I.C.T AI-5133D

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT Online 3D AOI

Dive into the I.C.T AI-5133D, a top-notch machine inspection aoi built for real-time checks right after SMT reflow. It grabs crisp board pictures with a super color camera and uses 3D light patterns plus AI smarts to measure heights spot-on and flag defects without guesswork. This machine inspection aoi hunts down problems like low solder, bridges, holes, hidden pins, dirt, shifts, lost parts, tilts, stand-ups, side flips, wrong items, breaks, lifts, polarity mix-ups, fake joints, dry spots, or glue overflows. Deep learning wipes out slow setups and annoying false calls from old tech. Hook it to a central PC for team control, link to MES for data flow, and tweak remotely. Pick from various setups to match your line, with clever bend fixes on the fly. In short, this optical inspection aoi machine turns quality checks into a breeze for busy electronics shops.

| Feature

Unlock magic with the AI-5133D machine inspection aoi's deep learning core—it spots parts and joints in one click after big data training. Say goodbye to endless programming and pesky false alarms; CNN thinks like a pro eye for all kinds of tricky boards. This keeps detection super high and errors super low, perfect for fast SMT runs. It even streamlines industrial tests, nailing the big headaches of time and mistakes in everyday use.

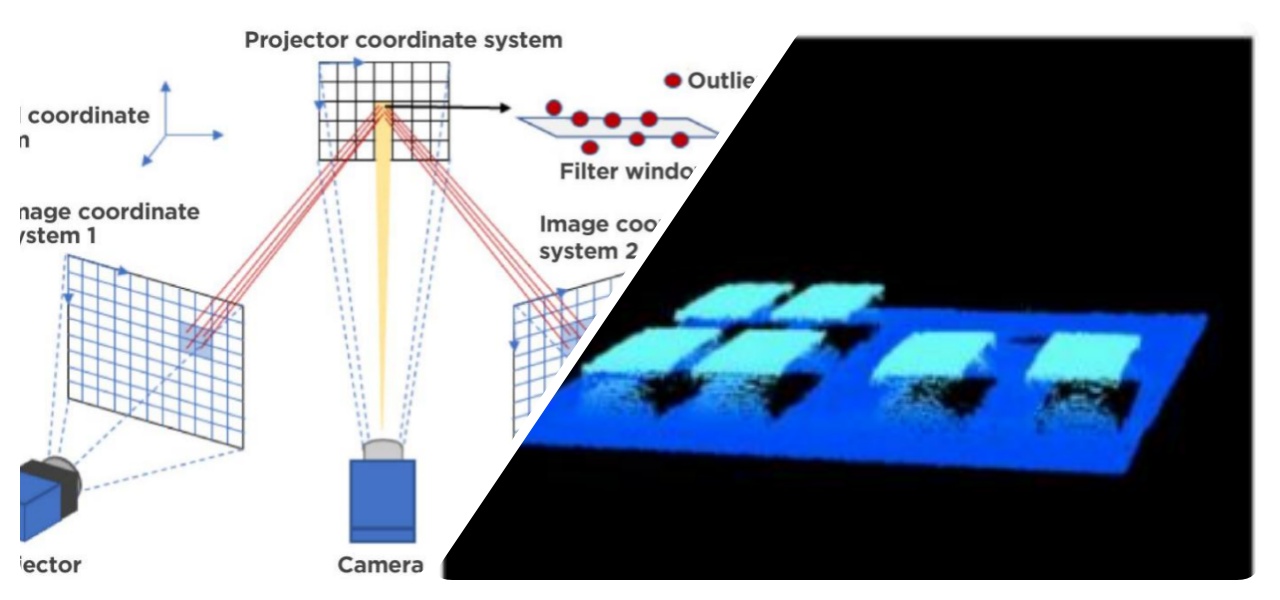

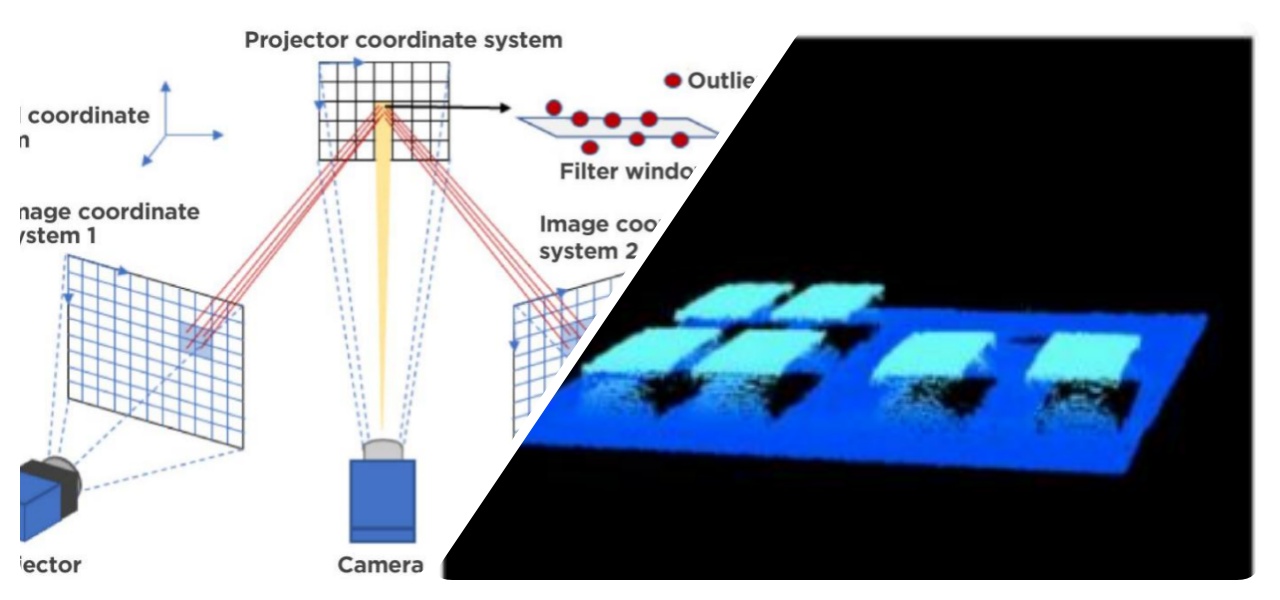

The machine inspection aoi shines with lights shooting from every angle to zap interference and odd depth spots. Phase maps calibrate cleanly, depth filters hush noise, and reflection tricks fix twists. Use four or eight projectors to chase away shadows via smart neighbor blending. Edge tweaks and AI polish give crystal 3D views every time. Result? Pinpoint catches on height quirks like lifts or skimpy solder, making this a cheap and high quality aoi machine for PCB a go-to for clear, trustworthy scans.

Jumpstart with AI magic in the AI-5133D machine inspection aoi: box it once, auto-match tricks, and batch-shift settings in a snap. Work online or off without pausing the belt. Central hub ties machines, feeds MES, and sorts via cloud brains. This bendy approach handles quick swaps and remote tweaks, suiting any inspection flavor your factory throws at it.

Rock-solid performance defines this machine inspection aoi—GR&R dips below 10% at 6 Sigma, shifts under ±0.25mm. Self-tuning planes adjust board bases, dodging track wobbles or camera jiggles. Instant bend compensation locks in accuracy. Big data boosts part spotting and adapts to wild board changes. It nails fuzzies like dirt or shifts, slashing misses and wrong calls for rock-steady quality.

| Specification

| Model | I.C.T SMT AOI AI-5146-3D | I.C.T SMT AOI AI-5133D-3D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 15um@60*45mm | 10um@40*30mm |

| Camera | 12M Area scan high speed industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4-color integral light source + 4-direction structured light projection unit | |

| Inspection Speed | 0.55sec/FOV | |

| Inspection Algorithm | CNN, OCR, Color Contrast, Outline Recognition, Image contrast,etc | |

| Inspection Item | Component: Lifting legs, floating height, missing parts, excessive, flipping, reverse, mis-alignment, damage, skew, foreign objects, contamination, etc. Solder: Tin climbing height, excessive, insufficient, Briging, missing, pseudo, etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm) | Single rail: 50*50mm~510*610mm (Large board mode: Left to right: max 710*610mm) Dual rail: 50*50mm~510*330mm (Large board mode: Left to right: max 710*330mm) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:50(80)mm | Top:25mm,Bottom:50 (60)mm |

| PCB Thickness | 0.6 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 870Kg | 1080Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our SMT assembly line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB loader machine | Automatically loads bare PCBs to the line. |

| SMT stencil printer machine | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Solder Oven | Melts solder to form solid joints. |

| SMT X-ray | Inspects solder joints and placement defects. |

| 3d solder paste inspection | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: PCBA laser marking machine/Label Mounter/Inkjet Printer |

| Customer Success Video

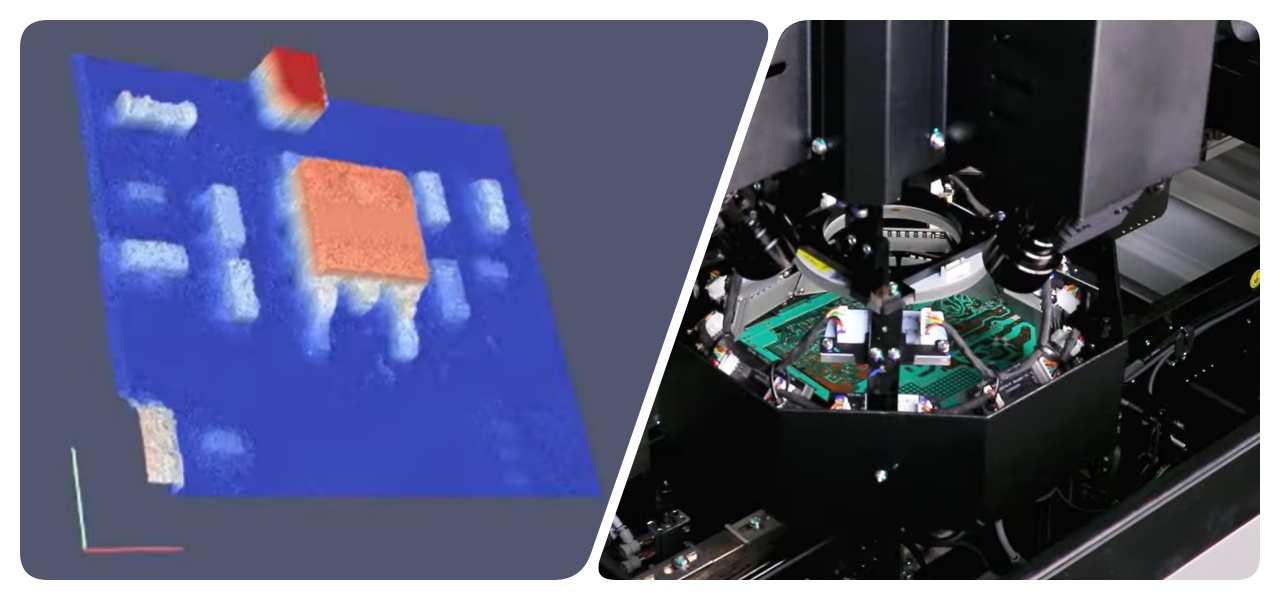

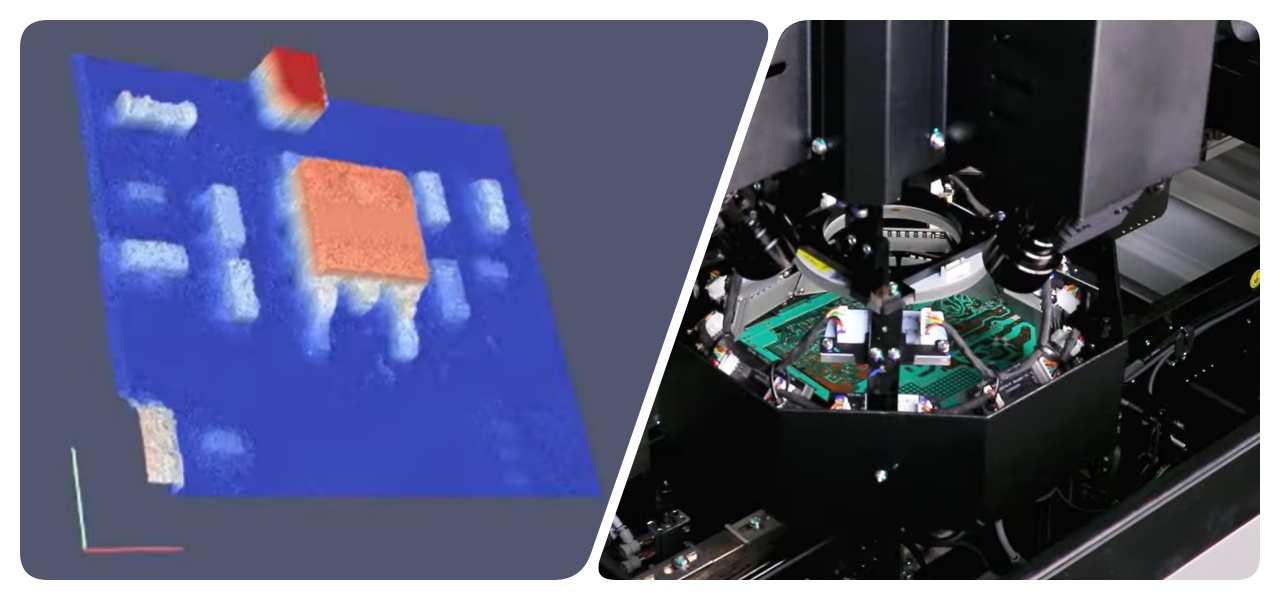

Our video introduces the AI-5146-3D aoi machine SMT's exterior and key features, showcasing its sleek design and functional highlights like 3D light sensors. It displays the internal components, such as cameras and projectors, for a clear view of build quality. The footage shows the machine in operation, scanning boards at high speed with real-time defect detection. AI programming is demonstrated through one-click setups and algorithm adjustments, highlighting efficiency. In one electronics factory, this 3d aoi machine caught solder issues early, reducing defects by 40% and rework time. Our team supported integration, leading to smoother lines and higher yields.

| Service and Training Support

I.C.T backs the AI-5133D machine inspection aoi with end-to-end help: installs, fixes, and custom lessons. Tech pros handle site starts and far-off tweaks for instant saves. Lessons dive into setups, runs, and fixes over 3-5 days to fit you. Grab parts, fresh code, and round-clock aid from world spots. This keeps stops rare and amps up your cheap and high quality aoi machine for PCB to peak power and lasting wins.

| Customer Reviews

Folks rave about our tech team's slick installs and speedy solves. They dig the machine inspection aoi's spot-on finds and no-fuss controls. Packs arrive safe, no dings ever. Queries get answers in hours, locking in faith. All in, this setup lifts work flows with trusty quality and backup.

| Certifications and Standards

I.C.T boasts CE for safe ops, RoHS for green builds, ISO9001 for tight quality, and fresh patents on AOI breakthroughs. These stamps prove our machine inspection aoi hits global bars, handing you peace on strength, play, and rules.

| About I.C.T Company and Our SMT Factory

I.C.T runs its own idea labs and build shops with 89 crew and 20 brainiac engineers in 12,000m² digs. Born 2012, we've zoomed ahead, aiding 1,600+ pals in 72 lands. Factories run tough checks and quality nets for ace gear. As a world-spanning value spot in electronics, we live integrity, ease, open doors, team play, and share for forever ties.

| I.C.T SMT Online 3D AOI

Dive into the I.C.T AI-5133D, a top-notch machine inspection aoi built for real-time checks right after SMT reflow. It grabs crisp board pictures with a super color camera and uses 3D light patterns plus AI smarts to measure heights spot-on and flag defects without guesswork. This machine inspection aoi hunts down problems like low solder, bridges, holes, hidden pins, dirt, shifts, lost parts, tilts, stand-ups, side flips, wrong items, breaks, lifts, polarity mix-ups, fake joints, dry spots, or glue overflows. Deep learning wipes out slow setups and annoying false calls from old tech. Hook it to a central PC for team control, link to MES for data flow, and tweak remotely. Pick from various setups to match your line, with clever bend fixes on the fly. In short, this optical inspection aoi machine turns quality checks into a breeze for busy electronics shops.

| Feature

Unlock magic with the AI-5133D machine inspection aoi's deep learning core—it spots parts and joints in one click after big data training. Say goodbye to endless programming and pesky false alarms; CNN thinks like a pro eye for all kinds of tricky boards. This keeps detection super high and errors super low, perfect for fast SMT runs. It even streamlines industrial tests, nailing the big headaches of time and mistakes in everyday use.

The machine inspection aoi shines with lights shooting from every angle to zap interference and odd depth spots. Phase maps calibrate cleanly, depth filters hush noise, and reflection tricks fix twists. Use four or eight projectors to chase away shadows via smart neighbor blending. Edge tweaks and AI polish give crystal 3D views every time. Result? Pinpoint catches on height quirks like lifts or skimpy solder, making this a cheap and high quality aoi machine for PCB a go-to for clear, trustworthy scans.

Jumpstart with AI magic in the AI-5133D machine inspection aoi: box it once, auto-match tricks, and batch-shift settings in a snap. Work online or off without pausing the belt. Central hub ties machines, feeds MES, and sorts via cloud brains. This bendy approach handles quick swaps and remote tweaks, suiting any inspection flavor your factory throws at it.

Rock-solid performance defines this machine inspection aoi—GR&R dips below 10% at 6 Sigma, shifts under ±0.25mm. Self-tuning planes adjust board bases, dodging track wobbles or camera jiggles. Instant bend compensation locks in accuracy. Big data boosts part spotting and adapts to wild board changes. It nails fuzzies like dirt or shifts, slashing misses and wrong calls for rock-steady quality.

| Specification

| Model | I.C.T SMT AOI AI-5146-3D | I.C.T SMT AOI AI-5133D-3D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 15um@60*45mm | 10um@40*30mm |

| Camera | 12M Area scan high speed industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4-color integral light source + 4-direction structured light projection unit | |

| Inspection Speed | 0.55sec/FOV | |

| Inspection Algorithm | CNN, OCR, Color Contrast, Outline Recognition, Image contrast,etc | |

| Inspection Item | Component: Lifting legs, floating height, missing parts, excessive, flipping, reverse, mis-alignment, damage, skew, foreign objects, contamination, etc. Solder: Tin climbing height, excessive, insufficient, Briging, missing, pseudo, etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm) | Single rail: 50*50mm~510*610mm (Large board mode: Left to right: max 710*610mm) Dual rail: 50*50mm~510*330mm (Large board mode: Left to right: max 710*330mm) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:50(80)mm | Top:25mm,Bottom:50 (60)mm |

| PCB Thickness | 0.6 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 870Kg | 1080Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our SMT assembly line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB loader machine | Automatically loads bare PCBs to the line. |

| SMT stencil printer machine | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Solder Oven | Melts solder to form solid joints. |

| SMT X-ray | Inspects solder joints and placement defects. |

| 3d solder paste inspection | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: PCBA laser marking machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Our video introduces the AI-5146-3D aoi machine SMT's exterior and key features, showcasing its sleek design and functional highlights like 3D light sensors. It displays the internal components, such as cameras and projectors, for a clear view of build quality. The footage shows the machine in operation, scanning boards at high speed with real-time defect detection. AI programming is demonstrated through one-click setups and algorithm adjustments, highlighting efficiency. In one electronics factory, this 3d aoi machine caught solder issues early, reducing defects by 40% and rework time. Our team supported integration, leading to smoother lines and higher yields.

| Service and Training Support

I.C.T backs the AI-5133D machine inspection aoi with end-to-end help: installs, fixes, and custom lessons. Tech pros handle site starts and far-off tweaks for instant saves. Lessons dive into setups, runs, and fixes over 3-5 days to fit you. Grab parts, fresh code, and round-clock aid from world spots. This keeps stops rare and amps up your cheap and high quality aoi machine for PCB to peak power and lasting wins.

| Customer Reviews

Folks rave about our tech team's slick installs and speedy solves. They dig the machine inspection aoi's spot-on finds and no-fuss controls. Packs arrive safe, no dings ever. Queries get answers in hours, locking in faith. All in, this setup lifts work flows with trusty quality and backup.

| Certifications and Standards

I.C.T boasts CE for safe ops, RoHS for green builds, ISO9001 for tight quality, and fresh patents on AOI breakthroughs. These stamps prove our machine inspection aoi hits global bars, handing you peace on strength, play, and rules.

| About I.C.T Company and Our SMT Factory

I.C.T runs its own idea labs and build shops with 89 crew and 20 brainiac engineers in 12,000m² digs. Born 2012, we've zoomed ahead, aiding 1,600+ pals in 72 lands. Factories run tough checks and quality nets for ace gear. As a world-spanning value spot in electronics, we live integrity, ease, open doors, team play, and share for forever ties.