LD-L

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Pcb Destacker Magazine Loader – Automatic Loader Smt Machine

The I.C.T Pcb Destacker Magazine Loader is the Automatic Loader Smt Machine that stands at the head of the line and does the first work. It receives a magazine full of bare boards. It lowers the stack. It pushes the bottom board out. It does this again and again until the magazine is empty and another is ready. Customers take the standard model or the full CE model. Both carry thicker frames, sharper sensors, and software that waits for new commands. The Pcb Destacker Magazine Loader cuts the number of men needed. It raises the number of boards finished each day. It runs through every shift without rest. It speaks to every printer and conveyor it meets.

| Detailed Product Features

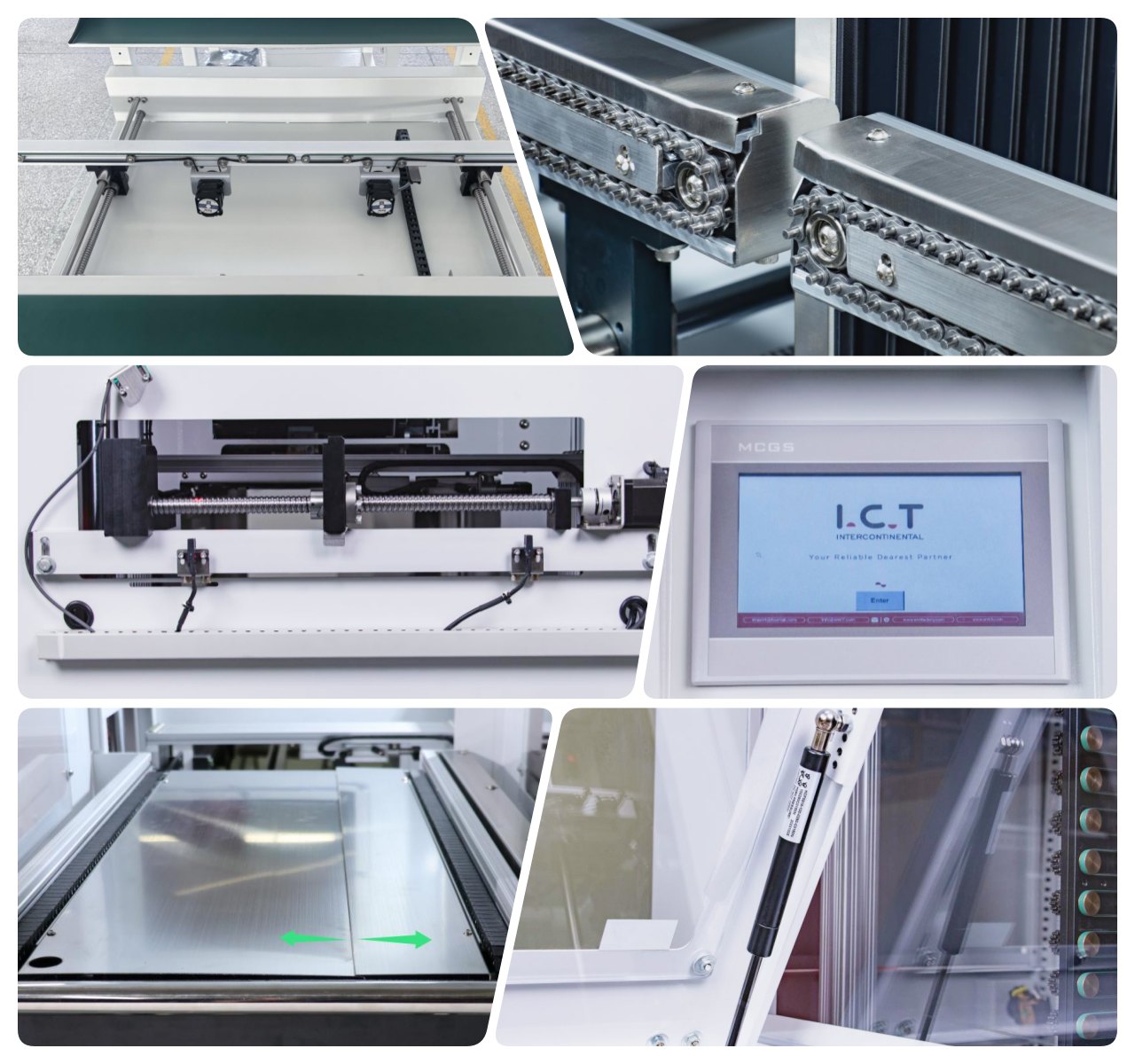

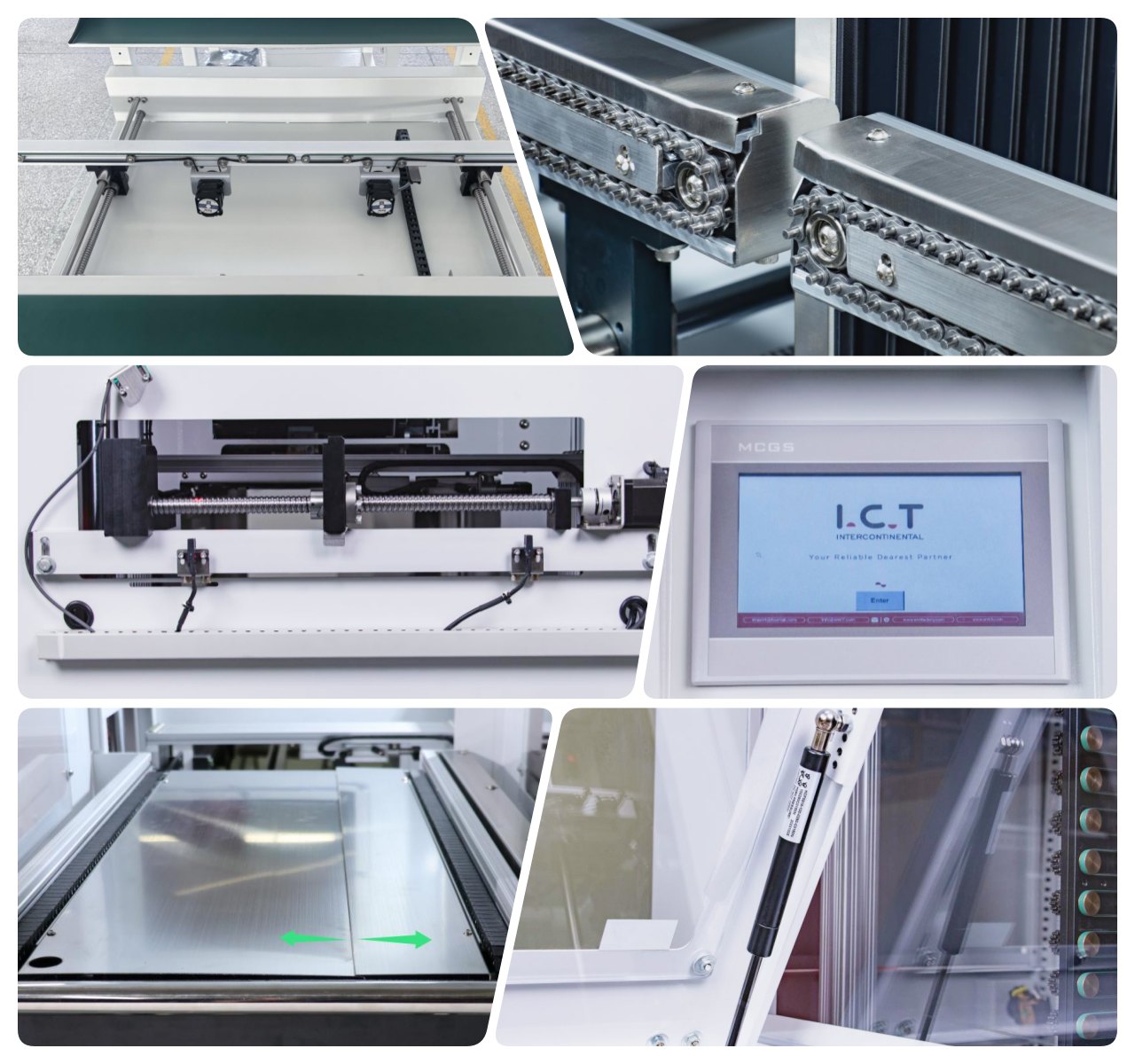

The Pcb Destacker Magazine Loader rests on rails and lifts of heavier steel. All parts follow ISO and CE marks. The base stays still. Maintenance comes easy. The machine feeds boards for years.

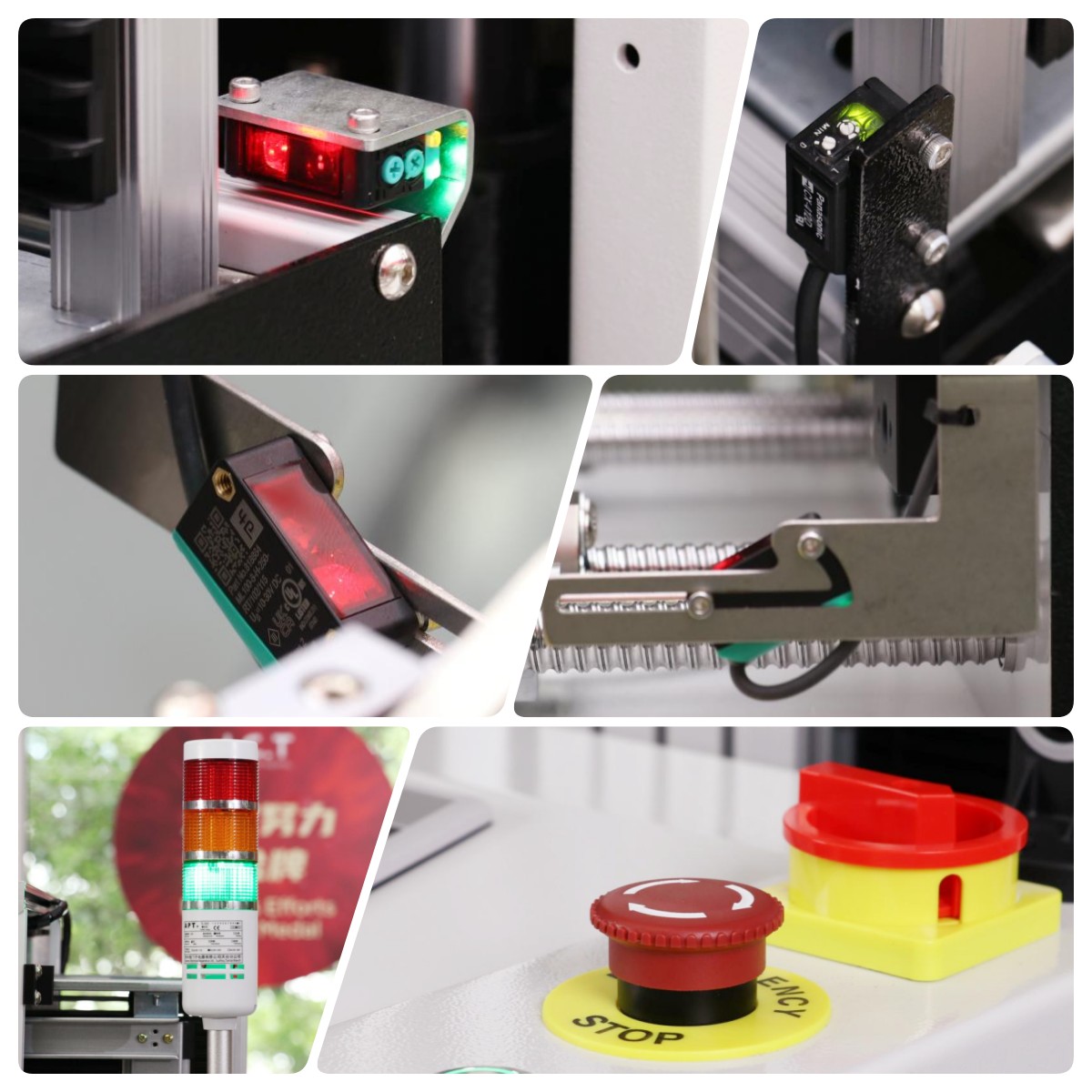

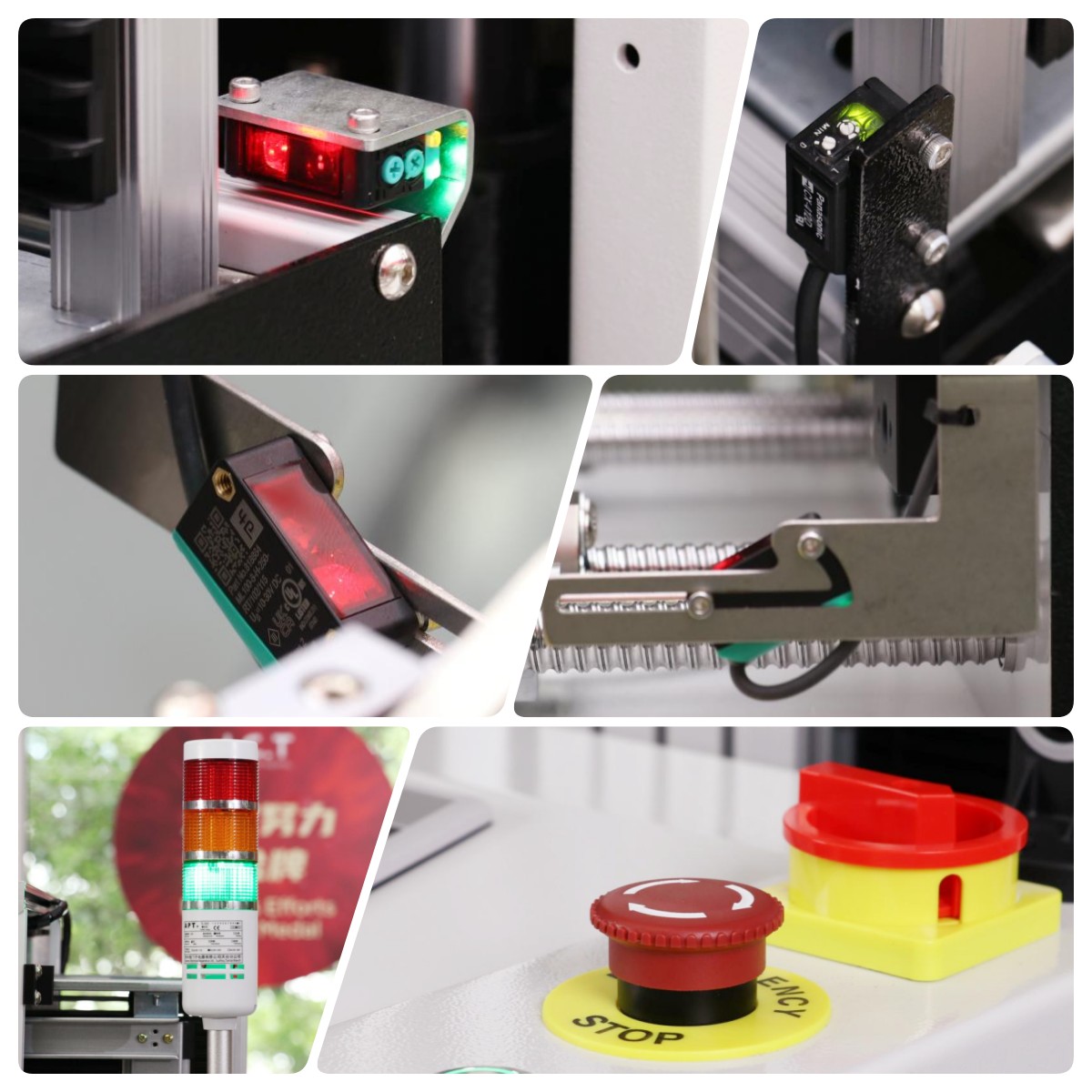

Lights burn red and green. Buttons answer fast. Sensors see the edge of every board the moment it appears. The Pcb Destacker Magazine Loader knows when a board is gone and when the next must come.

Software carries Industry 4.0 inside it. IPC-CFX, Hermes, SEMI SMT-ELS stand ready as options. New orders arrive and the system takes them. The Pcb Destacker Magazine Loader speaks to the factory computer the same day.

The stack lowers. The bottom board slides out. The next board waits its turn. The Pcb Destacker Magazine Loader does this thousands of times and never scratches a single board.

SMEMA cables carry the message forward. Smart cables wait if they are needed. The Pcb Destacker Magazine Loader sends boards down the line and the line never stops.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

The I.C.T turnkey line takes bare boards and returns finished panels without cease. The Pcb Destacker Magazine Loader feeds the first board. Printing, placing, reflow, and inspection follow in order. Men stand few. Good boards come many. The line stays awake. It answers to automotive, medical, consumer, and lighting demands while the cost stays low.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T engineers crossed the sea to Finland. They built a full LED panel line for a great European lighting house. The line held the Pcb Destacker Magazine Loader, the 1.5 m printer, the SM482PLUS placer, the L8 reflow oven, buffers, conveyors, splitter, and mixer. They set the machines and taught the men in five days. On the first true day of work the line ran at full speed. No board was lost. The customer looked at the Pcb Destacker Magazine Loader and said it never paused. They passed the European judges without remark. They ordered another line the same week.

| Professional Training & Support

I.C.T checks the crate before it leaves. Engineers land for the start. Operators and repairmen train free. The telephone rings and a voice answers any hour. Parts fly from warehouses across the world. Visits come on schedule. The Pcb Destacker Magazine Loader almost never stands still when it should be moving.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

Every Pcb Destacker Magazine Loader bears CE, RoHS, ISO9001, and private patents. Each one runs seventy-two hours under full load and passes inspection before the door closes. Customers receive proof that the machine is true.

| About Us and Factory

Since 2012 I.C.T has kept a twelve-thousand-square-meter plant with nearly ninety souls and its own research rooms. All steel is cut, all wires laid, all tests run under one roof by strict rule. More than sixteen hundred buyers in seventy-two lands run I.C.T iron—from one Pcb Destacker Magazine Loader to whole lines.

| Pcb Destacker Magazine Loader – Automatic Loader Smt Machine

The I.C.T Pcb Destacker Magazine Loader is the Automatic Loader Smt Machine that stands at the head of the line and does the first work. It receives a magazine full of bare boards. It lowers the stack. It pushes the bottom board out. It does this again and again until the magazine is empty and another is ready. Customers take the standard model or the full CE model. Both carry thicker frames, sharper sensors, and software that waits for new commands. The Pcb Destacker Magazine Loader cuts the number of men needed. It raises the number of boards finished each day. It runs through every shift without rest. It speaks to every printer and conveyor it meets.

| Detailed Product Features

The Pcb Destacker Magazine Loader rests on rails and lifts of heavier steel. All parts follow ISO and CE marks. The base stays still. Maintenance comes easy. The machine feeds boards for years.

Lights burn red and green. Buttons answer fast. Sensors see the edge of every board the moment it appears. The Pcb Destacker Magazine Loader knows when a board is gone and when the next must come.

Software carries Industry 4.0 inside it. IPC-CFX, Hermes, SEMI SMT-ELS stand ready as options. New orders arrive and the system takes them. The Pcb Destacker Magazine Loader speaks to the factory computer the same day.

The stack lowers. The bottom board slides out. The next board waits its turn. The Pcb Destacker Magazine Loader does this thousands of times and never scratches a single board.

SMEMA cables carry the message forward. Smart cables wait if they are needed. The Pcb Destacker Magazine Loader sends boards down the line and the line never stops.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

The I.C.T turnkey line takes bare boards and returns finished panels without cease. The Pcb Destacker Magazine Loader feeds the first board. Printing, placing, reflow, and inspection follow in order. Men stand few. Good boards come many. The line stays awake. It answers to automotive, medical, consumer, and lighting demands while the cost stays low.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T engineers crossed the sea to Finland. They built a full LED panel line for a great European lighting house. The line held the Pcb Destacker Magazine Loader, the 1.5 m printer, the SM482PLUS placer, the L8 reflow oven, buffers, conveyors, splitter, and mixer. They set the machines and taught the men in five days. On the first true day of work the line ran at full speed. No board was lost. The customer looked at the Pcb Destacker Magazine Loader and said it never paused. They passed the European judges without remark. They ordered another line the same week.

| Professional Training & Support

I.C.T checks the crate before it leaves. Engineers land for the start. Operators and repairmen train free. The telephone rings and a voice answers any hour. Parts fly from warehouses across the world. Visits come on schedule. The Pcb Destacker Magazine Loader almost never stands still when it should be moving.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

Every Pcb Destacker Magazine Loader bears CE, RoHS, ISO9001, and private patents. Each one runs seventy-two hours under full load and passes inspection before the door closes. Customers receive proof that the machine is true.

| About Us and Factory

Since 2012 I.C.T has kept a twelve-thousand-square-meter plant with nearly ninety souls and its own research rooms. All steel is cut, all wires laid, all tests run under one roof by strict rule. More than sixteen hundred buyers in seventy-two lands run I.C.T iron—from one Pcb Destacker Magazine Loader to whole lines.