I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT Online 3D AOI

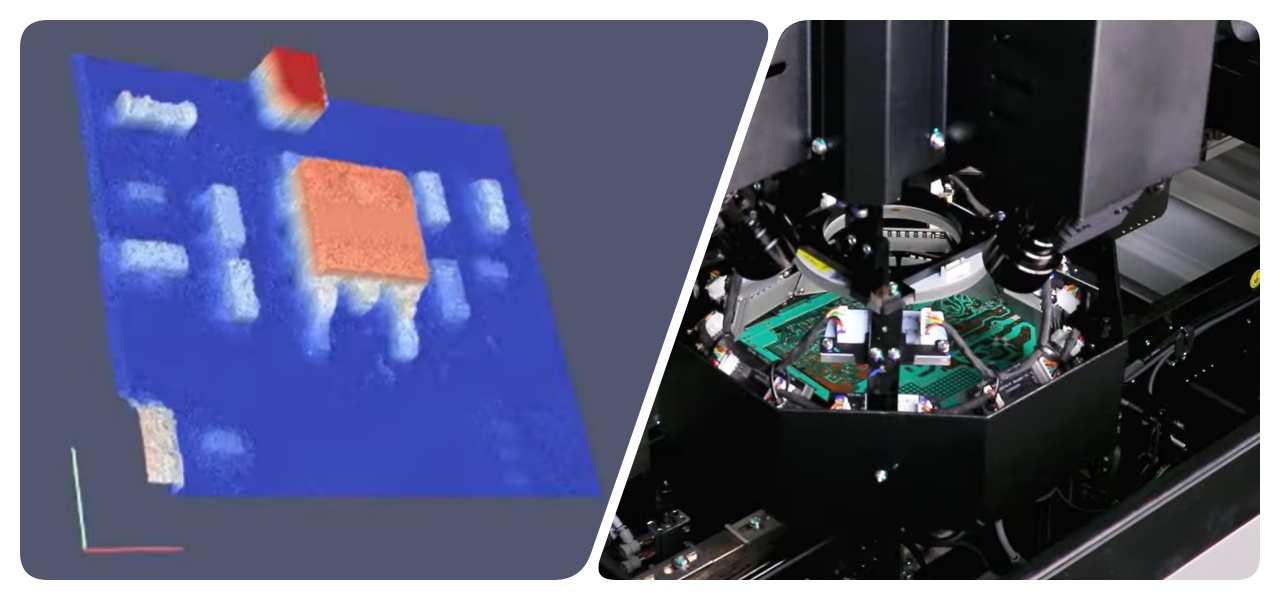

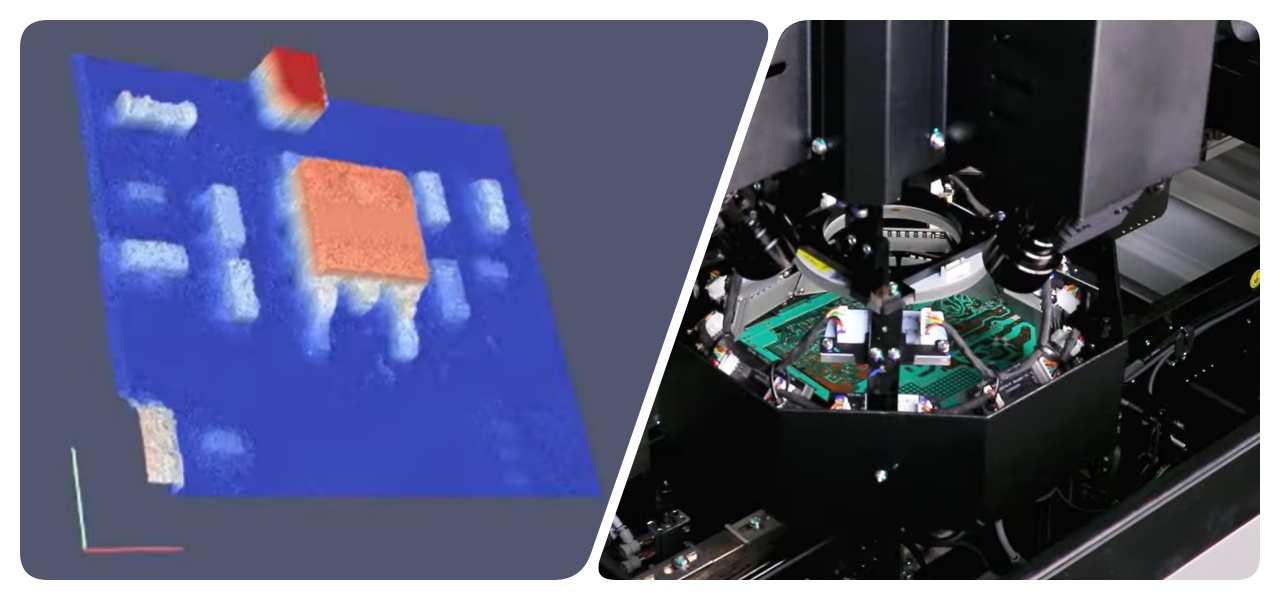

The I.C.T SMT Online 3D AOI is an automatic pcb aoi machine designed for high-accuracy inspection in SMT production lines. It uses a high-precision color industrial camera to capture real-time images of circuit boards. With advanced 3D structured light imaging and AI algorithms, it measures heights precisely and detects component and soldering defects intelligently. This machine fits well in post-reflow soldering checks, reducing errors like insufficient solder or misalignment. It supports multiple configurations to meet different needs, ensuring low false alarms and efficient operation. Data tracing features help with quality control, making it ideal for modern electronics manufacturing. Its stability, with GR&R under 10% and CPK over 1.33, guarantees reliable results even on warped boards.

| Feature

This feature in the automatic pcb aoi machine applies deep learning for quick component and solder joint identification. It cuts down programming time and false alarms compared to old methods. Big data optimization allows one-click auto-detection, handling complex defects like floating or reversed parts. The system intelligently judges issues without manual tweaks, boosting efficiency in high-volume production.

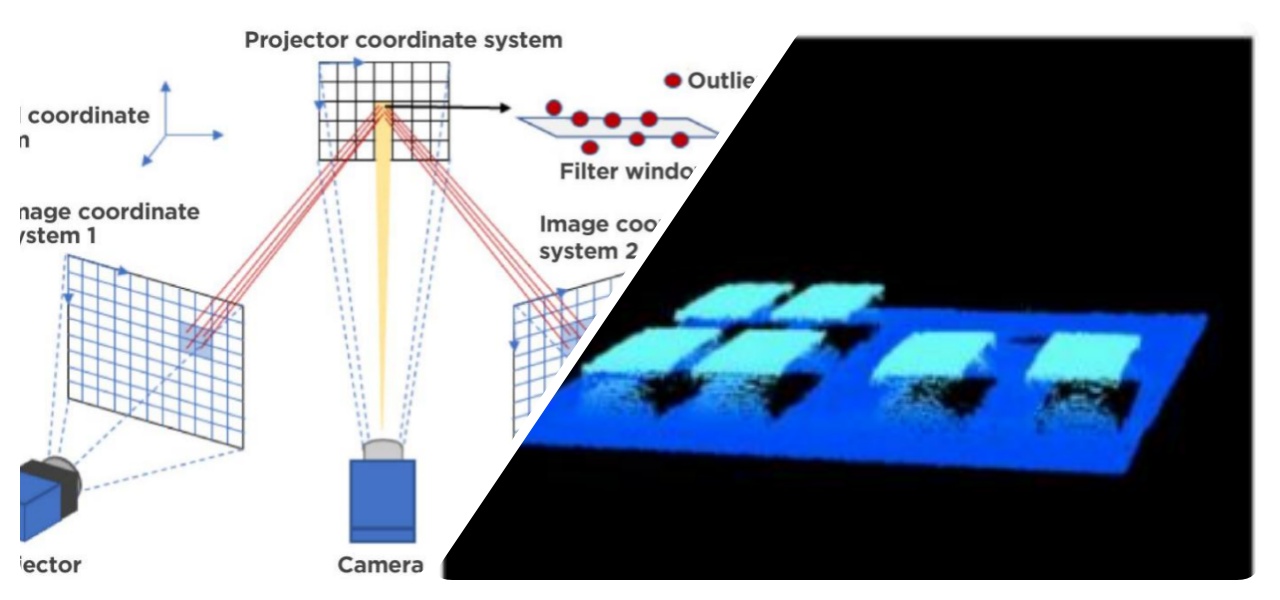

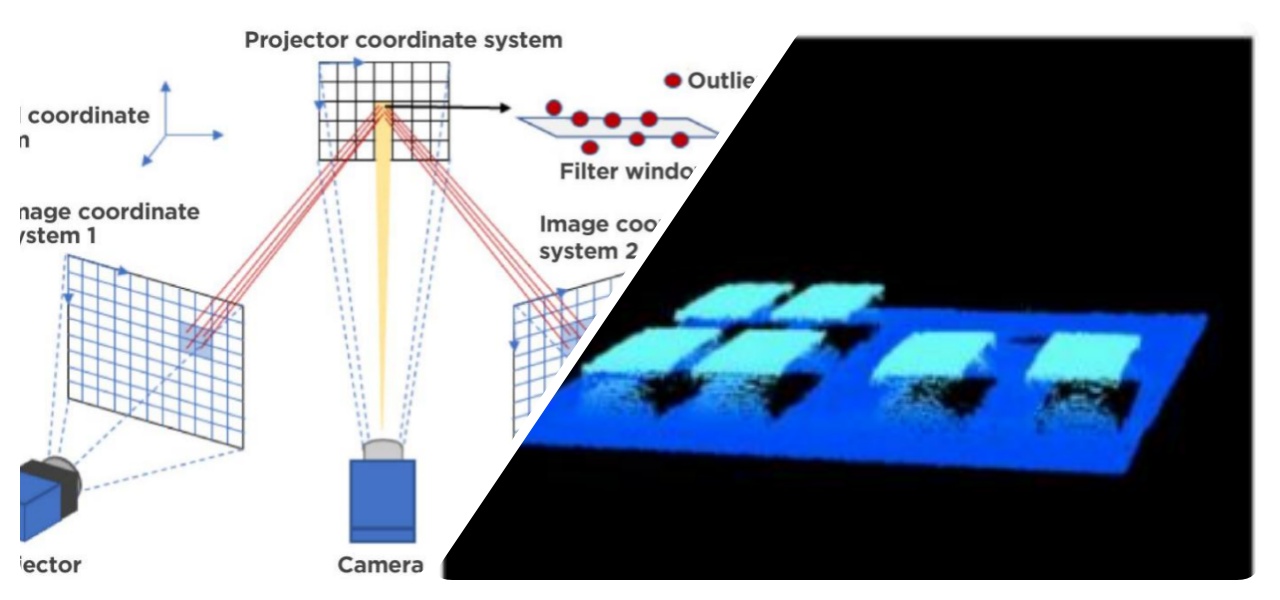

The machine optimizes 3D images using multi-directional structured light sensors. It removes noise and outliers for clear views, solving problems like shadowing or distortion. With four or eight projectors and AI algorithms, it ensures accurate height mapping. This leads to stable imaging, even at edges, making inspections more reliable for various PCB types.

This algorithm calibrates accuracy with phase height mapping and self-adapting reference planes. It handles board warpage automatically, fixing mechanical errors from clamping or camera movement. Deep learning removes noise, while multi-frequency phase shifts keep images robust against brightness changes. The result is precise detection in dynamic production environments.

Trained on big data, the automatic pcb aoi machine identifies components and solder with high accuracy. It corrects alarms from overhangs or deviations, reducing false calls. It handles fuzzy features, color changes, and irregular parts effectively. For IC pins, it auto-generates check boxes to judge multiple defects at once, ensuring low false alarm rates.

| Specification

| Model | I.C.T SMT AOI AI-5146-3D | I.C.T SMT AOI AI-5133D-3D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 15um@60*45mm | 10um@40*30mm |

| Camera | 12M Area scan high speed industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4-color integral light source + 4-direction structured light projection unit | |

| Inspection Speed | 0.55sec/FOV | |

| Inspection Algorithm | CNN, OCR, Color Contrast, Outline Recognition, Image contrast,etc | |

| Inspection Item | Component: Lifting legs, floating height, missing parts, excessive, flipping, reverse, mis-alignment, damage, skew, foreign objects, contamination, etc. Solder: Tin climbing height, excessive, insufficient, Briging, missing, pseudo, etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm) | Single rail: 50*50mm~510*610mm (Large board mode: Left to right: max 710*610mm) Dual rail: 50*50mm~510*330mm (Large board mode: Left to right: max 710*330mm) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:50(80)mm | Top:25mm,Bottom:50 (60)mm |

| PCB Thickness | 0.6 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 870Kg | 1080Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The video showcases the I.C.T-5146 3D AOI machine in action, highlighting its sleek exterior and key features like high-precision imaging. It demonstrates internal components, such as the camera and light projectors, working together for detailed scans. Viewers see the machine operating on a production line, detecting defects like missing parts or poor soldering in real time. The AI programming section illustrates one-click setup, where the system auto-matches algorithms and adjusts parameters quickly. This marketing video emphasizes how the 3d aoi machine omran improves quality control, reducing errors and saving time for electronics manufacturers worldwide.

| Service and Training Support

I.C.T offers comprehensive service and training to ensure smooth operation of the automatic pcb aoi machine. Our team provides on-site installation, remote debugging, and ongoing maintenance. Training covers programming, defect analysis, and MES integration, tailored to your needs. With global support centers, we respond quickly to issues, minimizing downtime. This helps users master the system, optimize production, and achieve long-term reliability.

| Customer Reviews

Clients praise our engineers for expert setup and quick fixes. They love the automatic pcb aoi machine for accurate defect detection and ease of use. Secure packaging and fast shipping impress many. Rapid responses to queries build trust and efficiency.

| Certifications and Standards

I.C.T holds key certifications like CE, RoHS, ISO9001, and various patents. These ensure our products meet global safety and environmental standards. They reflect our commitment to quality and innovation in manufacturing.

| About I.C.T Company and Our SMT Factory

I.C.T is a leading electronics manufacturer with in-house R&D and production. With over 89 staff and rapid growth in 25 years, we serve 1600 customers across 72 countries. Our factories feature strict testing processes and quality management systems for reliable products.

| I.C.T SMT Online 3D AOI

The I.C.T SMT Online 3D AOI is an automatic pcb aoi machine designed for high-accuracy inspection in SMT production lines. It uses a high-precision color industrial camera to capture real-time images of circuit boards. With advanced 3D structured light imaging and AI algorithms, it measures heights precisely and detects component and soldering defects intelligently. This machine fits well in post-reflow soldering checks, reducing errors like insufficient solder or misalignment. It supports multiple configurations to meet different needs, ensuring low false alarms and efficient operation. Data tracing features help with quality control, making it ideal for modern electronics manufacturing. Its stability, with GR&R under 10% and CPK over 1.33, guarantees reliable results even on warped boards.

| Feature

This feature in the automatic pcb aoi machine applies deep learning for quick component and solder joint identification. It cuts down programming time and false alarms compared to old methods. Big data optimization allows one-click auto-detection, handling complex defects like floating or reversed parts. The system intelligently judges issues without manual tweaks, boosting efficiency in high-volume production.

The machine optimizes 3D images using multi-directional structured light sensors. It removes noise and outliers for clear views, solving problems like shadowing or distortion. With four or eight projectors and AI algorithms, it ensures accurate height mapping. This leads to stable imaging, even at edges, making inspections more reliable for various PCB types.

This algorithm calibrates accuracy with phase height mapping and self-adapting reference planes. It handles board warpage automatically, fixing mechanical errors from clamping or camera movement. Deep learning removes noise, while multi-frequency phase shifts keep images robust against brightness changes. The result is precise detection in dynamic production environments.

Trained on big data, the automatic pcb aoi machine identifies components and solder with high accuracy. It corrects alarms from overhangs or deviations, reducing false calls. It handles fuzzy features, color changes, and irregular parts effectively. For IC pins, it auto-generates check boxes to judge multiple defects at once, ensuring low false alarm rates.

| Specification

| Model | I.C.T SMT AOI AI-5146-3D | I.C.T SMT AOI AI-5133D-3D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 15um@60*45mm | 10um@40*30mm |

| Camera | 12M Area scan high speed industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4-color integral light source + 4-direction structured light projection unit | |

| Inspection Speed | 0.55sec/FOV | |

| Inspection Algorithm | CNN, OCR, Color Contrast, Outline Recognition, Image contrast,etc | |

| Inspection Item | Component: Lifting legs, floating height, missing parts, excessive, flipping, reverse, mis-alignment, damage, skew, foreign objects, contamination, etc. Solder: Tin climbing height, excessive, insufficient, Briging, missing, pseudo, etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm) | Single rail: 50*50mm~510*610mm (Large board mode: Left to right: max 710*610mm) Dual rail: 50*50mm~510*330mm (Large board mode: Left to right: max 710*330mm) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:50(80)mm | Top:25mm,Bottom:50 (60)mm |

| PCB Thickness | 0.6 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 870Kg | 1080Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

|---|---|

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| Customer Success Video

The video showcases the I.C.T-5146 3D AOI machine in action, highlighting its sleek exterior and key features like high-precision imaging. It demonstrates internal components, such as the camera and light projectors, working together for detailed scans. Viewers see the machine operating on a production line, detecting defects like missing parts or poor soldering in real time. The AI programming section illustrates one-click setup, where the system auto-matches algorithms and adjusts parameters quickly. This marketing video emphasizes how the 3d aoi machine omran improves quality control, reducing errors and saving time for electronics manufacturers worldwide.

| Service and Training Support

I.C.T offers comprehensive service and training to ensure smooth operation of the automatic pcb aoi machine. Our team provides on-site installation, remote debugging, and ongoing maintenance. Training covers programming, defect analysis, and MES integration, tailored to your needs. With global support centers, we respond quickly to issues, minimizing downtime. This helps users master the system, optimize production, and achieve long-term reliability.

| Customer Reviews

Clients praise our engineers for expert setup and quick fixes. They love the automatic pcb aoi machine for accurate defect detection and ease of use. Secure packaging and fast shipping impress many. Rapid responses to queries build trust and efficiency.

| Certifications and Standards

I.C.T holds key certifications like CE, RoHS, ISO9001, and various patents. These ensure our products meet global safety and environmental standards. They reflect our commitment to quality and innovation in manufacturing.

| About I.C.T Company and Our SMT Factory

I.C.T is a leading electronics manufacturer with in-house R&D and production. With over 89 staff and rapid growth in 25 years, we serve 1600 customers across 72 countries. Our factories feature strict testing processes and quality management systems for reliable products.