SMT PCB Loader Unloader

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Your Reliable PCB SMT Unloader machine

With your new PCB SMT Unloader machine, you receive finished boards straight from reflow or AOI and stack them neatly into magazines—no operator needed. This SMT PCB Horizontal Loader smoothly lowers each board with perfect alignment so you never worry about scratches or misalignment. You choose standard or full CE version and get upgraded hardware, smarter electrics, and future-proof controls that slash labor and keep your line flowing 24/7. You drop it in and it talks perfectly to every major brand.

| Detailed Product Features

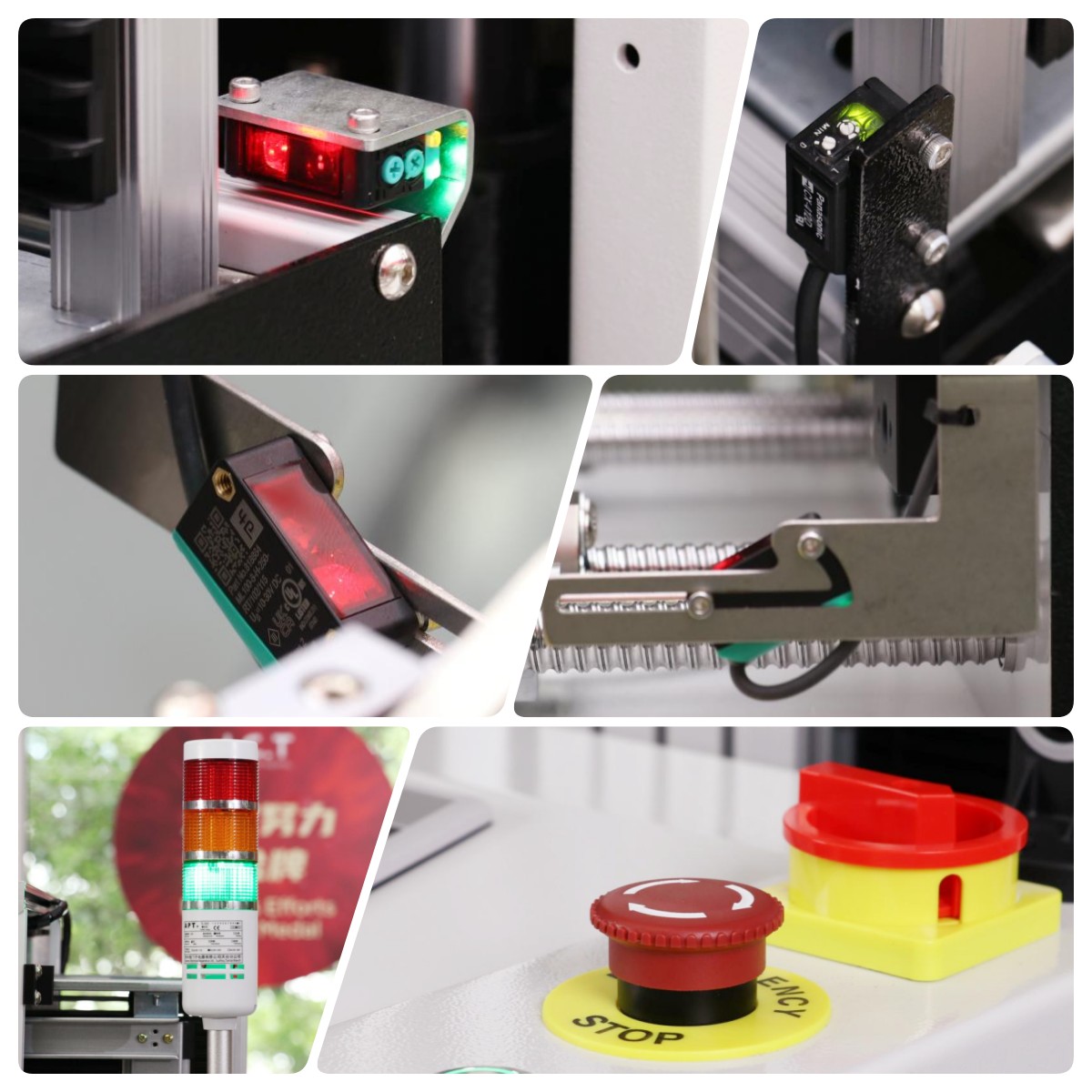

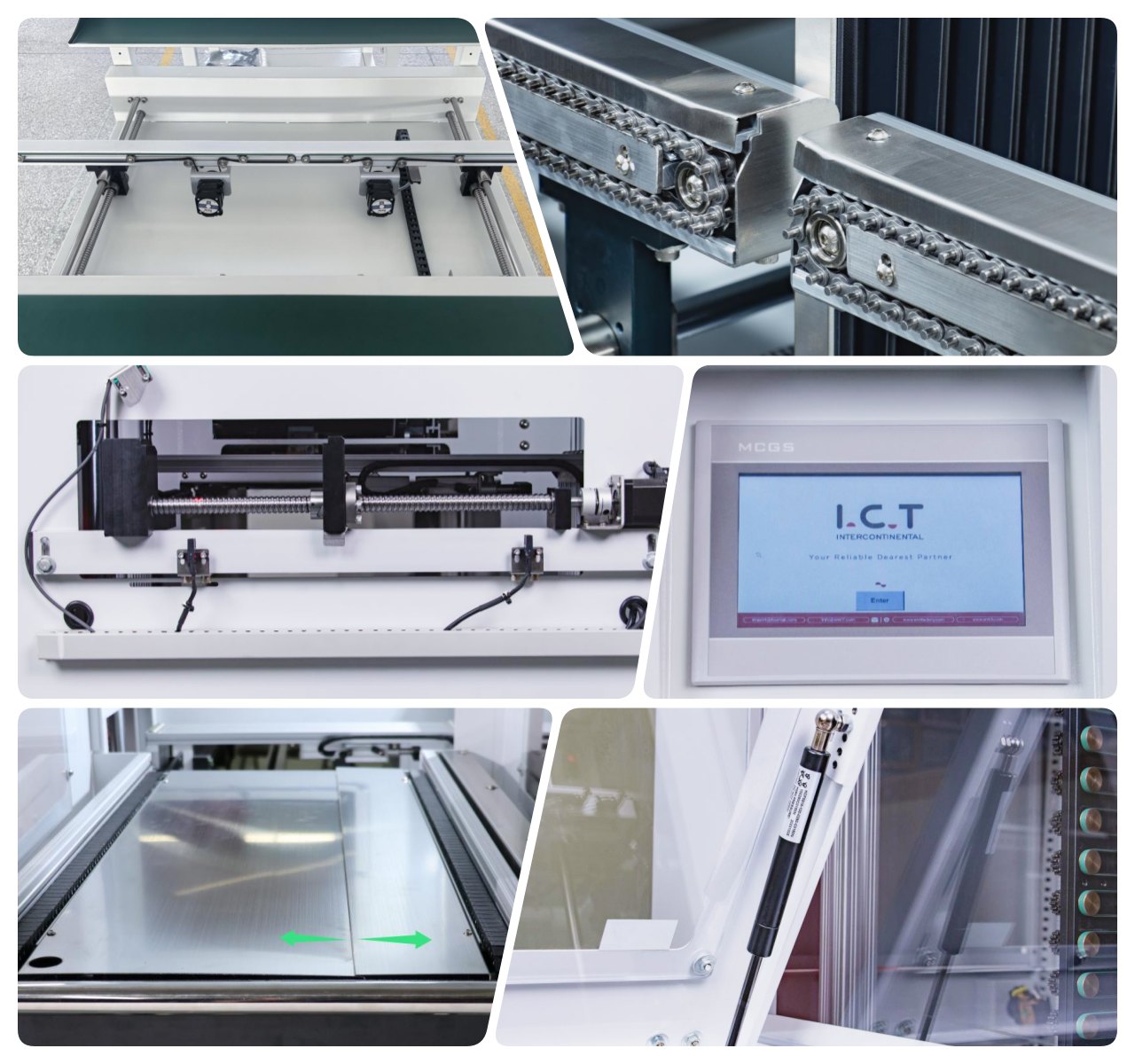

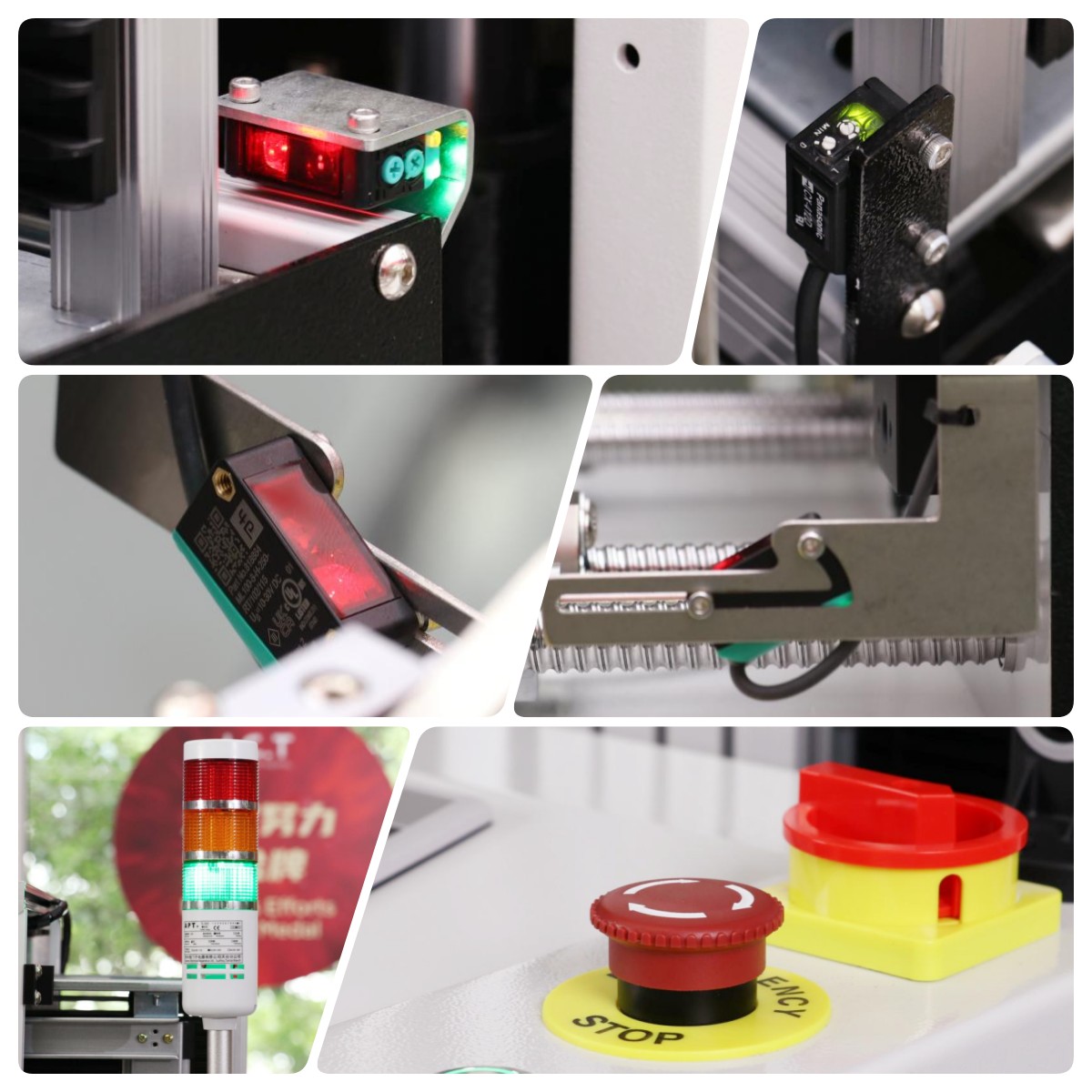

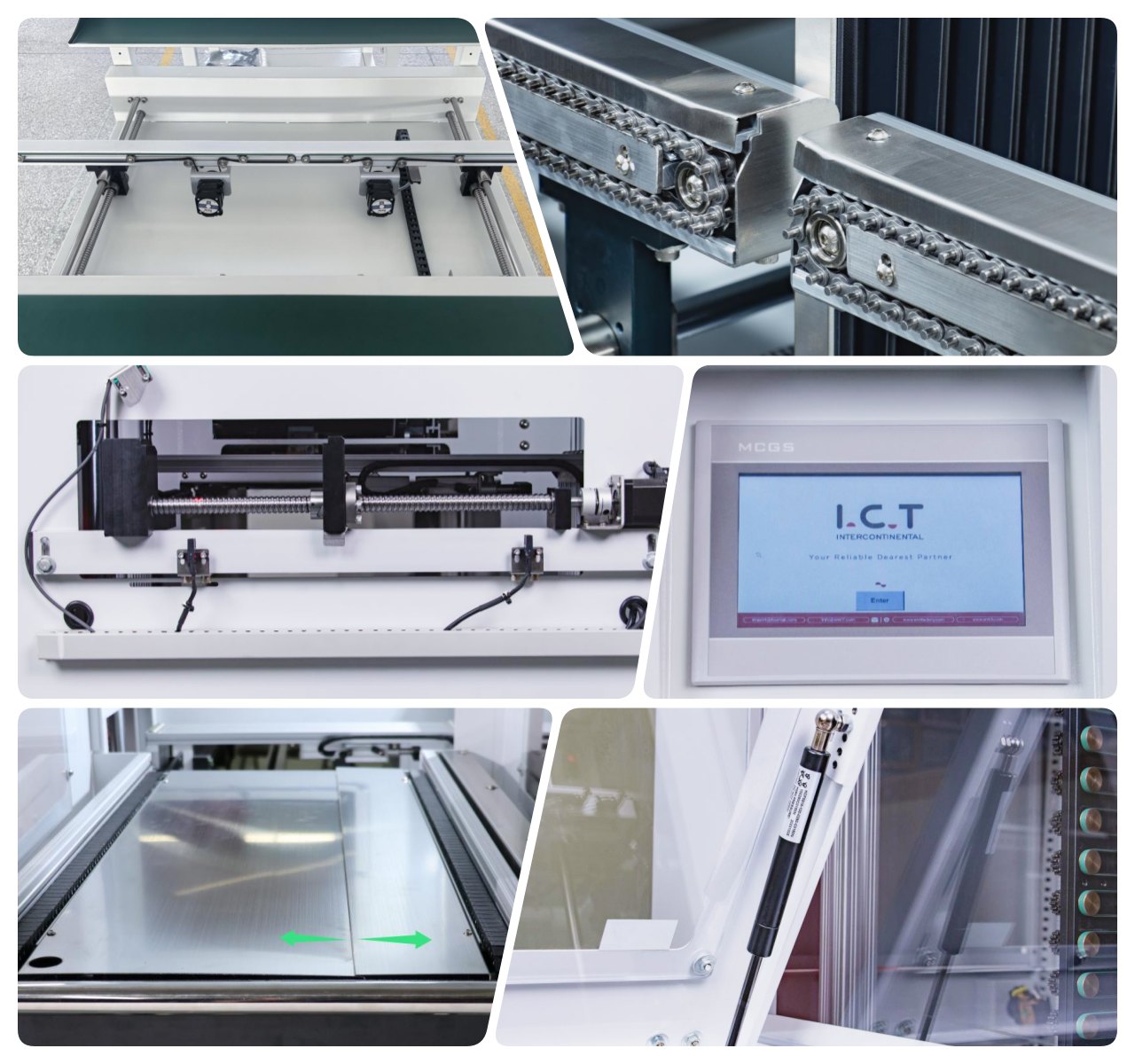

Your PCB SMT Unloader machine uses upgraded high-grade rails, lifts, and frames that meet strict ISO and CE standards. You feel the reinforced base and ergonomic design that keep everything vibration-free and make daily operation and maintenance dead simple.

Your machine comes with top-tier sensors, bright tower lights, and high-frequency buttons so you get instant board detection and crystal-clear status on every cycle. You stay in total control even at full line speed—no errors, just smooth unloading.

Your PCB SMT Unloader machine supports IPC-CFX, Hermes, and SEMI SMT-ELS right out of the box (optional). You connect to your MES or add new features in minutes and turn your line into a true smart factory.

Your precision lifter and pusher handle every board quietly and perfectly. You get flawless positioning into magazines—zero scratches, zero misalignment, total protection for your finished product quality.

PCB SMT Unloader machine talks directly to reflow ovens, AOI, conveyors, and the rest of your line. You switch magazine sizes instantly and keep floor space tight while running at maximum speed.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Your turnkey High-Quality SMT Production Line gives you fully automatic, high-speed, ultra-reliable PCBA manufacturing from bare board to final inspection. You feed with precision, print and place at top speed, reflow perfectly, and finish with your flawless PCB SMT Unloader machine—all linked seamlessly. You keep labor low, first-pass yield sky-high, and uptime exceptional while meeting automotive, medical, consumer, and LED standards at the lowest possible cost.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

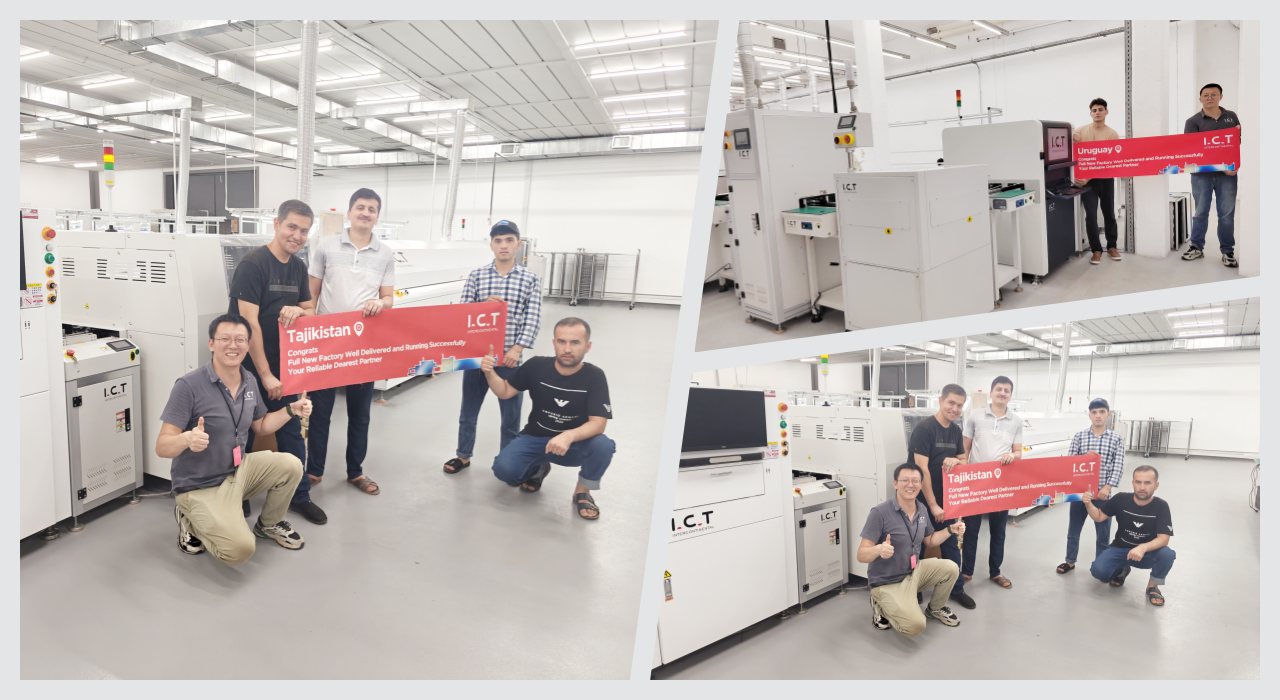

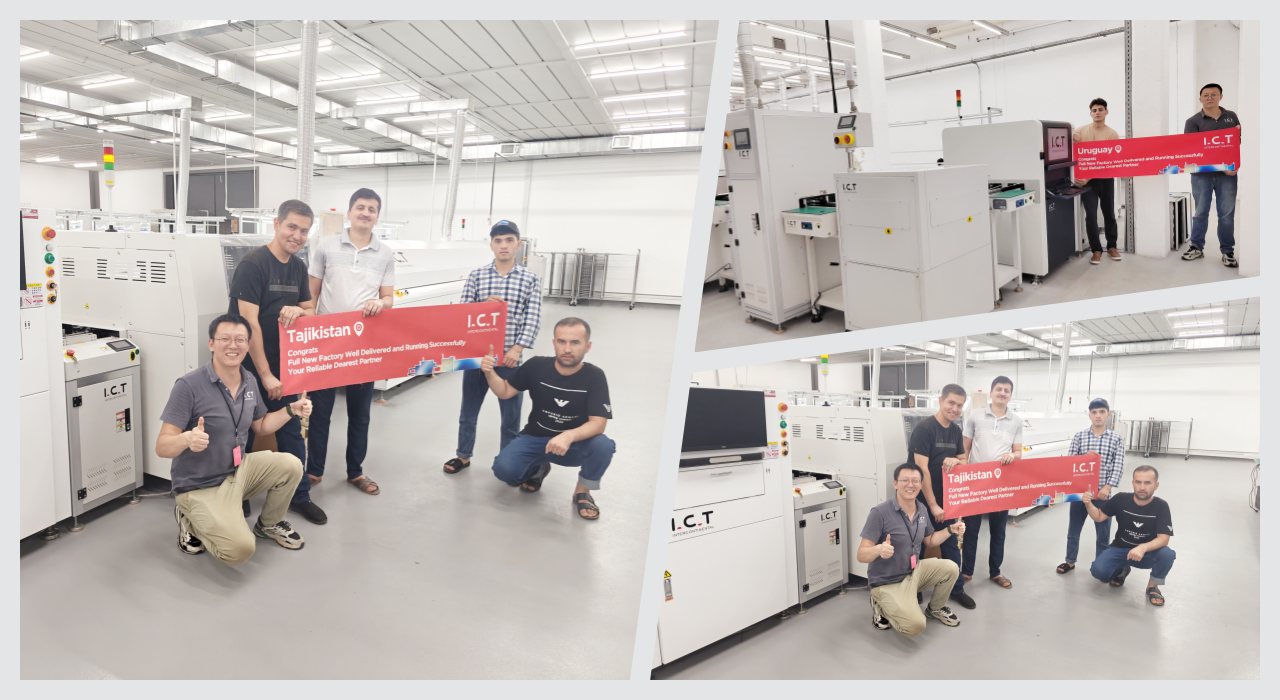

| Customer Success Story

In 2024 our engineers flew to Finland and set up a complete LED panel line for one of Europe’s biggest lighting manufacturers. Your turnkey package included the PCB SMT Unloader machine, 1.5 m auto printer, SM482PLUS mounter, L8 reflow, buffers, conveyors, and more. You watched us finish installation, debugging, and full operator training in only five days. On day one of official production you hit target speed with zero defects. You told us the PCB SMT Unloader machine ran perfectly and machine-to-machine communication was flawless. You passed the tough European audit first time and ordered another line the same week.

| Professional Training & Support

You get remote pre-checks, on-site commissioning, free hands-on training for your operators and technicians, a real 24/7 global hotline, spare-parts warehouses worldwide, and scheduled preventive visits—so your PCB SMT Unloader machine keeps running at peak performance with almost zero unexpected stops.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

Your PCB SMT Unloader machine comes with CE, RoHS, ISO9001 marks and several exclusive patents. Before it leaves our factory you know it has passed a full 72-hour loaded burn-in test and detailed quality inspection—so you get proven reliability and full compliance from day one.

| About Us and Factory

Since 2012 we’ve grown into a 12,000 m² modern factory with nearly 90 team members and our own R&D center. You benefit from everything designed, built, and tested under one roof with strict quality systems. You join over 1,600 customers in 72 countries who trust us—from one PCB SMT Unloader machine to complete turnkey lines.

| Your Reliable PCB SMT Unloader machine

With your new PCB SMT Unloader machine, you receive finished boards straight from reflow or AOI and stack them neatly into magazines—no operator needed. This SMT PCB Horizontal Loader smoothly lowers each board with perfect alignment so you never worry about scratches or misalignment. You choose standard or full CE version and get upgraded hardware, smarter electrics, and future-proof controls that slash labor and keep your line flowing 24/7. You drop it in and it talks perfectly to every major brand.

| Detailed Product Features

Your PCB SMT Unloader machine uses upgraded high-grade rails, lifts, and frames that meet strict ISO and CE standards. You feel the reinforced base and ergonomic design that keep everything vibration-free and make daily operation and maintenance dead simple.

Your machine comes with top-tier sensors, bright tower lights, and high-frequency buttons so you get instant board detection and crystal-clear status on every cycle. You stay in total control even at full line speed—no errors, just smooth unloading.

Your PCB SMT Unloader machine supports IPC-CFX, Hermes, and SEMI SMT-ELS right out of the box (optional). You connect to your MES or add new features in minutes and turn your line into a true smart factory.

Your precision lifter and pusher handle every board quietly and perfectly. You get flawless positioning into magazines—zero scratches, zero misalignment, total protection for your finished product quality.

PCB SMT Unloader machine talks directly to reflow ovens, AOI, conveyors, and the rest of your line. You switch magazine sizes instantly and keep floor space tight while running at maximum speed.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Your turnkey High-Quality SMT Production Line gives you fully automatic, high-speed, ultra-reliable PCBA manufacturing from bare board to final inspection. You feed with precision, print and place at top speed, reflow perfectly, and finish with your flawless PCB SMT Unloader machine—all linked seamlessly. You keep labor low, first-pass yield sky-high, and uptime exceptional while meeting automotive, medical, consumer, and LED standards at the lowest possible cost.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

In 2024 our engineers flew to Finland and set up a complete LED panel line for one of Europe’s biggest lighting manufacturers. Your turnkey package included the PCB SMT Unloader machine, 1.5 m auto printer, SM482PLUS mounter, L8 reflow, buffers, conveyors, and more. You watched us finish installation, debugging, and full operator training in only five days. On day one of official production you hit target speed with zero defects. You told us the PCB SMT Unloader machine ran perfectly and machine-to-machine communication was flawless. You passed the tough European audit first time and ordered another line the same week.

| Professional Training & Support

You get remote pre-checks, on-site commissioning, free hands-on training for your operators and technicians, a real 24/7 global hotline, spare-parts warehouses worldwide, and scheduled preventive visits—so your PCB SMT Unloader machine keeps running at peak performance with almost zero unexpected stops.

| Customer Praise

“Your engineer fixed it at 3 a.m. their time—best support on the planet!” “Forty-five days at sea and the crate arrived perfect—no damage.” “My PCB SMT Unloader machine has run three shifts for 20 straight months—no failures.” “After one day of training our newest operators ran the whole line alone.”

| Our Certification

Your PCB SMT Unloader machine comes with CE, RoHS, ISO9001 marks and several exclusive patents. Before it leaves our factory you know it has passed a full 72-hour loaded burn-in test and detailed quality inspection—so you get proven reliability and full compliance from day one.

| About Us and Factory

Since 2012 we’ve grown into a 12,000 m² modern factory with nearly 90 team members and our own R&D center. You benefit from everything designed, built, and tested under one roof with strict quality systems. You join over 1,600 customers in 72 countries who trust us—from one PCB SMT Unloader machine to complete turnkey lines.