I.C.T

PCB Laser Marking

| Availability: | |

|---|---|

| Quantity: | |

| Advanced 3D Laser Marking for Modern PCB Traceability

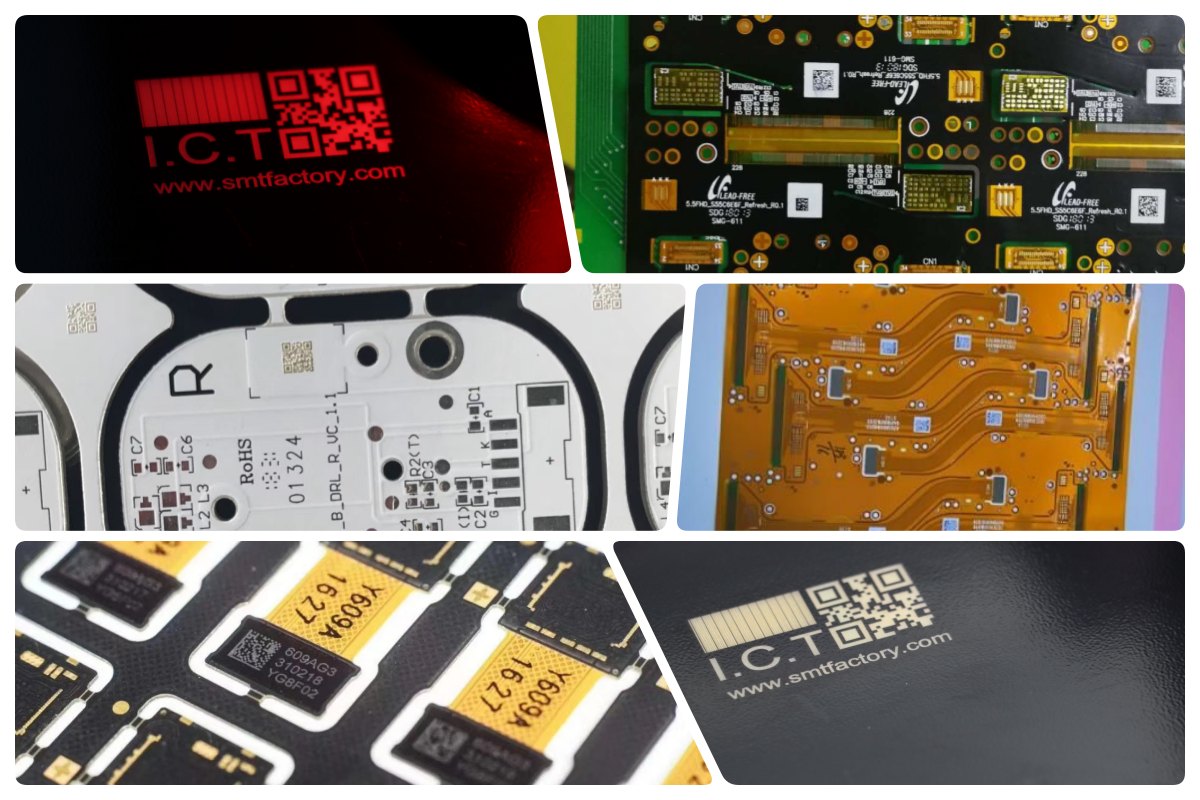

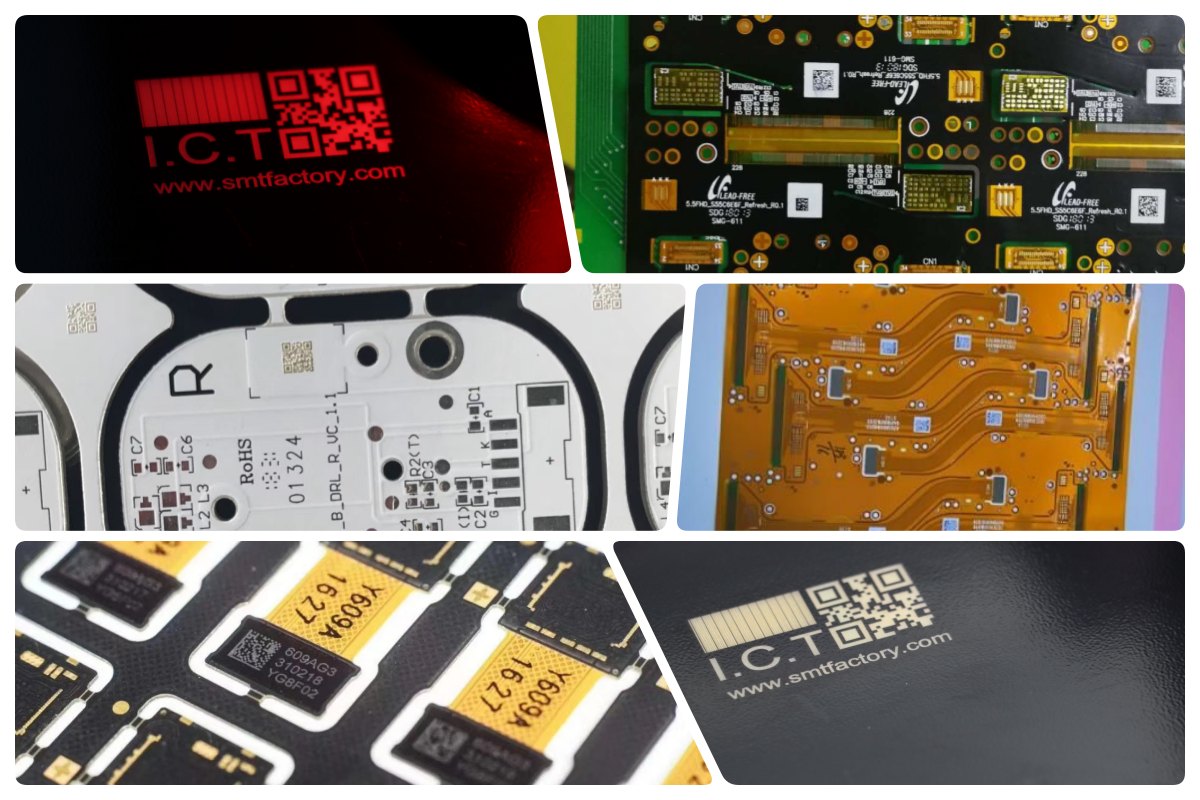

The 50W laser marking machine excels at creating durable, high-contrast marks such as text, barcodes, QR codes, and graphics on PCBs in demanding SMT environments. It offers ±0.05 mm precision and supports PCB sizes up to 510×460 mm across models like I.C.T-400, 460, 510, and 510L. The fiber laser option handles metals and conductive traces effectively, while CO₂ variants suit FR4 and solder mask, making this fiber marked laser machine highly versatile. It connects directly to assembly lines for real-time MES data sharing and supports both online and offline modes. Free from inks, labels, or other supplies, it lowers running costs, prevents environmental impact, and eliminates reprint risks. With marking speeds up to 7000 mm/s and stable performance, the machine supports high-volume production while ensuring consistent, readable results that meet strict traceability needs in electronics manufacturing.

| Feature

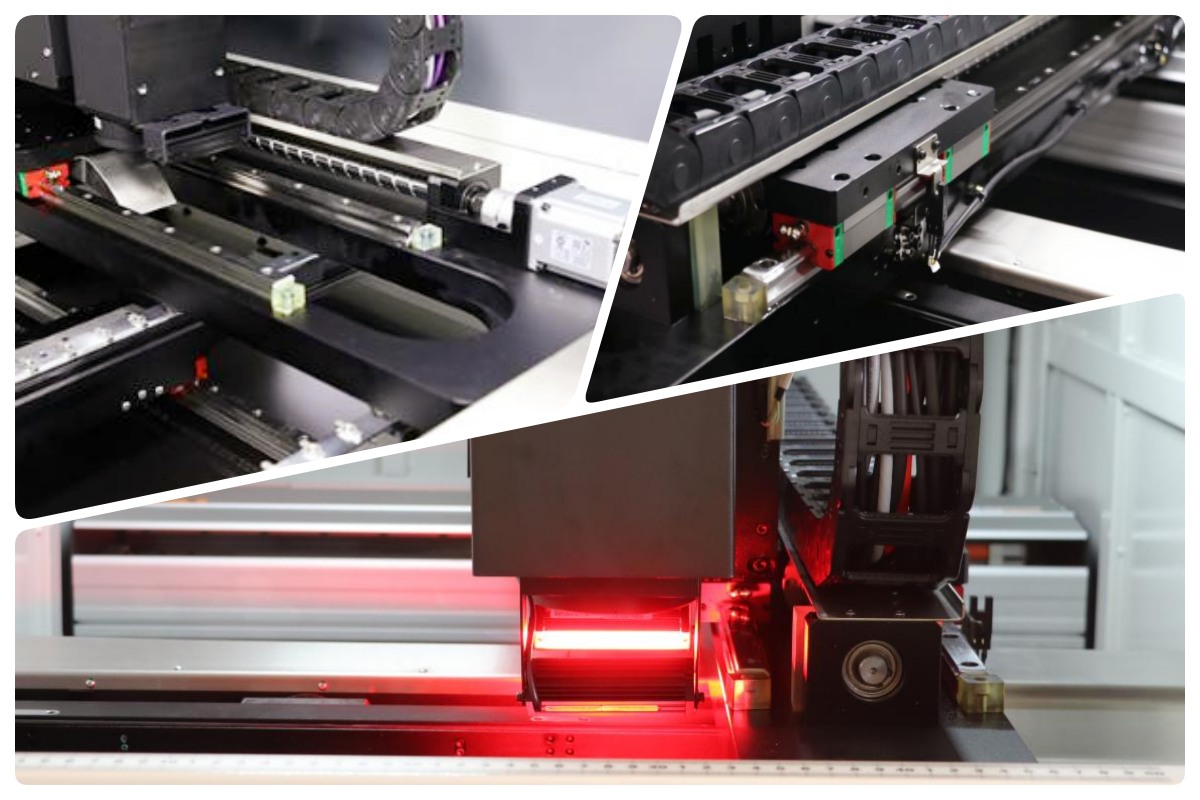

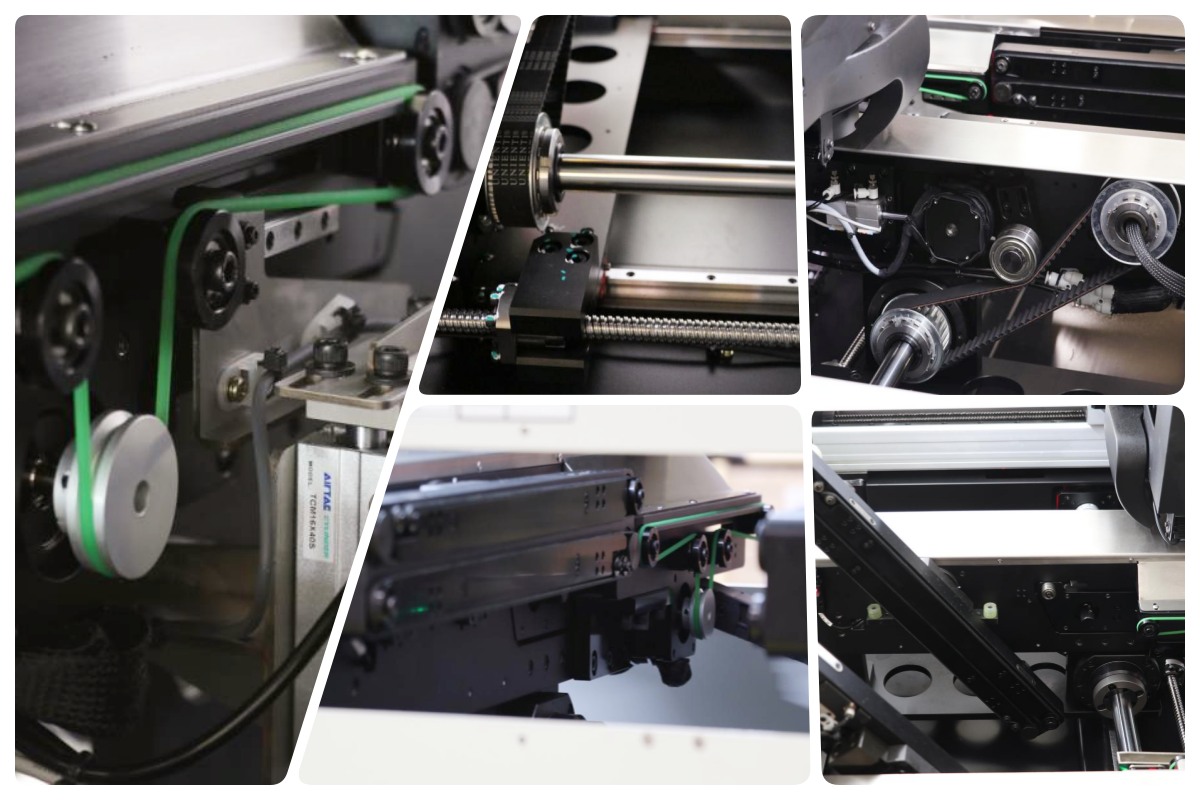

Heavy-Duty Driving System for Steady Performance

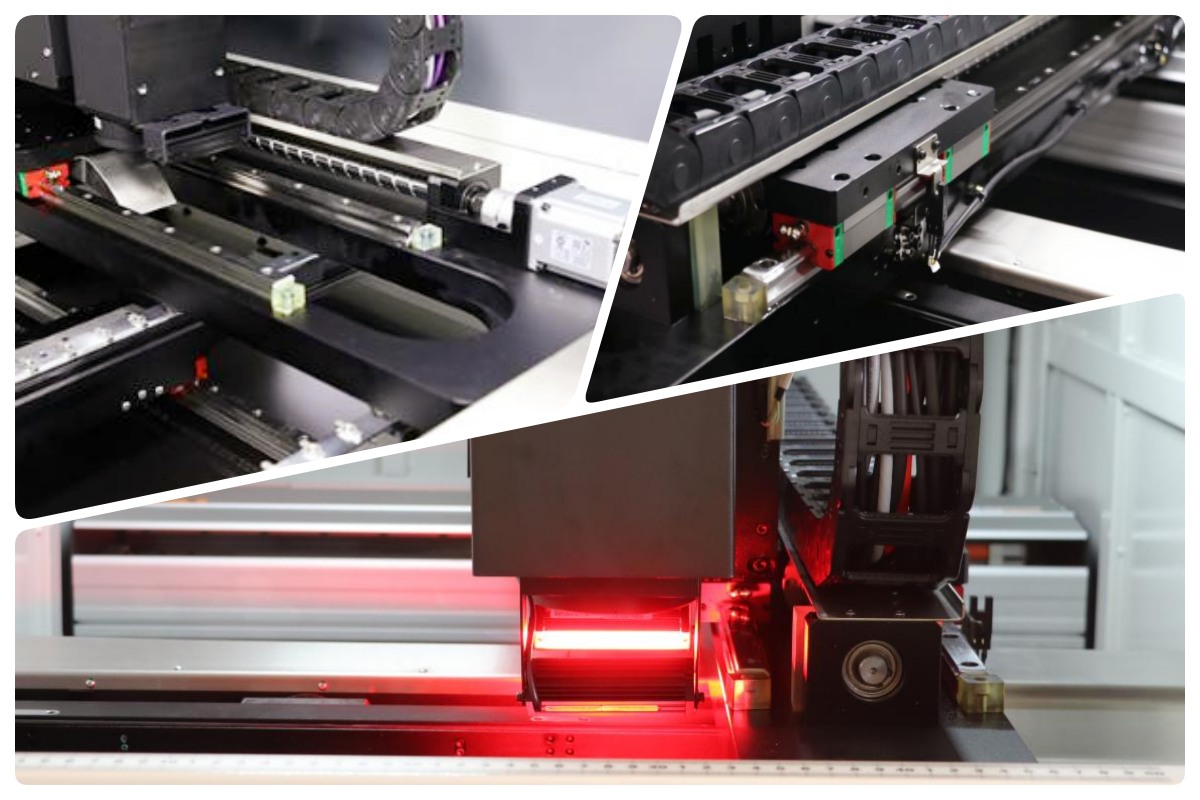

I.C.T built the driving system with an arch bridge suspension structure that teams up with premium ball screws and linear guides from TBI and HIWIN/PMI. Two independent high-precision servo motors manage X and Y movements, keeping positioning accurate under different loads. Flexible closed tank chains, reinforced by auxiliary profiles, guarantee smooth, vibration-free travel during long hours of use. The unique dust cover shields internal parts from dust and debris, which greatly reduces cleaning needs and maintenance expenses. This robust setup allows the 50W laser marking machine to maintain reliable motion and high accuracy in busy SMT factories, directly supporting consistent mark quality and fewer production stops.

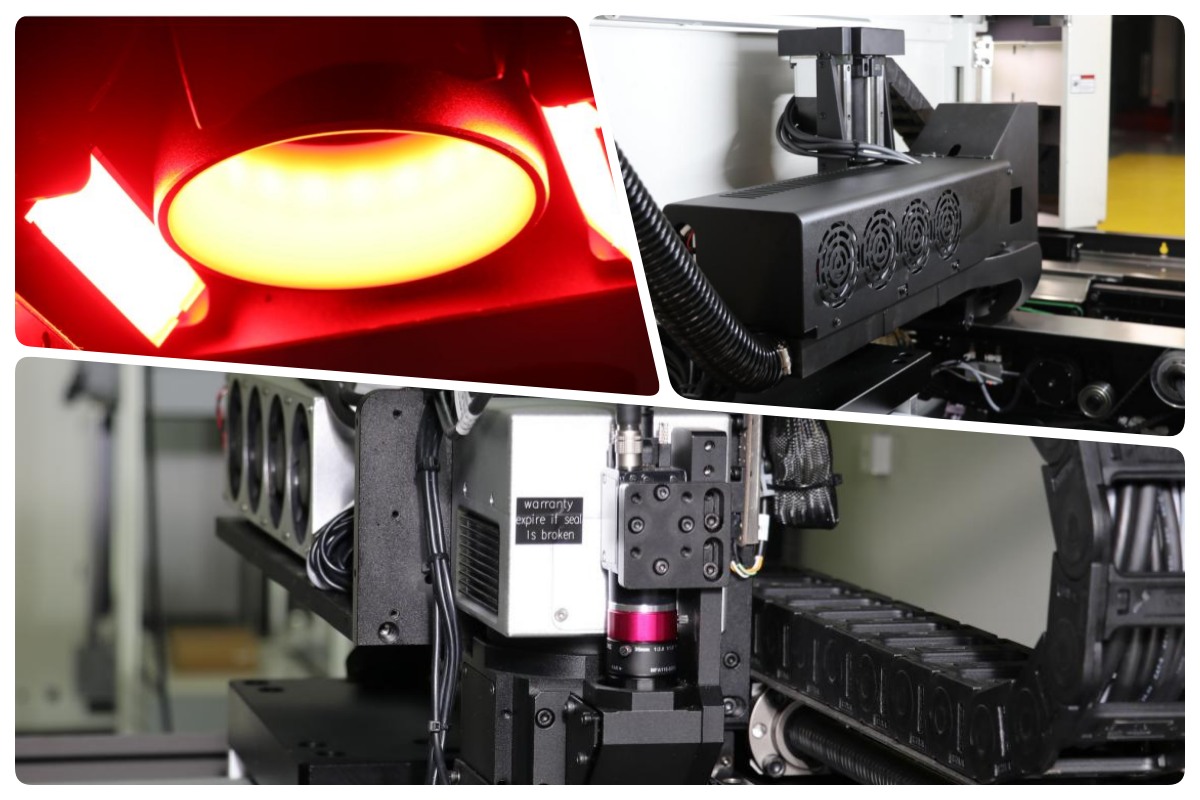

Multi-Laser Marking System for Material Versatility

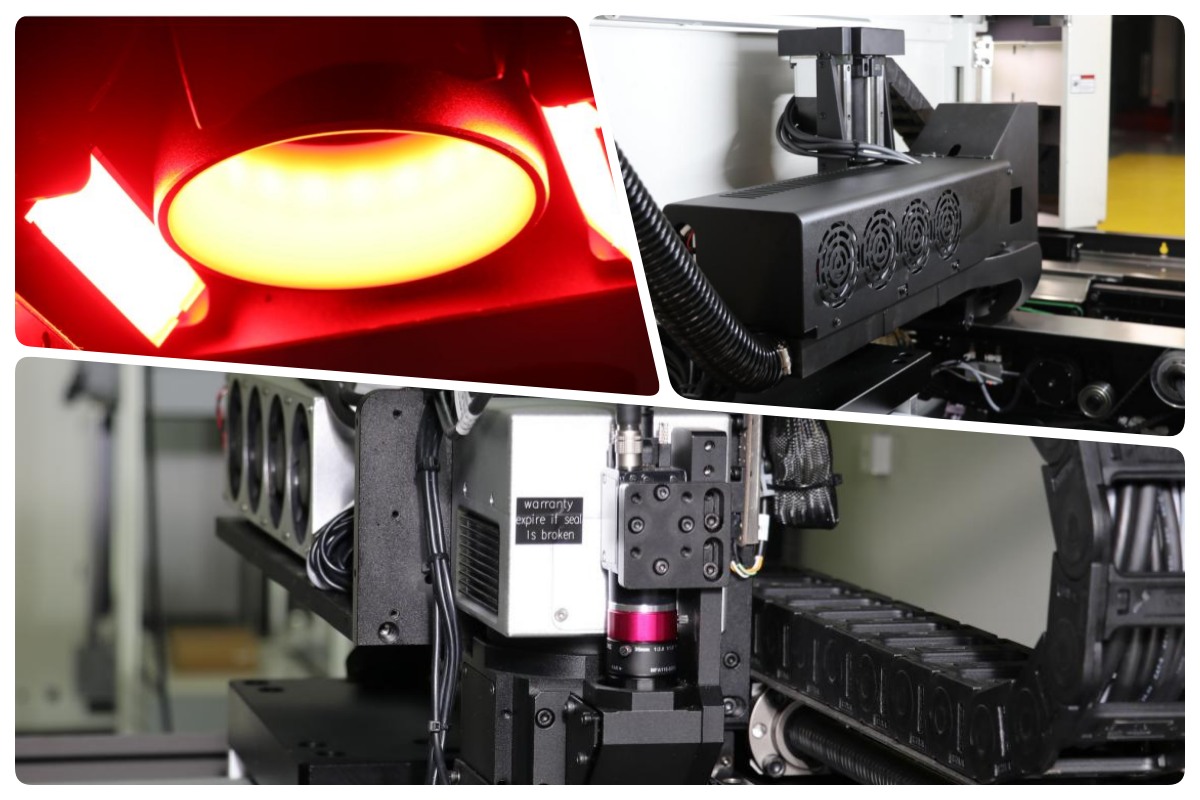

The marking system lets operators pick UV, Green, Fiber, or CO₂ lasers to best match their PCB materials and production requirements. Each laser provides stable output, precise wavelength, and a long lifespan for dependable everyday performance. Factory calibration sets the focal length perfectly, so no on-site tweaking is needed, and the Z-axis auto-adjusts to board height. Cooling solutions are tailored to each laser type to avoid overheating in continuous runs. Various beam options handle intricate designs and difficult surfaces well. This adaptable system ensures the 50W laser marking machine creates sharp, uniform marks that deliver strong traceability across a broad range of electronics applications.

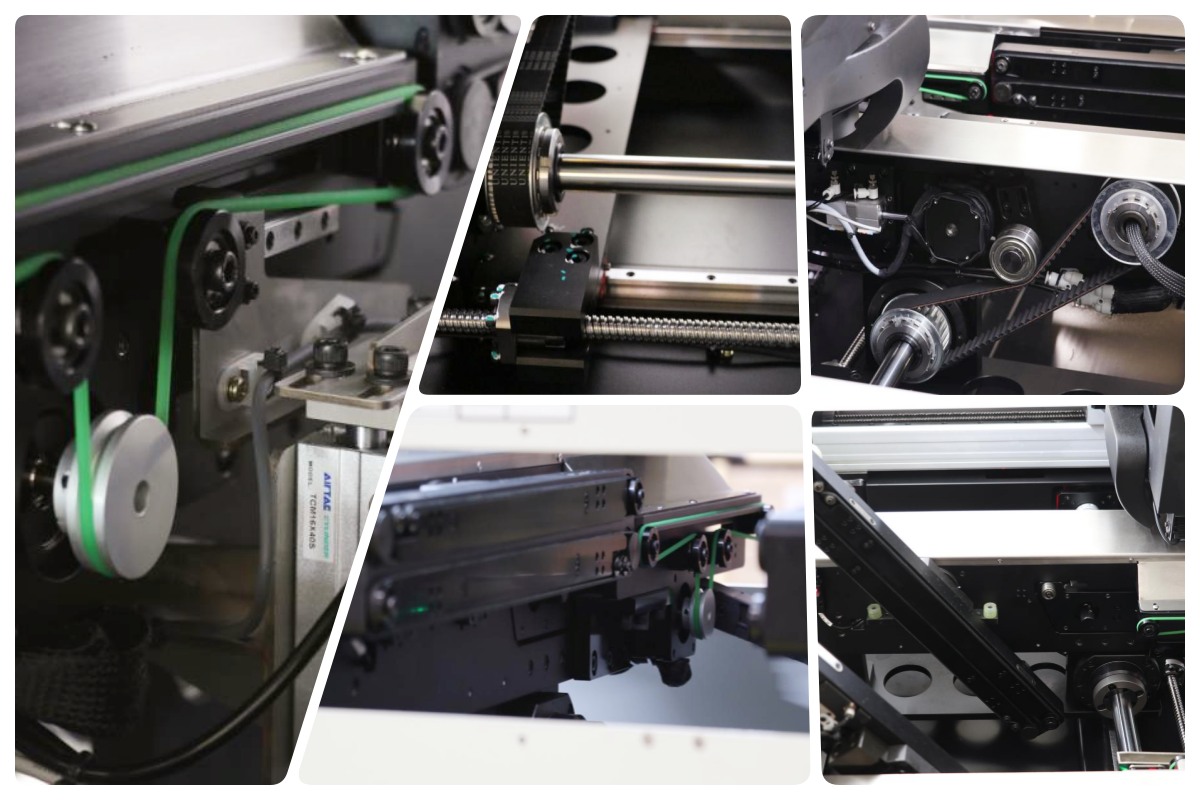

Secure Transport System for Gentle Board Flow

Select models feature a built-in flip function that processes double-sided boards in one pass, simplifying complex marking tasks. Segmented guide rails use ESD anti-static belts to protect components from static harm. High-strength synchronous belts allow adjustable speed to match line pace, with special tensioning devices keeping belts tight and aligned. Ball screws and rigid shafts make width adjustments synchronous, maintaining exact front-to-rear rail parallelism to prevent skewing. Cylinder baffles offer precise stopping control. These features work together to transport PCBs safely and accurately, helping keep production steady, yields high, and defects low throughout the SMT process.

Reliable Control System with Easy Maintenance

The control layout features organized wiring and clear markings that make inspections and repairs simple for technicians. High-precision servo drives and motors provide smooth, low-vibration operation for repeatable results. Air convection cooling keeps electronics at safe temperatures in warm factory conditions. I.C.T’s integrated control board runs stably with minimal wiring issues and straightforward service steps. A separate leakage protection switch adds extra electrical safety, and the system meets CE and UL international standards. This practical design keeps the 50W laser marking machine running safely and consistently, letting teams concentrate on output rather than frequent fixes.

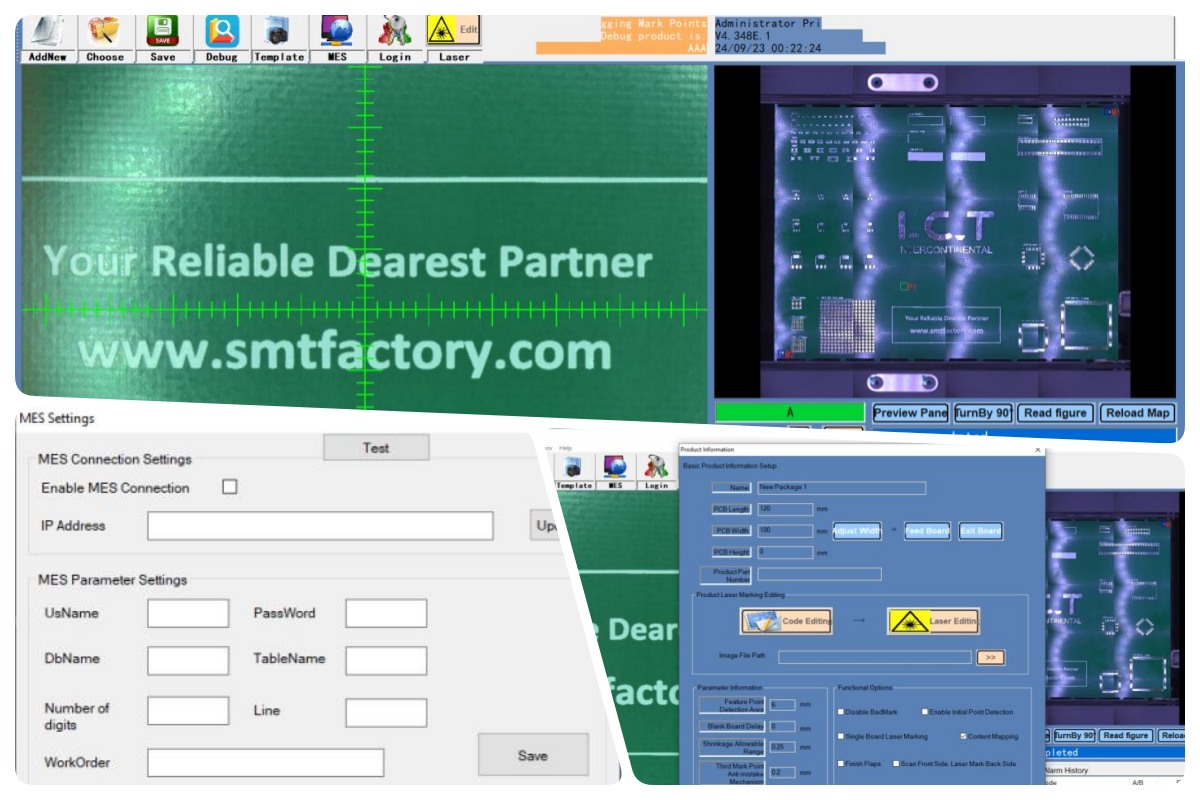

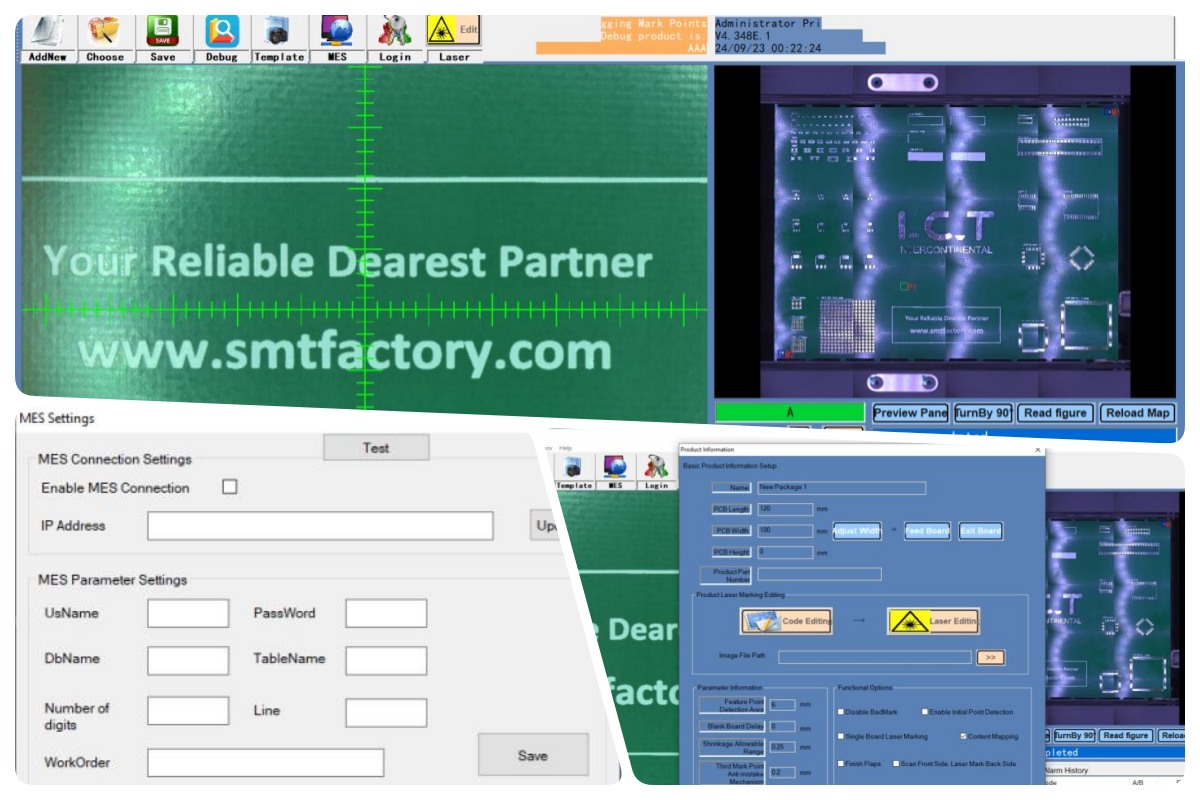

Simple Operator Interface for Fast Adoption

The operator interface uses a clear, step-by-step design that shortens training time for new users. Running on a genuine Windows platform, it stores multiple job programs for quick switches between products. Full-frame scanning shows alignment patterns right on the screen, speeding up setup work. The coaxial camera setup skips separate calibration entirely. Standard MES ports allow direct factory system links, with custom protocol options available. These thoughtful features cut learning time, reduce mistakes, and support easy integration of the machine into current SMT lines with little disruption.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Integrated SMT Production Line Solution

I.C.T provides complete full-auto SMT production lines designed for demanding sectors like automotive electronics, medical devices, and LED lighting. The line starts with a PCB stacker loader that feeds clean PCBs into the process. Next, an automatic solder paste printer deposits paste with high precision. High-speed The pick and place machine place components accurately and efficiently. Multi-zone Lyra reflow ovens create strong, reliable solder joints. Advanced AOI systems detect defects early to maximize yield. Robust PCB conveyors ensure smooth, synchronized movement across stations. PCBA cleaning machines remove flux residues for enhanced reliability. A fully automatic solder paste storage and tempering cabinet maintains paste quality at all times. This integrated solution delivers high yield, lower costs, and consistent performance, supported by I.C.T's full-service commitment from installation to ongoing technical support.

| Customer Project Case

I.C.T successfully installed and supported Factory Acceptance Testing (FAT) for two complete SMT production lines at a North American manufacturer of beauty instruments. The lines passed full production acceptance with excellent results. Each line featured our 3D laser marking machine for reliable traceability, plus an SMT printer with SPI, Panasonic mounter, Heller reflow oven, AOI inspection system, PCB transfer conveyors, PCBA cleaning equipment, and an automatic solder paste storage and warming unit. Our engineers managed on-site setup, provided thorough training, and adjusted processes to match exact needs. The customer now operates efficient, high-quality lines ready to scale up production of advanced personal-care products.

| Global Service and Training Support

I.C.T delivers complete technical support starting with professional installation and commissioning to bring machines online quickly. Training programs cover machine operation, software use, code creation, routine maintenance, and basic troubleshooting steps. Engineers share practical tips to maximize marking quality and line throughput. After startup, customers receive prompt remote assistance, fast spare-part shipping, and scheduled follow-up visits. This ongoing commitment reduces unplanned stops, extends machine life, and keeps production running at peak levels. With dedicated support, manufacturers gain confidence that their investment in the 3D laser marking machine continues delivering strong returns over many years.

| Customer Experience and Operational Benefits

Customers regularly thank our engineers for their thorough knowledge, patient explanations, and rapid resolution of setup challenges. Many point to the 3D laser marking machine as delivering sharp, consistent marks that hold up well under production stress. Feedback often mentions the secure packing and safe international delivery that protect equipment from transit damage. Quick responses to questions—whether by phone, email, or remote login—build lasting trust. Overall, clients value the reliable performance combined with attentive, professional service that helps them maintain high standards and smooth operations day after day.

| Standards, Control and Production Discipline

I.C.T machines carry essential certifications that confirm compliance with global safety and quality requirements. These include CE for electrical and mechanical safety, RoHS to restrict harmful substances, and ISO9001 for a structured quality management approach. Additional patents cover unique advancements in laser control, motion accuracy, and system integration. These credentials verify that the 3D laser marking machine meets rigorous international benchmarks, operates safely, supports environmentally responsible manufacturing, and earns trust from electronics producers around the world.

| About I.C.T Company and Factory

I.C.T maintains its own R&D team and manufacturing plant in Dongguan, China, spanning 12,000 square meters with 89 employees including 20 experienced engineers. Since starting in 2012, the company has grown steadily and now serves over 1,600 customers in 72 countries. The factory applies strict testing at every production stage, supported by a comprehensive quality system that ensures consistent machine performance. We supply complete SMT solutions—from project planning and equipment delivery to installation, training, and ongoing optimization—helping clients worldwide build efficient, scalable manufacturing operations with confidence.

| Advanced 3D Laser Marking for Modern PCB Traceability

The 50W laser marking machine excels at creating durable, high-contrast marks such as text, barcodes, QR codes, and graphics on PCBs in demanding SMT environments. It offers ±0.05 mm precision and supports PCB sizes up to 510×460 mm across models like I.C.T-400, 460, 510, and 510L. The fiber laser option handles metals and conductive traces effectively, while CO₂ variants suit FR4 and solder mask, making this fiber marked laser machine highly versatile. It connects directly to assembly lines for real-time MES data sharing and supports both online and offline modes. Free from inks, labels, or other supplies, it lowers running costs, prevents environmental impact, and eliminates reprint risks. With marking speeds up to 7000 mm/s and stable performance, the machine supports high-volume production while ensuring consistent, readable results that meet strict traceability needs in electronics manufacturing.

| Feature

Heavy-Duty Driving System for Steady Performance

I.C.T built the driving system with an arch bridge suspension structure that teams up with premium ball screws and linear guides from TBI and HIWIN/PMI. Two independent high-precision servo motors manage X and Y movements, keeping positioning accurate under different loads. Flexible closed tank chains, reinforced by auxiliary profiles, guarantee smooth, vibration-free travel during long hours of use. The unique dust cover shields internal parts from dust and debris, which greatly reduces cleaning needs and maintenance expenses. This robust setup allows the 50W laser marking machine to maintain reliable motion and high accuracy in busy SMT factories, directly supporting consistent mark quality and fewer production stops.

Multi-Laser Marking System for Material Versatility

The marking system lets operators pick UV, Green, Fiber, or CO₂ lasers to best match their PCB materials and production requirements. Each laser provides stable output, precise wavelength, and a long lifespan for dependable everyday performance. Factory calibration sets the focal length perfectly, so no on-site tweaking is needed, and the Z-axis auto-adjusts to board height. Cooling solutions are tailored to each laser type to avoid overheating in continuous runs. Various beam options handle intricate designs and difficult surfaces well. This adaptable system ensures the 50W laser marking machine creates sharp, uniform marks that deliver strong traceability across a broad range of electronics applications.

Secure Transport System for Gentle Board Flow

Select models feature a built-in flip function that processes double-sided boards in one pass, simplifying complex marking tasks. Segmented guide rails use ESD anti-static belts to protect components from static harm. High-strength synchronous belts allow adjustable speed to match line pace, with special tensioning devices keeping belts tight and aligned. Ball screws and rigid shafts make width adjustments synchronous, maintaining exact front-to-rear rail parallelism to prevent skewing. Cylinder baffles offer precise stopping control. These features work together to transport PCBs safely and accurately, helping keep production steady, yields high, and defects low throughout the SMT process.

Reliable Control System with Easy Maintenance

The control layout features organized wiring and clear markings that make inspections and repairs simple for technicians. High-precision servo drives and motors provide smooth, low-vibration operation for repeatable results. Air convection cooling keeps electronics at safe temperatures in warm factory conditions. I.C.T’s integrated control board runs stably with minimal wiring issues and straightforward service steps. A separate leakage protection switch adds extra electrical safety, and the system meets CE and UL international standards. This practical design keeps the 50W laser marking machine running safely and consistently, letting teams concentrate on output rather than frequent fixes.

Simple Operator Interface for Fast Adoption

The operator interface uses a clear, step-by-step design that shortens training time for new users. Running on a genuine Windows platform, it stores multiple job programs for quick switches between products. Full-frame scanning shows alignment patterns right on the screen, speeding up setup work. The coaxial camera setup skips separate calibration entirely. Standard MES ports allow direct factory system links, with custom protocol options available. These thoughtful features cut learning time, reduce mistakes, and support easy integration of the machine into current SMT lines with little disruption.

| Specification

| Parameter | I.C.T-400 | I.C.T-460 | I.C.T-510 | I.C.T-510L |

|---|---|---|---|---|

| Max PCB Size | 380 × 380 mm | 510 × 450 mm | 510 × 400 mm | 510 × 460 mm |

| Marking Range | 280 × 380 mm | 460 × 450 mm | 430 × 400 mm | 510 × 460 mm |

| PCB Flip Function | Yes (built-in flipper) | Yes (built-in flipper) | No | No |

| Machine Dimension | 835 × 1488 × 1566 mm | 974 × 1528 × 1616 mm | 1054 × 1568 × 1523 mm | 1054 × 1470 × 1523 mm |

| Machine Weight | 700 kg | 800 kg | 750 kg | 800 kg |

| Marking Precision | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) | ±0.05 mm (same for all) |

| PCB Thickness | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) | 0.5–5 mm (same for all) |

| Marking Speed | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) | <7000 mm/s (same for all) |

| Laser Types Supported | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) | UV, Green, Fiber, CO₂ (same for all) |

| PCB Safety Height | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) | Top <25 mm, Bottom <20 mm (same for all) |

How to choose the Laser:

UV laser (355nm): Best for heat-sensitive PCBs, FR4 solder mask, flexible circuits. Cold marking, minimal damage, high contrast.

Green laser (532nm): Ideal for plastics, silicon wafers, ceramics, reflective coatings. Excellent absorption, ultra-fine marks, low heat impact.

Fiber laser (1064nm): Perfect for metals, copper/aluminum traces, metallic PCBs. Deep, permanent, fast, high-contrast marks.

CO₂ laser (10600nm): Suitable for standard FR4, solder mask, organic coatings. Stable, good contrast, cost-effective for rigid boards.

| Integrated SMT Production Line Solution

I.C.T provides complete full-auto SMT production lines designed for demanding sectors like automotive electronics, medical devices, and LED lighting. The line starts with a PCB stacker loader that feeds clean PCBs into the process. Next, an automatic solder paste printer deposits paste with high precision. High-speed The pick and place machine place components accurately and efficiently. Multi-zone Lyra reflow ovens create strong, reliable solder joints. Advanced AOI systems detect defects early to maximize yield. Robust PCB conveyors ensure smooth, synchronized movement across stations. PCBA cleaning machines remove flux residues for enhanced reliability. A fully automatic solder paste storage and tempering cabinet maintains paste quality at all times. This integrated solution delivers high yield, lower costs, and consistent performance, supported by I.C.T's full-service commitment from installation to ongoing technical support.

| Customer Project Case

I.C.T successfully installed and supported Factory Acceptance Testing (FAT) for two complete SMT production lines at a North American manufacturer of beauty instruments. The lines passed full production acceptance with excellent results. Each line featured our 3D laser marking machine for reliable traceability, plus an SMT printer with SPI, Panasonic mounter, Heller reflow oven, AOI inspection system, PCB transfer conveyors, PCBA cleaning equipment, and an automatic solder paste storage and warming unit. Our engineers managed on-site setup, provided thorough training, and adjusted processes to match exact needs. The customer now operates efficient, high-quality lines ready to scale up production of advanced personal-care products.

| Global Service and Training Support

I.C.T delivers complete technical support starting with professional installation and commissioning to bring machines online quickly. Training programs cover machine operation, software use, code creation, routine maintenance, and basic troubleshooting steps. Engineers share practical tips to maximize marking quality and line throughput. After startup, customers receive prompt remote assistance, fast spare-part shipping, and scheduled follow-up visits. This ongoing commitment reduces unplanned stops, extends machine life, and keeps production running at peak levels. With dedicated support, manufacturers gain confidence that their investment in the 3D laser marking machine continues delivering strong returns over many years.

| Customer Experience and Operational Benefits

Customers regularly thank our engineers for their thorough knowledge, patient explanations, and rapid resolution of setup challenges. Many point to the 3D laser marking machine as delivering sharp, consistent marks that hold up well under production stress. Feedback often mentions the secure packing and safe international delivery that protect equipment from transit damage. Quick responses to questions—whether by phone, email, or remote login—build lasting trust. Overall, clients value the reliable performance combined with attentive, professional service that helps them maintain high standards and smooth operations day after day.

| Standards, Control and Production Discipline

I.C.T machines carry essential certifications that confirm compliance with global safety and quality requirements. These include CE for electrical and mechanical safety, RoHS to restrict harmful substances, and ISO9001 for a structured quality management approach. Additional patents cover unique advancements in laser control, motion accuracy, and system integration. These credentials verify that the 3D laser marking machine meets rigorous international benchmarks, operates safely, supports environmentally responsible manufacturing, and earns trust from electronics producers around the world.

| About I.C.T Company and Factory

I.C.T maintains its own R&D team and manufacturing plant in Dongguan, China, spanning 12,000 square meters with 89 employees including 20 experienced engineers. Since starting in 2012, the company has grown steadily and now serves over 1,600 customers in 72 countries. The factory applies strict testing at every production stage, supported by a comprehensive quality system that ensures consistent machine performance. We supply complete SMT solutions—from project planning and equipment delivery to installation, training, and ongoing optimization—helping clients worldwide build efficient, scalable manufacturing operations with confidence.