I.C.T-5700

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced PCB Depaneling Router

The PCB depaneling router finds essential application in manufacturing smartphones, smart wearables, tablets, automotive electronics, medical devices, and aerospace systems. It accommodates PCB sizes from 340×380mm to 450×600mm and thicknesses ranging from 0.5 to 5.0mm. The modern CCD vision system recognizes diverse mark types and performs automatic visual correction for exact alignment. Operating at up to 80,000rpm, the spindle achieves cuts with greatly reduced stress, high precision, low inertia, and immediate response. Dual platforms facilitate handling different products concurrently or combining into one extended workspace. The ion air gun neutralizes surface static electricity, preventing dust adhesion. Continuous sensor monitoring safeguards the milling cutter. A separate high-efficiency vacuum collector maintains low noise while providing powerful suction. The humanized operation system remains simple, flexible, and stable for everyday use.

| Feature

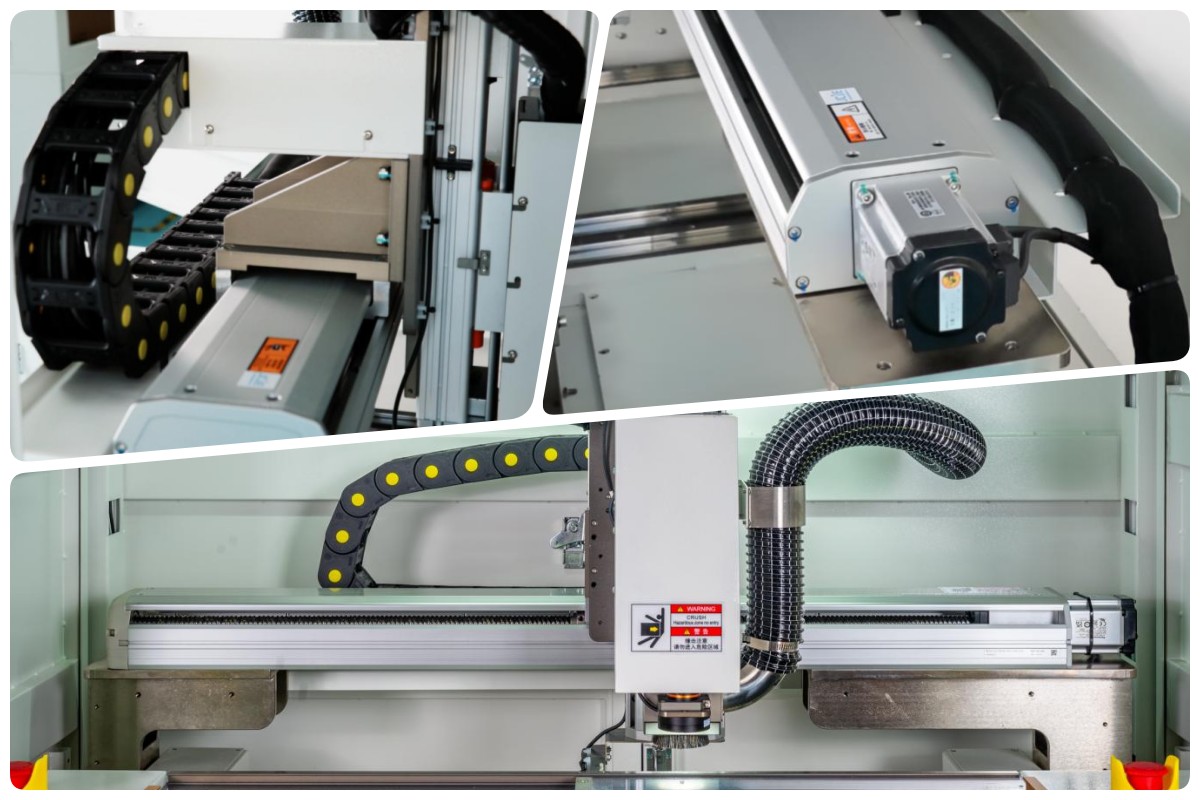

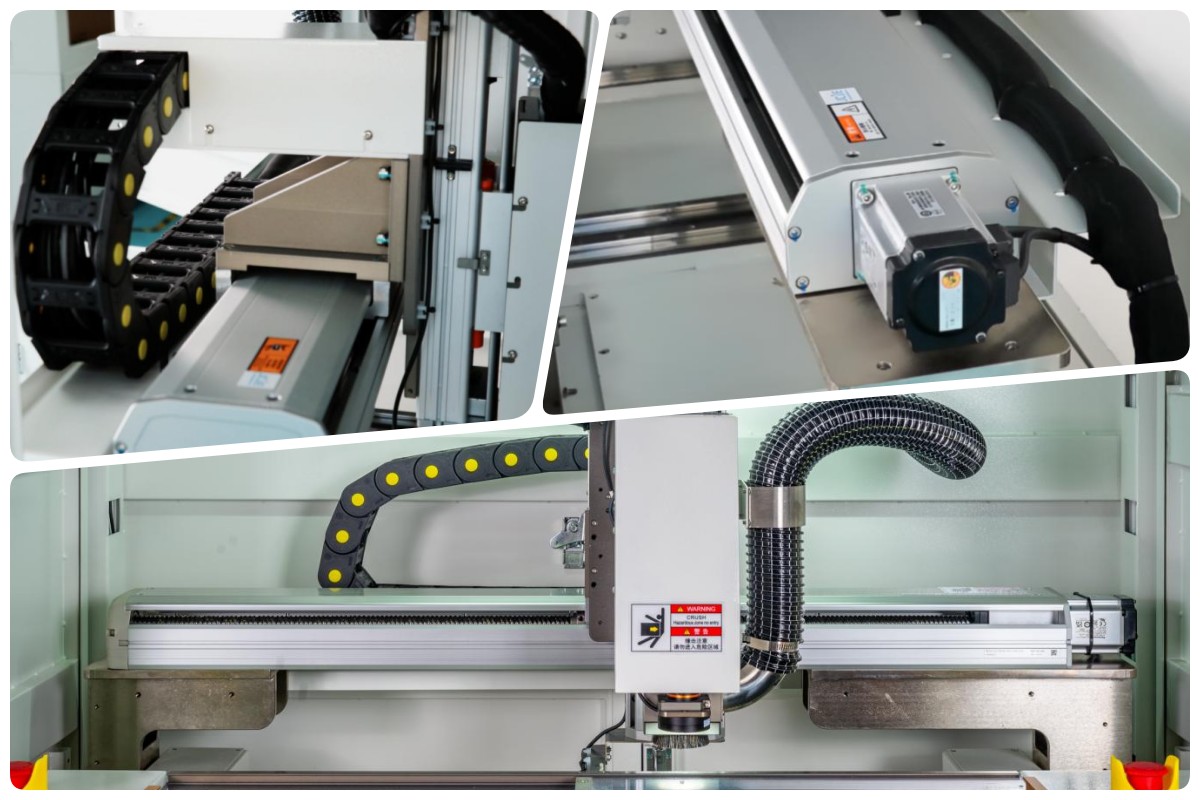

Transmission System

Imported Panasonic servo motors, combined with high-precision screw rods, establish the foundation for motion accuracy throughout the system. Guide rails and ball screws from Taiwan contribute to consistent repeatability. The mechanical structure, reinforced with greater thickness, significantly enhances operational stability under prolonged workloads. Flexible tank chains organize cable routing aesthetically while eliminating interference with dynamic components. The X-axis module incorporates a distinctive dust-proof design that substantially decreases maintenance intervals and associated costs. Through this meticulously engineered integration, the PCB depaneling router maintains exceptional positional precision and durability, supporting uninterrupted performance in rigorous manufacturing conditions.

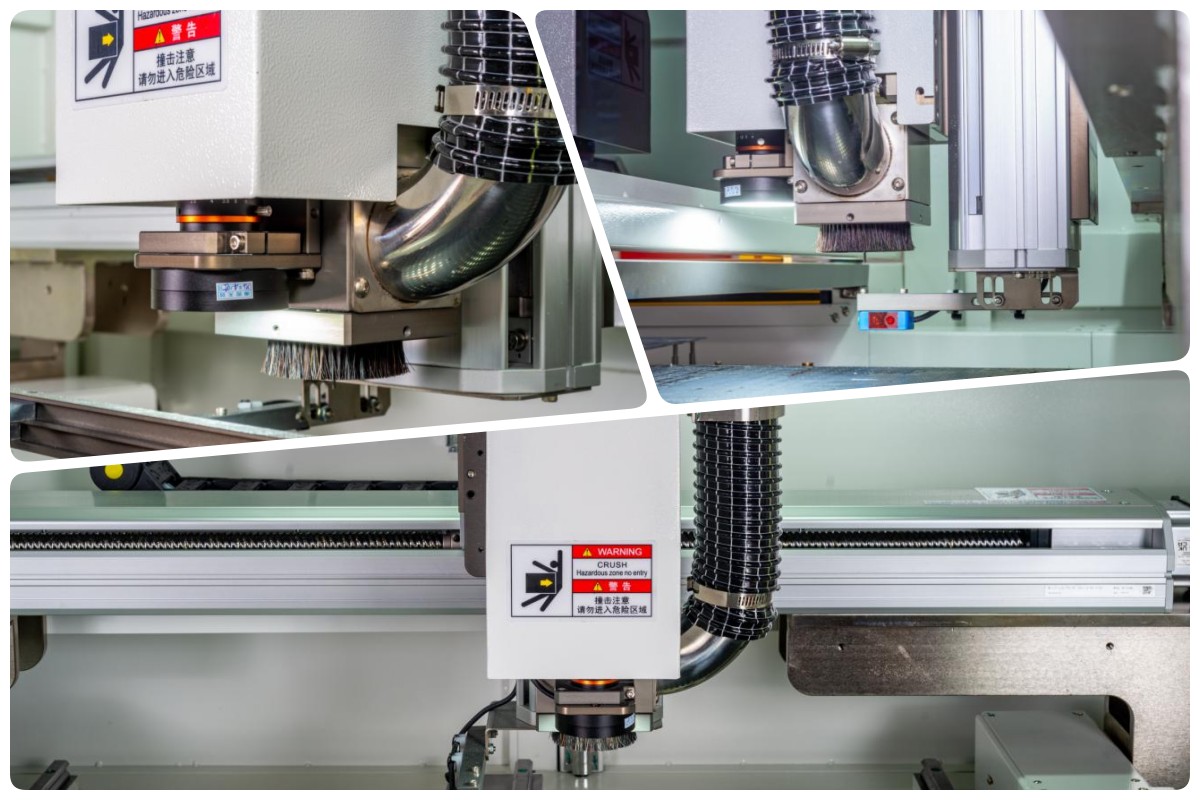

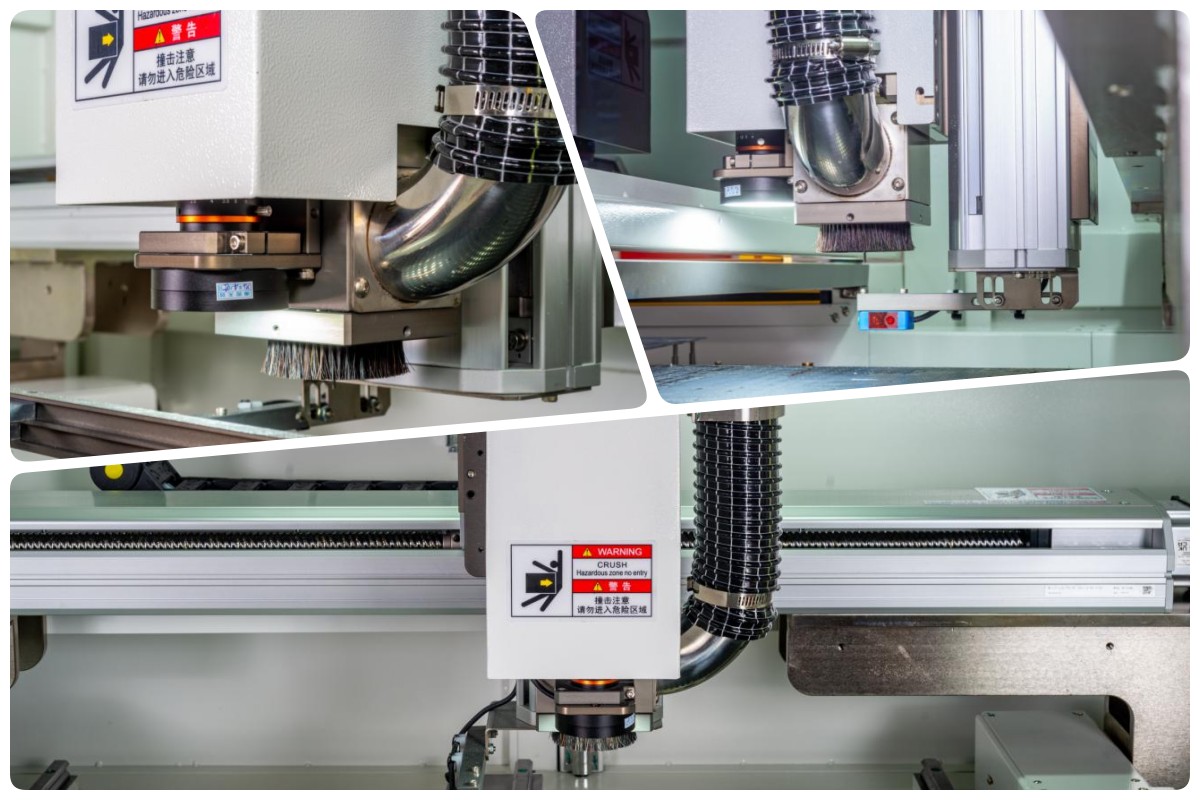

Router System

The high-definition vision system aligns coaxially with the milling cutter, facilitating straightforward and reliable calibration procedures. Standard tool breakage detection activates an immediate alarm upon detecting cutter wear or fracture. The optional automatic tool changing mechanism enables continuous machining without interruption, thereby elevating production efficiency. An ion air gun systematically removes static electricity from the PCB surface, effectively preventing dust adhesion during operation. The imported high-speed spindle substantially lowers cutting stress while delivering superior precision, minimal inertia, and swift dynamic response. Collectively, these advanced elements ensure consistently clean separation results on the PCB Board Lead Cutter Separator Depaneling Router Machine.

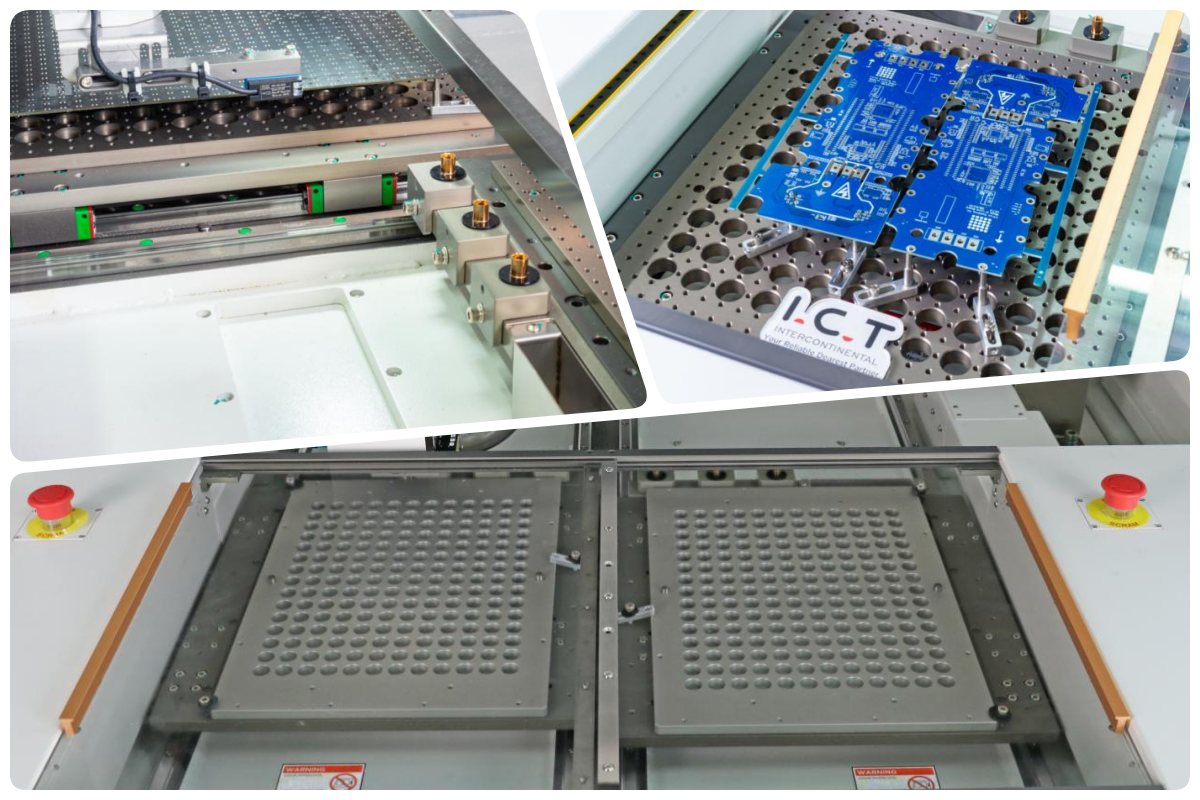

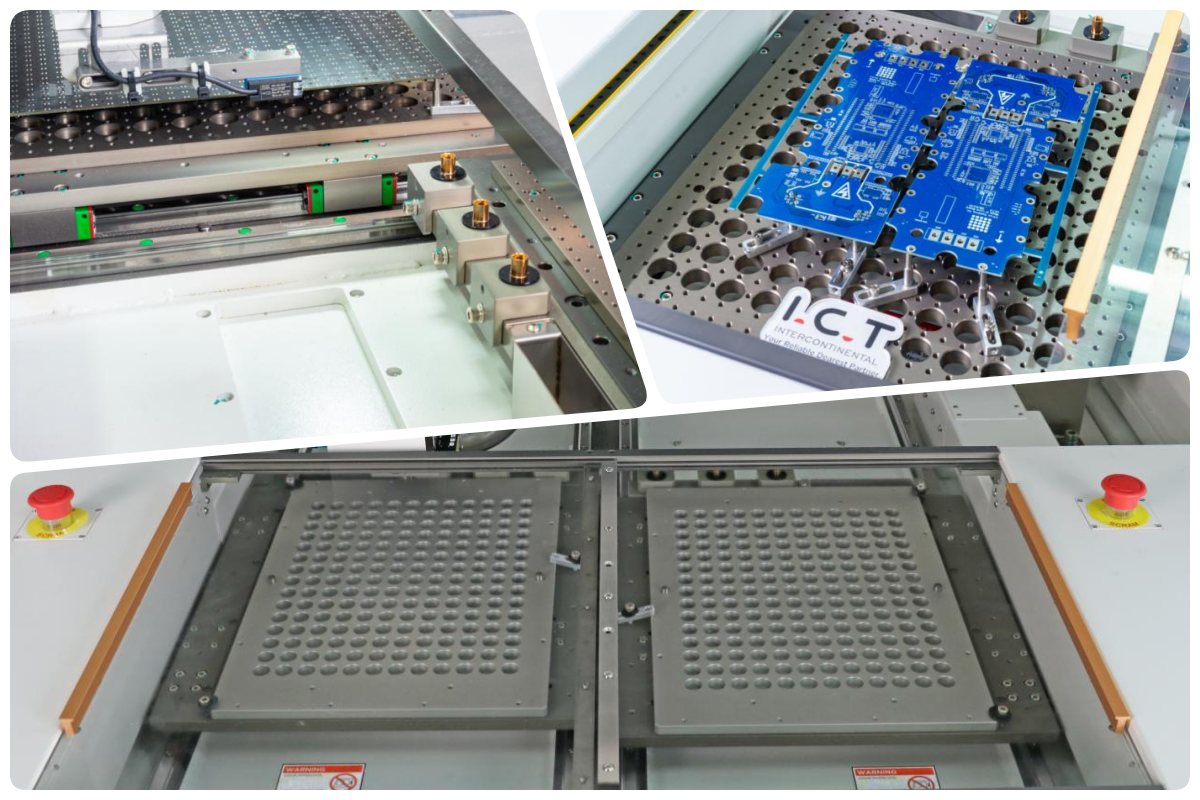

Platform System

Y-axis control is achieved through precision slide rails paired with a servo motor, securing outstanding mechanical stability. Dual emergency stop buttons, comprehensive safety covers, and protective light curtains establish multiple safeguards for operators. Start buttons positioned on both sides necessitate simultaneous activation, embedding inherent safety into the initiation process. The standard honeycomb porous base provides robust suction and broad compatibility with various fixture configurations. Dual platforms permit independent processing of dissimilar products or unification into a single enlarged working area. This configuration renders the PCB depaneling router both secure and highly adaptable for complex, high-throughput assembly environments.

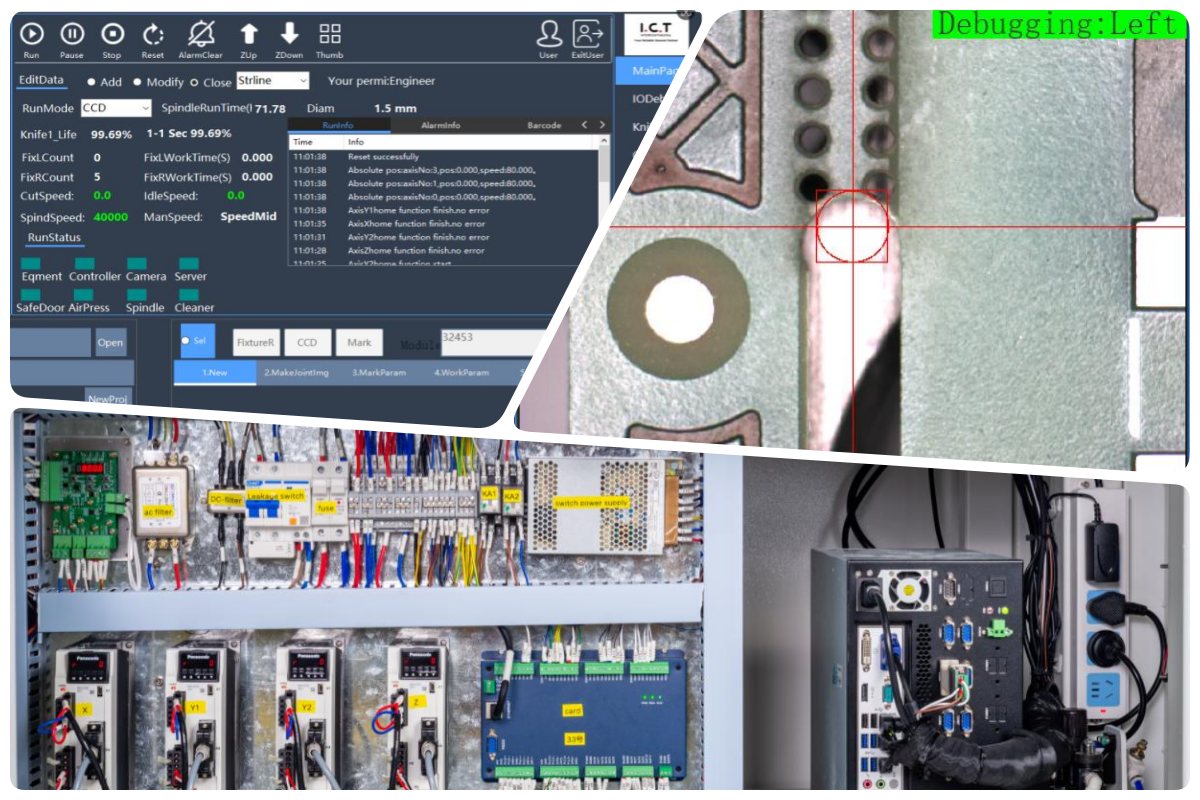

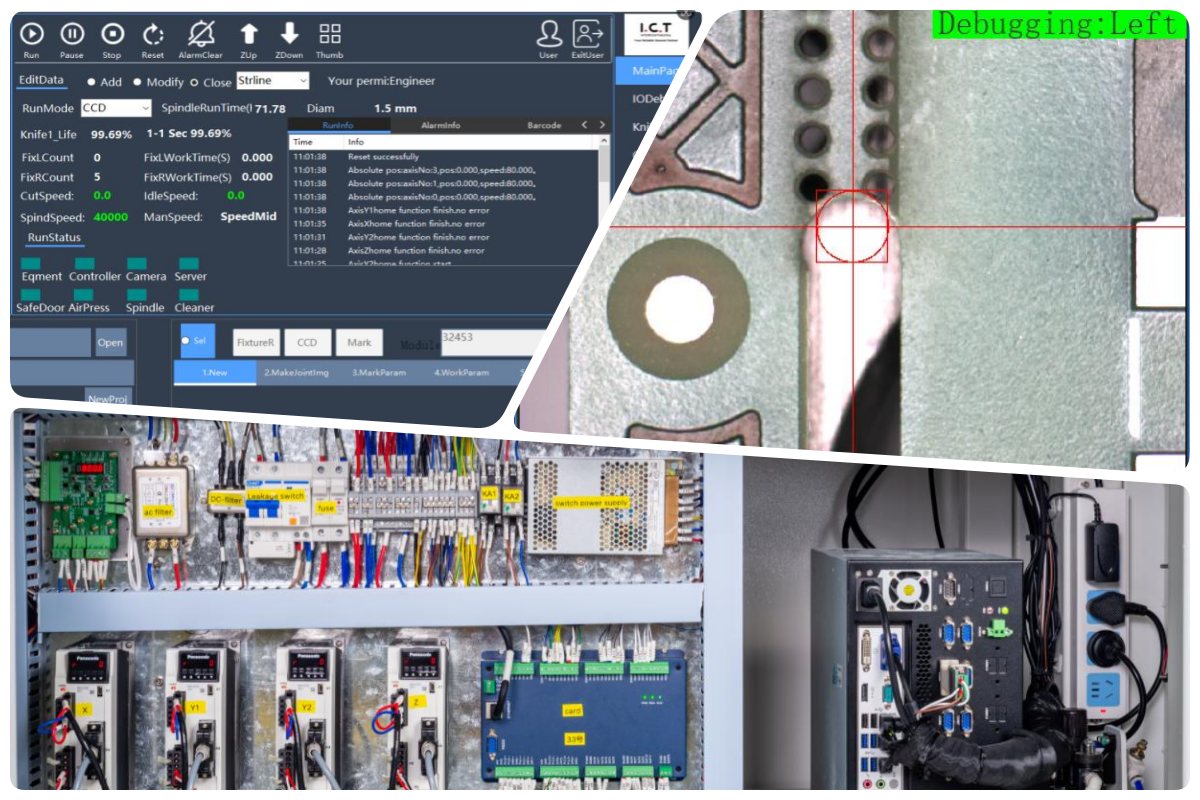

Control System

An industrial-grade computer interfaces with a specialized CNC controller to deliver precise command execution and robust resistance against industrial electrical interference. Comprehensive production data logging generates traceable reports essential for quality assurance protocols. The operator interface adheres to CE standards and supports rapid program transitions between diverse board types. Coaxial CCD imaging supplies continuous real-time visualization of the cutting operation. Operators master the system swiftly, achieving uniform outcomes across extended production cycles. These integrated control features guarantee the PCB depaneling router operates with unwavering stability and accuracy in demanding factory settings.

Detail Display

The convection fan sustains uniform internal temperatures throughout operation. Side door safety sensors interrupt motion immediately upon door opening. ESD interface connections protect sensitive electronics from electrostatic discharge. Optional automatic tool changer facilitates seamless bit replacement without production halts. Broken knife detection sensor perpetually monitors cutter integrity. Self-locking pneumatic struts maintain secure positioning of access doors during service. Each carefully implemented detail enhances overall operational safety, user convenience, and long-term reliability within the PCB cutting machine PCB lead cutter framework.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| Fully Automatied SMD Line | Turnkey Ful-auto SMT assembly line |

| SMT Loader and Unloader | Automatically loads bare PCBs to the line. |

| SMT PCB printing machine | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| SMT Soldering Oven | Melts solder to form solid joints. |

| Customer Success Video

A customer specializing in feature phone production from Algeria visited our Dongguan facility, bringing more than ten PCB panels and complete material kits for thorough acceptance verification. Our team executed a full SMT line demonstration: automatic solder paste printing, SPI deposit inspection, RX-8 placement of miniature components, RS-1R handling of larger parts, tray feeder supply of shield covers, reflow soldering completion, AOI defect scanning, and precise final separation via the I.C.T PCB depaneling router. The sequence proceeded without disruption, exhibiting high throughput, minimal board stress, and flawless edge quality. The customer closely monitored each phase, acknowledged the seamless efficiency and superior results, and granted full equipment approval prior to departure.

| Service and Training Support

I.C.T dispatches qualified engineers for on-site installation and structured, practical training programs customized to client requirements. Training encompasses safe operation protocols, program configuration, tool management, routine maintenance procedures, and basic troubleshooting for the PCB depaneling router. Remote diagnostic support responds expeditiously, complemented by swift global shipment of spare parts to minimize operational interruptions. Service centers distributed worldwide deliver prompt technical intervention and ongoing process refinement as production demands evolve. This integrated support framework ensures rapid commissioning, sustained machine availability, and optimal long-term performance, enabling customers to maximize return on investment with minimal concern.

| Client Testimonials

Customers consistently praise our engineers for their rapid, expert problem resolution and thorough professional guidance during installation and subsequent support interactions. They express high satisfaction with the PCB depaneling router's reliable precision, clean cutting performance, and gentle handling of sensitive assemblies. Many commend the meticulous, secure packaging that ensures equipment arrives in pristine condition after extended transport. Swift responses to inquiries and technical questions further solidify confidence and loyalty. Overall, clients recognize I.C.T for superior equipment quality, attentive service, and unwavering commitment to production excellence.

| Certifications and Standards

CE certification verifies compliance with stringent international safety requirements. RoHS certification confirms adherence to environmental standards by restricting hazardous substances. ISO9001 certification attests to a systematic quality management framework governing all production stages. Multiple patented technologies protect innovative design elements and functional improvements. These authoritative certifications collectively affirm that every PCB depaneling router meets elevated global benchmarks for safety, environmental responsibility, and manufacturing quality.

| About I.C.T Company and Factory

I.C.T operates development facilities alongside comprehensive in-house production capabilities, supported by a substantial workforce including specialized engineers. Established in 2012, the company has achieved rapid expansion, currently serving over 1600 customers across more than 72 countries through an extensive network of branch offices, sales centers, and warehouses. The advanced factory implements rigorous inspection protocols and a robust ISO9001-compliant quality management system to verify every machine prior to shipment. Committed to continuous technological advancement and dependable worldwide service, I.C.T fosters enduring collaborative relationships within the global electronics manufacturing sector.

| Advanced PCB Depaneling Router

The PCB depaneling router finds essential application in manufacturing smartphones, smart wearables, tablets, automotive electronics, medical devices, and aerospace systems. It accommodates PCB sizes from 340×380mm to 450×600mm and thicknesses ranging from 0.5 to 5.0mm. The modern CCD vision system recognizes diverse mark types and performs automatic visual correction for exact alignment. Operating at up to 80,000rpm, the spindle achieves cuts with greatly reduced stress, high precision, low inertia, and immediate response. Dual platforms facilitate handling different products concurrently or combining into one extended workspace. The ion air gun neutralizes surface static electricity, preventing dust adhesion. Continuous sensor monitoring safeguards the milling cutter. A separate high-efficiency vacuum collector maintains low noise while providing powerful suction. The humanized operation system remains simple, flexible, and stable for everyday use.

| Feature

Transmission System

Imported Panasonic servo motors, combined with high-precision screw rods, establish the foundation for motion accuracy throughout the system. Guide rails and ball screws from Taiwan contribute to consistent repeatability. The mechanical structure, reinforced with greater thickness, significantly enhances operational stability under prolonged workloads. Flexible tank chains organize cable routing aesthetically while eliminating interference with dynamic components. The X-axis module incorporates a distinctive dust-proof design that substantially decreases maintenance intervals and associated costs. Through this meticulously engineered integration, the PCB depaneling router maintains exceptional positional precision and durability, supporting uninterrupted performance in rigorous manufacturing conditions.

Router System

The high-definition vision system aligns coaxially with the milling cutter, facilitating straightforward and reliable calibration procedures. Standard tool breakage detection activates an immediate alarm upon detecting cutter wear or fracture. The optional automatic tool changing mechanism enables continuous machining without interruption, thereby elevating production efficiency. An ion air gun systematically removes static electricity from the PCB surface, effectively preventing dust adhesion during operation. The imported high-speed spindle substantially lowers cutting stress while delivering superior precision, minimal inertia, and swift dynamic response. Collectively, these advanced elements ensure consistently clean separation results on the PCB Board Lead Cutter Separator Depaneling Router Machine.

Platform System

Y-axis control is achieved through precision slide rails paired with a servo motor, securing outstanding mechanical stability. Dual emergency stop buttons, comprehensive safety covers, and protective light curtains establish multiple safeguards for operators. Start buttons positioned on both sides necessitate simultaneous activation, embedding inherent safety into the initiation process. The standard honeycomb porous base provides robust suction and broad compatibility with various fixture configurations. Dual platforms permit independent processing of dissimilar products or unification into a single enlarged working area. This configuration renders the PCB depaneling router both secure and highly adaptable for complex, high-throughput assembly environments.

Control System

An industrial-grade computer interfaces with a specialized CNC controller to deliver precise command execution and robust resistance against industrial electrical interference. Comprehensive production data logging generates traceable reports essential for quality assurance protocols. The operator interface adheres to CE standards and supports rapid program transitions between diverse board types. Coaxial CCD imaging supplies continuous real-time visualization of the cutting operation. Operators master the system swiftly, achieving uniform outcomes across extended production cycles. These integrated control features guarantee the PCB depaneling router operates with unwavering stability and accuracy in demanding factory settings.

Detail Display

The convection fan sustains uniform internal temperatures throughout operation. Side door safety sensors interrupt motion immediately upon door opening. ESD interface connections protect sensitive electronics from electrostatic discharge. Optional automatic tool changer facilitates seamless bit replacement without production halts. Broken knife detection sensor perpetually monitors cutter integrity. Self-locking pneumatic struts maintain secure positioning of access doors during service. Each carefully implemented detail enhances overall operational safety, user convenience, and long-term reliability within the PCB cutting machine PCB lead cutter framework.

| Specification

| Model | I.C.T-5700M | I.C.T-5700L | I.C.T-5700LL |

| Pcb Size(Double platform,Special size optional) | 290*350mm | 350*450mm | 450*500mm |

| PCB thickness | 0.3~6.0mm | ||

| Weight(with vacuum cleaner) | 1000kg | ||

| Dimension | 1075*1430*1460mm | 1125*1530*1460mm | 1225*1530*1460mm |

| Dust Collection Method | Vacuum cleaning | ||

| Air volume of vacuum cleaner | 28~35cm3/min | ||

| Vacuum cleaner Dimension | 640*785*1760mm | ||

| Voltage of the Dust Collector | 380V,50/60HZ,3kw | ||

| SMT Line Equipment List

I.C.T make real High-Quality PCBA Production Line. Vacuum loader give board clean. Auto printer put paste right. Placer set chip true. Many zone reflow solder hard. Good AOI find all bad. Line stay tight. Yield high. Cost low. No play. Make for hard work car health light. Board come ready real world. We back full.

| Product Name | Purpose in SMT Line |

|---|---|

| Fully Automatied SMD Line | Turnkey Ful-auto SMT assembly line |

| SMT Loader and Unloader | Automatically loads bare PCBs to the line. |

| SMT PCB printing machine | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| SMT Soldering Oven | Melts solder to form solid joints. |

| Customer Success Video

A customer specializing in feature phone production from Algeria visited our Dongguan facility, bringing more than ten PCB panels and complete material kits for thorough acceptance verification. Our team executed a full SMT line demonstration: automatic solder paste printing, SPI deposit inspection, RX-8 placement of miniature components, RS-1R handling of larger parts, tray feeder supply of shield covers, reflow soldering completion, AOI defect scanning, and precise final separation via the I.C.T PCB depaneling router. The sequence proceeded without disruption, exhibiting high throughput, minimal board stress, and flawless edge quality. The customer closely monitored each phase, acknowledged the seamless efficiency and superior results, and granted full equipment approval prior to departure.

| Service and Training Support

I.C.T dispatches qualified engineers for on-site installation and structured, practical training programs customized to client requirements. Training encompasses safe operation protocols, program configuration, tool management, routine maintenance procedures, and basic troubleshooting for the PCB depaneling router. Remote diagnostic support responds expeditiously, complemented by swift global shipment of spare parts to minimize operational interruptions. Service centers distributed worldwide deliver prompt technical intervention and ongoing process refinement as production demands evolve. This integrated support framework ensures rapid commissioning, sustained machine availability, and optimal long-term performance, enabling customers to maximize return on investment with minimal concern.

| Client Testimonials

Customers consistently praise our engineers for their rapid, expert problem resolution and thorough professional guidance during installation and subsequent support interactions. They express high satisfaction with the PCB depaneling router's reliable precision, clean cutting performance, and gentle handling of sensitive assemblies. Many commend the meticulous, secure packaging that ensures equipment arrives in pristine condition after extended transport. Swift responses to inquiries and technical questions further solidify confidence and loyalty. Overall, clients recognize I.C.T for superior equipment quality, attentive service, and unwavering commitment to production excellence.

| Certifications and Standards

CE certification verifies compliance with stringent international safety requirements. RoHS certification confirms adherence to environmental standards by restricting hazardous substances. ISO9001 certification attests to a systematic quality management framework governing all production stages. Multiple patented technologies protect innovative design elements and functional improvements. These authoritative certifications collectively affirm that every PCB depaneling router meets elevated global benchmarks for safety, environmental responsibility, and manufacturing quality.

| About I.C.T Company and Factory

I.C.T operates development facilities alongside comprehensive in-house production capabilities, supported by a substantial workforce including specialized engineers. Established in 2012, the company has achieved rapid expansion, currently serving over 1600 customers across more than 72 countries through an extensive network of branch offices, sales centers, and warehouses. The advanced factory implements rigorous inspection protocols and a robust ISO9001-compliant quality management system to verify every machine prior to shipment. Committed to continuous technological advancement and dependable worldwide service, I.C.T fosters enduring collaborative relationships within the global electronics manufacturing sector.