temperature protection and multiple safety layers, ensuring secure operation of this Automatic DIP Soldering Machine. The horizontal heating design prevents interference between zones, delivering an accurate temperature curve suitable for sensitive electronics like automotive and communication devices. This robust protection extends equipment lifespan and provides peace of mind.

The heating module’s horizontal design ensures independent zone operation, offering high production capacity and heat exchange efficiency. With PLC and PID control for real-time temperature monitoring, it adapts to diverse welding needs, preheating to 150°C in just 15 minutes. This efficiency suits fast-paced manufacturing environments, enhancing productivity for PCB Wave Soldering Equipment users.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2024, two I.C.T engineers traveled to Uruguay to service a client manufacturing smart meters, as showcased in a video featuring positive customer feedback. The footage highlights the use of equipment including a board loader, placement machines 471 and 481, Lyra622, AOI, corner conveyor, W2 PCB Wave Soldering Equipment, junction station, material frame belt line, roller line, and bullseye workbench.

Clients praised the engineers’ expertise and rapid response, noting the W2’s stable performance and excellent welding quality, which boosted smart meter production efficiency and fostered future collaboration interest.

| Expert Services and Training

I.C.T offers comprehensive services and training, including equipment installation, maintenance, and operational guidance for the automatic wave soldering machine. Our global network of engineers, spanning 72 countries, provides on-site support and tailored training to optimize production processes. We also offer technical upgrades and process adjustments to keep clients competitive. With 25 years of experience and a team of 20 engineers, I.C.T ensures timely responses and long-term partnerships, making us a trusted partner in PCB manufacturing.

| Customer Testimonials

Customers consistently praise I.C.T engineers for their professional skills and quick problem-solving, especially during overseas services like in Uruguay. The PCB Wave Soldering Equipment is lauded for its reliable welding quality and high efficiency, meeting the demands of smart meter production.

Clients also commend our sturdy packaging, ensuring safe equipment delivery, and our rapid response to technical issues, often resolved within hours. Many consider I.C.T a dependable partner, with feedback highlighting our commitment to customer satisfaction and innovative solutions.

| Quality Certifications

I.C.T’s PCB Wave Soldering Equipment holds prestigious certifications including CE, RoHS, ISO9001, and multiple patents, reflecting our adherence to global safety and quality standards. These credentials ensure the automatic wave soldering machine’s reliability and performance, tested rigorously in our 12,000m² factory. With a focus on innovation, our patented technologies enhance durability and efficiency, giving customers confidence in choosing I.C.T for their manufacturing needs.

| About I.C.T Company and Factory

I.C.T is a leading innovator with in-house research, development, and production capabilities, employing a large team that has grown rapidly over 25 years. Serving over 1,600 clients across 72 countries, we provide full SMT factory solutions from our 12,000m² industrial park in Dongguan, China. Our factory features strict quality control processes and a robust management system, ensuring top-tier PCB Wave Soldering Equipment. With eight branch offices and a $30 million registered fund, I.C.T continues to expand globally, delivering reliable, high-quality products and services worldwide.

| W-Series Lead-Free PCB Wave Soldering Equipment

The W-Series Lead-Free PCB Wave Soldering Equipment is a mature product from I.C.T, proven through years of market testing and receiving long-term positive feedback from customers. It features unmatched heating performance and a precise temperature control system, meeting the needs of various welding processes, especially with its energy-saving design that significantly reduces operating costs.

Supporting a maximum PCB size of 400mm, a solder pot capacity of 180kg, and a transmission height of 750±20mm, this automatic wave soldering machine is ideal for automotive electronics, communications, and consumer products. Equipped with Japan Kuroda nozzles and PLC control, it ensures safety and efficiency. I.C.T provides global installation, maintenance, and training services, helping customers optimize production and enhance efficiency.

| Feature

The W-Series features a precise spray system with adjustable Japan Kuroda nozzles, ensuring long-term spray uniformity and reliability. PLC or manual switch control allows accurate adjustment of spray time, speed, and FLUX flow, with digital settings for flow, angle, density, and width that can be recorded. This system promotes economy and environmental protection while reducing FLUX waste with a pyramid-shaped mask and filter screen, making it a cost-effective choice for high-volume PCB production.

Safety is prioritized with third-party over-temperature protection and multiple safety layers, ensuring secure operation of this Automatic DIP Soldering Machine. The horizontal heating design prevents interference between zones, delivering an accurate temperature curve suitable for sensitive electronics like automotive and communication devices. This robust protection extends equipment lifespan and provides peace of mind.

The heating module’s horizontal design ensures independent zone operation, offering high production capacity and heat exchange efficiency. With PLC and PID control for real-time temperature monitoring, it adapts to diverse welding needs, preheating to 150°C in just 15 minutes. This efficiency suits fast-paced manufacturing environments, enhancing productivity for PCB Wave Soldering Equipment users.

| DIP Line Equipment List

| Model | W4 | W3 | W2 |

| Dimension:(mm) | 4200X1250X1500 | 3600X1250X1500 | 2900X1160X1500 |

| Weight(kg) | Approx.1500kg | Approx.1200kg | Approx.790kg |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 32kw | 24kw | 16kw |

| Operation Power | 12kw | 9kw | 7kw |

| Control System | PLC | ||

| Spray System | |||

| Transmission Method | Step motor | ||

| Spray Pressure | 0.25Mpa--0.4Mpa | ||

| lux flow | 10--100ml/min | ||

| Exhaust Diameter | Φ200mm | ||

| Exhaust Capacity | 25m3/min | ||

| Preheating System | |||

| Preheating Mode | Hot air | ||

| Control Mode | PID + SSR | ||

| Preheating Zone | 4 | 3 | 2 |

| Preheating Length | 1800mm | 1600mm | 1200mm |

| Preheating Temp. | (Room Temperature)-250°C | ||

| Warm-up Time(min) | Approx.15min (setting 150°C) | ||

| Conveyor System | |||

| PCB Size:LxW(mm) | Min:80x60mm; Max:400x300mm | ||

| Conveyor Speed | 0-2000(mm/min) | ||

| Conveyor Height | 750+/-20 (mm) | ||

| Finger | Double hook claw (Standard) | ||

| Conveyor width control | Manually | ||

| Conveyor Angle | 4~7degree | ||

| Soldering System | |||

| Solder Pot style | Mechanical Motor drive | ||

| Solder Pot Material | Full Titanium (Standard FT) | ||

| Solder pot temperature | 300°C | ||

| Solder pot capacity | Lead-free 350kg | Lead-free 300kg | Lead-free 250kg |

| Other | |||

| Finger cleaning system | Brush | ||

| DIP Line Equipment List

Our DIP production line offers advanced tools for efficient and precise PCB assembly. The fully automated DIP line includes a DIP insertion line for accurate component placement, a wave loader for smooth PCB entry, a wave unloader for safe exit, and an assembly belt line for final checks. This high-quality PCB DIP production line ensures stable operation, reliable THT insertion, and cost-effective assembly, meeting diverse industry needs. With modular designs and global support from I.C.T, it boosts productivity for through-hole tasks.

| Customer Success Video

In 2024, two I.C.T engineers traveled to Uruguay to service a client manufacturing smart meters, as showcased in a video featuring positive customer feedback. The footage highlights the use of equipment including a board loader, placement machines 471 and 481, Lyra622, AOI, corner conveyor, W2 PCB Wave Soldering Equipment, junction station, material frame belt line, roller line, and bullseye workbench.

Clients praised the engineers’ expertise and rapid response, noting the W2’s stable performance and excellent welding quality, which boosted smart meter production efficiency and fostered future collaboration interest.

| Expert Services and Training

I.C.T offers comprehensive services and training, including equipment installation, maintenance, and operational guidance for the automatic wave soldering machine. Our global network of engineers, spanning 72 countries, provides on-site support and tailored training to optimize production processes. We also offer technical upgrades and process adjustments to keep clients competitive. With 25 years of experience and a team of 20 engineers, I.C.T ensures timely responses and long-term partnerships, making us a trusted partner in PCB manufacturing.

| Customer Testimonials

Customers consistently praise I.C.T engineers for their professional skills and quick problem-solving, especially during overseas services like in Uruguay. The PCB Wave Soldering Equipment is lauded for its reliable welding quality and high efficiency, meeting the demands of smart meter production.

Clients also commend our sturdy packaging, ensuring safe equipment delivery, and our rapid response to technical issues, often resolved within hours. Many consider I.C.T a dependable partner, with feedback highlighting our commitment to customer satisfaction and innovative solutions.

| Quality Certifications

I.C.T’s PCB Wave Soldering Equipment holds prestigious certifications including CE, RoHS, ISO9001, and multiple patents, reflecting our adherence to global safety and quality standards. These credentials ensure the automatic wave soldering machine’s reliability and performance, tested rigorously in our 12,000m² factory. With a focus on innovation, our patented technologies enhance durability and efficiency, giving customers confidence in choosing I.C.T for their manufacturing needs.

| About I.C.T Company and Factory

I.C.T is a leading innovator with in-house research, development, and production capabilities, employing a large team that has grown rapidly over 25 years. Serving over 1,600 clients across 72 countries, we provide full SMT factory solutions from our 12,000m² industrial park in Dongguan, China. Our factory features strict quality control processes and a robust management system, ensuring top-tier PCB Wave Soldering Equipment. With eight branch offices and a $30 million registered fund, I.C.T continues to expand globally, delivering reliable, high-quality products and services worldwide.