T650

I.C.T

SMT PCBA Conformal Coating Machine

| Availability: | |

|---|---|

| Quantity: | |

| I.C.T SMT PCBA Conformal Coating Machine

I.C.T conformal coating machine is the new benchmark for simple and efficient PCBA coating. Its easy program making, fast line change settings bring best results in all directions. Meeting various needs. PCB conformal coating machine widely used in drive power, industrial control, LED, automotive electronics, communication, instrumentation, consumer electronics, electronic appliances, military, medical fields. Programming can edit any spraying trajectory, main interface displays spraying path. Running track can be mirrored, arrayed, copied—for multiple boards, edit one track is quick and convenient. Automatically count and display production data, output, single product working time. SMT PCBA conformal coating machine ensures accurate protection.

| Feature

Transmission System

SMT PCBA conformal coating machine transmission uses high-strength platform ensuring machine stability. Imported servo motors and drivers power movement. Servo motor + slide rail design ensures X/Y/Z repeatability and accuracy. Unique dust cover keeps screw rod and slide rail clean, reducing maintenance complexity. Highly flexible tank chain makes each pipeline, line neat and beautiful. PCB conformal coating machine lowers downtime, supports continuous operation, cuts costs 15%. Perfect for demanding production environments requiring precision coating

Transport System

SMT PCBA conformal coating machine transport features unique chain conveying system preventing PCB getting stuck. Motor controls speed and stops precisely. Cylinder clamping ensures PCB will not shift during operation. Guide rail width adjusts semi-automatically allowing PCB enter/exit freely. Rail designed with chains and profiles can bear heavy PCB without deformation. PCB conformal coating machine boosts throughput 25%, reduces defects significantly. Seamless integration with loaders/unloaders. Tool-free adjustments for high-mix production.

Coating System

SMT PCBA conformal coating machine control adopts reasonable layout, standardized labeling for easy inspection/maintenance. High-precision servo control components ensure stable operation. Heat dissipation design uses convection cooling of air. PC+control board mode greatly improves stability. PCB conformal coating machine real-time monitoring integrates MES systems. Error rate under 0.5%, remote troubleshooting saves time. Perfect coordination between valves and movements for IP67 protection. Energy saving 20%.

Control System

SMT PCBA conformal coating machine operator system: New program <10 minutes, change over <2 minutes, Windows 10. User friendly software with teaching/navigation function. Real-time display working path, simple intuitive operation. CCD vision optional. Operating platform adjustable adapting different operators flexibly. PCB conformal coating machine reduces training to one shift. Multi-language support, video tutorials. Touchscreen interface minimizes errors completely.

Operator System

SMT PCBA conformal coating machine general features: Imported precision air pressure regulator with digital gauge. Humanized operation panel improves operator efficiency. Conveyor rail hardened equipped stainless steel wear-resistant strips extend life. Rail width adjustment synchronous belt transmission ensures accurate rail transportation. Independent pure steel gantry ensures machine stability. Air curtains at entrance/exit prevent gas leakage improving workshop environment. PCB conformal coating machine perfect precision coating solution.

Advanced Dual Valve Coating System

The coating system dual valve design suitable complex PCBA scenarios. Modular design quick replacement different valve bodies. H-808 precision atomization fine dots (<50μm) LED parts. H-818 wide fan 200mm automotive boards. H-828 high-flow 10ml/min power modules. Optional U-axis 360° rotation, 45° tilt reaches shadows. PCB conformal coating machine UV lamp real-time verification, CCD ±0.05mm accuracy. Waste reduction 20-30%. IP67 protection guaranteed.

| Specification

| Selective Conformal Coating Machines | ||||

| Model | I.C.T-T550 | I.C.T-T550U | I.C.T-T600 | I.C.T-T650 |

| Number of valves | 2 (atomization valve 1 head, precision valve 1 head) | 2 (atomization valve 1 head, precision valve 1 head) | 2 (atomization valve 2 head) | 4 (atomization valve 2 head, precision valve 2 head) |

| Control method | PC + Motion Control Card | |||

| Number of spindles | X, Y, Z | X, Y, Z,U | X, Y, Z | X, Y, Z |

| PCB size | 50*50~450*460mm | |||

| Spindle drive | Imported servo motor+ball screw module | |||

| Automatic cleaning of valves | with 5L Pressure Tank | |||

| Power supply | AC 220V±10%, 50/60HZ, 2.2KW | |||

| Dimension | L910*W1600*H1700mm | |||

| Net weight | 1000KG | |||

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

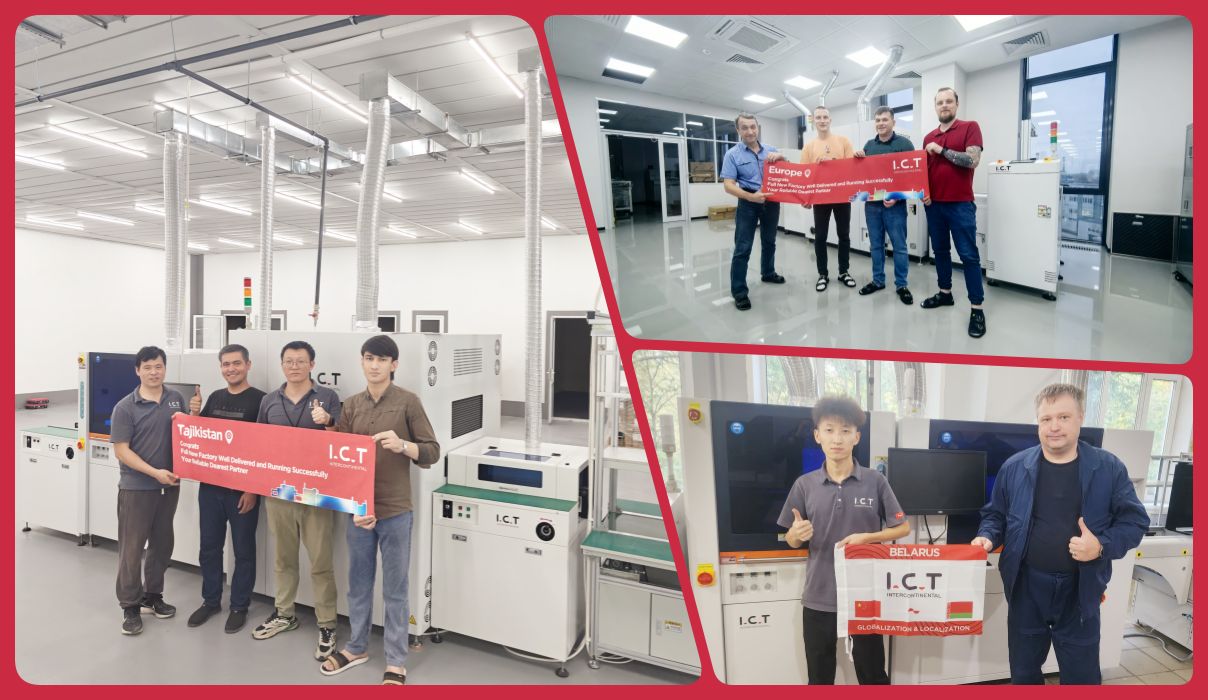

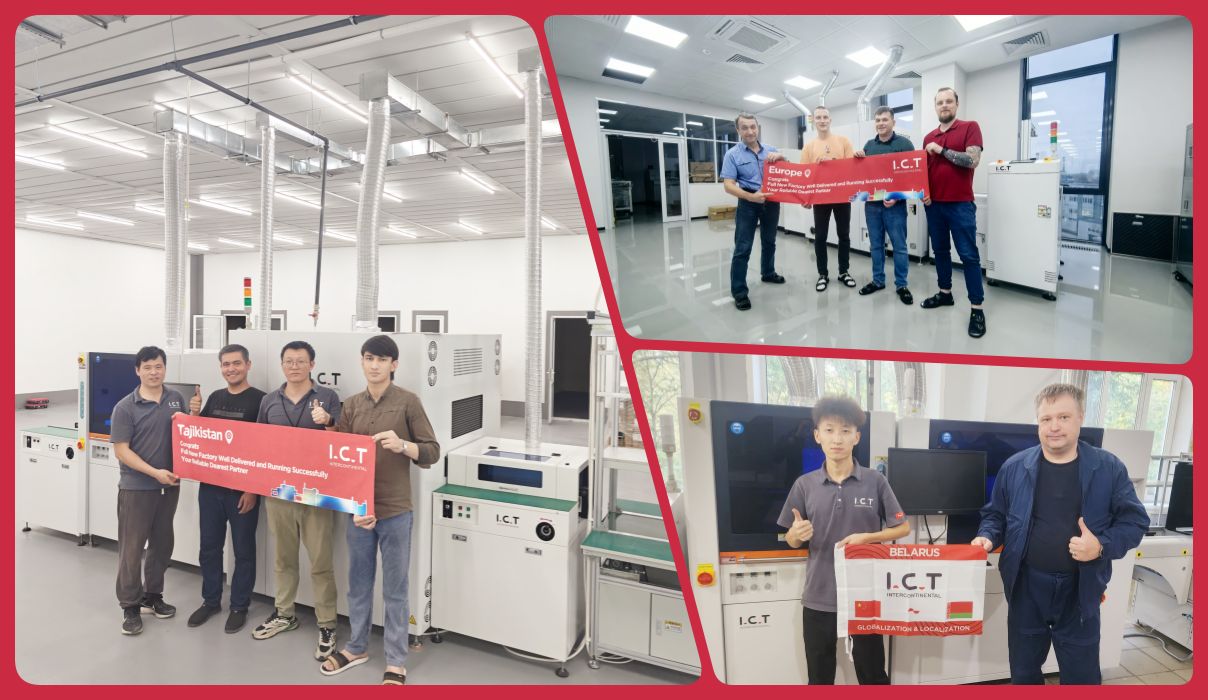

Video shows I.C.T engineer Europe journey providing SMT PCBA conformal coating machine technical support. Client specializes automotive electronics manufacturing car dashboards. Complete PCBA coating line: PCB Loader, SMT PCBA conformal coating machine, UV Curing Oven, PCB Unloader. Plus Selective Wave Soldering, AOI system. Engineer handles equipment installation/debugging ensuring optimal operation. PCB conformal coating machine comprehensive training covers operation, maintenance, troubleshooting. Trial production support resolves issues achieving high-quality output fast. Demonstrates precision coating automotive reliability.

| Services and Training

I.C.T provides complete SMT PCBA conformal coating machine installation, commissioning, maintenance services. Experienced engineers deliver hands-on training: programming, operation, cleaning, troubleshooting—onsite or remote. 24/7 support responds within hours using AR diagnostics. Global spare parts <48h delivery. PCB conformal coating machine process optimization audits maximize efficiency. Annual refresher training keeps operators certified. Material compatibility upgrades available. Zero-risk approach guarantees <1% downtime, maximum ROI. Trusted worldwide 72 countries.

| What Clients Say

European automotive clients praise SMT PCBA conformal coating machine engineers' expertise, rapid onsite resolutions. Uniform bubble-free coating dashboards achieves 99.9% yield. PCB conformal coating machine robust packing survives international shipping perfectly. Support responds <12 hours preventing production delays. Modular valves cut changeover 80%, boost throughput dramatically. "Best conformal coating investment ever—completely reliable," says dashboard manufacturer. Dramatically extends PCBA lifespan harsh environments.

| Certifications and Standards

The Coating Machine certified CE safety, RoHS environmental, ISO9001 quality management. Multiple patents modular valves, path optimization technology. Every unit 72-hour burn-in testing, precision validation, material compatibility checks. IPC-A-610 compliant, complete traceability QR codes. Third-party audits confirm <0.1% defect rate. PCB conformal coating machine guarantees safe sustainable operation automotive, medical, military sectors worldwide.

| About I.C.T Company and Factory

I.C.T owns R&D/production 12,000m² facilities since 2012. 89 professional staff including 20 engineers, $30M registered capital, 8 global branches. Serves 1,600+ customers 72 countries complete SMT solutions. SMT PCBA conformal coating machine strict ISO quality systems, 100% inspection, cleanroom assembly. Covers semiconductor, PCBA, SMT, DIP, coating, robot, assembly processes. Globalization + localization creates cross-value platform. PCB conformal coating machine 98% uptime guaranteed.

| I.C.T SMT PCBA Conformal Coating Machine

I.C.T conformal coating machine is the new benchmark for simple and efficient PCBA coating. Its easy program making, fast line change settings bring best results in all directions. Meeting various needs. PCB conformal coating machine widely used in drive power, industrial control, LED, automotive electronics, communication, instrumentation, consumer electronics, electronic appliances, military, medical fields. Programming can edit any spraying trajectory, main interface displays spraying path. Running track can be mirrored, arrayed, copied—for multiple boards, edit one track is quick and convenient. Automatically count and display production data, output, single product working time. SMT PCBA conformal coating machine ensures accurate protection.

| Feature

Transmission System

SMT PCBA conformal coating machine transmission uses high-strength platform ensuring machine stability. Imported servo motors and drivers power movement. Servo motor + slide rail design ensures X/Y/Z repeatability and accuracy. Unique dust cover keeps screw rod and slide rail clean, reducing maintenance complexity. Highly flexible tank chain makes each pipeline, line neat and beautiful. PCB conformal coating machine lowers downtime, supports continuous operation, cuts costs 15%. Perfect for demanding production environments requiring precision coating

Transport System

SMT PCBA conformal coating machine transport features unique chain conveying system preventing PCB getting stuck. Motor controls speed and stops precisely. Cylinder clamping ensures PCB will not shift during operation. Guide rail width adjusts semi-automatically allowing PCB enter/exit freely. Rail designed with chains and profiles can bear heavy PCB without deformation. PCB conformal coating machine boosts throughput 25%, reduces defects significantly. Seamless integration with loaders/unloaders. Tool-free adjustments for high-mix production.

Coating System

SMT PCBA conformal coating machine control adopts reasonable layout, standardized labeling for easy inspection/maintenance. High-precision servo control components ensure stable operation. Heat dissipation design uses convection cooling of air. PC+control board mode greatly improves stability. PCB conformal coating machine real-time monitoring integrates MES systems. Error rate under 0.5%, remote troubleshooting saves time. Perfect coordination between valves and movements for IP67 protection. Energy saving 20%.

Control System

SMT PCBA conformal coating machine operator system: New program <10 minutes, change over <2 minutes, Windows 10. User friendly software with teaching/navigation function. Real-time display working path, simple intuitive operation. CCD vision optional. Operating platform adjustable adapting different operators flexibly. PCB conformal coating machine reduces training to one shift. Multi-language support, video tutorials. Touchscreen interface minimizes errors completely.

Operator System

SMT PCBA conformal coating machine general features: Imported precision air pressure regulator with digital gauge. Humanized operation panel improves operator efficiency. Conveyor rail hardened equipped stainless steel wear-resistant strips extend life. Rail width adjustment synchronous belt transmission ensures accurate rail transportation. Independent pure steel gantry ensures machine stability. Air curtains at entrance/exit prevent gas leakage improving workshop environment. PCB conformal coating machine perfect precision coating solution.

Advanced Dual Valve Coating System

The coating system dual valve design suitable complex PCBA scenarios. Modular design quick replacement different valve bodies. H-808 precision atomization fine dots (<50μm) LED parts. H-818 wide fan 200mm automotive boards. H-828 high-flow 10ml/min power modules. Optional U-axis 360° rotation, 45° tilt reaches shadows. PCB conformal coating machine UV lamp real-time verification, CCD ±0.05mm accuracy. Waste reduction 20-30%. IP67 protection guaranteed.

| Specification

| Selective Conformal Coating Machines | ||||

| Model | I.C.T-T550 | I.C.T-T550U | I.C.T-T600 | I.C.T-T650 |

| Number of valves | 2 (atomization valve 1 head, precision valve 1 head) | 2 (atomization valve 1 head, precision valve 1 head) | 2 (atomization valve 2 head) | 4 (atomization valve 2 head, precision valve 2 head) |

| Control method | PC + Motion Control Card | |||

| Number of spindles | X, Y, Z | X, Y, Z,U | X, Y, Z | X, Y, Z |

| PCB size | 50*50~450*460mm | |||

| Spindle drive | Imported servo motor+ball screw module | |||

| Automatic cleaning of valves | with 5L Pressure Tank | |||

| Power supply | AC 220V±10%, 50/60HZ, 2.2KW | |||

| Dimension | L910*W1600*H1700mm | |||

| Net weight | 1000KG | |||

| Coating Line Equipment List

Our PCBA Coating Line offers advanced tools for efficient and precise circuit board protection. The fully automated coating line includes a selective coating machine for accurate application, a curing oven for durable finishes, AOI for quality checks, a lift and flipper for smooth handling, and a conveyor system for seamless production.

This high-quality PCBA Coating Line ensures stable operation, reliable dustproof, waterproof, and explosion-proof coating, meeting diverse industry needs. With modular designs and global support from I.C.T, it enhances productivity for protective coating tasks.

| Product Name | Purpose in PCBA Coating Line |

|---|---|

Applies precise protective coatings to circuit boards for dustproof, waterproof, and explosion-proof protection. | |

Hardens coatings with IR or UV light, ensuring durable and strong protection. | |

Transports circuit boards smoothly through the coating line for efficient processing. | |

Provides and stores PCB for the production line, ensuring smooth input and output. | |

| Conformal coating AOI | Inspects coating quality and detects defects to ensure high standards. |

| Customer Success Video

Video shows I.C.T engineer Europe journey providing SMT PCBA conformal coating machine technical support. Client specializes automotive electronics manufacturing car dashboards. Complete PCBA coating line: PCB Loader, SMT PCBA conformal coating machine, UV Curing Oven, PCB Unloader. Plus Selective Wave Soldering, AOI system. Engineer handles equipment installation/debugging ensuring optimal operation. PCB conformal coating machine comprehensive training covers operation, maintenance, troubleshooting. Trial production support resolves issues achieving high-quality output fast. Demonstrates precision coating automotive reliability.

| Services and Training

I.C.T provides complete SMT PCBA conformal coating machine installation, commissioning, maintenance services. Experienced engineers deliver hands-on training: programming, operation, cleaning, troubleshooting—onsite or remote. 24/7 support responds within hours using AR diagnostics. Global spare parts <48h delivery. PCB conformal coating machine process optimization audits maximize efficiency. Annual refresher training keeps operators certified. Material compatibility upgrades available. Zero-risk approach guarantees <1% downtime, maximum ROI. Trusted worldwide 72 countries.

| What Clients Say

European automotive clients praise SMT PCBA conformal coating machine engineers' expertise, rapid onsite resolutions. Uniform bubble-free coating dashboards achieves 99.9% yield. PCB conformal coating machine robust packing survives international shipping perfectly. Support responds <12 hours preventing production delays. Modular valves cut changeover 80%, boost throughput dramatically. "Best conformal coating investment ever—completely reliable," says dashboard manufacturer. Dramatically extends PCBA lifespan harsh environments.

| Certifications and Standards

The Coating Machine certified CE safety, RoHS environmental, ISO9001 quality management. Multiple patents modular valves, path optimization technology. Every unit 72-hour burn-in testing, precision validation, material compatibility checks. IPC-A-610 compliant, complete traceability QR codes. Third-party audits confirm <0.1% defect rate. PCB conformal coating machine guarantees safe sustainable operation automotive, medical, military sectors worldwide.

| About I.C.T Company and Factory

I.C.T owns R&D/production 12,000m² facilities since 2012. 89 professional staff including 20 engineers, $30M registered capital, 8 global branches. Serves 1,600+ customers 72 countries complete SMT solutions. SMT PCBA conformal coating machine strict ISO quality systems, 100% inspection, cleanroom assembly. Covers semiconductor, PCBA, SMT, DIP, coating, robot, assembly processes. Globalization + localization creates cross-value platform. PCB conformal coating machine 98% uptime guaranteed.