I.C.T

PCB Cleaning Machine

| Availability: | |

|---|---|

| Quantity: | |

| Advanced PCB Residue Removal Solution

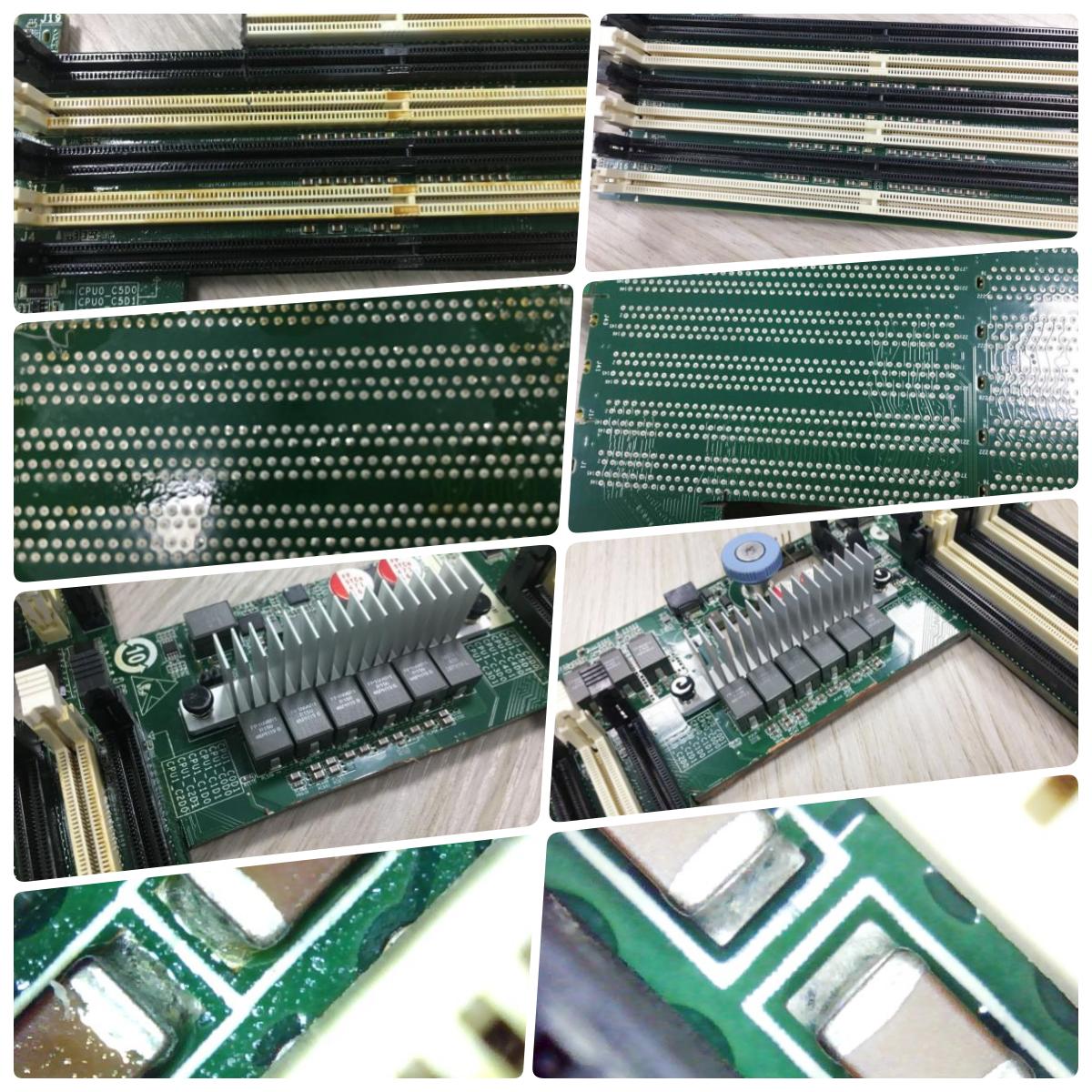

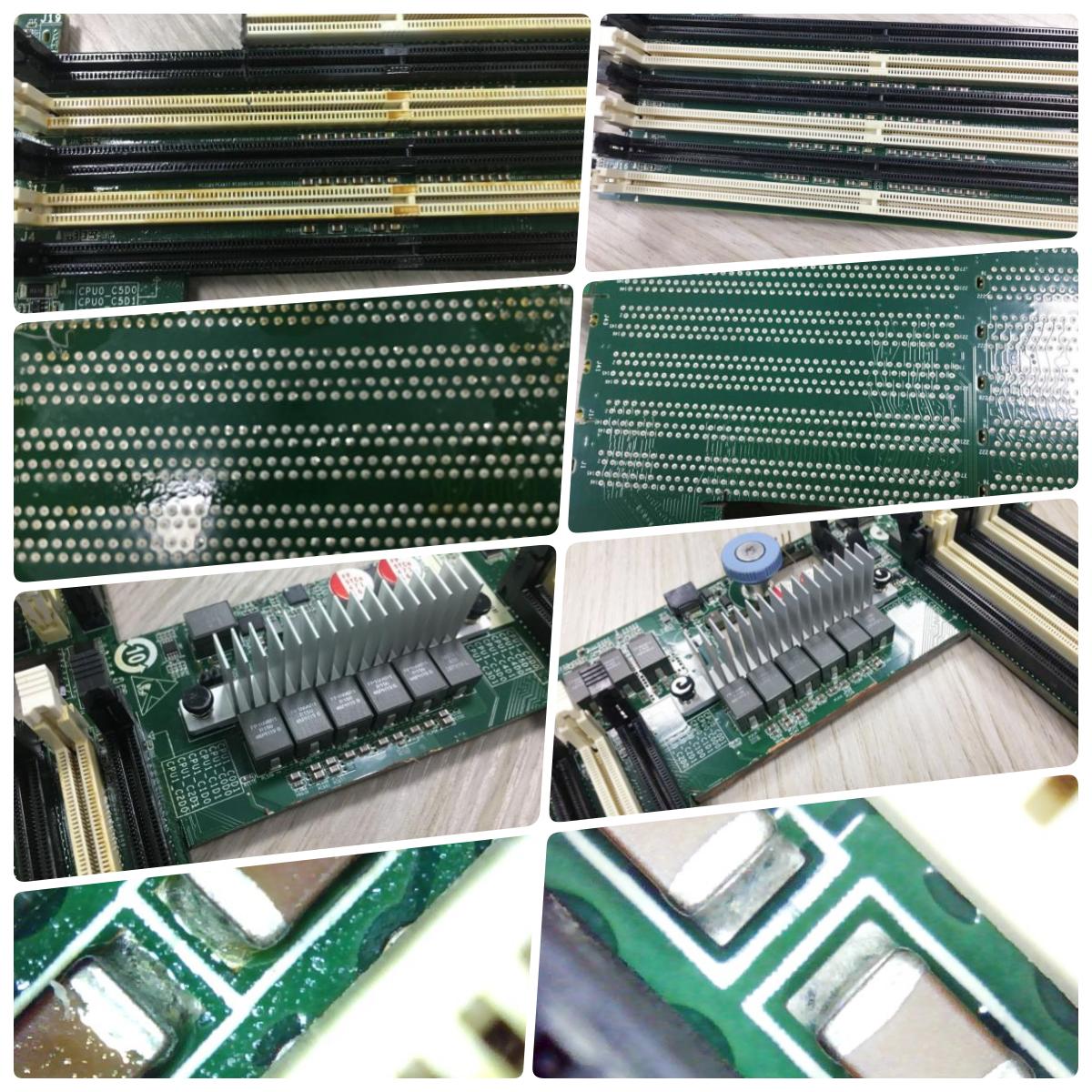

During SMT and mixed-technology production, residues and fine particles often remain on circuit boards after soldering, marking, or handling. The Circuit PCB Board ultrasonic Vacuum cleaner Machine is designed to address these challenges through a controlled off-line cleaning process. By combining ultrasonic energy with vacuum-based removal, the system targets contamination in tight component gaps and complex board layouts. As a Circuit PCB Board ultrasonic Vacuum cleaner Machine, it supports manufacturers who require higher cleanliness standards without increasing line complexity. The equipment operates independently from the SMT line, allowing cleaning to be scheduled according to inspection results or product requirements, improving overall production flexibility and quality control.

| Feature

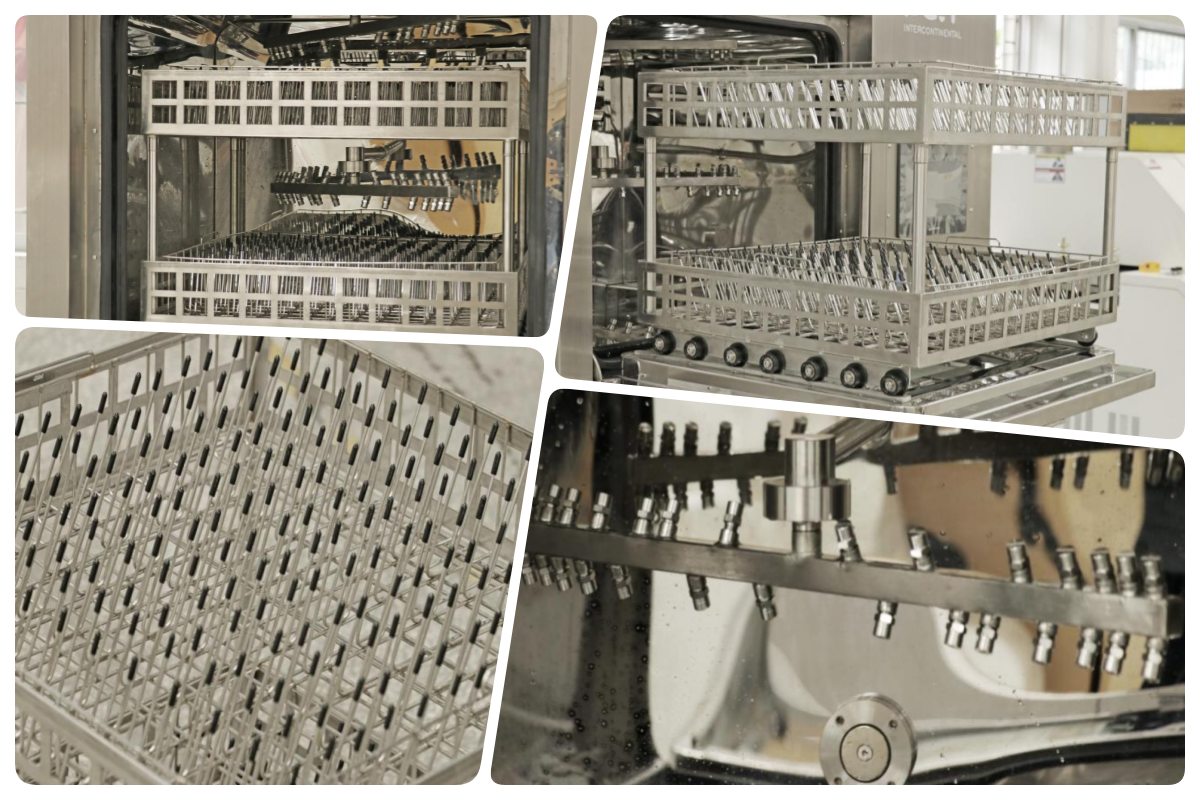

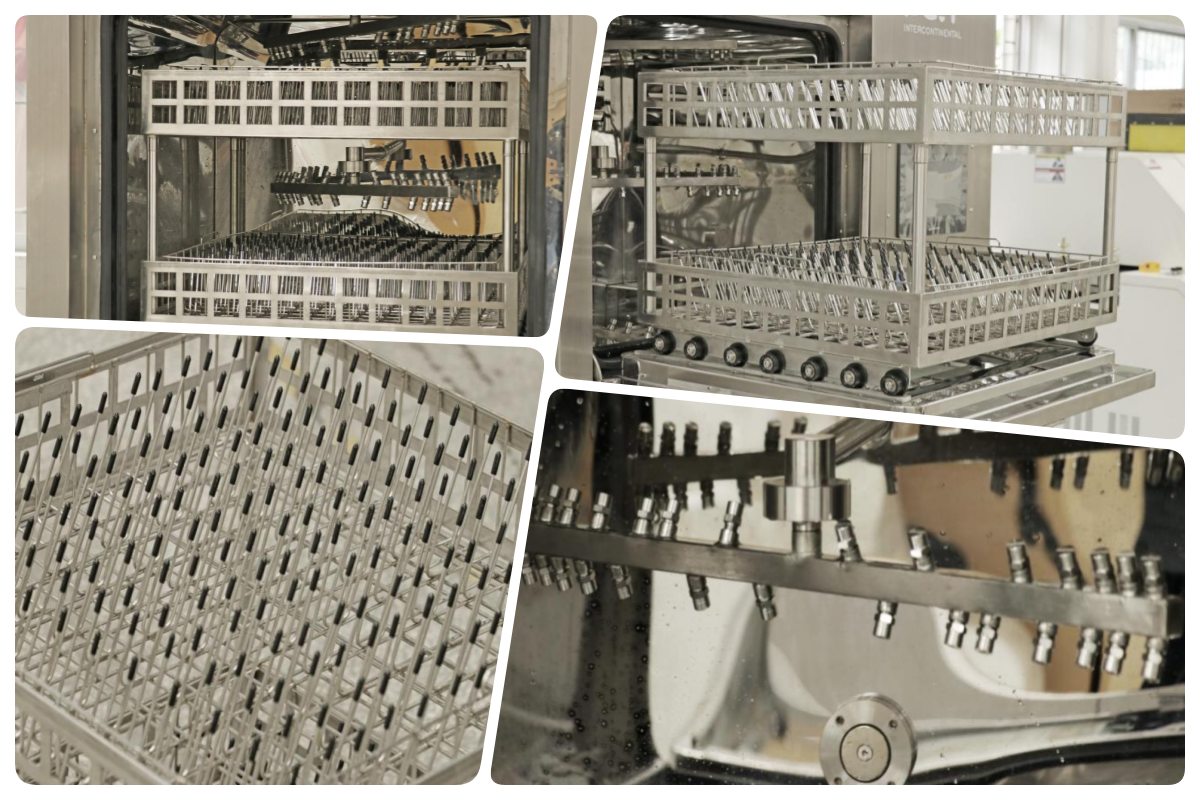

The cleaning room is designed as a closed processing space where ultrasonic action and vacuum cleaning work together in a controlled environment. PCB assemblies are positioned securely to ensure uniform exposure during the cleaning cycle. This structure allows contaminants to be loosened by ultrasonic energy and removed efficiently through vacuum extraction. For manufacturers handling dense or irregular PCB designs, the enclosed cleaning room improves consistency and reduces variation between batches. By isolating the process from external interference, the system supports stable and repeatable cleaning results across different product types and production schedules.

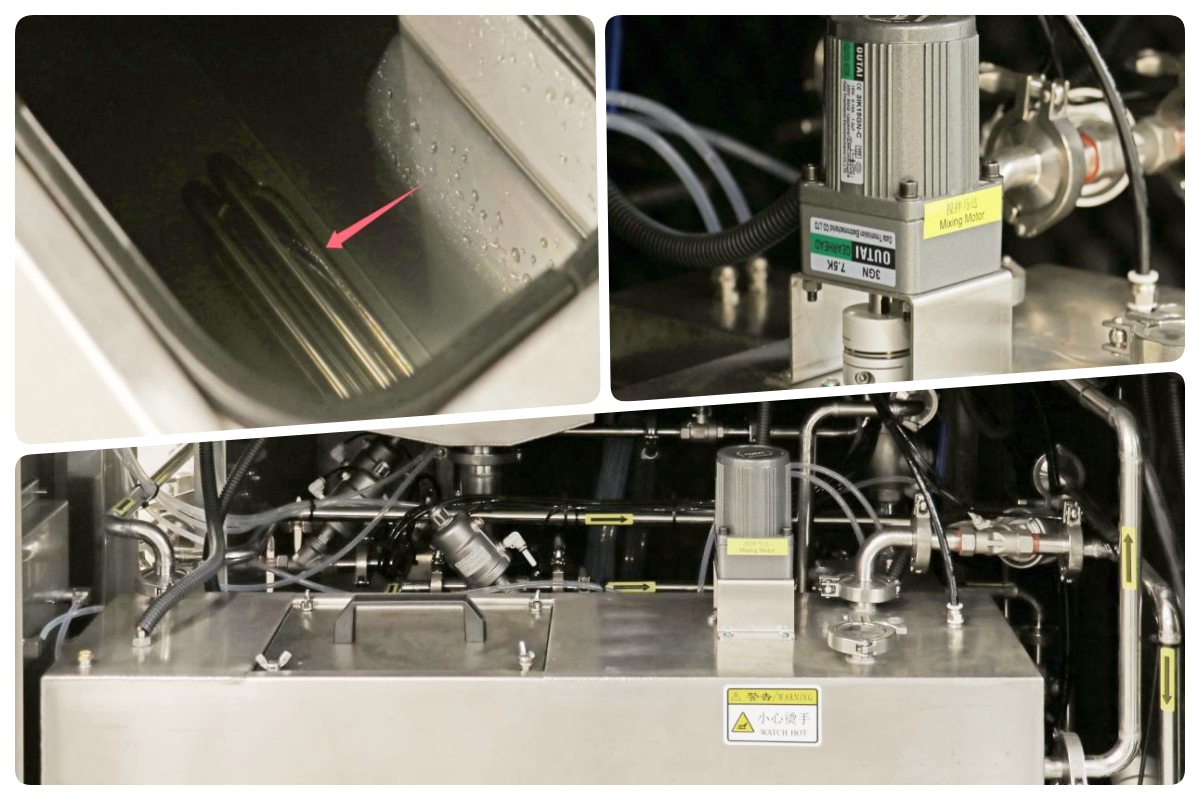

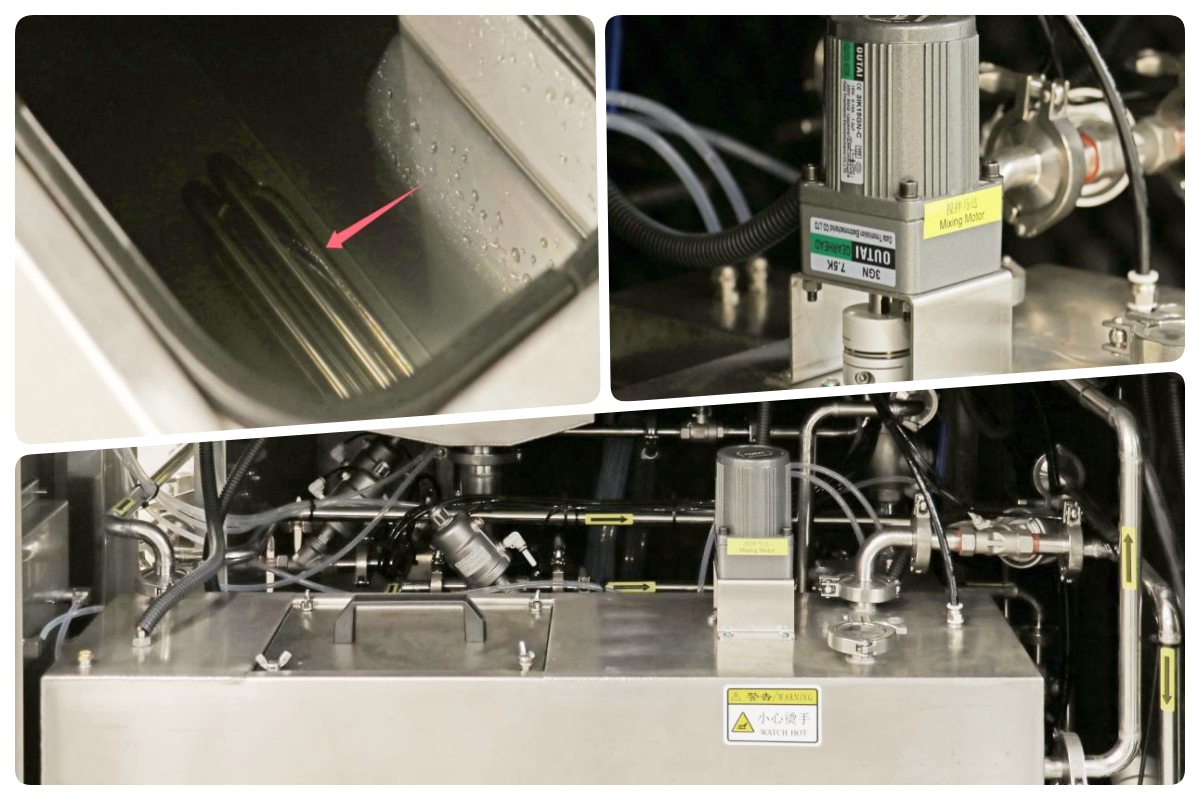

The circulation pipe system manages the movement of cleaning media and extracted residues during operation. Flow paths are designed to maintain stable pressure while preventing redeposition of contaminants onto the board surface. Collected residues are guided through filtration stages before the system continues operation. This design supports long-term process stability and reduces internal contamination. In daily production, the circulation structure helps maintain consistent cleaning performance even during repeated cycles. For off-line cleaning environments, this predictable flow behavior simplifies maintenance planning and helps extend equipment service life.

The washer fluid tank plays a central role in maintaining cleaning effectiveness during extended operation. It stores and filters the cleaning medium used in the ultrasonic process, removing particles and residues before reuse. Operators can monitor fluid condition and manage replacement schedules clearly. This controlled approach reduces the risk of cross-contamination between different PCB products. For factories using customized circuit PCB vacuum cleaner configurations, the washer fluid tank supports stable performance across various board types while keeping operating costs and process variables under control.

The drying module ensures that PCB assemblies are completely dry after the cleaning stage. Controlled airflow removes residual moisture from component gaps, connectors, and solder joints. Drying parameters can be adjusted to match board thickness and component density. This step is essential for protecting sensitive electronic components and ensuring boards are ready for inspection or testing. In production environments where appearance and reliability are critical, the drying module helps prevent secondary defects and supports smooth downstream processing.

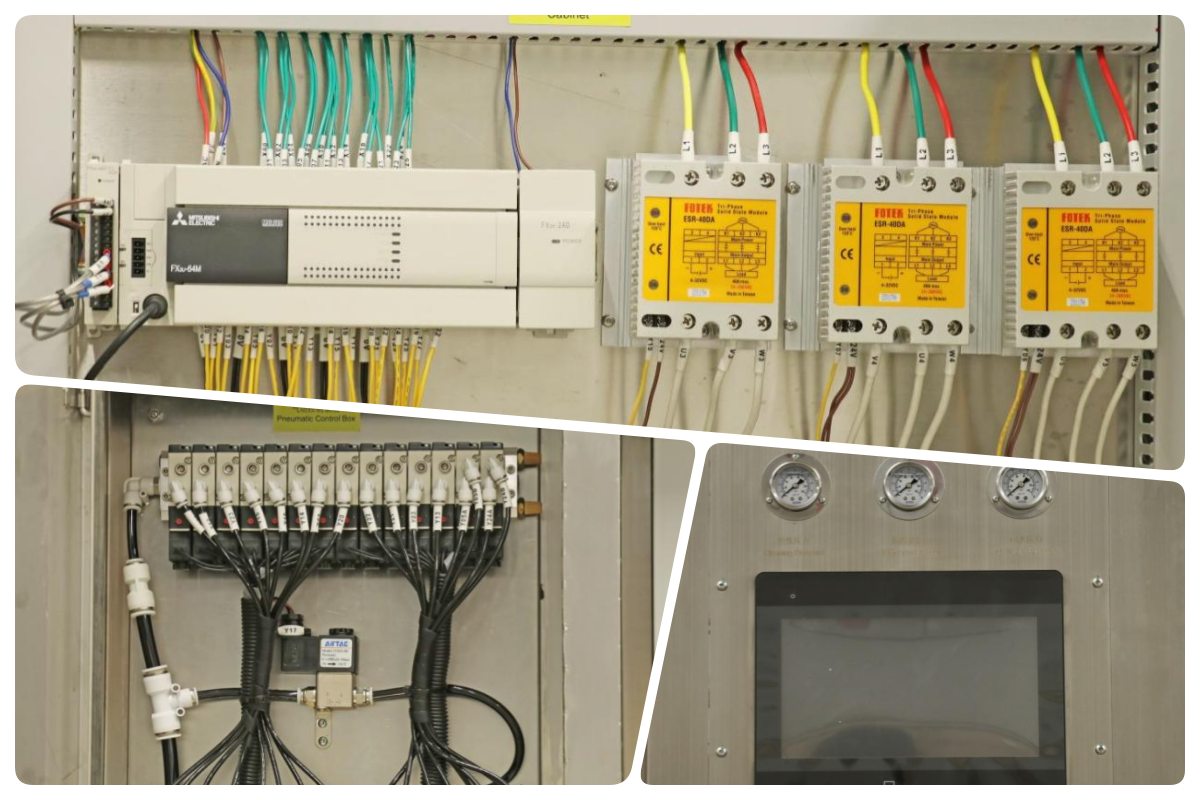

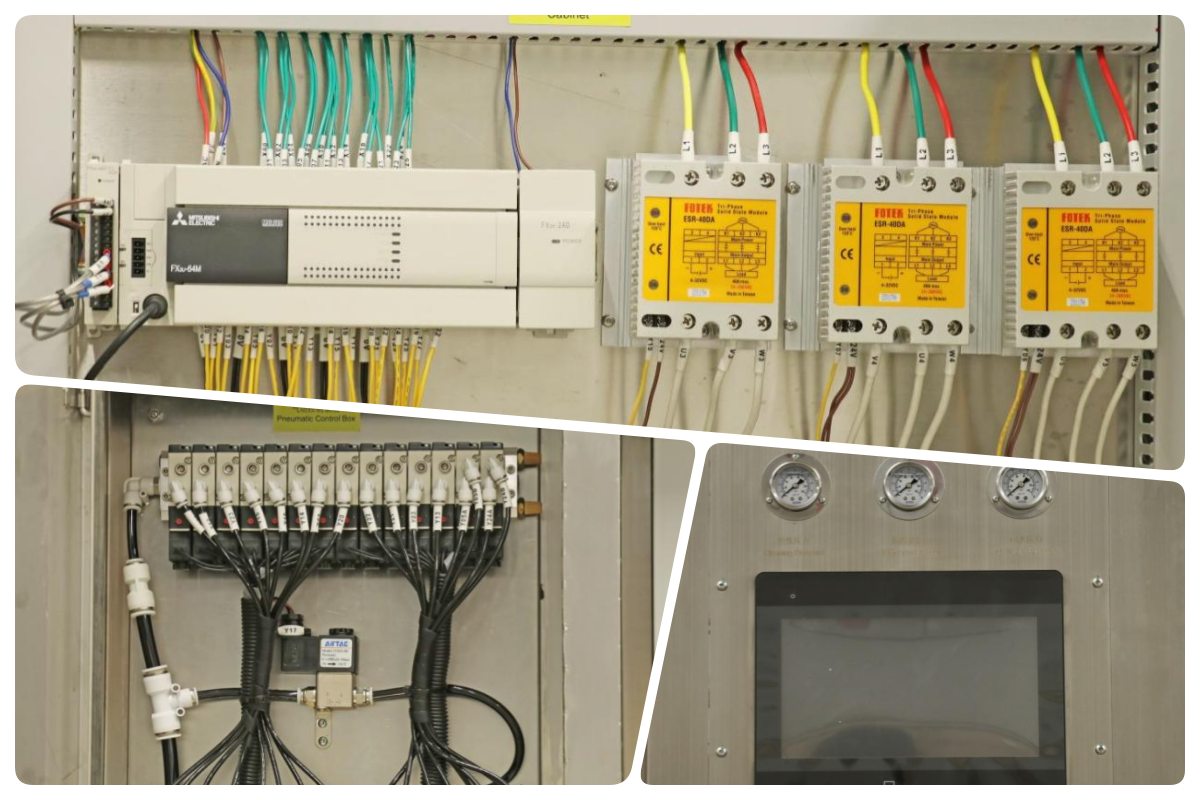

The control system is designed to manage ultrasonic intensity, vacuum timing, and process duration through a clear and structured interface. Multiple programs can be stored for different PCB designs and contamination levels. Real-time monitoring allows operators to track system status and maintain stable operation. Alarm and protection functions reduce the risk of abnormal conditions. Rather than focusing on complex automation, the control system emphasizes repeatability and process discipline, helping manufacturers achieve consistent cleaning quality across shifts and product changes.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

I.C.T successfully completed overseas installation and FAT support for two SMT production lines for a North American beauty device manufacturer. The project included laser marking systems, solder paste printing and SPI inspection, Panasonic placement machines, Heller reflow ovens, AOI inspection equipment, PCB handling systems, PCBA cleaning machines, and fully automatic solder paste storage and warming cabinets. I.C.T engineers supported installation, process setup, and trial production. Both SMT lines passed production acceptance smoothly, enabling stable mass production and improved cleanliness control across assembled boards.

| Service and Training

I.C.T provides comprehensive engineering support that extends beyond individual machines. Services include full-line planning, installation coordination, process alignment, and operator training. Cleaning processes are configured in relation to upstream soldering and downstream inspection requirements. Training focuses on building internal process understanding and long-term operational capability. This integrated approach helps customers maintain stable production, reduce rework, and improve consistency across the entire SMT line rather than optimizing isolated equipment only.

| Customer Reviews

Customers often recognize I.C.T as a reliable long-term manufacturing partner. Feedback highlights the practical experience of I.C.T engineers during overseas installation and acceptance stages. Stable equipment performance and predictable cleaning results are frequently mentioned. Customers also value the secure packaging and logistics arrangements that protect equipment during international transport. Fast technical response and clear problem resolution further strengthen trust and cooperation across multiple projects.

| Our Certification

I.C.T equipment is designed and produced in compliance with global manufacturing standards. Certifications include CE and RoHS, supporting safety and environmental requirements. ISO9001 certification ensures structured quality management across design, production, and testing stages. Multiple patents demonstrate continuous technical development. These certifications help customers deploy equipment confidently in different markets and meet regulatory expectations for electronic manufacturing facilities.

| About I.C.T and SMT Factory

I.C.T is a professional manufacturer and solution provider for SMT, DIP, and electronic assembly production lines. With strong in-house research, engineering, and manufacturing capabilities, the company supports customers worldwide. I.C.T employs a large technical team and continues to grow rapidly across global markets. The factory follows strict inspection and quality control procedures to ensure reliable equipment delivery. Through extensive project experience, I.C.T helps customers build scalable, efficient, and high-quality manufacturing operations.

| Advanced PCB Residue Removal Solution

During SMT and mixed-technology production, residues and fine particles often remain on circuit boards after soldering, marking, or handling. The Circuit PCB Board ultrasonic Vacuum cleaner Machine is designed to address these challenges through a controlled off-line cleaning process. By combining ultrasonic energy with vacuum-based removal, the system targets contamination in tight component gaps and complex board layouts. As a Circuit PCB Board ultrasonic Vacuum cleaner Machine, it supports manufacturers who require higher cleanliness standards without increasing line complexity. The equipment operates independently from the SMT line, allowing cleaning to be scheduled according to inspection results or product requirements, improving overall production flexibility and quality control.

| Feature

The cleaning room is designed as a closed processing space where ultrasonic action and vacuum cleaning work together in a controlled environment. PCB assemblies are positioned securely to ensure uniform exposure during the cleaning cycle. This structure allows contaminants to be loosened by ultrasonic energy and removed efficiently through vacuum extraction. For manufacturers handling dense or irregular PCB designs, the enclosed cleaning room improves consistency and reduces variation between batches. By isolating the process from external interference, the system supports stable and repeatable cleaning results across different product types and production schedules.

The circulation pipe system manages the movement of cleaning media and extracted residues during operation. Flow paths are designed to maintain stable pressure while preventing redeposition of contaminants onto the board surface. Collected residues are guided through filtration stages before the system continues operation. This design supports long-term process stability and reduces internal contamination. In daily production, the circulation structure helps maintain consistent cleaning performance even during repeated cycles. For off-line cleaning environments, this predictable flow behavior simplifies maintenance planning and helps extend equipment service life.

The washer fluid tank plays a central role in maintaining cleaning effectiveness during extended operation. It stores and filters the cleaning medium used in the ultrasonic process, removing particles and residues before reuse. Operators can monitor fluid condition and manage replacement schedules clearly. This controlled approach reduces the risk of cross-contamination between different PCB products. For factories using customized circuit PCB vacuum cleaner configurations, the washer fluid tank supports stable performance across various board types while keeping operating costs and process variables under control.

The drying module ensures that PCB assemblies are completely dry after the cleaning stage. Controlled airflow removes residual moisture from component gaps, connectors, and solder joints. Drying parameters can be adjusted to match board thickness and component density. This step is essential for protecting sensitive electronic components and ensuring boards are ready for inspection or testing. In production environments where appearance and reliability are critical, the drying module helps prevent secondary defects and supports smooth downstream processing.

The control system is designed to manage ultrasonic intensity, vacuum timing, and process duration through a clear and structured interface. Multiple programs can be stored for different PCB designs and contamination levels. Real-time monitoring allows operators to track system status and maintain stable operation. Alarm and protection functions reduce the risk of abnormal conditions. Rather than focusing on complex automation, the control system emphasizes repeatability and process discipline, helping manufacturers achieve consistent cleaning quality across shifts and product changes.

| Comparison Before and After

| Specification

| Parameter | I.C.T-5600 (Offline) | I.C.T-6300 (Online) |

|---|---|---|

| Cleaning Type | Offline batch, basket loading | Online continuous, belt conveyor |

| PCBA/Basket Size | 610 × 560 × 100 mm × 2 layers | Up to 600 × 400 × 100 mm (max conveyor width) |

| Cleaning Method | Multi-spray with heating, rinse, hot air dry | High-pressure spray, chemical + DI rinse + hot air dry |

| Tank Capacity (Diluent/Clean) | 60L (dilution) / 17L (spray tank) | 240L (clean liquid tank) |

| Concentrate Tank | 30-32L | Equipped with concentrated tank + auto add/discharge |

| Power Supply | Not specified (typically lower, ~30-50 kW est.) | 380V 3P 50/60Hz, 110-122 kW |

| Machine Dimensions | Compact (exact not listed, smaller footprint) | 5200 × 1750 × 1650-1700 mm |

| Drying | Hot air dry 10-30 min | Multi-stage hot air dry (dry 1 & dry 2) |

| Control System | Touch screen, easy parameters, password | PC + PLC, English software, adjustable pressures |

| DI Water Resistivity Monitoring | Yes, real-time | Yes, monitoring system |

| Typical Use | Small-multi variety, high-mix batches | High-volume batch, inline SMT lines |

| SMT Line Equipment List

I.C.T constructs multiple SMT production line that complement the PCB board cleaning machine seamlessly. Typical builds incorporate PCB laser marking system for traceability, printers plus SPI for accurate paste application, JUKI placement machines for rapid assembly, reflow ovens for strong solder joints, AOI scanners for thorough inspection, and conveyors for fluid transfer. Automated solder paste storage systems preserve material quality. Selective wave soldering options handle through-hole requirements. Each piece integrates expertly to form productive, customized lines. I.C.T experts guide equipment choices and installation for optimal results throughout the process.

| Customer Success Video

I.C.T successfully completed overseas installation and FAT support for two SMT production lines for a North American beauty device manufacturer. The project included laser marking systems, solder paste printing and SPI inspection, Panasonic placement machines, Heller reflow ovens, AOI inspection equipment, PCB handling systems, PCBA cleaning machines, and fully automatic solder paste storage and warming cabinets. I.C.T engineers supported installation, process setup, and trial production. Both SMT lines passed production acceptance smoothly, enabling stable mass production and improved cleanliness control across assembled boards.

| Service and Training

I.C.T provides comprehensive engineering support that extends beyond individual machines. Services include full-line planning, installation coordination, process alignment, and operator training. Cleaning processes are configured in relation to upstream soldering and downstream inspection requirements. Training focuses on building internal process understanding and long-term operational capability. This integrated approach helps customers maintain stable production, reduce rework, and improve consistency across the entire SMT line rather than optimizing isolated equipment only.

| Customer Reviews

Customers often recognize I.C.T as a reliable long-term manufacturing partner. Feedback highlights the practical experience of I.C.T engineers during overseas installation and acceptance stages. Stable equipment performance and predictable cleaning results are frequently mentioned. Customers also value the secure packaging and logistics arrangements that protect equipment during international transport. Fast technical response and clear problem resolution further strengthen trust and cooperation across multiple projects.

| Our Certification

I.C.T equipment is designed and produced in compliance with global manufacturing standards. Certifications include CE and RoHS, supporting safety and environmental requirements. ISO9001 certification ensures structured quality management across design, production, and testing stages. Multiple patents demonstrate continuous technical development. These certifications help customers deploy equipment confidently in different markets and meet regulatory expectations for electronic manufacturing facilities.

| About I.C.T and SMT Factory

I.C.T is a professional manufacturer and solution provider for SMT, DIP, and electronic assembly production lines. With strong in-house research, engineering, and manufacturing capabilities, the company supports customers worldwide. I.C.T employs a large technical team and continues to grow rapidly across global markets. The factory follows strict inspection and quality control procedures to ensure reliable equipment delivery. Through extensive project experience, I.C.T helps customers build scalable, efficient, and high-quality manufacturing operations.