I.C.T-AI-5146-3D

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT Online 3D AOI

The I.C.T AI-5146-3D is an advanced aoi machine SMT for online inspection after SMT reflow soldering. It uses a high-precision color camera to capture board images in real time and applies 3D structured light with AI algorithms to measure heights accurately and detect defects intelligently. This aoi machine SMT spots issues like insufficient solder, shorts, holes, misalignments, missing parts, skews, billboards, flips, wrong parts, floats, polarities, pseudo solders, and excess glue. With deep learning, it cuts programming time and false alarms from traditional methods. The system supports central control, MES docking, and remote debugging. It handles warpage with dynamic compensation and offers multiple configurations for different needs. Overall, this 3d aoi inspection machine boosts production reliability and speed in electronics factories.

| Feature

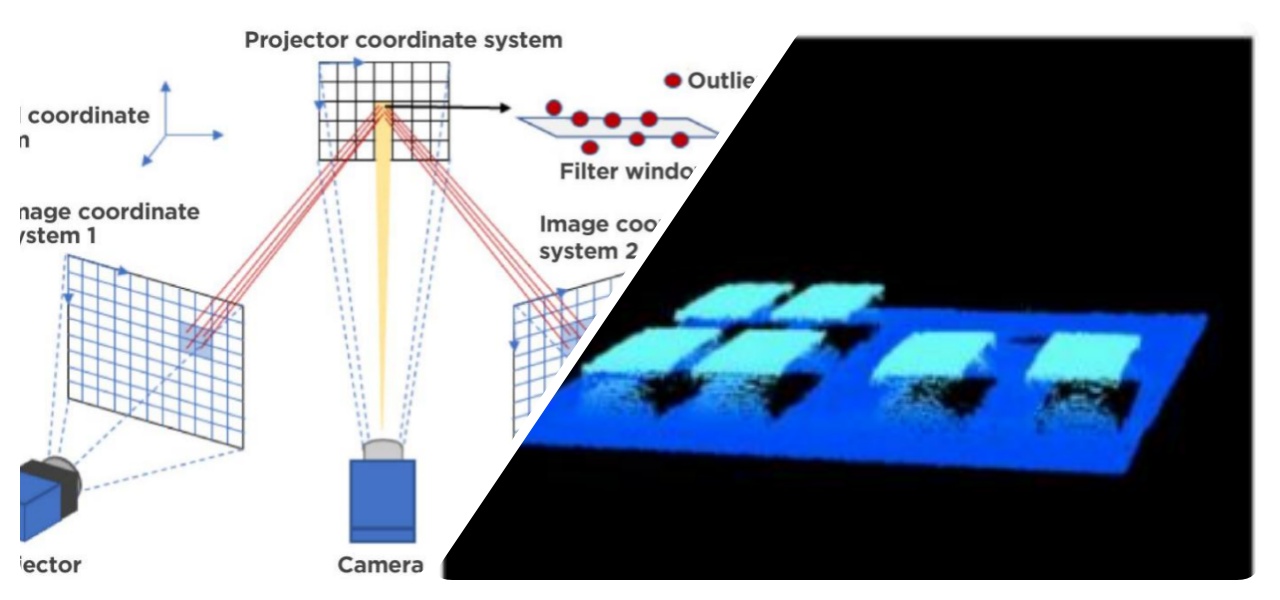

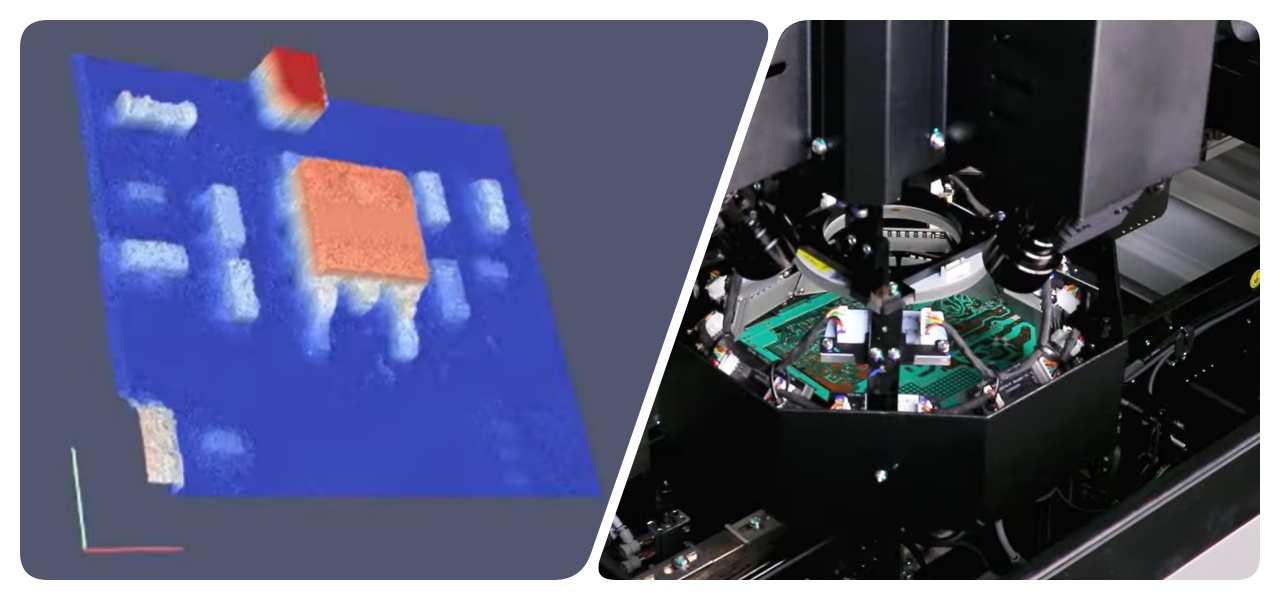

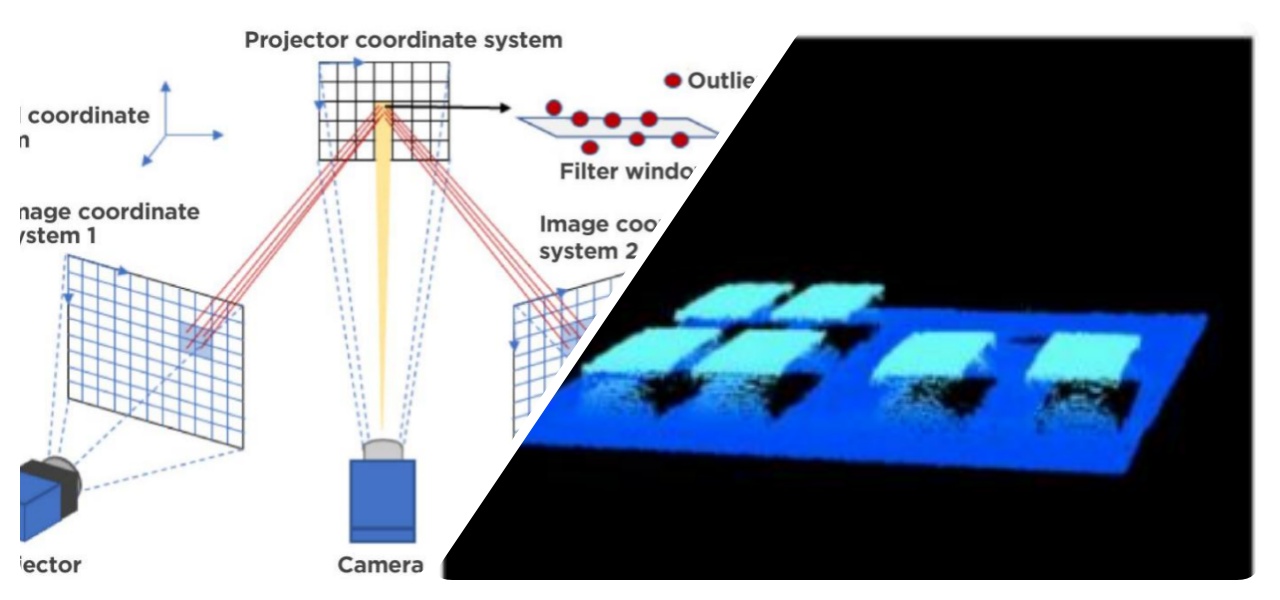

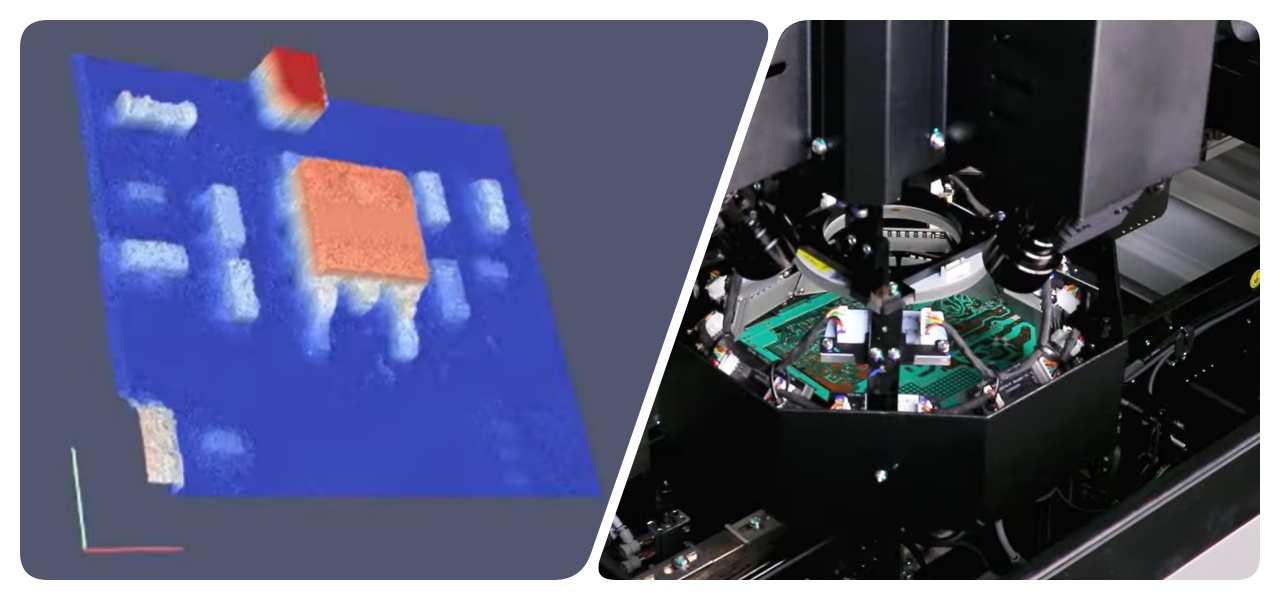

The AI-5146-3D aoi machine SMT uses deep learning for one-click identification of components and joints. Trained on big data, it enables smart judgments, addressing long programming and high false alarms. CNN processes images like human vision, handling diverse scenarios effectively. This ensures high inspection rates with low errors, ideal for complex SMT lines. It also optimizes 3D imaging by removing noise and outliers using multi-directional light and phase consistency.

This aoi machine SMT features multi-directional structured light sensors to minimize imaging interference. It removes deep outliers and noise with phase mapping and multiple reflection compensation. Shadowing issues are solved via four or eight projectors and neighborhood filtering. FOV edge correction and AI algorithms provide stable, accurate 3D reconstructions. This leads to reliable detection of height-related defects like floats or insufficient solder, enhancing overall quality control in aoi inspection machine for PCB tasks.

The AI-5146-3D aoi machine SMT offers online and offline programming without stopping the line. It takes minutes for setup with one-click box selection and batch parameter adjustments. Intelligent algorithms auto-match components like resistors and diodes. Audible alarms and intuitive reminders speed up fixes. This flexibility supports quick changeovers and file calls, fitting busy production environments.

Built for SMT, this aoi machine SMT has high accuracy in identifying components and solder with big data training. It corrects overhangs and reduces false alarms through fuzzy recognition. Irregular parts and varied colors are handled without interference. Generalization manages deviations and complex situations effectively. This results in thorough checks for defects like tombstoning or absent parts, maintaining low false rates.

| Specification

| Model | I.C.T SMT AOI AI-5146-3D | I.C.T SMT AOI AI-5133D-3D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 15um@60*45mm | 10um@40*30mm |

| Camera | 12M Area scan high speed industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4-color integral light source + 4-direction structured light projection unit | |

| Inspection Speed | 0.55sec/FOV | |

| Inspection Algorithm | CNN, OCR, Color Contrast, Outline Recognition, Image contrast,etc | |

| Inspection Item | Component: Lifting legs, floating height, missing parts, excessive, flipping, reverse, mis-alignment, damage, skew, foreign objects, contamination, etc. Solder: Tin climbing height, excessive, insufficient, Briging, missing, pseudo, etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm) | Single rail: 50*50mm~510*610mm (Large board mode: Left to right: max 710*610mm) Dual rail: 50*50mm~510*330mm (Large board mode: Left to right: max 710*330mm) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:50(80)mm | Top:25mm,Bottom:50 (60)mm |

| PCB Thickness | 0.6 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 870Kg | 1080Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Our video introduces the AI-5146-3D aoi machine SMT's exterior and key features, showcasing its sleek design and functional highlights like 3D light sensors. It displays the internal components, such as cameras and projectors, for a clear view of build quality. The footage shows the machine in operation, scanning boards at high speed with real-time defect detection. AI programming is demonstrated through one-click setups and algorithm adjustments, highlighting efficiency. In one electronics factory, this 3d aoi machine caught solder issues early, reducing defects by 40% and rework time. Our team supported integration, leading to smoother lines and higher yields.

| Service and Training Support

I.C.T provides full services for the AI-5146-3D aoi machine SMT, including installation, maintenance, and customized training. Engineers offer on-site setup and remote assistance for quick issue resolution. Training covers programming, operation, and troubleshooting, typically 3-5 days. We supply spare parts, updates, and 24-hour global support. This minimizes downtime and maximizes value from aoi machine manufacturers like us.

| Customer Reviews

Clients praise our engineers for skilled installations and fast fixes. They appreciate the equipment's accurate detection and easy interface. Shipping and packaging ensure safe arrival without damage. Quick responses to queries, often in hours, build strong trust. Overall, users say this system exceeds expectations in reliability and support.

| Certifications and Standards

I.C.T holds CE for safety, RoHS for eco-friendly materials, ISO9001 for quality management, and patents for innovative tech. These ensure our aoi machine SMT meets global standards, providing users with confidence in performance and compliance.

| About I.C.T Company and Our SMT Factory

I.C.T handles in-house R&D and production with over 89 staff and 20 engineers in a 12,000m² space. Since 2012, we've grown rapidly, serving 1,600+ customers in 72 countries. Our factory uses strict testing and quality systems to deliver top products. As a cross-value platform, we focus on integrity, coordination, and sharing for lasting partnerships.

| I.C.T SMT Online 3D AOI

The I.C.T AI-5146-3D is an advanced aoi machine SMT for online inspection after SMT reflow soldering. It uses a high-precision color camera to capture board images in real time and applies 3D structured light with AI algorithms to measure heights accurately and detect defects intelligently. This aoi machine SMT spots issues like insufficient solder, shorts, holes, misalignments, missing parts, skews, billboards, flips, wrong parts, floats, polarities, pseudo solders, and excess glue. With deep learning, it cuts programming time and false alarms from traditional methods. The system supports central control, MES docking, and remote debugging. It handles warpage with dynamic compensation and offers multiple configurations for different needs. Overall, this 3d aoi inspection machine boosts production reliability and speed in electronics factories.

| Feature

The AI-5146-3D aoi machine SMT uses deep learning for one-click identification of components and joints. Trained on big data, it enables smart judgments, addressing long programming and high false alarms. CNN processes images like human vision, handling diverse scenarios effectively. This ensures high inspection rates with low errors, ideal for complex SMT lines. It also optimizes 3D imaging by removing noise and outliers using multi-directional light and phase consistency.

This aoi machine SMT features multi-directional structured light sensors to minimize imaging interference. It removes deep outliers and noise with phase mapping and multiple reflection compensation. Shadowing issues are solved via four or eight projectors and neighborhood filtering. FOV edge correction and AI algorithms provide stable, accurate 3D reconstructions. This leads to reliable detection of height-related defects like floats or insufficient solder, enhancing overall quality control in aoi inspection machine for PCB tasks.

The AI-5146-3D aoi machine SMT offers online and offline programming without stopping the line. It takes minutes for setup with one-click box selection and batch parameter adjustments. Intelligent algorithms auto-match components like resistors and diodes. Audible alarms and intuitive reminders speed up fixes. This flexibility supports quick changeovers and file calls, fitting busy production environments.

Built for SMT, this aoi machine SMT has high accuracy in identifying components and solder with big data training. It corrects overhangs and reduces false alarms through fuzzy recognition. Irregular parts and varied colors are handled without interference. Generalization manages deviations and complex situations effectively. This results in thorough checks for defects like tombstoning or absent parts, maintaining low false rates.

| Specification

| Model | I.C.T SMT AOI AI-5146-3D | I.C.T SMT AOI AI-5133D-3D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 15um@60*45mm | 10um@40*30mm |

| Camera | 12M Area scan high speed industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4-color integral light source + 4-direction structured light projection unit | |

| Inspection Speed | 0.55sec/FOV | |

| Inspection Algorithm | CNN, OCR, Color Contrast, Outline Recognition, Image contrast,etc | |

| Inspection Item | Component: Lifting legs, floating height, missing parts, excessive, flipping, reverse, mis-alignment, damage, skew, foreign objects, contamination, etc. Solder: Tin climbing height, excessive, insufficient, Briging, missing, pseudo, etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm) | Single rail: 50*50mm~510*610mm (Large board mode: Left to right: max 710*610mm) Dual rail: 50*50mm~510*330mm (Large board mode: Left to right: max 710*330mm) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:50(80)mm | Top:25mm,Bottom:50 (60)mm |

| PCB Thickness | 0.6 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 870Kg | 1080Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

Our video introduces the AI-5146-3D aoi machine SMT's exterior and key features, showcasing its sleek design and functional highlights like 3D light sensors. It displays the internal components, such as cameras and projectors, for a clear view of build quality. The footage shows the machine in operation, scanning boards at high speed with real-time defect detection. AI programming is demonstrated through one-click setups and algorithm adjustments, highlighting efficiency. In one electronics factory, this 3d aoi machine caught solder issues early, reducing defects by 40% and rework time. Our team supported integration, leading to smoother lines and higher yields.

| Service and Training Support

I.C.T provides full services for the AI-5146-3D aoi machine SMT, including installation, maintenance, and customized training. Engineers offer on-site setup and remote assistance for quick issue resolution. Training covers programming, operation, and troubleshooting, typically 3-5 days. We supply spare parts, updates, and 24-hour global support. This minimizes downtime and maximizes value from aoi machine manufacturers like us.

| Customer Reviews

Clients praise our engineers for skilled installations and fast fixes. They appreciate the equipment's accurate detection and easy interface. Shipping and packaging ensure safe arrival without damage. Quick responses to queries, often in hours, build strong trust. Overall, users say this system exceeds expectations in reliability and support.

| Certifications and Standards

I.C.T holds CE for safety, RoHS for eco-friendly materials, ISO9001 for quality management, and patents for innovative tech. These ensure our aoi machine SMT meets global standards, providing users with confidence in performance and compliance.

| About I.C.T Company and Our SMT Factory

I.C.T handles in-house R&D and production with over 89 staff and 20 engineers in a 12,000m² space. Since 2012, we've grown rapidly, serving 1,600+ customers in 72 countries. Our factory uses strict testing and quality systems to deliver top products. As a cross-value platform, we focus on integrity, coordination, and sharing for lasting partnerships.