RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| JUKI SMD IC Pick and Place Machine

Look, when you run a factory, you want machines that just work—no fuss, no drama. This SMT PCB assembly machine line from Juki does exactly that. It picks chips and ICs and sets them down perfect on circuit boards, fast as you please. The setup is modular, so you add pieces as business grows. Cameras watch every move live. Programming is straightforward; anybody with basic training can handle it. The narrow footprint slides right into crowded lines. I.C.T stands by from planning to daily fixes, making sure output stays high and trouble stays low for all kinds of electronics work.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

Well now, the RS-1R and RS-1XL are the practical choices for shops that run mixed jobs. The RS-1R pushes 47,000 parts per hour with dead-on ±35µm accuracy. Standard boards up to 650×370mm fit fine, and the RS-1XL takes wider ones to 650×560mm—handy for big LED panels. That Takumi head shifts smart during runs, handling odd shapes without slowing. Feeders go clear to 112 for fast switches. Vision spots issues quick, force control treats delicate boards gentle. These two play nice together in flexible lines and keep production steady all shift long.

RX-7R / RX-8 Series Features

If speed is what you’re chasing, the RX-7R and RX-8 won’t disappoint. The RX-7R hits 75,000 CPH steady, while the RX-8 climbs all the way to 100,000 with its clever P20 head. Both stay skinny at 998mm wide, giving the best parts-per-square-foot numbers around. They place super-small 03015 chips without blinking. Parallel heads team up smooth, coaxial lights make tiny details crystal clear. Low-impact mode protects fragile parts, data shares easy between units. Perfect for high-volume runs of phone boards or driver circuits—pure production muscle in a small package.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T builds complete PCBA lines that hold up under real work. PCB loader pulls boards in spotless. SMT Printer spreads paste even every time. The SMT PCB assembly machine drops each component exactly where needed. Multi-zone reflow soldering oven locks solder solid and strong. Sharp AOI catches any mistake early. Conveyors link everything tight, buffers keep flow steady. Yield runs high, costs stay low, no weak spots anywhere. These lines handle tough automotive power jobs and more. Finished boards come out ready for the real world. We back the whole setup start to finish.

| Customer Success Video

There’s this customer building power supplies for cars, and their video tells the story plain. It opens on the full SMT and DIP lines running smooth. Boards slide in clean through the loader, get perfect paste, then the JUKI SMD IC Pick and Place Machine fills them fast and accurate. Conveyors carry on to reflow, cooling, AOI checks, and unload. Over on DIP, wave solder handles through-hole, flippers turn boards, ICT tests function. The owner talks straight—everything connects, nothing stalls, quality stays top-notch. You see clear shots of steady flow and precise work from beginning to end. Tough car standards get met easy.

| Service and Training Support

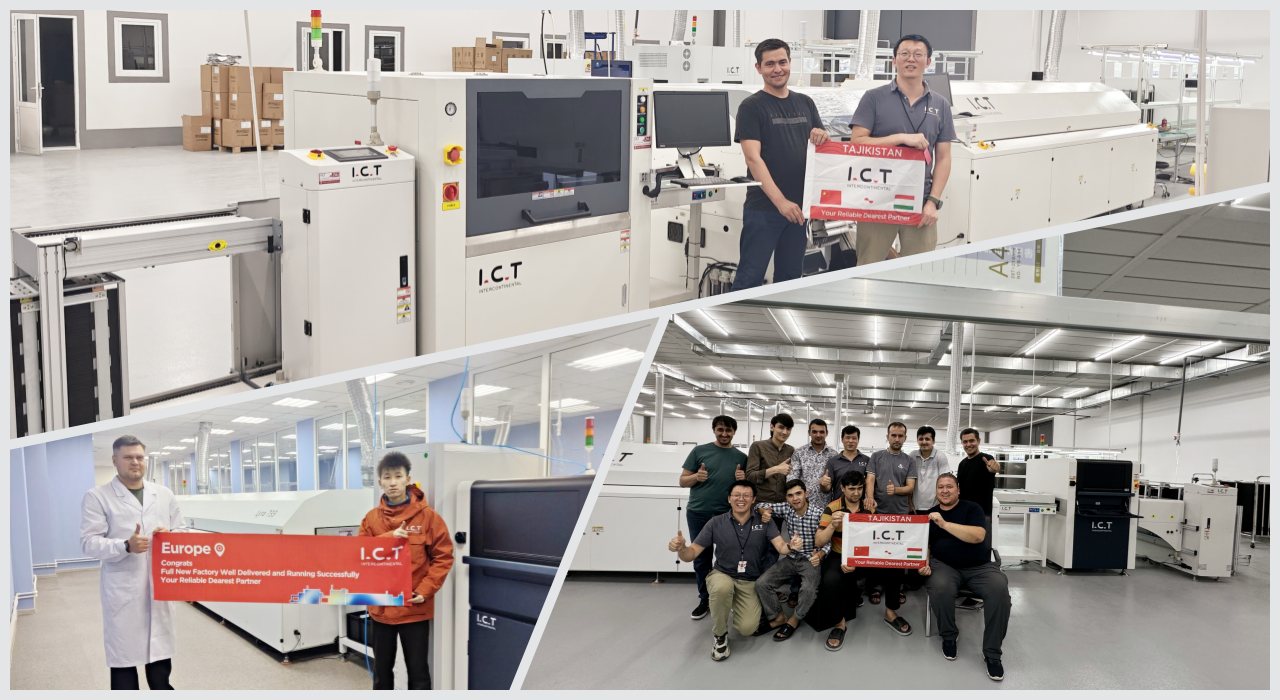

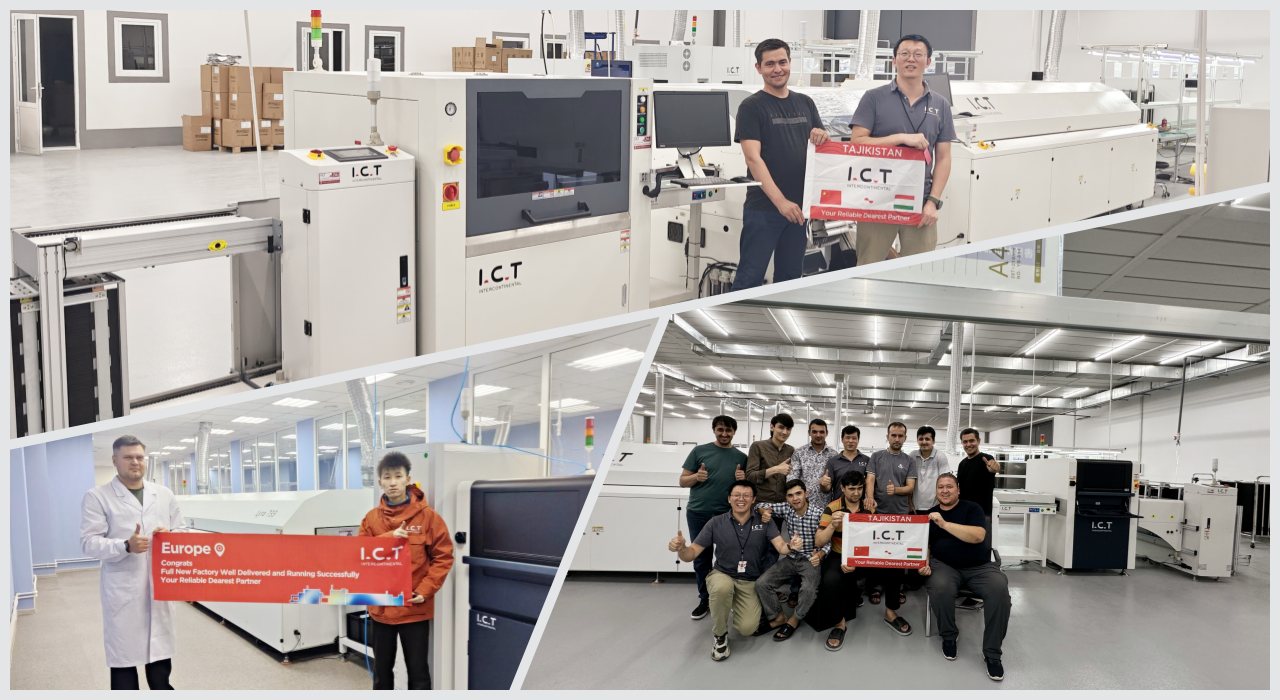

I.C.T doesn’t leave you hanging after the sale. Our engineers show up, install the SMT PCB assembly machine, and run full tests. Training is practical—operators learn programming, daily care, quick repairs right on the floor. Remote links fix most issues in hours. Regular maintenance plans keep performance sharp year after year. We study your line and suggest real improvements. Upgrades drop in simple. With offices worldwide, help gets to you fast no matter the country. Customers keep running full tilt with almost no long stops. Good partnership starts day one and lasts.

| Customer Feedback

Folks who bought from us talk straight and plain. They like engineers that arrive prepared and solve problems quick. The SMT PCB assembly machine earns praise for steady speed and rare mistakes. Packing is careful—machines arrive safe every time. Questions get answered fast, often same day. Service feels close even halfway around the world. Lines run longer, numbers climb higher. Overall, buyers say the machines, people, and support together deliver honest value every single shift. Trust just keeps growing.

| Certifications and Standards

Every SMT PCB assembly machine carries solid proof of quality. CE mark means it meets tough European safety rules. RoHS confirms no harmful materials inside. ISO9001 keeps strict control from factory to shipping. Plenty of patents cover the smart heads and vision tech. These stamps tell customers the equipment is safe for workers, friendly to the environment, and built to last years. You can buy knowing global standards are fully met, no questions asked.

| About I.C.T Company and Factory

I.C.T keeps its own research teams busy turning fresh ideas into working machines quick. We build everything in big, modern plants with checks at every step. Staff count keeps growing steady. New offices open worldwide regular. More than 1600 customers across 72 countries run our lines today. Growth comes from plain hard work and real results delivered. Strict quality systems watch over each part. Every SMT PCB assembly machine rolls out ready for tough daily duty. We aim to stay a dependable partner everywhere electronics get made.

| JUKI SMD IC Pick and Place Machine

Look, when you run a factory, you want machines that just work—no fuss, no drama. This SMT PCB assembly machine line from Juki does exactly that. It picks chips and ICs and sets them down perfect on circuit boards, fast as you please. The setup is modular, so you add pieces as business grows. Cameras watch every move live. Programming is straightforward; anybody with basic training can handle it. The narrow footprint slides right into crowded lines. I.C.T stands by from planning to daily fixes, making sure output stays high and trouble stays low for all kinds of electronics work.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

Well now, the RS-1R and RS-1XL are the practical choices for shops that run mixed jobs. The RS-1R pushes 47,000 parts per hour with dead-on ±35µm accuracy. Standard boards up to 650×370mm fit fine, and the RS-1XL takes wider ones to 650×560mm—handy for big LED panels. That Takumi head shifts smart during runs, handling odd shapes without slowing. Feeders go clear to 112 for fast switches. Vision spots issues quick, force control treats delicate boards gentle. These two play nice together in flexible lines and keep production steady all shift long.

RX-7R / RX-8 Series Features

If speed is what you’re chasing, the RX-7R and RX-8 won’t disappoint. The RX-7R hits 75,000 CPH steady, while the RX-8 climbs all the way to 100,000 with its clever P20 head. Both stay skinny at 998mm wide, giving the best parts-per-square-foot numbers around. They place super-small 03015 chips without blinking. Parallel heads team up smooth, coaxial lights make tiny details crystal clear. Low-impact mode protects fragile parts, data shares easy between units. Perfect for high-volume runs of phone boards or driver circuits—pure production muscle in a small package.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T builds complete PCBA lines that hold up under real work. PCB loader pulls boards in spotless. SMT Printer spreads paste even every time. The SMT PCB assembly machine drops each component exactly where needed. Multi-zone reflow soldering oven locks solder solid and strong. Sharp AOI catches any mistake early. Conveyors link everything tight, buffers keep flow steady. Yield runs high, costs stay low, no weak spots anywhere. These lines handle tough automotive power jobs and more. Finished boards come out ready for the real world. We back the whole setup start to finish.

| Customer Success Video

There’s this customer building power supplies for cars, and their video tells the story plain. It opens on the full SMT and DIP lines running smooth. Boards slide in clean through the loader, get perfect paste, then the JUKI SMD IC Pick and Place Machine fills them fast and accurate. Conveyors carry on to reflow, cooling, AOI checks, and unload. Over on DIP, wave solder handles through-hole, flippers turn boards, ICT tests function. The owner talks straight—everything connects, nothing stalls, quality stays top-notch. You see clear shots of steady flow and precise work from beginning to end. Tough car standards get met easy.

| Service and Training Support

I.C.T doesn’t leave you hanging after the sale. Our engineers show up, install the SMT PCB assembly machine, and run full tests. Training is practical—operators learn programming, daily care, quick repairs right on the floor. Remote links fix most issues in hours. Regular maintenance plans keep performance sharp year after year. We study your line and suggest real improvements. Upgrades drop in simple. With offices worldwide, help gets to you fast no matter the country. Customers keep running full tilt with almost no long stops. Good partnership starts day one and lasts.

| Customer Feedback

Folks who bought from us talk straight and plain. They like engineers that arrive prepared and solve problems quick. The SMT PCB assembly machine earns praise for steady speed and rare mistakes. Packing is careful—machines arrive safe every time. Questions get answered fast, often same day. Service feels close even halfway around the world. Lines run longer, numbers climb higher. Overall, buyers say the machines, people, and support together deliver honest value every single shift. Trust just keeps growing.

| Certifications and Standards

Every SMT PCB assembly machine carries solid proof of quality. CE mark means it meets tough European safety rules. RoHS confirms no harmful materials inside. ISO9001 keeps strict control from factory to shipping. Plenty of patents cover the smart heads and vision tech. These stamps tell customers the equipment is safe for workers, friendly to the environment, and built to last years. You can buy knowing global standards are fully met, no questions asked.

| About I.C.T Company and Factory

I.C.T keeps its own research teams busy turning fresh ideas into working machines quick. We build everything in big, modern plants with checks at every step. Staff count keeps growing steady. New offices open worldwide regular. More than 1600 customers across 72 countries run our lines today. Growth comes from plain hard work and real results delivered. Strict quality systems watch over each part. Every SMT PCB assembly machine rolls out ready for tough daily duty. We aim to stay a dependable partner everywhere electronics get made.