LD-L

I.C.T

PCB unloader loader

| Availability: | |

|---|---|

| Quantity: | |

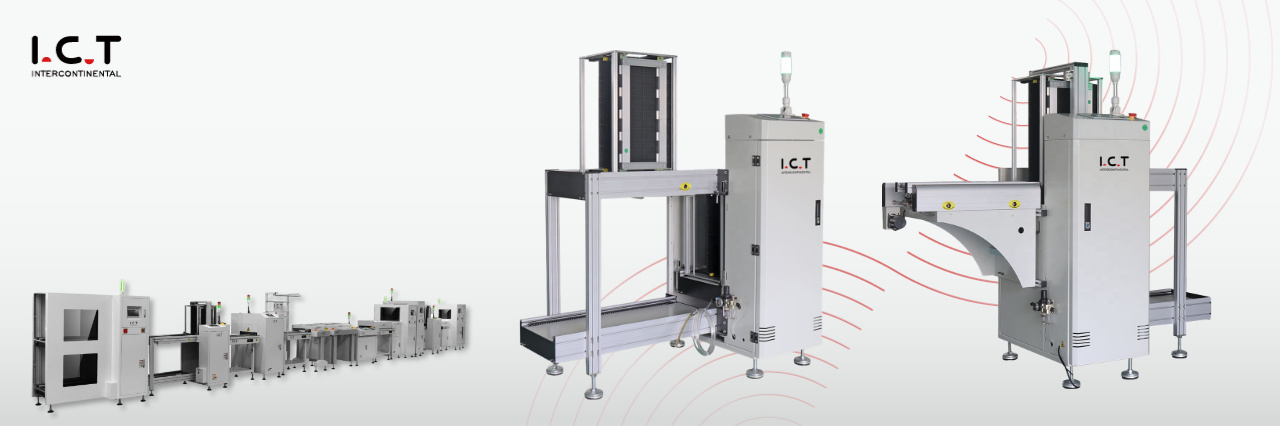

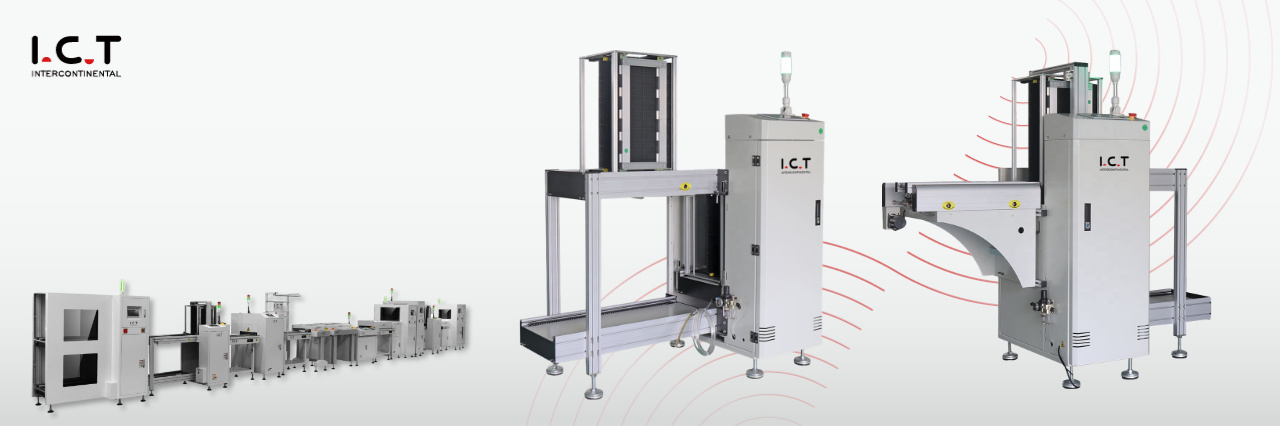

| Efficient PCB Substrate Loader for Modern SMT Lines

The I.C.T PCB substrate loader is the reliable machine that takes full magazines of bare substrates and feeds them one by one to your printer or placement machine. It uses a precise lifting system so every substrate arrives perfectly aligned—no scratches, no position errors. Choose standard or full CE version—both include stronger frames, advanced sensors, and smart software that learns new jobs quickly. The PCB substrate loader cuts labor costs, increases daily output, runs continuously for three shifts, and integrates seamlessly with any existing SMT line you already have.

| Detailed Product Features

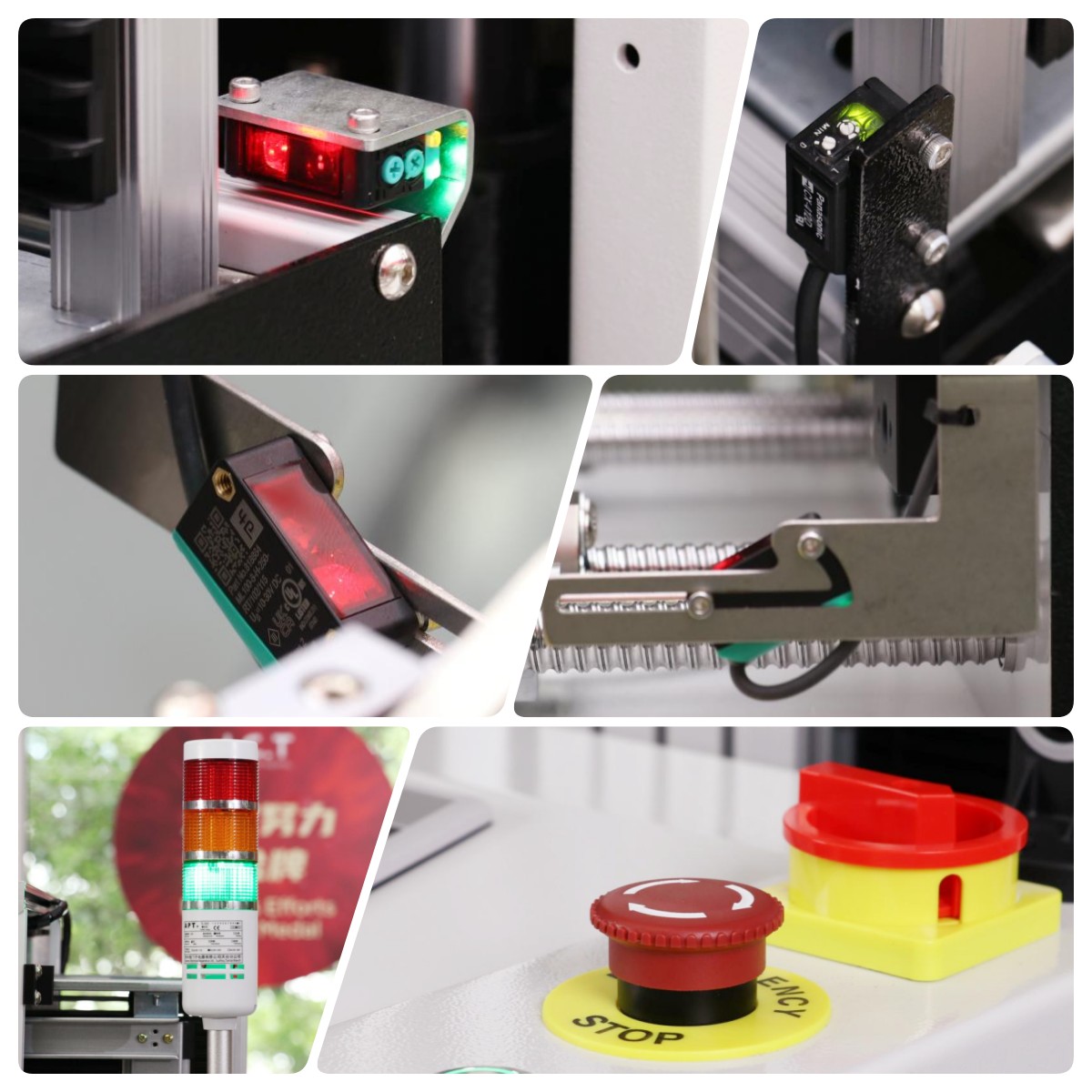

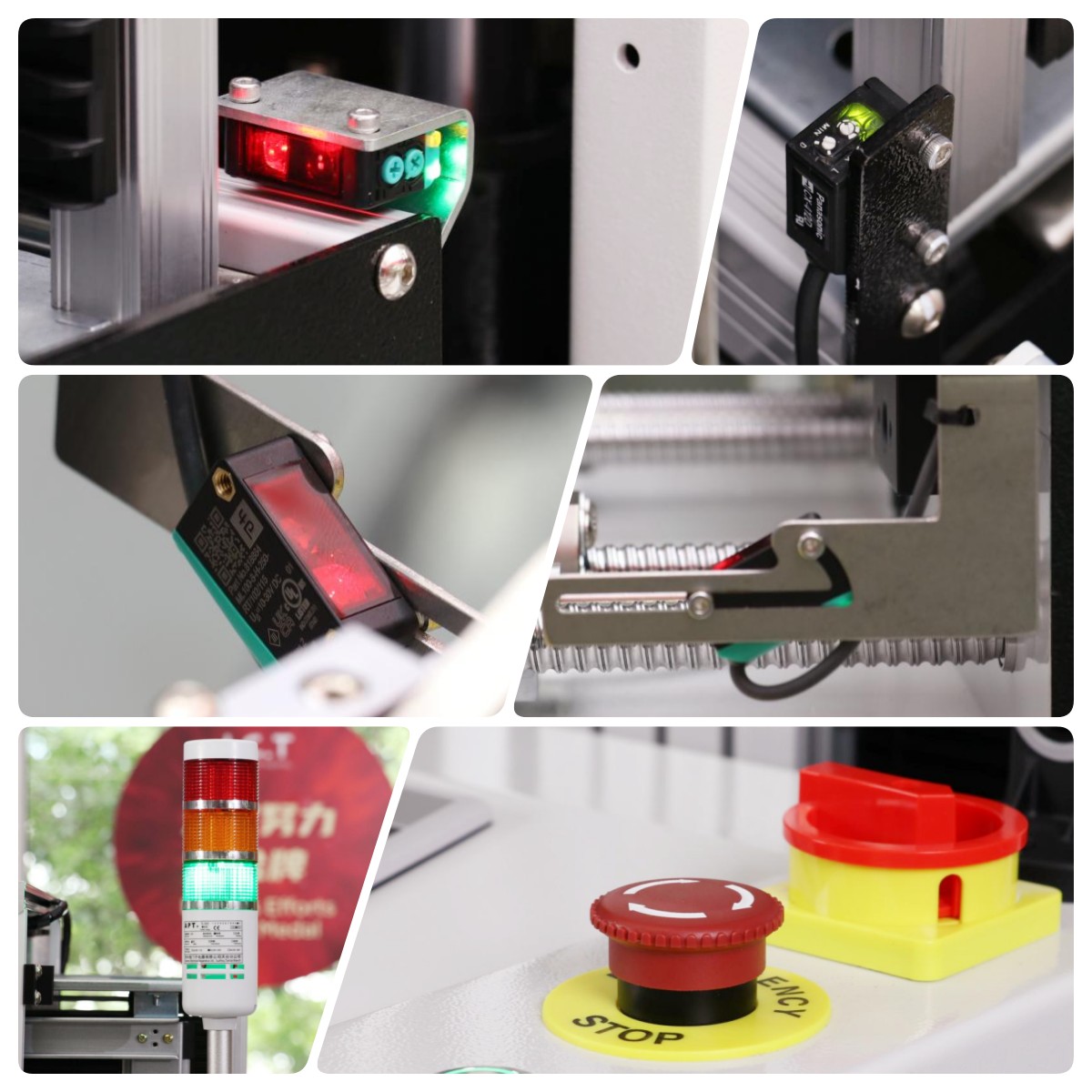

The PCB substrate loader features thicker steel rails and a solid base that follows strict ISO and CE standards. It stays stable even during high-speed operation. Maintenance is simple and takes only minutes. The machine performs reliably for many years in demanding production environments

High-quality sensors detect every substrate instantly. Bright tower lights show clear green or red status signals. Buttons respond quickly in any condition. The PCB substrate loader alerts operators immediately if anything needs attention, keeping production running smoothly without unnecessary stops.

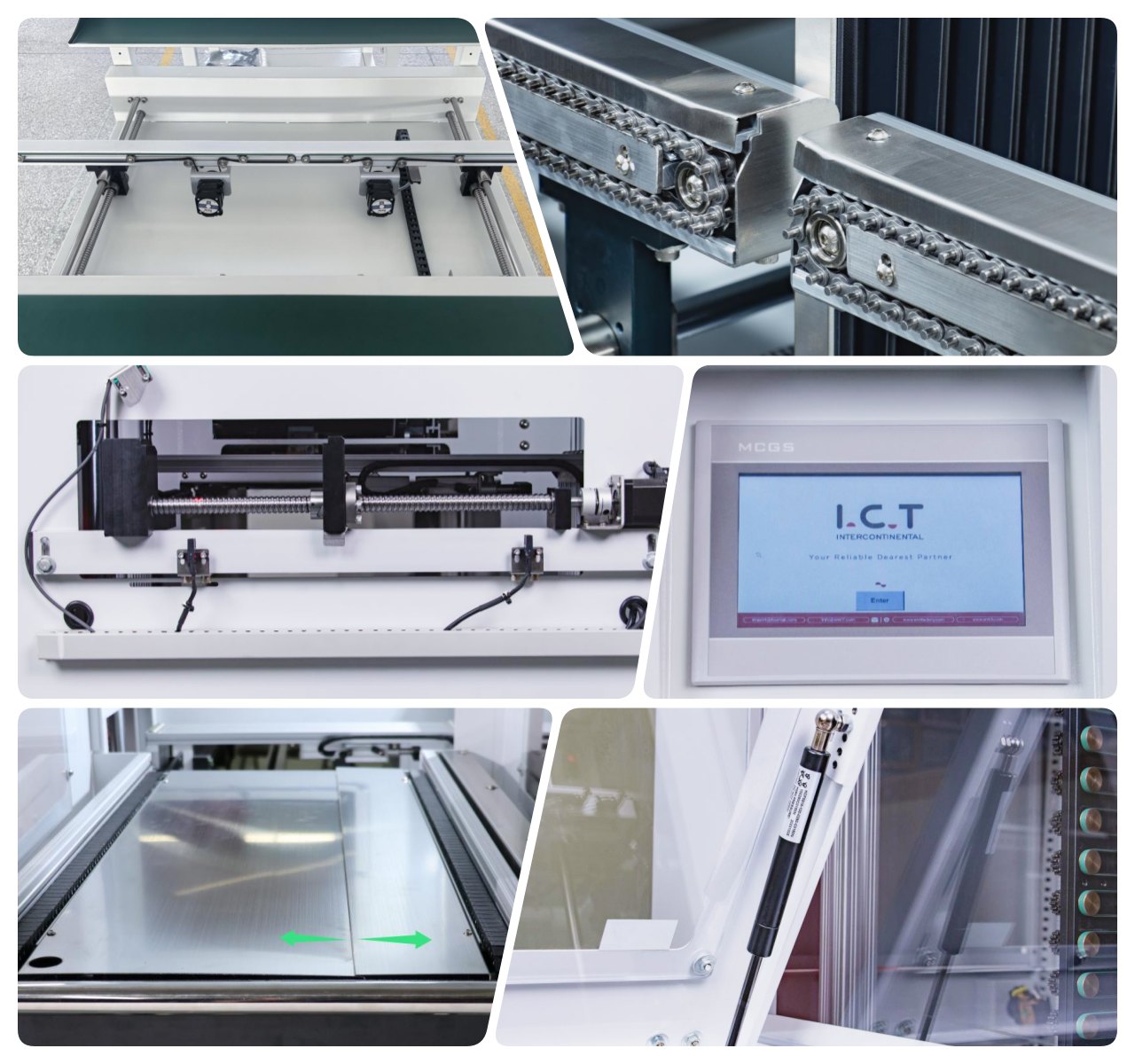

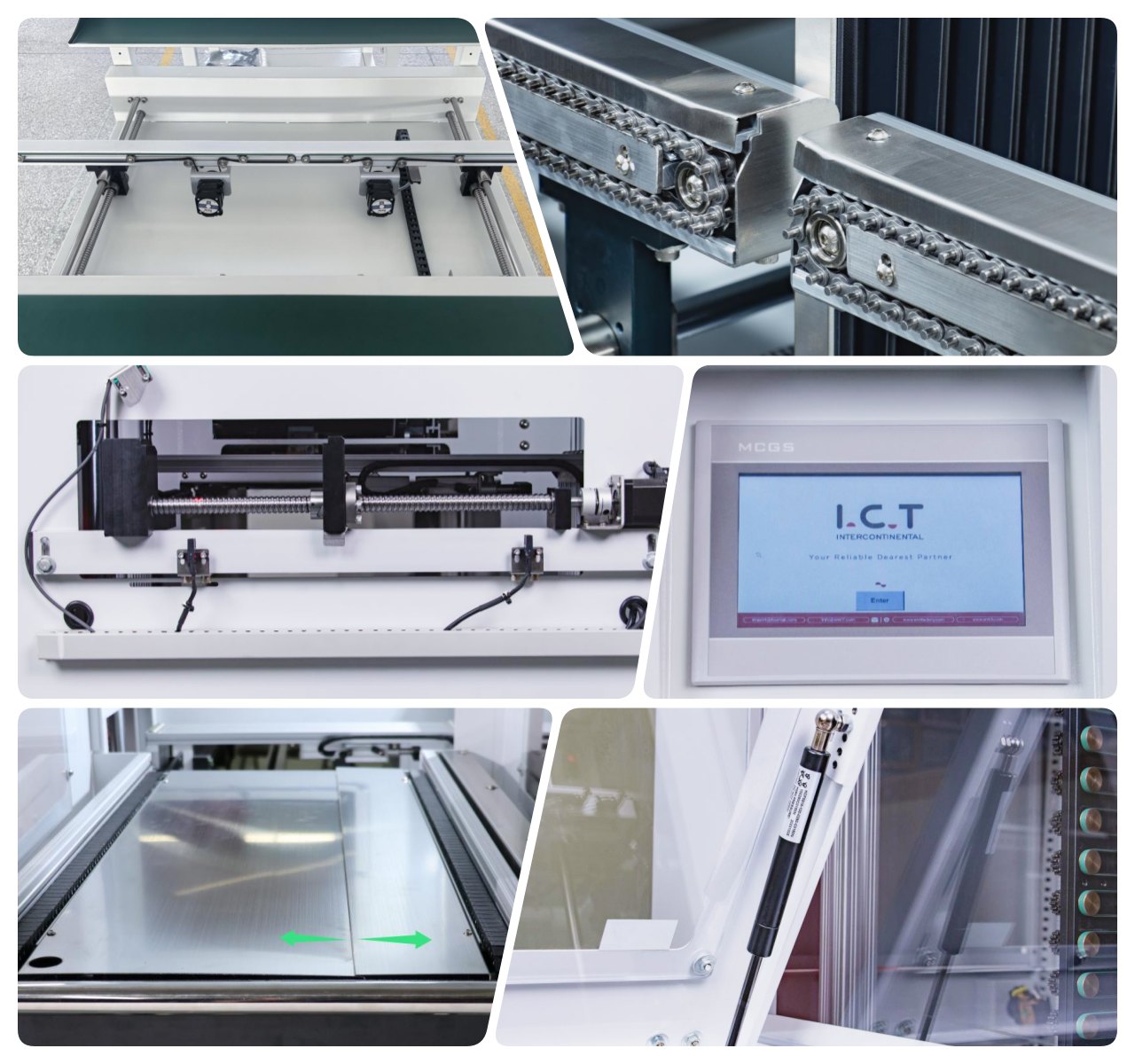

The control system is ready for Industry 4.0 standards. Add IPC-CFX, Hermes, or other protocols whenever needed. Load new product data in under two minutes. The PCB substrate loader connects to your factory MES and automatically adjusts for different substrate types.

The lifting mechanism moves slowly and precisely to avoid damaging thin or fragile substrates. The PCB substrate loader handles full magazines quietly and smoothly. Every substrate leaves the magazine in perfect position for the next process step.

SMEMA interface is built in and works immediately. Optional smart communication is available. The PCB substrate loader fits into any SMT line quickly and keeps the entire flow steady during product changeovers.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our turnkey SMT production line handles everything from bare substrates to finished products with high efficiency. The PCB substrate loader starts the process perfectly for all board sizes. Printing, high-speed placement, reflow soldering, and advanced inspection work together seamlessly. Labor requirements stay low. First-pass yield stays above 99.5%. The line runs almost continuously and meets strict standards for automotive, medical, consumer electronics, and LED applications while keeping your overall costs very competitive.

| Product Name | Purpose in SMT Line |

|---|---|

| Flexible SMD Production Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB vertical unloader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| SMT pick and place machine | Mounts components onto PCBs precisely. |

| BGA reflow oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI machine for PCB, SPI, X-ray Inspection Machine, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data like PCB laser marking system |

| SMT Peripheral | Auxiliary SMT equipment like ic programming for pcb assembly, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust |

| PCB Separator | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and dispenser robot for efficient SMT assembly. |

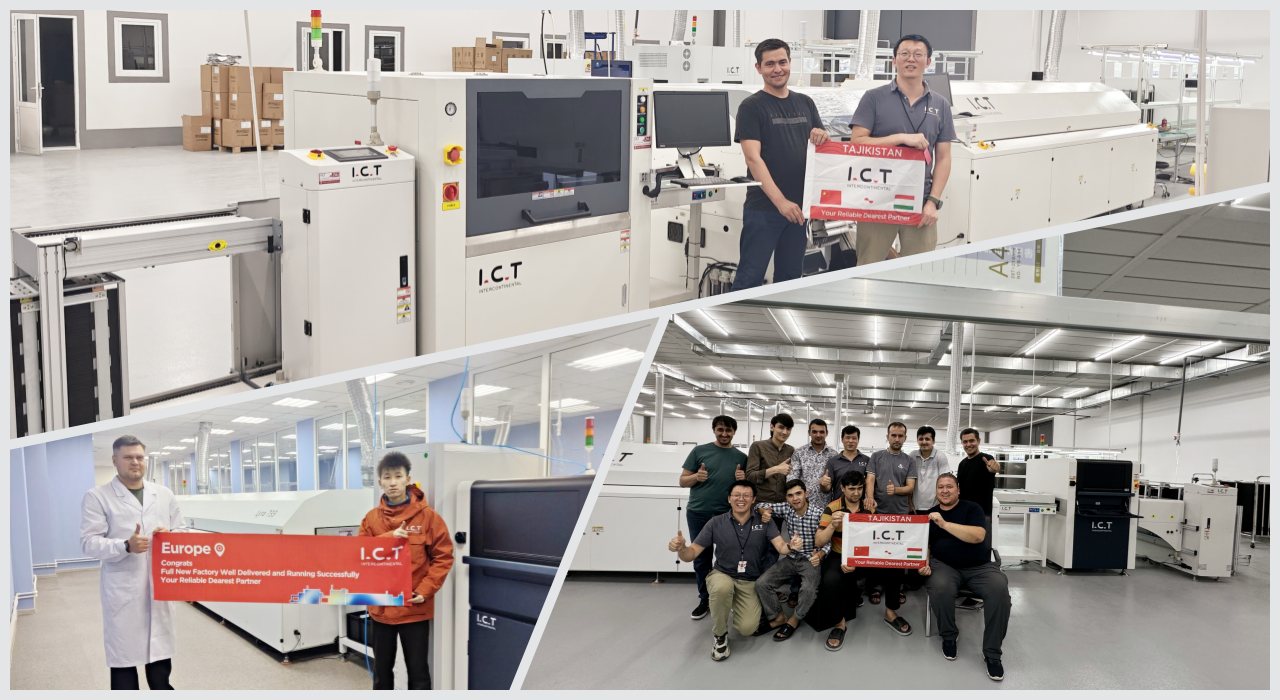

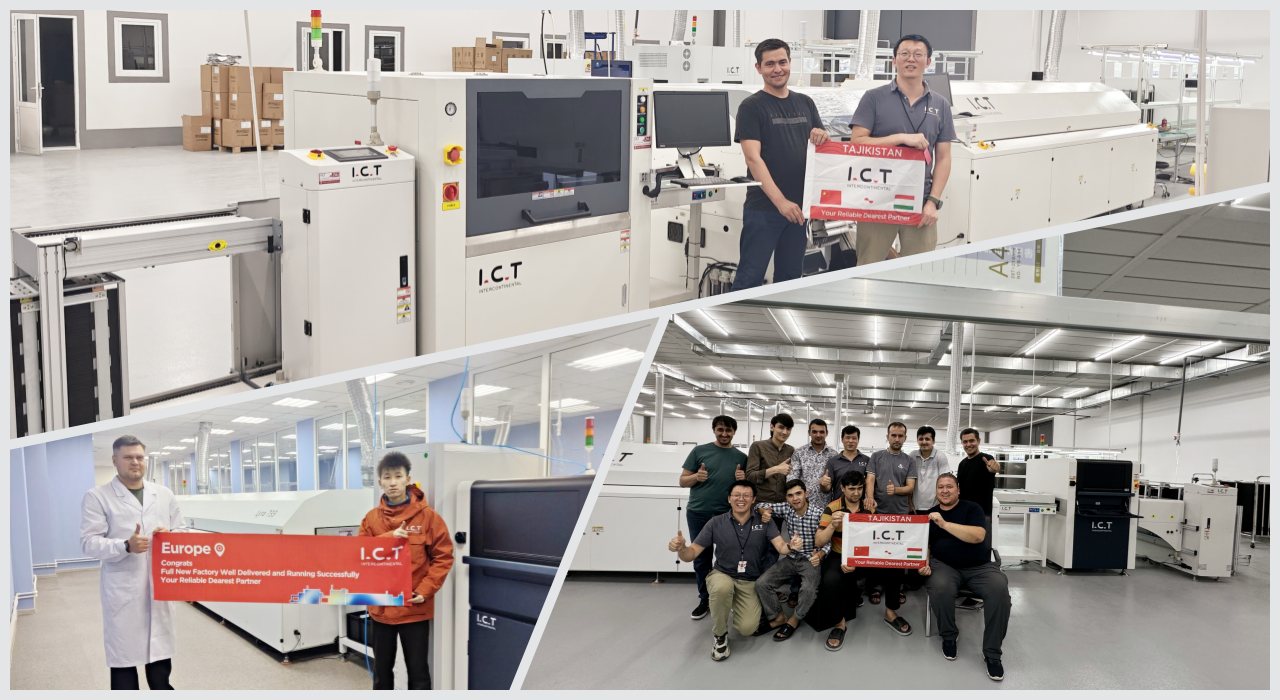

| Customer Success Story

In 2024 our engineers flew to Finland to set up a complete LED panel production line for a leading European lighting manufacturer. The line included the PCB substrate loader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. Installation, testing, and operator training were completed in only five days. The line reached full speed on the first official production day with zero defects. The customer was very happy with the stable feeding of the PCB substrate loader and perfect machine-to-machine communication. They passed the strict European audit on the first try and ordered a second line shortly after.

| Professional Training & Support

We provide remote support before shipping, on-site installation assistance, and two full days of free training for your operators and maintenance team. Our 24/7 hotline offers immediate help from English-speaking engineers. Spare parts are stocked in global warehouses. We schedule regular preventive maintenance visits. Your PCB substrate loader stays highly reliable with almost no unplanned downtime.

| Customer Praise

“Your engineer solved our problem at 2 a.m. their time—amazing response speed!” “After 45 days of ocean shipping the crate arrived perfect—no damage at all.” “Our PCB substrate loader has run three shifts for 20 months with zero failures.” “Training was very clear; our new operators started production independently after one day.”

| Our Certification

Every PCB substrate loader carries CE, RoHS, and ISO9001 certifications plus multiple technical patents. Each machine passes a full 72-hour loaded burn-in test and detailed final inspection before leaving the factory. Customers receive guaranteed quality and full compliance from the very first use.

| About Us and Factory

Since 2012 we have built a modern 12,000 m² factory with nearly 90 employees and our own dedicated R&D team. We design, manufacture, and test every machine in-house under strict quality systems. We serve over 1,600 customers in 72 countries, from a single PCB substrate loader to complete turnkey SMT factories.

| Efficient PCB Substrate Loader for Modern SMT Lines

The I.C.T PCB substrate loader is the reliable machine that takes full magazines of bare substrates and feeds them one by one to your printer or placement machine. It uses a precise lifting system so every substrate arrives perfectly aligned—no scratches, no position errors. Choose standard or full CE version—both include stronger frames, advanced sensors, and smart software that learns new jobs quickly. The PCB substrate loader cuts labor costs, increases daily output, runs continuously for three shifts, and integrates seamlessly with any existing SMT line you already have.

| Detailed Product Features

The PCB substrate loader features thicker steel rails and a solid base that follows strict ISO and CE standards. It stays stable even during high-speed operation. Maintenance is simple and takes only minutes. The machine performs reliably for many years in demanding production environments

High-quality sensors detect every substrate instantly. Bright tower lights show clear green or red status signals. Buttons respond quickly in any condition. The PCB substrate loader alerts operators immediately if anything needs attention, keeping production running smoothly without unnecessary stops.

The control system is ready for Industry 4.0 standards. Add IPC-CFX, Hermes, or other protocols whenever needed. Load new product data in under two minutes. The PCB substrate loader connects to your factory MES and automatically adjusts for different substrate types.

The lifting mechanism moves slowly and precisely to avoid damaging thin or fragile substrates. The PCB substrate loader handles full magazines quietly and smoothly. Every substrate leaves the magazine in perfect position for the next process step.

SMEMA interface is built in and works immediately. Optional smart communication is available. The PCB substrate loader fits into any SMT line quickly and keeps the entire flow steady during product changeovers.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our turnkey SMT production line handles everything from bare substrates to finished products with high efficiency. The PCB substrate loader starts the process perfectly for all board sizes. Printing, high-speed placement, reflow soldering, and advanced inspection work together seamlessly. Labor requirements stay low. First-pass yield stays above 99.5%. The line runs almost continuously and meets strict standards for automotive, medical, consumer electronics, and LED applications while keeping your overall costs very competitive.

| Product Name | Purpose in SMT Line |

|---|---|

| Flexible SMD Production Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB vertical unloader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| SMT pick and place machine | Mounts components onto PCBs precisely. |

| BGA reflow oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI machine for PCB, SPI, X-ray Inspection Machine, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data like PCB laser marking system |

| SMT Peripheral | Auxiliary SMT equipment like ic programming for pcb assembly, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust |

| PCB Separator | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and dispenser robot for efficient SMT assembly. |

| Customer Success Story

In 2024 our engineers flew to Finland to set up a complete LED panel production line for a leading European lighting manufacturer. The line included the PCB substrate loader, 1.5 m automatic printer, SM482PLUS placement machine, L8 reflow oven, cooling buffers, linking conveyors, board splitter, and solder paste mixer. Installation, testing, and operator training were completed in only five days. The line reached full speed on the first official production day with zero defects. The customer was very happy with the stable feeding of the PCB substrate loader and perfect machine-to-machine communication. They passed the strict European audit on the first try and ordered a second line shortly after.

| Professional Training & Support

We provide remote support before shipping, on-site installation assistance, and two full days of free training for your operators and maintenance team. Our 24/7 hotline offers immediate help from English-speaking engineers. Spare parts are stocked in global warehouses. We schedule regular preventive maintenance visits. Your PCB substrate loader stays highly reliable with almost no unplanned downtime.

| Customer Praise

“Your engineer solved our problem at 2 a.m. their time—amazing response speed!” “After 45 days of ocean shipping the crate arrived perfect—no damage at all.” “Our PCB substrate loader has run three shifts for 20 months with zero failures.” “Training was very clear; our new operators started production independently after one day.”

| Our Certification

Every PCB substrate loader carries CE, RoHS, and ISO9001 certifications plus multiple technical patents. Each machine passes a full 72-hour loaded burn-in test and detailed final inspection before leaving the factory. Customers receive guaranteed quality and full compliance from the very first use.

| About Us and Factory

Since 2012 we have built a modern 12,000 m² factory with nearly 90 employees and our own dedicated R&D team. We design, manufacture, and test every machine in-house under strict quality systems. We serve over 1,600 customers in 72 countries, from a single PCB substrate loader to complete turnkey SMT factories.