5146C

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT AOI Coating Inspector

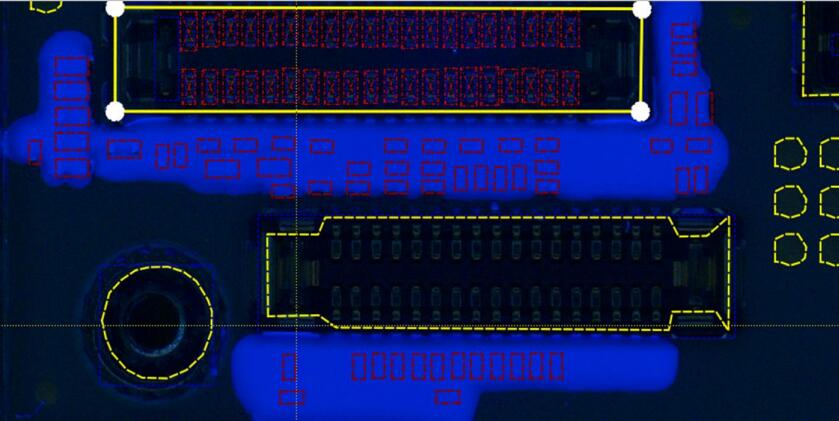

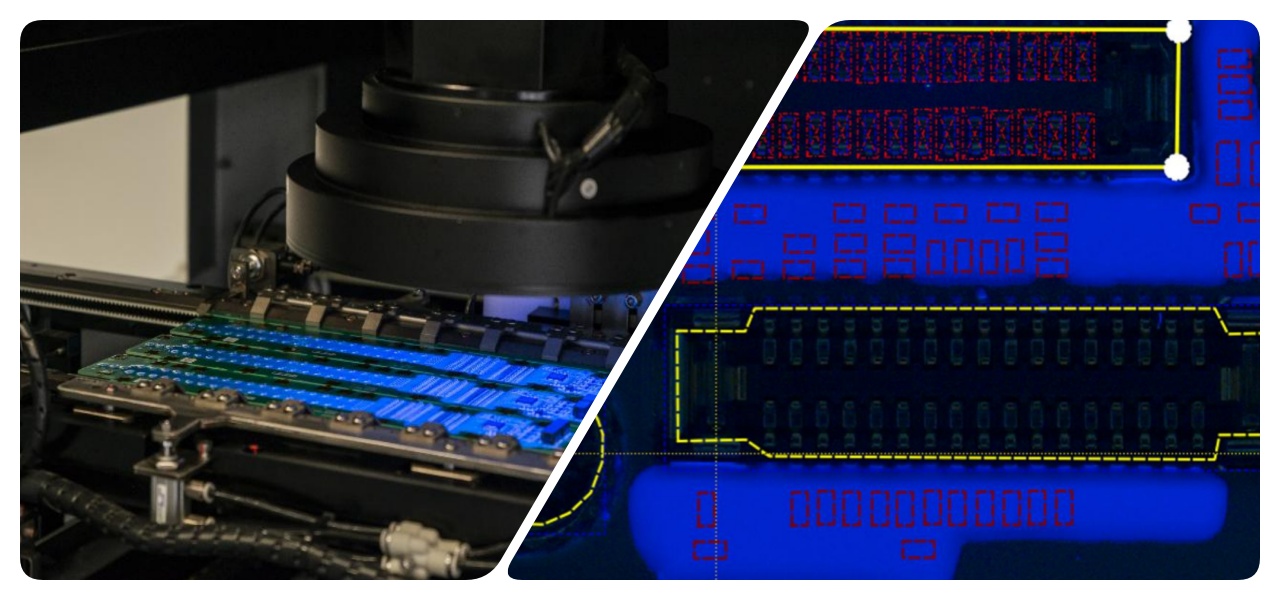

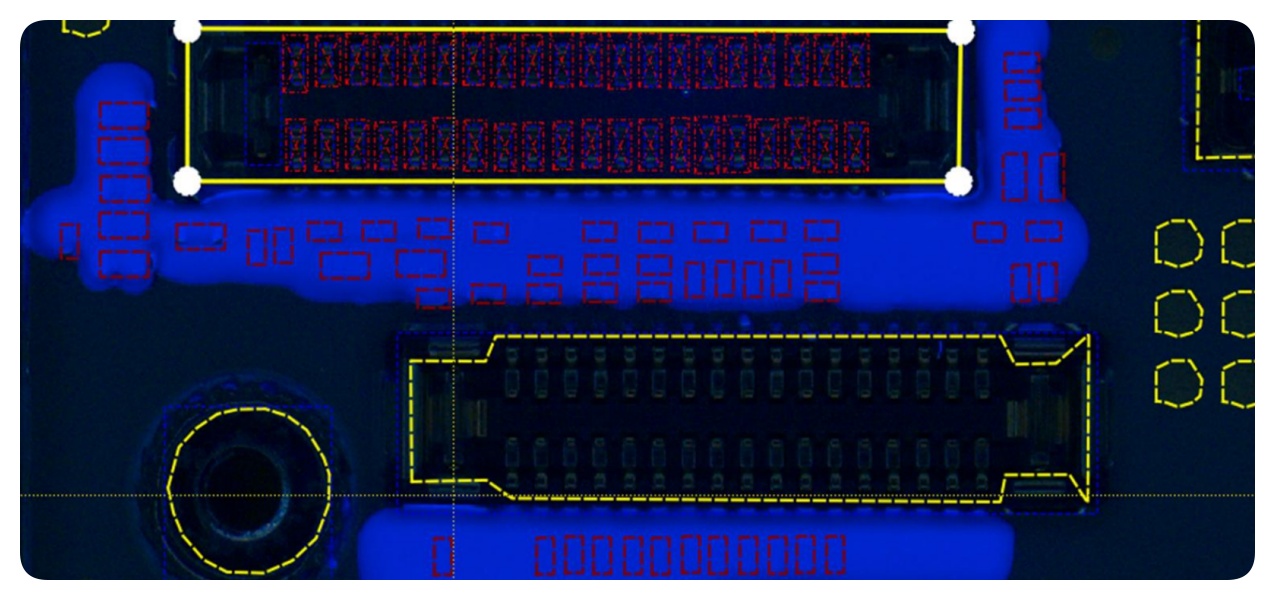

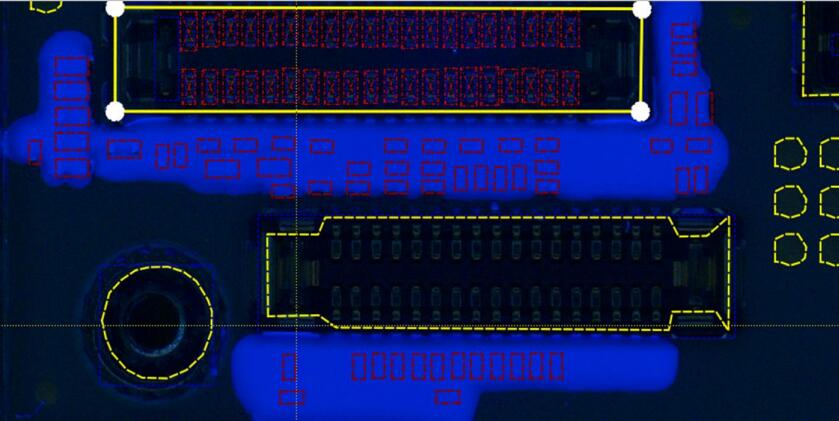

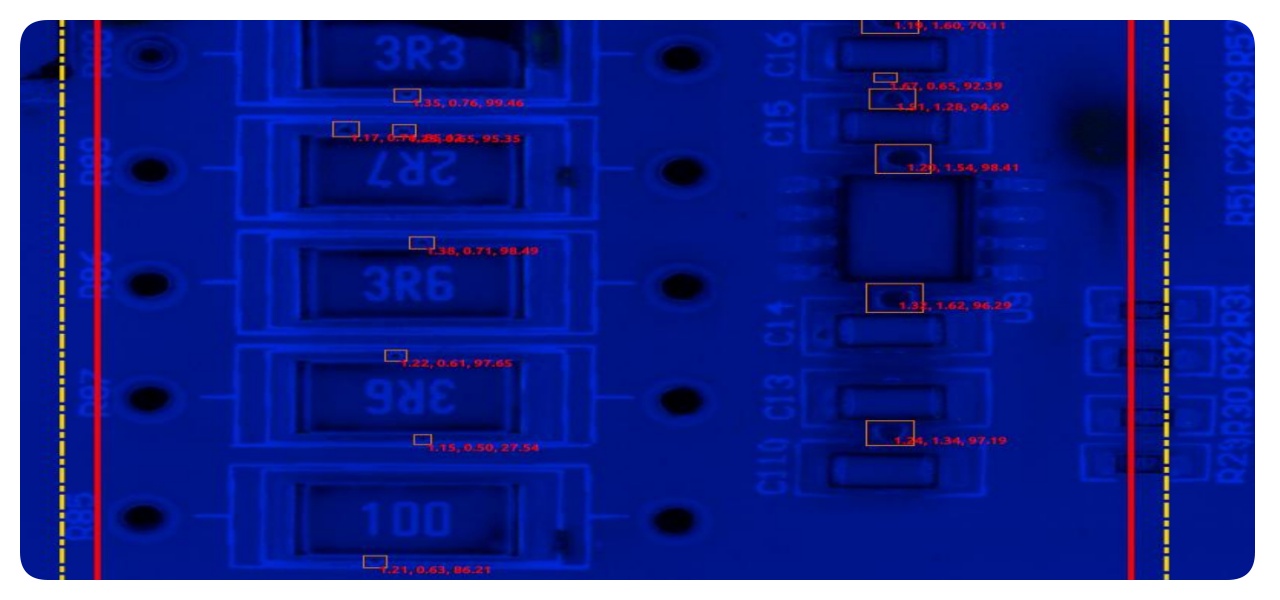

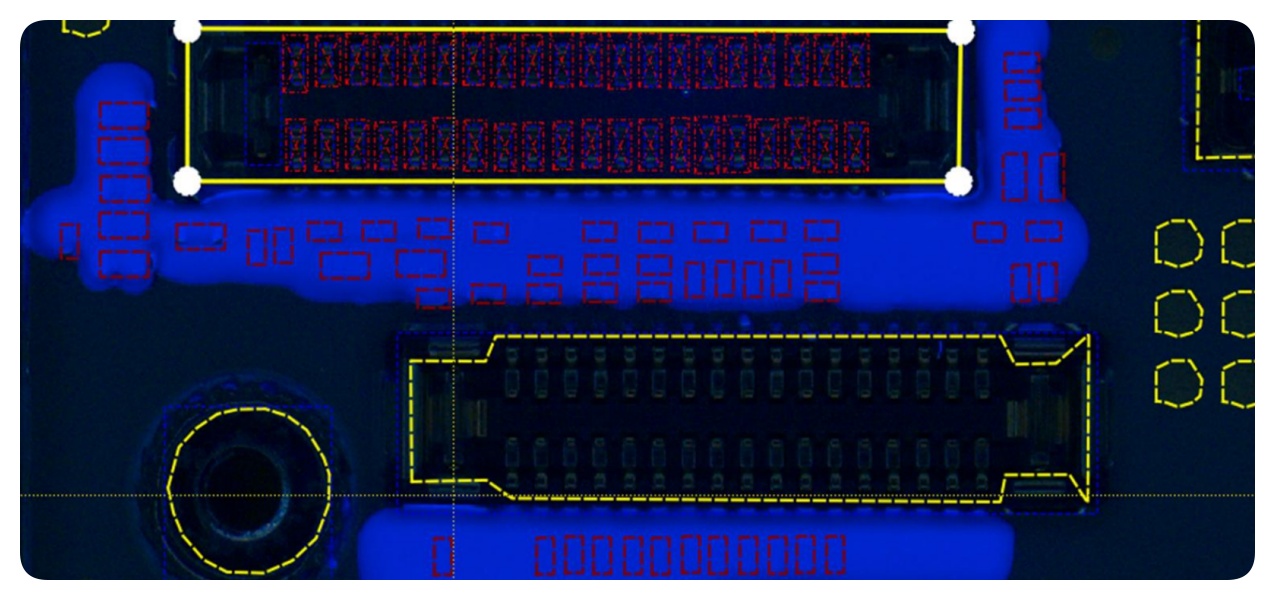

Model AI-5146C is built as a true aoi inspection machine for conformal coating lines. A 5-megapixel color camera takes pictures of the board as it travels, never stopping the conveyor. Deep neural networks then decide, in a fraction of a second, whether the coating is good or bad. Excess glue, missing glue, bubbles, splashes, and foreign material all show up clearly under UV light. The same aoi inspection machine can switch light sources and check SMT components, DIP parts, or solder joints. Programming takes only 10-15 minutes, data is stored forever, and managers can watch or fix the machine from the office or from home.

| Feature

The heart of this aoi inspection machine is a convolutional neural network trained on millions of times. One click tells it what a good board looks like; after that it remembers and judges by itself. False alarms drop, programming time drops, and the line keeps running. Change from coating mode to SMT or DIP inspection by flipping a light switch.

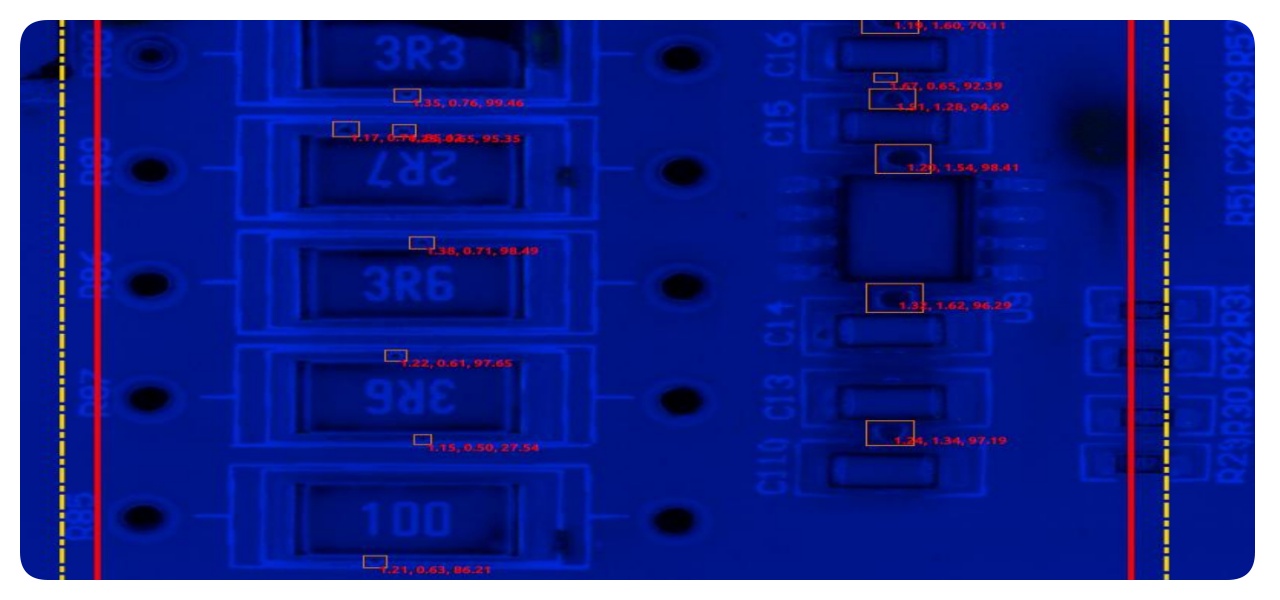

Bubbles as small as half the thickness of a hair show up instantly on the screen of the aoi inspection machine. The software draws a red circle around each one and writes the diameter beside it. Hair, dust, glue drops where they should not be; the same algorithm finds them without anyone touching the keyboard. Non-coated keep-out zones are masked with simple polygons so the machine never cries wolf.

A new program on this aoi inspection machine takes ten to fifteen minutes from start to finish. Draw a box, say “this must be coated” or “this must not be coated,” and the software does the rest. Existing CAD files load directly; no redraw needed. Bad-mark skipping, multi-angle rotation, batch parameter changes with one key; everything is made simple so the operator can go home on time.

Every board that passes the aoi inspection machine gets its own file. Barcode or QR code is read automatically, inspection pictures are saved, thickness values, bubble counts, pass or fail; everything is kept. One click exports a complete SPC report into the factory MES. Alarms sound when trends go wrong. Managers see the numbers on their phones.

| Specification

| Model | I.C.T Coating Online AOI AI-5146C | I.C.T Coating Online AOI AI-5146CW |

| FOV | 15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm | 21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution | 15um(Standard), 10um | 21.5um(standard) /15um /10um |

| Camera | Single side camera12M | Dual side camera 5M |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:25mm, Bottom:80mm | Top:75mm,Bottom:70mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | 570W |

| Communication | SMEMA | |

| Weight | 750Kg | 890Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

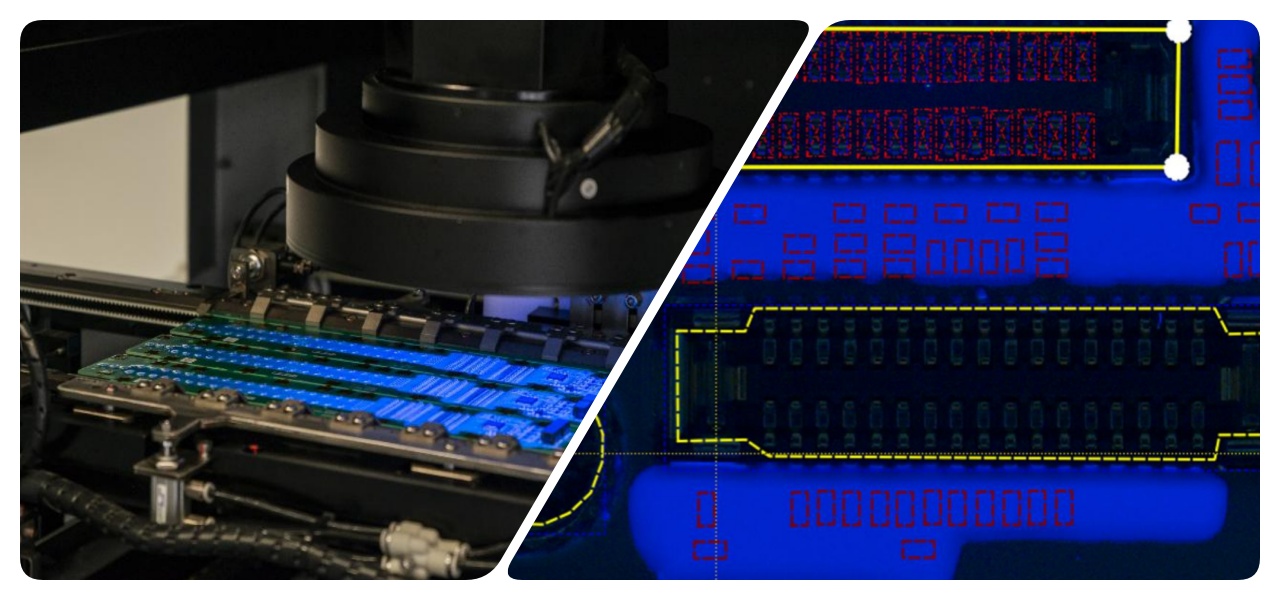

We recently built a complete double-sided coating line for a large automotive electronics customer. The video shows the entire run: boards leave the elevator, enter the coater, cure in the IR oven, then reach our aoi inspection machine. Barcode is read, top or bottom side is recognized, correct program loads in less than one second. Bottom jigs return underneath on a lower conveyor so nothing ever stops. After inspection, boards flip, run back through the same coater and the same aoi inspection machine for the second side, then unload perfectly dry and perfectly inspected. Rework dropped 87 %, throughput rose 42 %, and the customer now sleeps better at night.

| Service and Training Support

When you buy an aoi inspection machine from I.C.T, you get the machine and you get us. Installation team arrives, levels the frame, connects SMEMA, runs the first board. Training is done on your real products, in your language, until your operators feel comfortable. Remote connection is open 24/7; most problems are solved in minutes without a plane ticket.

| Customer Reviews

Engineers tell us they have never seen an aoi inspection machine so easy to program. Production managers say false stops almost disappeared after the first week. Purchasing departments like that one machine handles coating, SMT, and DIP without buying three separate machines. Everyone mentions the packing: thick wood crate, foam inside, not a scratch after sailing across the ocean.

| Certifications and Standards

The aoi inspection machine carries CE mark for Europe, RoHS for environment, ISO9001 for our factory system, and a thick folder of patents for the algorithms and optical designs. Every certificate is earned the hard way; third-party labs, yearly audits, real tests, not just stamps.

| About I.C.T Company and Our SMT Factory

We started in 2012 with twenty people in a rented building. Today eighty-nine people work in a 12,000 m² park we own in Dongguan. Twenty of them are engineers who write code and design optics every day. More than 1,600 factories in 72 countries run our equipment. Every machine, including this aoi inspection machine, is born in our own lines, tested on our own lines, shipped from our own warehouse. Quality system runs from the first screw to the final software line because we never let go of responsibility. That is how a company grows honest and strong.

| I.C.T SMT AOI Coating Inspector

Model AI-5146C is built as a true aoi inspection machine for conformal coating lines. A 5-megapixel color camera takes pictures of the board as it travels, never stopping the conveyor. Deep neural networks then decide, in a fraction of a second, whether the coating is good or bad. Excess glue, missing glue, bubbles, splashes, and foreign material all show up clearly under UV light. The same aoi inspection machine can switch light sources and check SMT components, DIP parts, or solder joints. Programming takes only 10-15 minutes, data is stored forever, and managers can watch or fix the machine from the office or from home.

| Feature

The heart of this aoi inspection machine is a convolutional neural network trained on millions of times. One click tells it what a good board looks like; after that it remembers and judges by itself. False alarms drop, programming time drops, and the line keeps running. Change from coating mode to SMT or DIP inspection by flipping a light switch.

Bubbles as small as half the thickness of a hair show up instantly on the screen of the aoi inspection machine. The software draws a red circle around each one and writes the diameter beside it. Hair, dust, glue drops where they should not be; the same algorithm finds them without anyone touching the keyboard. Non-coated keep-out zones are masked with simple polygons so the machine never cries wolf.

A new program on this aoi inspection machine takes ten to fifteen minutes from start to finish. Draw a box, say “this must be coated” or “this must not be coated,” and the software does the rest. Existing CAD files load directly; no redraw needed. Bad-mark skipping, multi-angle rotation, batch parameter changes with one key; everything is made simple so the operator can go home on time.

Every board that passes the aoi inspection machine gets its own file. Barcode or QR code is read automatically, inspection pictures are saved, thickness values, bubble counts, pass or fail; everything is kept. One click exports a complete SPC report into the factory MES. Alarms sound when trends go wrong. Managers see the numbers on their phones.

| Specification

| Model | I.C.T Coating Online AOI AI-5146C | I.C.T Coating Online AOI AI-5146CW |

| FOV | 15um@36*30mm(standard), 10um@24*20mm 15um@45x45mm,10um@40*30mm | 21.5um@52.6*44mm(standard), 15um@36*30mm/12MP:10um@40*30mm 15um@60*45mm |

| Resolution | 15um(Standard), 10um | 21.5um(standard) /15um /10um |

| Camera | Single side camera12M | Dual side camera 5M |

| Inspection Speed | 0.23sec/FOV | |

| PCB Height | Top:25mm, Bottom:80mm | Top:75mm,Bottom:70mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | 570W |

| Communication | SMEMA | |

| Weight | 750Kg | 890Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

We recently built a complete double-sided coating line for a large automotive electronics customer. The video shows the entire run: boards leave the elevator, enter the coater, cure in the IR oven, then reach our aoi inspection machine. Barcode is read, top or bottom side is recognized, correct program loads in less than one second. Bottom jigs return underneath on a lower conveyor so nothing ever stops. After inspection, boards flip, run back through the same coater and the same aoi inspection machine for the second side, then unload perfectly dry and perfectly inspected. Rework dropped 87 %, throughput rose 42 %, and the customer now sleeps better at night.

| Service and Training Support

When you buy an aoi inspection machine from I.C.T, you get the machine and you get us. Installation team arrives, levels the frame, connects SMEMA, runs the first board. Training is done on your real products, in your language, until your operators feel comfortable. Remote connection is open 24/7; most problems are solved in minutes without a plane ticket.

| Customer Reviews

Engineers tell us they have never seen an aoi inspection machine so easy to program. Production managers say false stops almost disappeared after the first week. Purchasing departments like that one machine handles coating, SMT, and DIP without buying three separate machines. Everyone mentions the packing: thick wood crate, foam inside, not a scratch after sailing across the ocean.

| Certifications and Standards

The aoi inspection machine carries CE mark for Europe, RoHS for environment, ISO9001 for our factory system, and a thick folder of patents for the algorithms and optical designs. Every certificate is earned the hard way; third-party labs, yearly audits, real tests, not just stamps.

| About I.C.T Company and Our SMT Factory

We started in 2012 with twenty people in a rented building. Today eighty-nine people work in a 12,000 m² park we own in Dongguan. Twenty of them are engineers who write code and design optics every day. More than 1,600 factories in 72 countries run our equipment. Every machine, including this aoi inspection machine, is born in our own lines, tested on our own lines, shipped from our own warehouse. Quality system runs from the first screw to the final software line because we never let go of responsibility. That is how a company grows honest and strong.